- Types of electric floor

- cable floor

- Heat mats (thermo mats)

- infrared floor

- Advantages and disadvantages of underfloor heating

- Main advantages

- Existing deficiencies

- Comparison with an alternative

- Laminate in the kitchen under floor heating

- Properties

- Advantages and disadvantages

- How to choose

- Structure

- Surface

- Rating of cable systems

- Varmel Mini Cable 17-255W

- SpyHeat Classic SHD-15-300

- Caleo Cable 18W-120

- How to choose an electric underfloor heating for tiles, laminate and other coatings?

- Under the laminate

- Under linoleum

- Under the carpet

- How to make a warm floor with your hands

- Preparatory part

- thermal insulation

- Heating system installation

- Test run of the system

- What type of underfloor heating is best for laminate

- Do-it-yourself installation

- Foundation preparation

- Frame manufacturing

- Pipe laying

- Connection

- Substrate

- Film floor installation

- Laminate with own heating

- General tips for laying underfloor heating under laminate

- Tips for laying electric underfloor heating under laminate

- Drawing conclusions

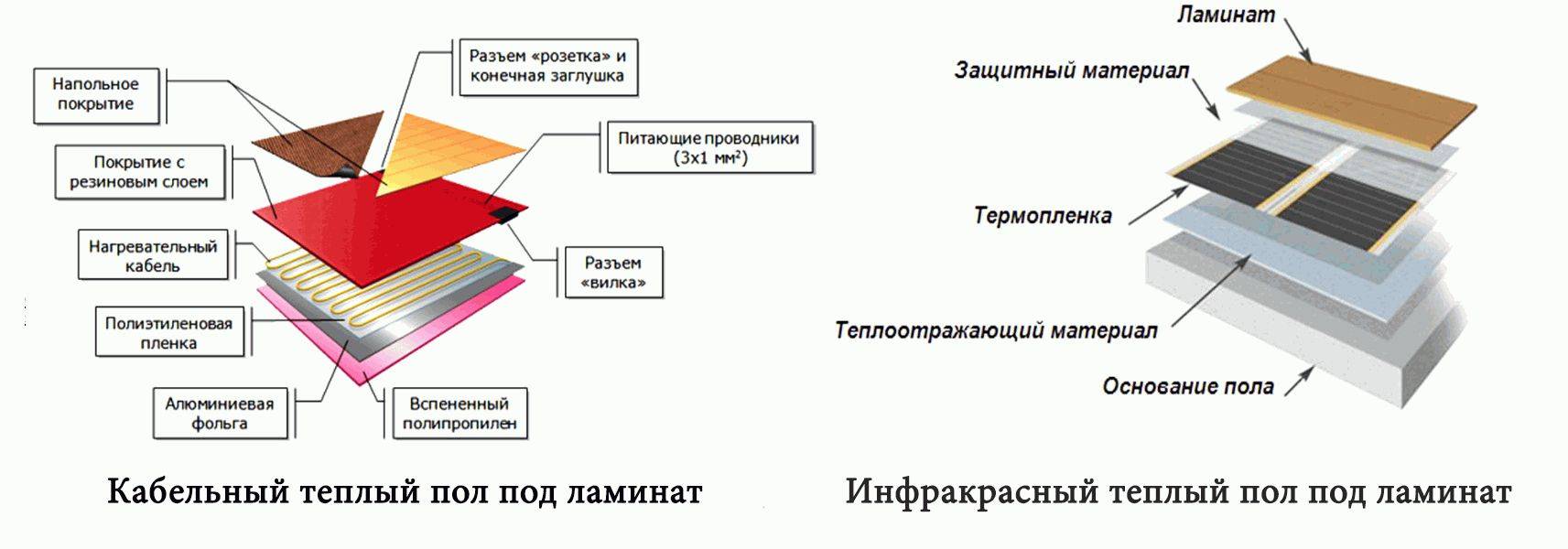

Types of electric floor

According to the heating element used, the classification includes several types of electrical construction.

cable construction

cable construction

cable floor

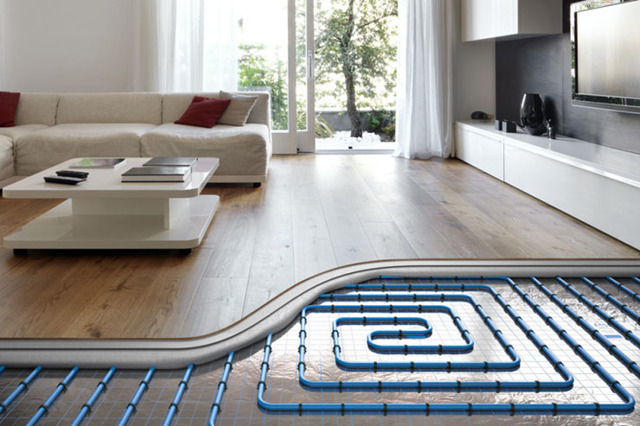

Heating during the installation of the cable circuit occurs through the flow of current to it. The cable is placed on the screed.

For full heating, you will have to wait a little more than 1 hour. To carry out repair work and troubleshoot the system, it is necessary to dismantle the floor laminate, damage the screed.

Heat mats (thermo mats)

Heat mats are made of fiberglass. Cables are attached to it in the form of a snake. Heating installation does not require installation of a screed.

