- What is better aluminum or bimetal radiators

- for installation in an apartment

- Aluminum or bimetallic radiator: which one to choose for your home

- Comparison of fundamental differences between aluminum and bimetallic radiators

- Bimetal or semi-bimetal radiators

- Bimetal or aluminum: which is better?

- Differences between bimetallic radiators and aluminum

- Those. individuality of aluminum batteries

- Bimetallic heating radiators, properties

- What is the difference between aluminum batteries and bimetallic

- Heat transfer indicators

- Corrosion resistance

- Resistant to pressure and water hammer

- Ease of installation

- Life time

- Interaction with coolants

- Features of bimetallic radiators

- Advantages of bimetallic batteries

- Cons of bimetal

- Comparison of aluminum and bimetal radiators

- Classification of batteries by manufacturing technology

- Type #1 - extrusion

- Type #2 - cast

- Features of mounting radiators

- Connection methods

- Sectional or monolithic bimetallic radiators

- 2 Aluminum radiators

- Comparison of classic bimetal and aluminum

- Types of bimetallic radiators

- Sectional radiators

- Monolithic radiators

- Tips & Tricks

What is better aluminum or bimetal radiators

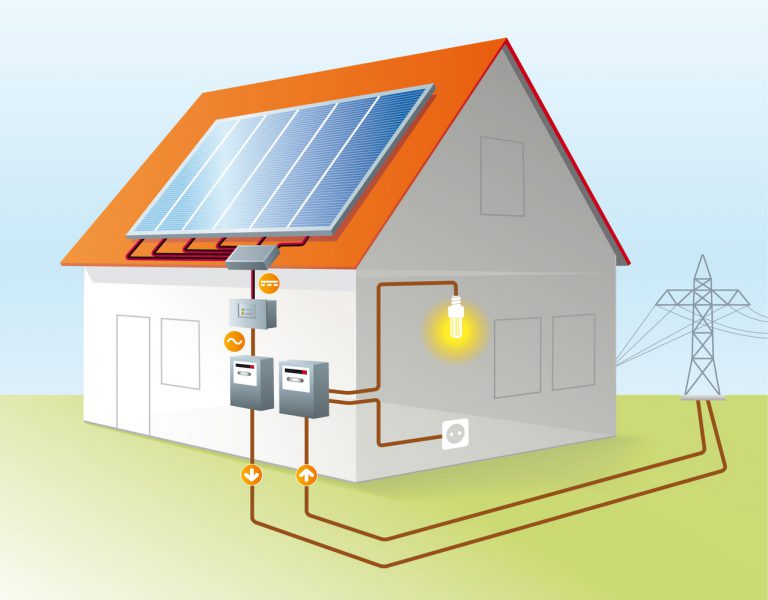

Each product has advantages and disadvantages. Therefore, the choice depends on:

- type of heating system (individual / centralized);

- presence/absence of coolant drain;

- the price the consumer is willing to pay.

for installation in an apartment

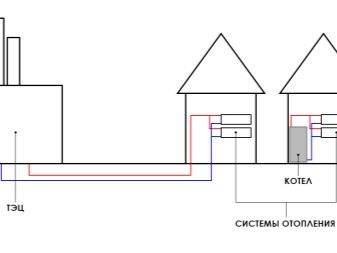

Apartments in high-rise buildings, as a rule, are heated centrally, so their owners cannot control the composition and acidity of the coolant.

In this case, preference should be given to bimetallic products that are more resistant to fluctuations in the acidity of the liquid involved in the heating process, as well as well tolerate its high working pressure and water hammer.

Aluminum or bimetallic radiator: which one to choose for your home

It may seem that a combined product is the best option for a heating device. However, such a conclusion should not be drawn. The expediency of using various devices depends on the conditions of their operation. So, aluminum batteries have proven themselves well in low-pressure networks. These are all systems in private and low-rise buildings. The best option for such models is heating in one, maximum three-story houses.

