- Which stabilizer is best suited for a gas heating boiler

- Specific examples of stabilizer selection

- Rating of the best stabilizers for gas boilers

- BASTION Teplocom ST-222 500

- RESANTA ACH-1000 1-C

- RESANTA LUX ASN-10000N 1-C

- SVEN AVR 500

- RUCELF SRWII-12000-L

- RUCELF SRW-10000-D

- Powercom TCA-1200

- Powercom TCA-2000

- Leader PS10000W-50

- Energy Classic 7500

- Types of stabilizers

- How to choose a stabilizer

- Manufacturers of electronic and mechanical stabilizers

- What types of stabilizers are suitable for boilers

- Electromechanical

- Relay

- Electronic

- inverter

- LENZ TECHNIC R500W - accuracy and price

- Mounting and connection technology

- Types of Voltage Stabilizers

- Relay stabilizers

- Servo Stabilizers

- Thyristor

- Inverter type stabilizer

- What you need to know when choosing a voltage stabilizer

- Requirements for the stabilizer

Which stabilizer is best suited for a gas heating boiler

First you need to choose a type. They are relay, electronic and electromechanical. In the first and second versions, there are from 4 to 20 autotransformer windings. It is thanks to them that tension is equalized. As for accuracy, the first one is from 5 to 8%, and the second one is from 2 to 3%.

First you need to choose a type. They are relay, electronic and electromechanical. In the first and second versions, there are from 4 to 20 autotransformer windings. It is thanks to them that tension is equalized. As for accuracy, the first one is from 5 to 8%, and the second one is from 2 to 3%.

But it is worth remembering that the heating is gas, which means the highest stability, even with a shorter run-up.Therefore, only electronic ones are suitable. Their run is compared to 214–226 V. In addition, during operation, you will not notice characteristic noises. The cost of such a device is high, but justified. It varies from 2500 rubles to 6000. The last model represents a completely different principle of activity. And with gas appliances nearby in the same room, it is forbidden to put them because of the possible occurrence of sparks.

Specific examples of stabilizer selection

The stabilizers of the Latvian company Resanta work well in terms of reliability. The range includes relay and electromechanical models of devices. In terms of power, two models of electromechanical stabilizers are suitable for gas boilers: Resanta ACH - 500 / 1-EM and Resanta ACH - 1000 / 1-EM. Below are their characteristics.

Technical characteristics of electromechanical stabilizers "Resanta" (click on the picture to enlarge)

If you look at the line "Regulation time" you will see just a deplorable figure - 10v / sec. That is, a 10V drop can be compensated in a second. In reality, on our networks, the differences are several times greater. What does it mean? Such stabilizers will not be able to guarantee the safety of a gas boiler.

Let's look at examples of the selection of stabilizers for specific boiler models. For example, the owner of a Vaillant gas boiler turboTEC plus VUW 362-5 is looking for a stabilizer, because during installation he was warned that the equipment would not be repaired under warranty if this device was not available. It's good that the guys got honest and warned. Often they just silently put a stamp, and then refuse to repair. In the place of residence, power outages and surges are common.Based on this situation, the best option is an on-line type UPS with batteries to ensure operation during outages.

If we talk about the power of the stabilizer, then in this case the power consumption of the boiler is 175W. To take into account peak loads, we multiply this figure by 5: 175W * 5 = 875W. That is, for this model of the Vialant gas boiler, a stabilizer with a power of 900 W or more is suitable.

Failure of the control board occurs due to voltage drops

Let's calculate the stabilizer power for the Baxi boiler model LUNA-3 COMFORT 240 i. This boiler consumes 80W. We calculate peak loads - 80W * 5 \u003d 400W. A very low-power stabilizer is suitable for this equipment, but such devices are rare less than 500W. Therefore, choose one of the five hundred. By the way, other boilers of the same line consume much more electricity, so a calculation is required for each modification.

All automated gas boilers require a stable input voltage. Let them, like Baxi, have surge protection boards, but they do not always cope with surges in our networks. Some service centers, as in the case of Vialant, officially warn about the need to install stabilizers. For others, like, for example, for Aristons, this is not a requirement, but a recommendation. But in the absence of a stabilizer at the boiler inlet or in an apartment / house, they simply declare a breakdown not guaranteed due to improper operating conditions. And the operating conditions are determined based on passport data.