It is most effective to fix the mats on the base with tile adhesive. The price for arranging mats is about 30% higher than for cables.

Heating mats for laminate flooring are easier to install. The mesh with wire is simply laid out on the surface of the rough base.

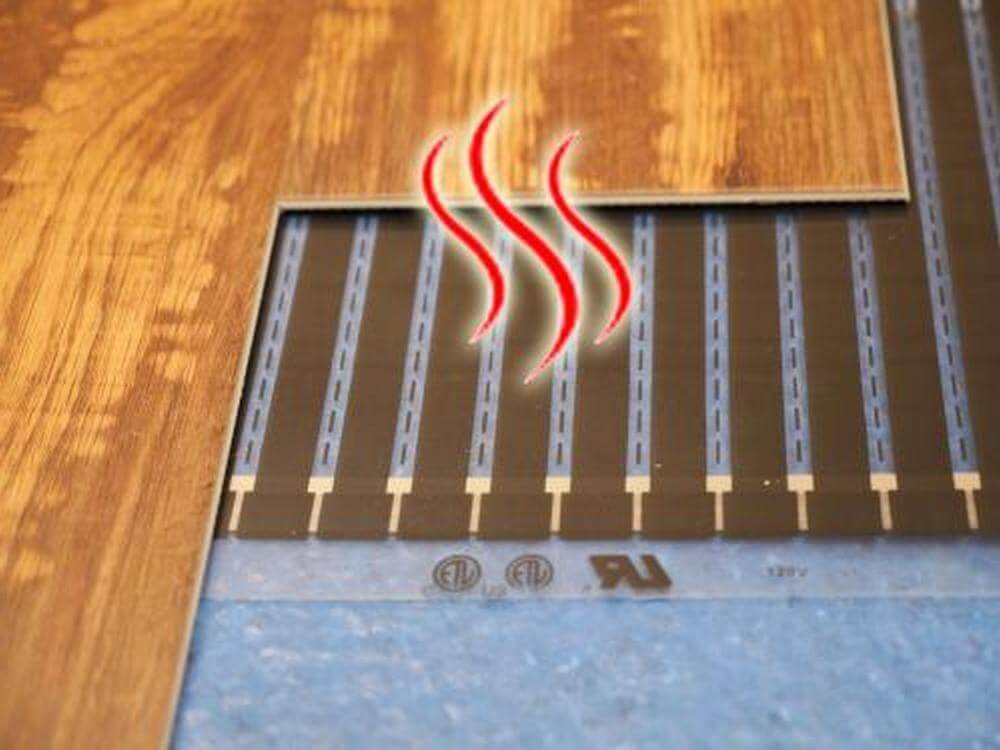

infrared floor

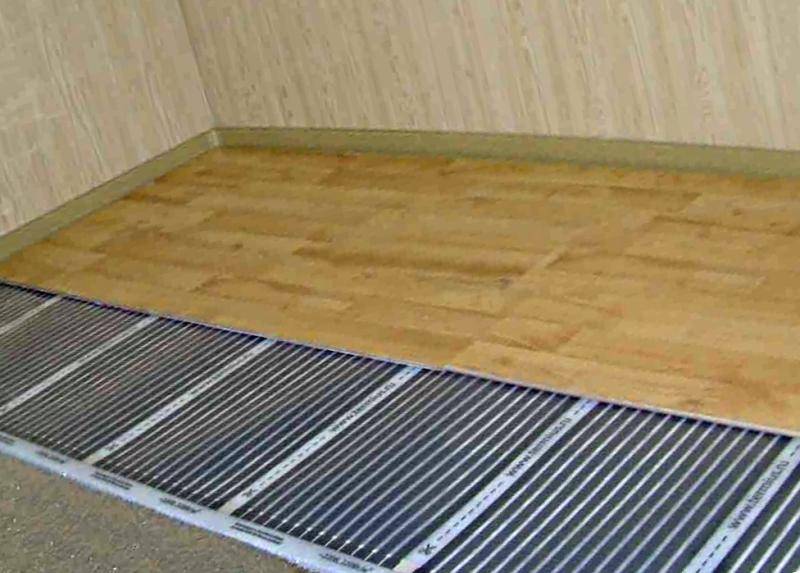

In this design, the heating element is a special film. It does not require the use of screed or glue.

During installation, the film is simply placed on the subfloor. The infrared layer heats not only the floor covering, but also the furniture. The thickness of the system is minimal, so you can organize it indoors without sacrificing height.

infrared design

infrared design

Advantages and disadvantages of underfloor heating

Main advantages

Among the main advantages of electric underfloor heating are:

- the possibility of application not only at home, but also in offices;

- can be used with any floor covering: tiles, laminate, linoleum, etc.;

- all elements of the system are hidden from view, thus do not spoil the interior of the room;

- using the included thermostat, you can adjust the temperature up to 0.1 ° C, while you can also set a certain time to turn on / off the heater;

- can be used as main and auxiliary heating;

- laying a warm floor under a tile (and even more so parquet) can be done by a person without the slightest experience, besides, no special tool should be at hand;

- long service life with proper handling of the system;

- the surface is heated evenly over the entire area;

- it will take a little time to determine the cause of the breakdown;

- the operation of the system does not require additional equipment (for example, for water heating, it is necessary to install an electric or gas boiler);

- the temperature of the heating element is not too high, which is good considering the safety of the application.