Best of all, they “feel” in open systems. The combined option is good for high pressure networks. It is able to withstand significant water hammer and temperature fluctuations. Such models are ideal for skyscrapers, large high-rise buildings with a large number of rooms, etc. Perhaps the problem of choice would simply not exist if both types of devices had approximately the same cost.

However, the price of bimetal is noticeably higher. In terms of an apartment or a house, a significant difference is obtained. Therefore, when choosing batteries, it is strongly recommended to take into account the conditions of their operation and, based on this, make a decision.Don't try to skimp on quality. Cheap fakes will not only last less, due to the increased risk of an accident, they pose a health hazard to those living in the house.

Comparison of fundamental differences between aluminum and bimetallic radiators

In appearance, both presented radiators are very similar to each other. They are made in the form of rectangles of metal, the shape of their ribs is flat. The number of sections for structures of both varieties ranges from 6 to 12 pieces. Their heat transfer is also almost on a par with each other, amounting to approximately 170-200 watts.

Today it is very popular to beat every household detail of the room, turning it into a fashion accessory. The same applies to bimetallic batteries installed in your home. The outer coating of the products is always painted in neutral white or gray colors. However, standard store options can be improved on their own by covering them with specialized bright paint. Customize the radiator with the pattern you like and breathe a special atmosphere into the room.

Manufacturer color options

Heating radiator decoration option

Important! Before buying paint, consult with experts. It is important to choose non-toxic and heat resistant to keep your health safe

So, let's summarize and name the main difference in the operation of aluminum and bimetal batteries:

- Aluminum batteries are well suited for installation in country cottages and ordinary private houses. It is there that it is necessary to obtain maximum heat transfer from radiators, especially in winter.Given the low pressure and high quality of the coolant, this is an ideal option for heating suburban housing equipped with an autonomous heating system. It makes no sense to install bimetallic sections, as they can quickly fail;

- Bimetallic batteries, on the other hand, were developed just for operation in the conditions of an urban centralized heating network. Aggressive chemicals have long been added to the water circulating through them to reduce heat loss. The steel core of bimetallic installations easily copes with these impurities, and also withstands hydrodynamic shocks and pressure drops in the system. That is why it is better to use this variety for installation in an apartment, office, etc.