Let's look at German boilers. Hinged gas boiler Buderus Logamax U052-28. Here are the power requirements.

Power requirements for "Buderus"

From which it follows that when more or less voltage is applied, the operating mode will be abnormal, that is, repairs in case of damage at the expense of the boiler owner. To ensure normal working conditions, install a voltage stabilizer, and for the Buderus boiler of this brand, the power of the device is 155W * 5 = 775W.

The same picture, approximately at the Wismans. There are no requirements on the site for installing a stabilizer (in Germany there is no need for such devices), and the operating voltage is also 210-230V. So please provide. This brand has a power consumption for wall-mounted gas boilers of 130-165W. Even if you do not want to bother and count for each model, take 1kW: none of the devices is needed anymore. In this case, the stock will not affect the performance in any way, although it is reflected in the price.

For gas boilers "Vissman" a stabilizer is required

From all of the above, we can conclude: no matter what brand your gas boiler is, Ariston, Buderus, Wisman, Baksi, Beretta or any other, install a stabilizer. And the safe operation of the gas boiler will be ensured only on thyristors. Let it be more expensive. Just remember that the cost of the control board (namely, it burns with increased / decreased voltage) is half the cost of the boiler.

Rating of the best stabilizers for gas boilers

The following models are popular among voltage stabilizers for gas boilers.

BASTION Teplocom ST-222 500

The stabilizer from the Bastion company should be chosen if there are no serious jumps in the network, since it does not have sufficient adjustment accuracy.The power is also low, but the pluses: universal installation on a DIN rail or on a wall, a compact case with a built-in socket and a 5-year manufacturer's warranty make it a worthy competitor for other review models.

Photo 1. Voltage stabilizer Bastion Teplocom ST-222 500. The device has a compact size, fits in the palm of your hand.

- Type: relay.

- Power: 180W.

- Input voltage: 165-260 V; at the output - 200-240 V.

- Stabilization Accuracy: 10%.

- Efficiency: 95%.

- Number of output sockets: 1.

- Weight: 1.5 kg.

- Cost: from 2400 r.

RESANTA ACH-1000 1-C

Good, "average" model for most applications. A power of 1 kW is enough for a typical boiler room in a private house, and output values \u200b\u200bof 202 to 238 V will allow almost any boiler to work. The stabilizer has an attractive price.

- Type: relay.

- Power: 1000W.

- Input voltage: 140-260 V; at the output - 202-238 V.

- Stabilization Accuracy: 8%.

- Efficiency: 97%.

- Number of output sockets: 1.

- Weight: 3.5 kg.

- Cost: from 1460 rubles.

Photo 2. Voltage stabilizer Resanta ASN-1000 / 1-C and a box from it. The power of the device is 1 kW.

RESANTA LUX ASN-10000N 1-C

Similar to the previous model, but 10 times more powerful.

- Type: relay.

- Power: 10 kW.

- Input voltage: 140-260 V; at the output - 202-238 V.

- Stabilization Accuracy: 8%.

- Efficiency: 97%.

- Terminals for connecting the load.

- Weight: 19.7 kg.

- Cost: from 8500 r.

SVEN AVR 500

A low-power budget stabilizer, however, will ensure reliable operation of the boiler during network surges from 100 to 280 V.

Photo 3. Voltage stabilizer for a gas boiler from the manufacturer Sven model AVR-500. The device has a convenient carrying handle.

- Type: relay.

- Power: 400W.

- Input voltage: 100-280 V; at the output - 202-238 V.

- Stabilization Accuracy: 8%.

- Efficiency: 95%.

- Number of output sockets: 1.

- Weight: 2.9 kg.

- Cost: from 1550 rubles.

RUCELF SRWII-12000-L

A good option from a Russian manufacturer. A wide range of input voltages allows you to operate the device in any conditions, and a power of 10 kW is enough for any equipment in the most advanced boiler room.

- Type: relay.

- Power: 10 kW.

- Input voltage: 110-270 V; at the output - 202-238 V.

- Stabilization Accuracy: 8%.

- Efficiency: 98%.

- Terminals for connecting the load.

- Weight: 22.5 kg.

- Cost: from 12190 rubles.

Photo 4. Voltage stabilizer Rucelf model SRW II-12000-L. The power of the device is 10 kW.