As you can see, the advantages of electric underfloor heating are significant, which makes this option quite competitive compared to other heating options.

Existing deficiencies

As always, something must be sacrificed when choosing a particular system. As for the disadvantages of electric underfloor heating, the main ones are:

- high cost of operation (if a heating cable is used for central heating of a large area, the required heater power can reach up to 15-20 kW, which will significantly increase the monthly electricity consumption);

- any type of electric heater has an increased risk of electric shock and electric underfloor heating is no exception, therefore, especially in wet rooms, this moment must be taken into account;

- to increase electrical safety, it is necessary to additionally spend money on the purchase and connection of an RCD, as well as the creation of reliable grounding;

- the heating cable, which is the main executive body of heating, creates an electromagnetic field that negatively affects the human body;

- the floor covering, in particular wood, suffers when heated: it cracks and deforms;

- when laying heaters (especially cables), the ceiling height can be reduced to 10 cm;

- if the heating will be used as the main one and at the same time a large house, then a rather powerful electrical wiring will be required for the system to work.

It can be seen that the disadvantages of the system are quite significant.

But still, we pay attention to the fact that with the right choice of underfloor heating, as well as installation work according to the instructions, most of the listed shortcomings are immediately cut off. This makes the floor heating system popular and in demand.

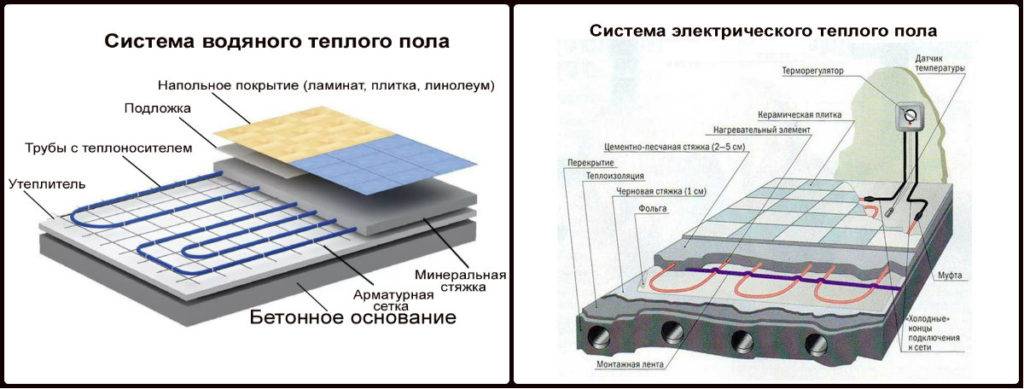

Comparison with an alternative

So that you are finally convinced of the correctness of your decision, now we will talk a little about how an electric underfloor heating is better than a water one.

So, we have highlighted the main points of comparison:

- It is more reasonable to use a water heated floor in large areas, especially if the heating is carried out by a gas boiler. In small rooms, it is more logical to give preference to the option powered by the mains, because. in this case, the cost of installation and operation will be small.

- Heating with hot water has a longer service life (according to manufacturers, the mark can reach up to 50 years).

- Water will not harm human health, which cannot be said about current.

- Installation of a cable (or thermomats) is much easier than water pipes.

- Adjustment of an electric heater is carried out much faster and more accurately than a water heater.

Here we have provided the pros and cons of electric underfloor heating.Summing up, it can be noted that both versions of the system have their own advantages and disadvantages, which in any case make them sacrifice something. We recommend giving preference to electric heating, because. it is more modern, efficient and multifunctional!

Laminate in the kitchen under floor heating

Should you put laminate flooring in your kitchen? Read below

With the growing popularity of underfloor heating, many companies have developed a special coating for laminate, which is suitable in all properties to the features of a warm floor.

Next to this symbol, the highest temperature limit is most often displayed, to which a warm floor can be heated without the risk of damage to the laminate. Most often, the aisle is marked around 28 ° C.

Read how to correctly calculate a warm electric floor in our article.

Properties

underfloor heating laminate

According to generally accepted standards, the thermal insulation properties of a floor covering cannot exceed 0.15 m² K/W. When choosing a laminate, you must immediately summarize the coefficient of the substrate to its thermal insulation performance. For example, laminate can be purchased at 0.052 m² K/W and underlay at 0.048 m² K/W. In sum, these values give 1 m² K / W, which does not exceed the norm.

The drag coefficient is determined by the thickness and density of the material. It is necessary to choose a laminate that has the lowest density and is not very thick. Care must be taken to ensure that the materials fit together, as a melted floor covering can also harm the design of a warm floor.

What linoleum to choose in the kitchen, find out.

Advantages and disadvantages

The advantages of laminate make it possible to use this flooring in the kitchen

Advantages:

-

- Beautiful and practical appearance.

- Small cost.

- Ease of installation.

- Durability.

- Laminate has sufficient rigidity. You can install heavy furniture on it; when rearranging, there will be no traces of it. This is possible due to the use of fiberboard.

- You can purchase an imitation of the texture not only of wood, but also of stone and other natural elements.

- The printing cover is of very high quality. Guests at home often cannot distinguish an artificial three-dimensional pattern from a real natural material.

- The patterned coating protects the finish layer made from adapted resin.