Bimetal or semi-bimetal radiators

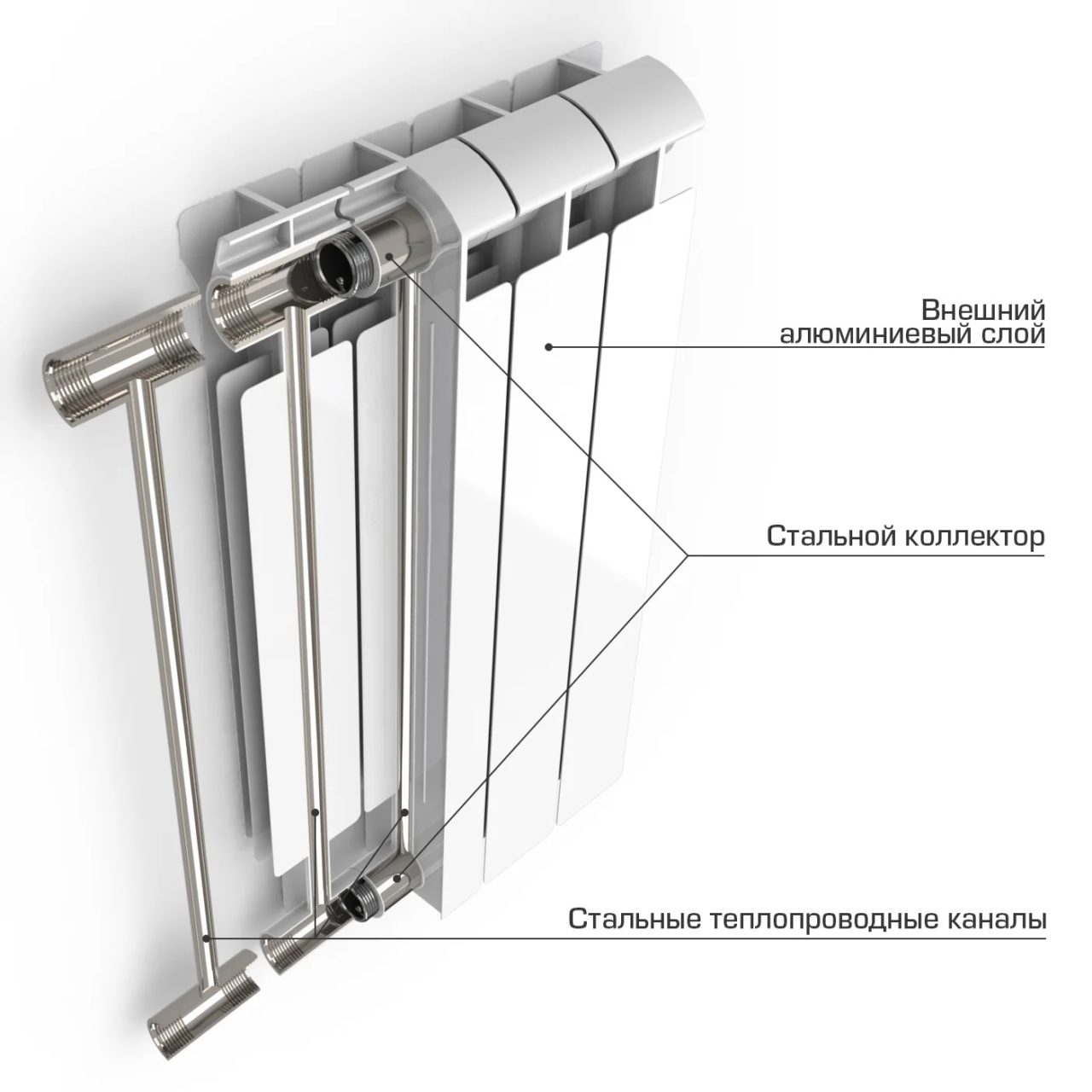

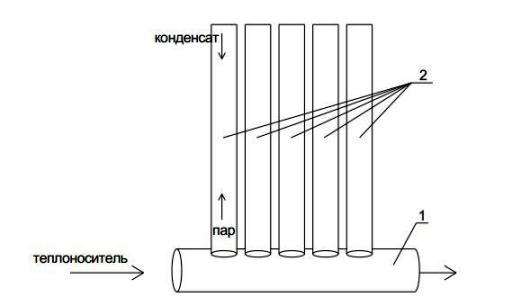

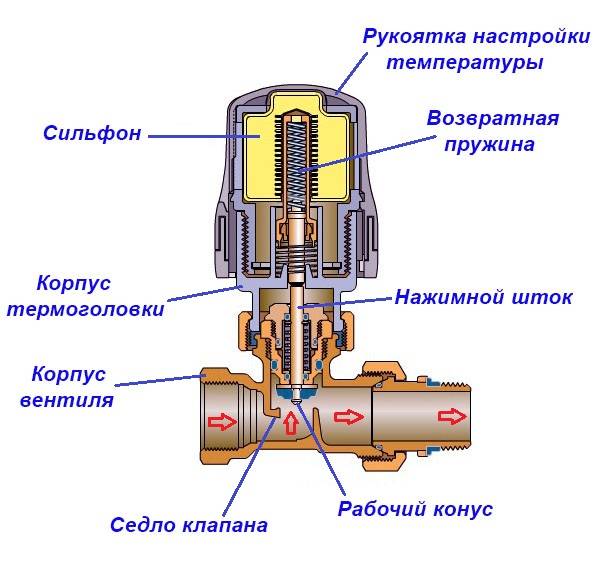

Bimetal heaters are steel pipes connected by cold welding, which are covered with a layer of aluminum. Due to this, hot water does not interact with the outer shell of the radiator, which helps to avoid corrosion. Moreover, aluminum is applied in the form of figured plates, and this significantly increases the heat transfer area.