RUCELF SRW-10000-D

With less power than SRWII-12000-L, it provides more precise stabilization suitable for most boilers.

- Type: relay.

- Power: 7 kW.

- Input voltage: 140-260 V; at the output - 207-233 V.

- Stabilization Accuracy: 6%.

- Efficiency: 97%.

- Terminals for connecting the load.

- Weight: 14.1 kg.

- Cost: from 8550 rubles.

Powercom TCA-1200

Good relay stabilizers, if the network drops are not too large.

Very compact, light and cheap, provides a favorable output voltage for any gas boiler.

- Type: relay.

- Power: 600W.

- Input voltage: 176-264 V; at the output - 209-231 V.

- Stabilization Accuracy: 5%.

- Efficiency: 95%.

- Number of output sockets: 4.

- Weight: 1.6 kg.

- Cost: from 1320 rubles.

Powercom TCA-2000

A more powerful counterpart to the TCA-1200 model at an attractive price.

- Type: relay.

- Power: 1000W.

- Input voltage: 176-264 V; at the output - 209-231 V.

- Stabilization Accuracy: 5%.

- Efficiency: 95%.

- Number of output sockets: 4.

- Weight: 1.6 kg.

- Cost: from 1790 rubles.

Leader PS10000W-50

This model is distinguished from the Russian company Inteps by its extremely high power - up to 10 kVA, which allows you to power a serious boiler house completely, and not just one boiler. At the same time, the stabilization accuracy is ideal for even the most “capricious” gas boilers. Among the disadvantages: high price and heavy weight, which can cause difficulties in placement.

- Type: electronic.

- Power: 8 kW.

- Input voltage: 128-320 V; at the output - 210-230 V.

- Stabilization Accuracy: 4.5%.

- Efficiency: 97%.

- Terminals for connecting the load.

- Weight: 41 kg.

- Cost: from 46700 rubles.

Energy Classic 7500

The largest range of input voltages: from 60 to 265 V. Excellent electronic stabilization, providing an ideal power supply for the boiler in the region of 210-230 V.

High efficiency, moderate weight and average price make this device the best in this series of models.

- Type: electronic.

- Power: 5.2 kW.

- Input voltage: 60-265 V; at the output - 209-231 V.

- Stabilization Accuracy: 5%.

- Efficiency: 98%.

- Terminals for connecting the load.

- Weight: 20 kg.

- Cost: from 23470 rubles.

Types of stabilizers

The period of maintenance-free operation of a gas boiler with a pump and ignition from the mains depends on a stable and constantly the same voltage. Therefore, the inclusion of a stabilizer in the boiler operation scheme, if not necessary, is highly desirable. Modern stabilizers are divided into three types:

- Relay type - the cheapest, but not the most durable devices. Burning contacts forces the owner to change the device every 3-4 years. The stabilization amplitude accuracy also leaves much to be desired.

- Servomotor-based stabilizers can smoothly equalize the output voltage, but they operate more slowly, which increases the risk of an accident.

- Electronic circuits based on controlled thyristors (triacs) and microprocessors are durable, have high stabilization accuracy, are silent in operation and instantly respond to power surges in the network.

According to other parameters, stabilizers are divided into direct or alternating current devices, floor or wall structures, single-phase or three-phase devices. The table shows the technical characteristics of the most popular stabilizer models in 2014. The analysis shows that the electronic device can work in any conditions, with any voltage drops. The electronic stabilizer does not distort the shape of the voltage, which means that the gas boiler will work stably and reliably.

A mechanical or servo stabilizer has a longer response time for input voltage and current fluctuations. That is, during amplitude jumps, the mechanical device does not have time to equalize the amplitude and voltage fluctuations enter the electronic and electrical devices of the boiler. Fluctuations are rare, but often cause damage to the load electronics.

Therefore, only the owner of the unit can answer the question of which voltage stabilizer for a gas boiler is better. The cost of the device, and the requirements for it, and even the dimensions of the stabilizer play a role. Since a gas boiler is expensive, it makes sense to put a more expensive, but high-quality stabilizer for its maintenance, and not save on trifles.

How to choose a stabilizer

When buying, start from the main parameters:

- The power of the stabilizer is determined by the total power of the loads - a pump, a control panel, a gas burner and other automation elements. The standard stabilizer power is 150-350 watts.

- Instrument output voltage range.