Laminate is a good and practical material, besides inexpensive

Flaws:

- Not all types of laminate are suitable for underfloor heating.

- There is a risk of overheating of the floor covering.

- Laminate edges are the weak point of this flooring. If the technology of its production is not followed, the edges can quickly begin to crumble, deteriorate, which negatively affects the overall appearance and properties of the floor covering.

- There is a need for additional protection of the edges from excessive moisture. To do this, they are carefully treated with a waterproof coating. This event should be carried out even with a tight fit of the boards.

- Sometimes there is a risk of purchasing defective parts. To protect yourself from this imperfection, you need to take products from well-known brands in the middle and high price segments.

See the difference between an expensive laminate and a cheap one. Analyze and do not make mistakes:

How to choose

kitchen floor renovation

The most successful option is class 31-33.It is chosen for the arrangement of hotels, offices, where, with proper operation, it has been serving for more than 20 years. In a private house in the kitchen, its service life is limited only by the desire of the owners.

Structure

Click to enlarge

All layers of the laminate structure add up to 8 mm or more. You can choose 7mm thick laminate to save on flooring purchases, but the smaller layer does not show sufficient strength characteristics.

Classic laminate structure:

- Melamine (protective layer. It is located under the base of the coating, does not allow moisture and other elements negative for the flooring to pass through).

- Panel. Used fiberboard or chipboard. This is the basis of the laminate. Gives strength and rigidity to the structure. The wear resistance of the coating, the possible need for repairs, depends on the quality of this layer.

- Moisture protective layer. Made from paper impregnated with resin. It is not done in all models, only in moisture-resistant laminates in the kitchen.

- Aesthetic cover. The natural pattern of the bark of a tree or stone is imitated.

- Film for protection against mechanical damage.

Surface

The smooth surface of the laminate looks chic. It fits any design where classic standards are used. Caring for a smooth laminate is very convenient. It can be simply washed with water. Contaminants do not stick or soak into the surface, so the house is always clean if wet cleaning is carried out regularly.

Smooth laminate looks chic

Corrugated laminate is more practical. It is impossible to slip on it, walking is absolutely safe even for a small child. If you lay a carpet on even a slightly corrugated surface, it will not move when you constantly walk on it.Caring for such a coating is quite difficult. You will have to thoroughly wash the floor to get rid of all contaminants. Blockages, like on a smooth laminate, do not stick and are not absorbed, however, they can be compacted between the cracks in the relief pattern.

The corrugated surface is safer, but is it practical?

Rating of cable systems

Varmel Mini Cable 17-255W

This heating cable can be installed both in the apartment and in the greenhouse. It is made of two current-carrying conductors with an armored screen and refractory insulation (self-extinguishing effect). It can be laid freely under tiles or laminate. The declared power of this particular kit is 255 watts. Operates from a standard 220 V outlet.

Please note that this coil has 17 m of cable that can be laid on the floor. However, depending on the scope of application, the laying step will change, and hence the size of the heated area.

On the floor in an apartment or house, on average, 7 linear meters of cable per 1 m2 of area are spent in increments of about 9 cm. Therefore, in an apartment, the cable can heat up to 2.5 m2. In a greenhouse, the laying pitch will be larger, so this cable bay will be able to heat up to 3.75 m2 of area. We recommend that you first accurately calculate the heated area in order to take the required number of coils without excess.

SpyHeat Classic SHD-15-300

A two-core heating cable from SpyHeat is designed to heat up to 2.6 m2 of an apartment or house area. However, with good insulation, it can be laid with a smaller step, and then the heated area will increase to 3 m2. Its maximum power consumption is 300 watts. The length of the cable in the bay is 20 running meters.

A two-core wire with a cross section of 4 mm is “dressed” in a metal screen with high-quality refractory insulation. The manufacturer claims that the cable system can last up to 50 years without repair.

Please note that this bay comes with a ground conductor. The length of the cold cable (the section that connects the warm floor to the mains) is 2 m

The cable can be used for both tiles and screed.

Caleo Cable 18W-120

This coil of heating cable is already designed to heat the entire room, up to 16.6 m2. It can be laid under a 2–5 cm thick screed, under parquet, tile or linoleum. For 120 meters of wire, the power declared by the manufacturer is 2160 W, which gives approximately 18 W per 1 running meter. This is a good indicator for a product, cheaper than 80 rubles per meter. The current-carrying conductors are double insulated: the inner one is made of TPEE, and the outer one is made of PVC. Also under the PVC is a layer of aluminum foil, which acts as a screen.

The total operating current of the entire bay (assuming the use of the entire product) is 9.8 A, so a separate outlet is required to connect it. Conductor cross section here 4 mm, and the resistivity is 22.3 ohms. The manufacturer claims that the cable will last 50 years, but gives a guarantee of 20 years.

How to choose an electric underfloor heating for tiles, laminate and other coatings?

Under the laminate

The most popular option is infrared thermal film. It is easy to lay, besides, for installation it is not necessary to raise the floor level - the thickness of the thermal film corresponds to the thickness of the substrate.

Thermomats are also suitable

Please note that there is a downside - not every laminate is compatible with a heating system.It must have appropriate properties of resistance to temperatures and temperature differences.

Read the manufacturer's instructions and be prepared to pay more.