There are also copper cores of bimetallic radiators. They are suitable if the coolant is water with antifreeze. Such a composition can quickly destroy steel, but copper is resistant to it.

For semi-bimetallic radiators, the core is made of two metals. All vertical channels are steel, and horizontal channels are aluminum. The disadvantage of such devices is that they are not suitable for water with a high content of alkalis. They necessarily require a coolant purified from impurities.

Now about which heating radiators are better.For heating systems of the central type, it is bimetallic devices that are more suitable, because they are resistant to pressure drops and poor-quality contaminated coolant.

For an apartment, it is better to choose bimetallic heating devices.

Semi-metal radiators are more efficient, but ideal conditions are needed for their normal operation. They are more suitable for private houses, and are much more expensive than bimetallic devices.

Bimetal or aluminum: which is better?

look exactly the same

The aluminum device has a high thermal power, while the bimetallic one has an average one. In the first case, the maximum working pressure is usually 16 atmospheres, and in the second - 20. Both of these metals are not very resistant to corrosion.

The warranty period for these heating devices is 20–25 years. They can be repaired by hand. But the cost of aluminum devices is much lower than that of a bimetallic product.

Given these facts, it is difficult to decide which radiator is better. They both do their job well. Therefore, it is best to choose a device, taking into account one point - in which system it will be operated.

Aluminum batteries are very light, the working pressure is always stable, the coolant is well controlled, so they are used for an autonomous heating system. Bimetal appliances are great for a central heating system, because they can withstand pressure surges and high coolant temperatures well.

Batteries made from materials such as aluminum and metal have their own advantages. They appear only if they are properly installed and used.Aluminum appliances are installed if a low-pressure system requires maximum heat transfer. In all other cases, bimetal devices are installed.

Differences between bimetallic radiators and aluminum

The choice of a device for heating is a serious matter, not only the temperature in the room during the winter depends on this, but the reliability and long-term use of batteries in different conditions. You need to know those. the capabilities of heating products produced by different materials and their main differences affecting the validity of the choice in any particular case.

At the moment, according to the responses of professionals, as well as users, 2 types of batteries are considered more effective - bimetallic and aluminum.

Before making comparisons, it is necessary to better understand the working abilities of aluminum and bimetallic batteries.

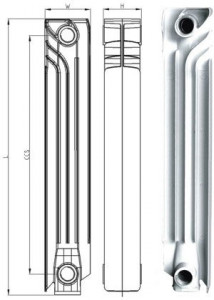

Those. individuality of aluminum batteries

The case of such products is made of aluminum or its alloys. For the production of products, a casting method or a press at a high temperature is used. Cast sections are the highest quality and most reliable. Batteries made of aluminum are equipped with ribs between sections and vertical panels in front, this makes it possible to achieve the highest thermal return, while thermal energy comes in the form of radiation, as well as in convection.

Aluminum radiators are not large, they have a lot of shapes. Traditionally, the segments are packed in 2-3 sections and are assembled into a heating battery of suitable volumes.At the joints, silicone or paronite gaskets are installed to isolate the joints. To connect the individual parts, bronze or brass nipples are used.

Those. the characteristics of aluminum radiators are good and not quite. The advantages of such products are:

- The highest heat output (up to 250 W per section).

- Little thermal inertia.

- Batteries are compact and not heavy.

The disadvantages of aluminum batteries include:

- Inability to withstand high pressure in the heating system (no more than 10 atm);

- Chemical instability of the material.

- Short shelf life (10 years).

- Demanding on the quality of the coolant.

Analyzing the properties listed above, it is clear that these radiators should not be used in central heating conditions, since aluminum devices are in no way adapted to work at high pressure and poor quality of the coolant.