- Mains voltage. To determine the voltage difference at different times of the day, measurements should be taken periodically, and then the arithmetic average should be taken.

Requirements for a quality stabilizer for a gas boiler:

- Aesthetic appearance.

- Small size and plenty of power.

- Possibility of wall or floor placement.

- Simplicity and reliability.

- Quiet operation and reliable thermal operation.

- Electronic execution.

- The price of the stabilizer should justify its technical characteristics.

If we talk about the price, then the miser pays twice. Choose a stabilizer with enhanced performance in relation to requirements - situations are different. If you have an expensive boiler installed, then the protection must match. Therefore, buy a stabilizer from a branded manufacturer, preferably with recommendations - from friends, from consultants or gas masters.

Manufacturers of electronic and mechanical stabilizers

Popular models of stabilizers of foreign and domestic production:

| Features \ Model | Snap-500 | VEGA-50-25 | RESANTA ASN-2000 | Shteel-1000 |

| Stabilizer | Mechanical | Electronic | ||

| Power | 500 W | 500 W | 2000 W | 1000 W |

| Adjustment speed, sec | 1,0 | 0,3 | 0,5-0,7 | 0,2 |

| Input voltage | 150-250V | 172-288 V | 140-260 V | 132-260 V |

| Voltage accuracy at the output of the stabilizer,% | 1 | 0,5 | 1,5 | 2,5 |

| Protection | Not | There is | There is | There is |

| Working temperature | -5/+40°C | -25/+45°C | 0/+45°C | +5/+40°C |

| Lifetime | 1-3 years | 7-15 years old | 5-10 years | 10-20 years |

| Dimensions | 175x190x140mm | 275x425x260mm | 100x183x240mm | 240x170x120mm |

| Weight | 4 kg | 16 kg | 4.2 kg | 6 kg |

| Service Warranty | 1 year | 5 years | 2 years | 5 years |

| Manufacturer | PRC | Italy | Russia | Ukraine |

| Price | 30 $ | 600 $ | 700 $ | 140 $ |

As you can see, the cheapest are Chinese mechanical devices. Russian stabilizers are the most expensive in their range of capacities and other technical characteristics. However, the cost is always justified. Therefore, advice from the pros: do not chase after savings - it can turn out to be expensive for you.

What types of stabilizers are suitable for boilers

Manufacturers produce many stabilizers of various models. The devices on the market can be divided into four types:

- electromechanical (servo)

- relay

- electronic (thyristor)

- inverter

Each type has its own characteristics, pros and cons, which must be considered when choosing. Here is a brief overview of equipment for each type.

Electromechanical

The principle of operation is based on the circular windings of the transformer, along which carbon brushes controlled by a servo drive move.

Pros: low cost, wide input voltage range, accuracy and smoothness of regulation, ability to tolerate overloads, ability to work at low temperatures and high humidity, reliable overvoltage and overheating protection system, long service life.

Cons: low adjustment (response) speed, increased noise level, increased weight and dimensions compared to other types of devices.

Such stabilizers can be installed for heating boilers, but it is not recommended to use them if there are frequent perceptible power surges. Also, for safety reasons, a separate installation site is required.

Relay

Widespread modern type of stabilizers.Here, the current passed through the transformer winding is regulated by special relays, and not mechanically. Some resources provide information that relay MVs are not suitable for heating boilers due to their low speed. Indeed, the response speed of previously produced stabilizers of this type was low, but modern models do not have this drawback.

Pros: affordable cost, wide range and high speed of regulation, reliable protection system, compact size and light weight.

Cons: step regulation, lack of power reserve, average noise level, short service life.

In terms of price / quality ratio, relay stabilizers are the best choice and are widely used with heating boilers.

Electronic

Electronic stabilizers also regulate the current by passing current through the transformer using electronic keys, which allows for the compact size of the device and its high efficiency.

Pros: wide range and high speed regulation, low noise level, compact size, long service life.

Cons: high cost, stepwise regulation, lack of power reserve.

Electronic stabilizers are a more perfect and versatile solution for heating boilers. They have a higher cost than relay ones, so they are less common.

inverter

There is no transformer in inverter stabilizers, here the alternating input current is first converted to direct current, and then the necessary alternating voltage is generated from it.

Pros: wide range of input and high accuracy of output voltage, high speed and smoothness of regulation, no noise, minimal dimensions and weight, long service life.