Under linoleum

For this coating, experts recommend two options: cable and infrared thermal film. The reason is that any irregularities are visible under the linoleum. And the cables, as you know, are mounted inside the screed, they do not affect the evenness in any way. As for infrared films, they are thin and will not be noticed under linoleum either.

For laying linoleum, double-sided tape or adhesive mastic is used, the latter being preferable.

In reviews, it is often noted that the cable is more economical, and thermomats will require more electricity.

This is important, because users often complain that this type of heating consumes a lot of electricity, so it is only justified in the bathroom and in a small kitchen (and then if you have children and the house as a whole is not hot). But that's about the price

But what they say about the choice of materials: ceramic tiles and porcelain tiles conduct heat well, so both heating cables and thermomats are suitable for them. Which one to choose depends on additional factors. Such as energy efficiency and installation.

We already wrote about installation above. If your choice is a cable, you will have to raise the floor level, as it fits into the screed. If the mat - it will be easier, it is enough for it to be mounted in an adhesive base.

Under the carpet

For carpet, the choice of design is limited to cable and thermal films.

The first option - heats up evenly, and does not deform the carpet. However, with such a system, the carpet can burn out. The fact is that in the cable type, the heating is uniform, but strong.And in places of strong and constant contact with the floor - for example, under heavy furniture, the carpet can "burn".

With thermal films it is easier - it does not overheat. Therefore, for carpet it is chosen more often.

The table contains brief marks for selection for tiles, laminate and other materials, including natural wood. Save it to your bookmarks or take a screenshot - this is a handy cheat sheet that, in principle, is easy to remember.

| cable floor | Thermomat | thermal film | |

|---|---|---|---|

| Ceramic tile | Yes | Yes | Not |

| Porcelain stoneware | Yes | Yes | Not |

| A natural stone | Yes | Yes | Not |

| Parquet and parquet board | Not | Not | Yes |

| Laminate | Not | Yes | Yes |

| Linoleum | Yes | Not | Yes |

| Wood | Not | Not | Yes |

| carpet | Not | Not | Yes |

| Other textile coverings | Not | Not | Yes |

How to make a warm floor with your hands

When installing a warm system under a laminate floor, factors must be taken into account:

- humidity;

- evenness and hardness of the base;

- building materials for laying under the laminate and wall cladding.

Before starting work, they make a layout of heating elements and areas for furniture. It is not necessary to install the heating elements of the system close to the radiators. Under furniture and in corners, the use of this system is not necessary, so as not to heat for nothing and not to spend money on extra materials.

Preparatory part

The first thing to take care of is waterproofing and thermal insulation of the base. To protect the wooden base from moisture, a waterproofing membrane and a vapor barrier film are used.

First, they remove the old plank floor and get to the rough wooden base. Check horizontality and condition.If you need restoration, then you need to do strengthening, because you have to lay more concrete on top, and this is a serious burden.

You can additionally protect yourself from moisture and cover the boards with antiseptic agents.

thermal insulation

How to make sure that the heat from the heating elements does not heat the underground space. To do this, make the so-called insulated floor.

The technology is next. Under the lags, a false floor is mounted from sheets of chipboard or plywood. As a result, peculiar niches are obtained, which are filled with insulation.

Then they are covered with waterproofing and vapor barrier material and mounted on top of the subfloor. It is worth noting that between the insulation and the subfloor, you need to make about 3-5 cm of space for ventilation. This will avoid the occurrence of condensation there and keep this "pie" in its original state.

A heat-reflecting element is laid on top of the subfloor, which will not allow convective heat to reach the underground. To mount the electrical system, only foil material with a thickness of not more than 5 mm can be used.

Heating system installation

Laying the electrical and infrared material of the system is not difficult, because they are sold ready-made sheets and rolls with heat supply elements built into them.

But with the water system, the situation is different. Here you need to properly distribute heat. As already mentioned, pipes are laid with a snake or a spiral.

The distance between the pipes is maintained so that the heat evenly heats the floor around the perimeter of the system. It should not be that on the surface 5 cm of the floor are warm, 5 cm are cold, 5 cm are warm, etc.

To evenly install the heating pipes, aluminum plates are used. They will play the role of heat guides. It has a recess plate in the central part.

The thermal contour of the pipes is laid in these recesses on the plates, after which they are wrapped with one half from the top and attached to the base.

It is also possible to lay pipes more simply by constructing cavities. For this, bars with a cross section of 20 mm are used, on which the flooring is stuffed from above. The bars will be the crate for the top layer of the flooring.

Laminate flooring requires a level and stable surface. Therefore, a plaster mesh is applied on top of the double floor.

Test run of the system

Before laying the laminate, check the operation of the heating system. It is better to check cyclically, for 3-4 days, gradually heating and allowing to cool.

Every day the temperature is increased by 5 degrees and at the end of the test check is brought to the maximum possible design power.

Water floors should be checked even before pouring concrete screed with high pressure. If there are facts of leakage due to poor connections in the system, then they must be eliminated. Also look at the dangerous areas for deformation, later they can become centers of leakage. After the system has been checked, the finishing work can be continued.