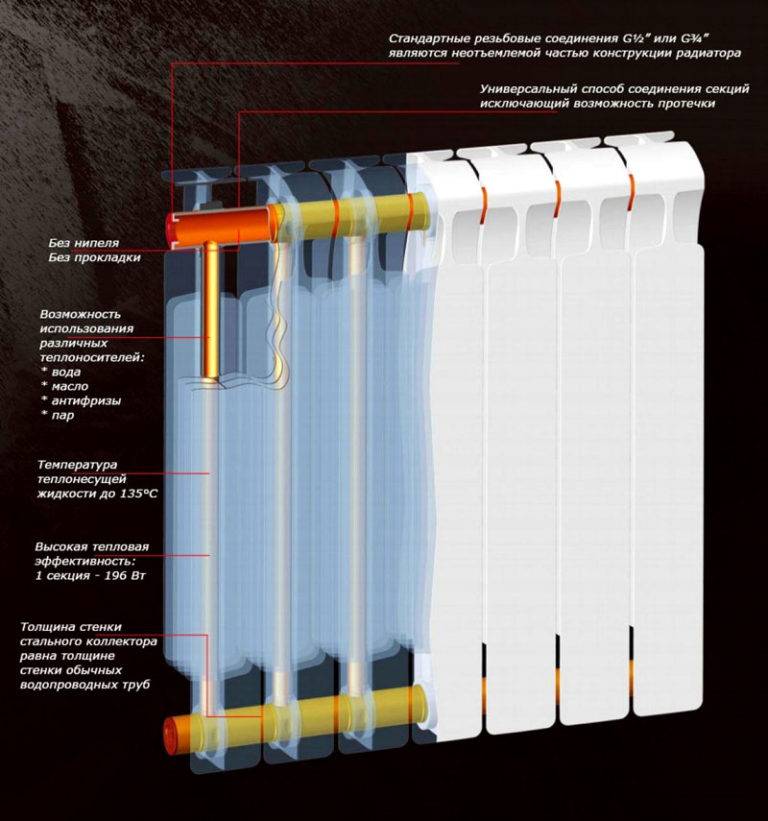

Bimetallic heating radiators, properties

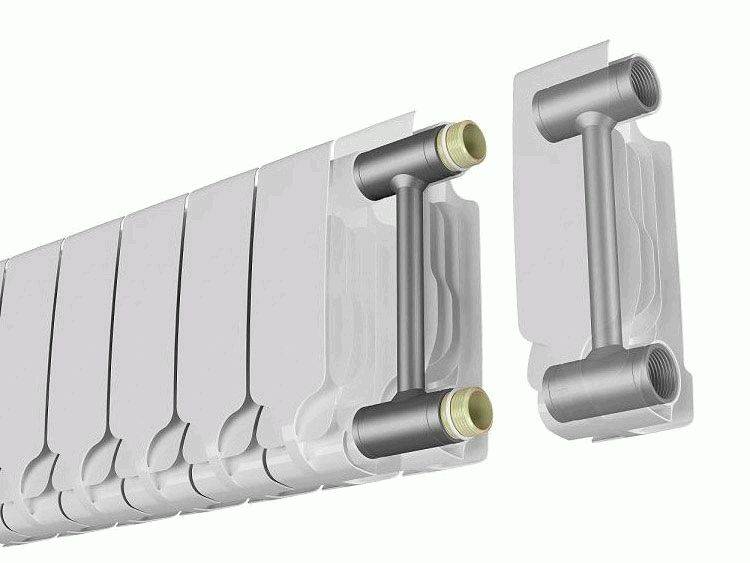

The name of these products says that their main highlight, in comparison with other batteries, is the use of 2 different metals in the manufacture of the frame. Radiators of this type are iron pipes, in accordance with which heated liquid circulates, they are pressed with external components made of aluminum or its alloy. Due to such a fruitful personality, bimetallic products retain excellent heat transfer characteristics due to aluminum and increased strength to iron parts .