Cons: high cost, lack of power reserve.

Stabilizers of this type provide the highest quality regulation, but have the highest price among the listed types.

Read more about the different types of voltage stabilizers for the home, written in the following article: what types and types of voltage stabilizers for the home exist?

LENZ TECHNIC R500W - accuracy and price

Automated input voltage stabilization device. It is used in private houses, medical institutions, office and administrative premises. Built-in protection mechanisms against overheating and overload during intensive work.

The stabilizer has a low error and high accuracy of the output parameters. It is provided to connect two consumers with a total power not exceeding 500 watts. Levels a wide range of voltages, has a 100% power factor.

Pros:

- Compactness, accuracy, low level of error.

- Bright color LCD screen. Simple connection.

- The power supply of two consumers, I have, is a gas boiler and a circulation pump.

Minuses:

Operation in 0.02 seconds, there are better indicators.

Mounting and connection technology

Before connecting the stabilizer, you need to find a suitable place for it. You need to understand that the electrician does not like dampness very much, so the room where the device will be installed must be dry, without excessive humidity in the air. Most often, the permissible parameters are indicated in the instructions for the device. If they are not, you can focus on your own feelings.If there is excessive humidity in the room, for example, in the basement, it is better not to install the equipment here.

The garage will also not be the best place to place the stabilizer. According to the instructions, the device should not be in close proximity to chemically active, combustible and flammable substances. The attic doesn't work either. In the warm season, the temperature here often rises very high, which will adversely affect the operation of the device. Another inappropriate place is a niche in the wall or a closed closet. Lack of natural air circulation leads to overheating of the equipment.

Actually connecting the stabilizer is very simple. A gas boiler is connected to the equipment, and it is simply connected to the network. If you have to install several single-phase stabilizers at the same time, for example, in the case when three phases enter the room, you cannot plug them into one outlet. Then the first one, when switching, will create network interference, and force the other to switch. This process is practically endless. Thus, a socket must be prepared for each of the devices.

The location for installing the voltage stabilizer must be chosen correctly. The room should not be too humid or hot. In addition, natural air circulation must be ensured, otherwise the device is threatened with overheating.

Manufacturers of gas boilers warn that all warranty obligations that are given when purchasing equipment will be canceled if their operating requirements are not met. In the first place among them is most often the high-quality power supply of the device.The role of a voltage stabilizer in its provision cannot be underestimated, so the choice of a device should be approached very responsibly. Properly selected equipment will allow the gas boiler to work for a long time and uninterruptedly in the most economical mode, which will enable its owner to save a decent amount.

Types of Voltage Stabilizers

Stabilization or regulation of mains voltage to power various radio and electrical devices has been used for a long time. The simplest device of this type is an autotransformer with step or continuously adjustable output voltage.

Currently, the following automatic voltage stabilization systems are used:

- Relay stabilizer;

- Servo stabilizer;

- Thyristor stabilizer;

- Inverter.

There are modern stabilizers for the home. using the principle of pulse-width modulation, but in gas heat supply systems they are used quite rarely.

Relay stabilizers

The principle of operation of a relay device is similar to that of an autotransformer. The voltage boost coil connected to the network is divided into sections, from which you can remove high or low voltage. The control module constantly scans the mains voltage and, in case of a change in the input voltage, turns on the corresponding relay.

With its contacts, the relay connects any of the sections to the output of the device. Since the relay device operates in a discrete mode, the output voltage may differ from 220V up or down by 5-8%.

The device is reliable in operation, does not require maintenance, and has the following parameters:

- Voltage regulation - step;

- Installation accuracy - 5-8%;

- Rated input voltage - from 190 to 250 V.

Servo Stabilizers

The servo stabilizer is an electromechanical device. The voltage regulating element is a metal or graphite contact moving along the transformer winding. The contact is fixed on the axis of the servomotor.

The control board monitors the input voltage and, if it changes, sends a signal to the electric motor. The motor rotor rotates at a certain angle, thereby changing the voltage at the output of the device.

Thyristor

The thyristor stabilizer is a fully electronic device. The principle of its operation is similar to a relay device, only the transformer winding sections are switched not by relay contacts, but by semiconductor switches.

Switches made on thyristors or triacs provide a reserve of up to a billion switching, which makes this stabilizer extremely reliable. The device provides voltage regulation in a discrete mode, but has a high response speed.