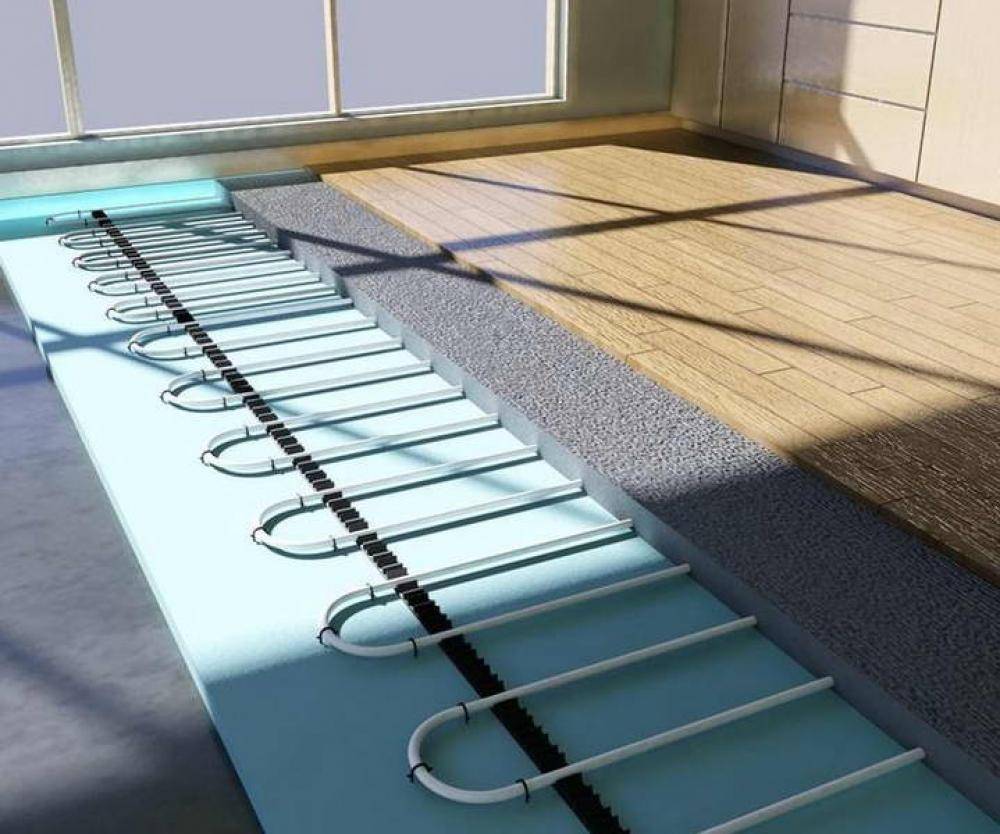

What type of underfloor heating is best for laminate

To date, there are three technologies for arranging underfloor heating. Each has its strengths and weaknesses, each has differences in the technological process. These features have an impact not only on the efficiency of space heating, but also on the requirements for an optimal floor finish.

The main types of underfloor heating

Table.Underfloor heating technology.

| Type of heating system | Specifications and technological features |

|---|---|

| Water | On the basis of the floor, a system of plastic pipes for heating the room is installed. In the future, it is closed with a screed with a thickness of at least five centimeters. The laying of the laminate is carried out according to the technology recommended by the manufacturer - a special substrate for eliminating irregularities, laminate lamellas. This is the most unfortunate version of the heated floor, it has three significant drawbacks. The first is low efficiency. A thick sand-cement screed and a foam pad under the laminate increase the loss of thermal energy. The second is the high estimated cost. This refers to the total cost of materials and the amount of lost time. The third is big problems in case of emergencies. Water leaks are discovered too late, during which time many architectural structures become unusable. In addition, the repair requires the complete dismantling of not only the laminate, but also the screed. It's long and expensive. Currently, underfloor heating is used very rarely. In addition to the above problems with topcoats, they also have their own purely technical disadvantages: it is necessary to install a special boiler, a complex system for distributing and regulating thermal energy, etc. |

| Electrical | A more modern and better system, in terms of the number of uses, is confidently leading due to its relatively low cost. The system consists of special electrical cables, the amount of heat (Q) depends on the square of the current (I2), the parameters of the resistance of the conductor (R) and time (T). Q=I2×R×T.Electric heating is much more efficient than water heating and has several advantages over it. First, emergency situations do not have such negative consequences. Secondly, the systems are much simpler from an engineering point of view, control and monitoring equipment can be mounted in any convenient place. Thirdly, the reduced thickness of the cement-sand screed increases the efficiency of operation, reduces material costs for maintaining comfortable conditions in the winter. |

| infrared | State of the art floor heating system. Heat carriers are electric, but not ordinary cables. These are special carbon threads sealed on both sides with plastic plates. The total thickness does not exceed one millimeter, it is realized in separate rolls, which can be cut to the required dimensions. Such systems have many advantages: high efficiency, ease of installation, reliability and safety of operation. Under infrared systems, a cement-sand screed is not made, which makes it possible to save time and money. The only drawback is the high cost, infrared floors are not available to all developers. |

Laying resistive heating cable

Infrared warm floor

As can be seen from the table, there are no fundamental restrictions on the use of laminate as a topcoat for underfloor heating. But this does not mean that you can buy any coatings and safely install them on heated floors.

Do-it-yourself installation

Before you put a warm floor under the laminate, you need to decide on the option of laying it. It can happen like this:

- According to the lags.To do this, it is convenient to use special modules made of chipboard, factory-equipped with grooves with special channels, metal heat-distributing plates and all necessary fasteners. They only need to be assembled in accordance with the instructions. But such a kit is very expensive.

- On rails. To do this, use a planed board, moisture-resistant plywood or chipboard with a thickness of 21-28 mm. The distance between the rails is usually equal to their width, and the width corresponds to the distance between the pipes in the circuit.

Foundation preparation

When laying the "water-heated floor" system on a wooden base, installation must be carried out after a set of preparatory works, which include:

- "Opening" the old coating and the base located under it. At the same time, old hydro- and heat-insulating materials are removed, and the base itself is cleaned of traces of dirt, fungus and mold.

- Visual assessment of the general condition of the foundation. It needs to be inspected for any damage. At this stage, sections of the beams that have become unusable should be dismantled, replacing them with new inserts. If strong distortions and blockages of the surface are detected, it must be leveled with metal corners, special linings and other fixing elements.

- Treatment of a wooden base with antiseptic preparations. This will avoid further decay and destruction of this material.

The last step in the preparation of the base is its cleaning from dust and debris. Detailed instructions for preparing a warm floor for a laminate can be found on the video presented on the Internet.

Frame manufacturing

When laying warm water floor on load-bearing wooden construction with a beam spacing of up to 60 cm, work can be carried out directly on this base. To do this, cranial bars are fixed in the lower part of the beams, acting as supports. Subfloor boards are stuffed on them.

It is possible to lay a draft floor without cranial bars. In this case, the boards are fixed directly into the supporting beams from the basement or underground side. The space between the supporting lags is filled with a vapor barrier material, on which a layer of thermal insulation 15-20 cm thick made of mineral wool, polystyrene foam or foam plastic is laid.

The distance between the primary floor and the heat-insulating layer should be at least 8-10 cm. For additional ventilation in the "rough base" near the wall, it is desirable to leave a small unwired area.

When making a frame for floors with a beam pitch of more than 60 cm, the cranial bars should be fixed at a higher height, since the subfloor in this case will be attached to chipboard or plywood nailed to the supporting beams.

After the insulation, it is necessary to attach a layer of vapor barrier. You can learn more about how the underfloor heating is laid under the laminate in the video.

Pipe laying

For the installation of water-based underfloor heating, pipes made of polypropylene and metal-plastic are used. Their layout can be done in two ways:

- in a spiral;

- snake.

The first method is more preferable, since in this case there is an alternation of "cold" and "warm" circuits.

At home, it is easier and more convenient to lay pipes with a “snake”. They should be laid out in increments of no more than 30 cm. Near the walls, the pitch can be minimal: 10-15 cm. This will avoid heat loss at the junctions.

Connection

Connecting underfloor heating to the heating system can be carried out in various ways. The most common are:

- Mixing nodes;

- collector system.

After that, a pressure testing procedure is performed, the main purpose of which is to identify leaks and malfunctions in the pipeline. This operation must be carried out before laying the flooring!

For "safety net" it is better to make a test run together with specialists. Additional information on connecting underfloor heating under the laminate with your own hands can be gleaned from the video.

Substrate

After the technical part of the structure has been tested under high pressure, a substrate is laid on top of the pipes, the function of which can be performed by the following materials:

- Cork;

- Foamed polyethylene with foil coating;

- Foil polystyrene;

- Extruded polypropylene.

The listed materials have different prices. For example, the most expensive is a polystyrene foil substrate. But it also has the highest thermal insulation characteristics.

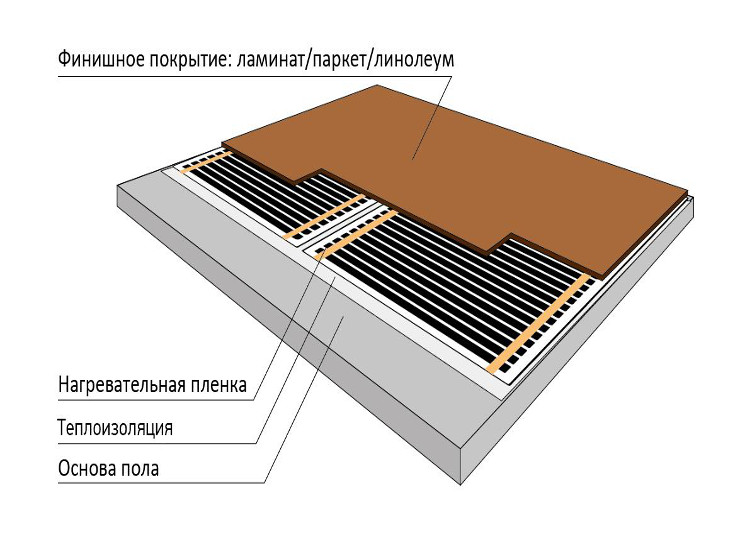

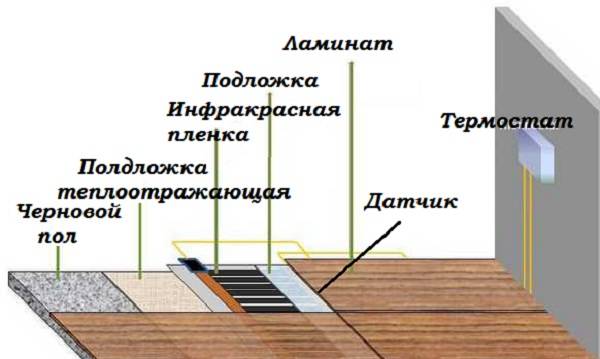

Film floor installation

Foundation preparation:

- Clean the surface of the base from dust, dirt, various debris.