Inverter type stabilizer

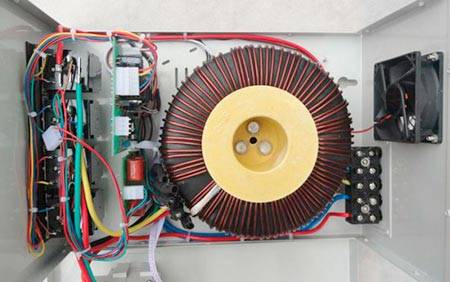

The most progressive stabilizer is an inverter-type device or a double conversion stabilizer. It lacks such a bulky element as an autotransformer. The alternating voltage, having passed through the filter, is rectified, while a certain energy is stored in the capacitor. Then the direct current is converted back to alternating current.

The principle of operation of the inverter stabilizer

Each type of stabilizer has its own advantages and disadvantages:

The relay device is characterized by low cost and good reliability, but due to step switching, the accuracy of setting the output voltage is low;

The servo stabilizer gives a very accurate voltage value, but has a low response speed and requires constant maintenance due to the rapid wear of the elements, it is not recommended for use with gas equipment, because the contacts may spark when worn;

The thyristor regulator has an instantaneous response speed, but costs much more than a relay stabilizer;

The double conversion device delivers ideal voltage, high speed, high accuracy and quiet operation.

What you need to know when choosing a voltage stabilizer

Voltage stabilizer device.

Among the manufactured types of devices that serve to protect electrical equipment from voltage surges, the most accurate is the electromechanical stabilizer. However, their use for gas equipment is strictly prohibited. The reason for the ban is the possibility of sparking contacts during their closure.

When choosing protection for a gas-fired boiler, it is better to pay attention to electronic devices. The electronic protection of the gas boiler reacts faster to changes in the power supply network; when it is connected, high-quality protection of the equipment is guaranteed

It is important that the electronic voltage stabilizer works almost without noise. Since most domestic gas boilers operate on a 220 V network, a single-phase stabilizer should be used to protect them.

If the boiler is designed to be connected to a 380 V network, then the choice of a voltage stabilizer is unambiguous - only three-phase.Since a three-phase device has a higher cost, another protection method can be used: install a single-phase modification of the device for each phase separately. Such protection will cost a little less.

Since most household gas boilers operate on a 220 V network, a single-phase stabilizer should be used to protect them. If the boiler is designed to be connected to a 380 V network, then the choice of a voltage stabilizer is unambiguous - only three-phase. Since a three-phase device has a higher cost, another protection method can be used: install a single-phase modification of the device for each phase separately. Such protection will cost a little less.

The voltage stabilizer is available with various installation methods. It can be designed for installation on a horizontal surface, some models are made for wall mounting. There are also models with a universal mount. In operation, a voltage stabilizer with a universal mount is more convenient, since, if necessary, you can easily change the place of its installation.

Requirements for the stabilizer

When choosing a model for specific operating conditions, it is necessary to take into account the main criteria that a normal voltage stabilizer must meet.

First of all, you need to pay attention to the following parameters:

- Response time as reported on the data sheet of the device, measured in milliseconds (ms). The lower this indicator, the better the automation and electronics of the boiler will work. It corresponds to the period of time during which the voltage can be corrected during the jump.

- Input voltage range.Indicates the set limits within which the boiler can operate normally. When the voltage reaches the limit value, the gas boiler automatically turns off. However, a large number of shutdowns of boiler equipment during the heating season can cause defrosting of the system pipes. Therefore, it is recommended to choose a stabilizer with a voltage difference of about 140-260 volts.

- Coefficient of correction levels. Determines how stable and accurate the output voltage will be maintained. More levels provide quality work.

- Temperature Range. A good device should maintain its performance at outdoor temperatures from +5 to +40 degrees. In industry, devices are additionally protected by special casings that allow them to work normally even at low temperatures.

- Much depends on the type of installation. With conventional gas boilers, hinged structures with small dimensions and weight are mainly used. Floor or ceiling appliances are used in conjunction with powerful three-phase boilers.

Considering these criteria and local operating conditions, it is quite possible to select the most suitable device that meets all technical requirements. As a rule, stabilizers successfully cope with voltage drops, ensure the normal operation of automation and electronics.