- The old floor covering can not be dismantled.

- Level the floor surface. Differences in height should not exceed 3-4 mm. You can do this with styrofoam.

Floor installation:

- Lay the heat-reflecting layer on the prepared base with the silver side up. Attach it with construction tape.

- Lay down the thermal tape. Sheets must not be overlapped. During installation, step back from all walls by 10-15 cm.

- Secure the sheets with tape.

- Install a thermostat.

- Connect the parts of the thermal film together using the wires that are included in the heating system kit. The connection must be in parallel.

- Attach clamps to the copper strips, and insulate the joints with a special bitumen tape.

- Attach the last strip to the thermostat.

- Using bituminous tape, attach a thermal sensor to the inside of the thermal film. Under it, make a hole in the heat-reflecting layer, and on the base - a groove for the wires.

- Connect the system to the network.

Laminate installation:

- On top of the film heater, it is imperative to lay a plastic film.

- Provide a layer of special soundproofing film under the warm floor.

- Lay laminate with Click, Lock connection.

This is interesting: Floor screed in the house: study with us

Laminate with own heating

This is an innovation in the construction market: the heating system is already built into the panels. Each lamella has its own heating elements.

Scheme of lamella with autonomous heating

The advantage of this system is that a warm floor is mounted under the laminate without screed and separate heating elements. Thus, there is a more efficient use of the thermal floor. Energy is not wasted on heating the screed, as with a conventional underfloor heating system.

Thus, heat losses are much lower. It is also not difficult to calculate the required thermal power. Per square meter of laminated tiles, it ranges from 40 to 70 watts. You can create zones without heating.

Laminate, as in other cases, is laid on a substrate. Its use does not affect the heating of the floor surface and does not violate the temperature regime.It is desirable that it be made of environmentally friendly material, but this is a rather expensive option. Cheaper will be a synthetic underlay that has the same thermal resistance as the laminate.

General tips for laying underfloor heating under laminate

Before installing a heating floor, it is necessary to draw up a work plan in advance. For low ceilings, it is recommended to use thermal film. In the case of self-assembly, it is better to choose the most simple and understandable system:

- a waterproofing layer is required in private houses or apartments on the ground floor;

- to save on the length of the wires, the temperature sensor is built into the center of the floor;

- it is necessary to mount the structure so that in the future it can be disassembled, if repair requires it;

- it is forbidden to use thermal film in rooms with high humidity;

- lay the thermal film away from heating devices;

- length of one strip up to 15 meters;

- at temperatures below zero, infrared floors are not mounted;

- you need to ground the structure;

- if heavy furniture is planned to be placed on infrared floors, it is necessary to equip air pockets.

Thus, the system of self-heating floors is convenient and comfortable to use. She has proven herself very well. More and more people are opting for it. This is both practical and aesthetically pleasing: no radiators or other heating devices.

Underfloor heating for the whole family

Today there are a large number of building materials. The efficiency of the “heating floor” system directly depends on the right choice of material. Linoleum, ceramic tiles and other materials are widely used. Laminate is as good as these more traditional floorings.

However, when choosing, it is very important to consider the characteristics of the coating:

- resistance to high temperatures, so that deformation does not occur during temperature changes;

- good thermal conductivity, so that there is no overheating and the entire room is heated evenly;

- low level of formaldehyde emission;

- when choosing a lock, it is better to give preference to the “click” system. The likelihood of cracks with such a lock is minimized.

Choosing the right laminate flooring, combined with the right kind of heating system, will ensure a comfortable, warm home.

Tips for laying electric underfloor heating under laminate

Professionals give advice for more efficient selection and installation of electric heating:

- It is allowed to install only electric heating in a high-rise building, it is unlikely that managing organizations will give approval for a water system.

- To determine the fault location in the cable, you will need a special device. It will allow you to find a problem area even through a cement screed.

- The electrical system must occupy at least 70% of the area of the room. This is the only way to achieve effective heating.

- Optimum operating power 160 - 190 watts.

- When buying a laminate, you should check the markings for combining with heating.

- Even high quality laminate should not be heated above 30 degrees. This will lead to the release of hazardous components.

- The minimum thickness of the laminate is 8 mm, otherwise it may be deformed due to constant heating.

- For residential premises, it is better to combine heating sources: floors, radiators.

- The correct setting of the heating intensity and its adjustment will help save energy costs by 20-30%.

- It is not recommended to lay the electrical structure too close to the heating devices, as the risk of its breakdown increases.

- When arranging the screed, the floor must not be turned on until it is completely dry.

- The maximum length of infrared bands is 7 m.

Installation recommendations

Installation recommendations

Drawing conclusions

So, in order to choose an electric underfloor heating for tiles and other coatings, you need to consider several factors.

- At what stage do you install the structure? After rough work or before. The choice depends on the method of installation.

- What will be the final cover? Tiles, laminate or more sophisticated options?

- Will it be the main heating or as an addition to the central one? This determines the power.

- In what room will you mount the system?

- What control do you need? Are you ready to invest in a thermostat?

- Do you have a furniture layout plan? Are you sure it won't change? The installation area and your future energy costs depend on this.