The use of a steel core will reduce to a minimum the number of shortcomings of a heating battery made of only 1 aluminum.

Here are the main characteristics of batteries made using 2 metals:

- Excellent heat dissipation (200 W from one section).

- Fast heating speed.

- The devices are small and not heavy.

- They don't hold a lot of coolant.

- Withstand high pressure (20 atm working)

- The metal core is inert, it is affected by the modification of the reaction of the coolant medium.

- Reliable (20 years of work and more).

Poor quality of bimetallic devices. The narrow gap of the iron core, this can lead to rapid contamination and the high price of products (on average, thirty percent more expensive than similar aluminum ones). Bimetallic radiators are outwardly similar to aluminum ones, their outer part is made of the same material.

It can be seen from the features of aluminum batteries and those produced by 2 alloys, their constant use in the same conditions is not possible. Particularly for products made of aluminum, they are not suitable for operation in centralized heating medium supply conditions due to their inability to tolerate dangerous pressure surges and sensitivity to water quality.

This means that from these 2 radiators, only bimetallic devices are suitable for central heating. Aluminum products are suitable for weak heating systems and are good for independent heating systems where the temperature of the circulating water is relatively low.

When choosing a suitable device in the presence of an autonomous boiler, it is necessary to take into account the differences between aluminum radiators and bimetallic ones, taking into account not just one characteristic, but their complex. Devices made of 2 metals are more expensive and heat transfer is lower, but they are 2 times more durable.

What is the difference between aluminum batteries and bimetallic

Aluminum radiators are made of one metal and do not have a core, bimetallic ones, on the contrary, have internal steel tubes for coolant circulation and external aluminum fins for good heat transfer.

However, outwardly both types of products are similar and have an attractive aesthetic appearance that can match any interior.

Heat transfer indicators

Since the outer part responsible for heat dissipation in both types of batteries is made of aluminum, they have good heat dissipation performance.

But for products consisting of only one metal, it is approximately 15 ... 20% higher.

Corrosion resistance

Corrosion resistance is higher for bimetallic batteries, since the coolant circulates through steel pipes, which are more resistant to corrosion and aggressive environments.

However, steel is also susceptible to rust when air masses enter the system, which is possible with seasonal drains of the coolant.

Resistant to pressure and water hammer

Due to the internal steel pipes that can withstand the high working pressure of the liquid and its differences, the bimetallic battery is more resistant to water hammer.

Ease of installation

Both types of the described elements of the heat supply system are easy to install, however, aluminum batteries are lighter, which makes their installation somewhat easier.

Life time

The possibility of long-term operation depends on many factors:

- operating pressure in the system;

- chemical composition of the coolant;

- presence/absence of water hammer;

- the temperature of the circulating fluid;

- seasonal coolant drains.

If the radiator is selected and installed correctly, the service life declared by the manufacturer is:

- for aluminum products - 20 ... 25 years;

- for bimetallic - 25 ... 30 years.

Interaction with coolants

Aluminum batteries are highly dependent on the quality of the coolant. If the pH level rises above a certain value, they are susceptible to corrosion and further leakage.

For bimetallic products, a steel pipe comes into contact with the coolant, which is more resistant to adverse environments and pH fluctuations.

Features of bimetallic radiators

In the production of these products, two types of metal are used - steel and aluminum ("bi" means two). The section is a steel pipe, poured under high pressure into an aluminum jacket. Steel elements are joined to the pipeline, withstanding pressure surges and successfully resisting corrosion. The aluminum coating ensures high heat dissipation. Sections are connected to each other by means of nipples.

Steel tube in aluminum casing

Advantages of bimetallic batteries

- Durability and long service life (more than 25 years) due to the internal steel pipe. This is the main difference between bimetallic radiators and aluminum ones.

- High heat dissipation. A small amount of energy is spent on heating the radiator itself. Heat almost immediately begins to be transferred to the room.

- Working pressure up to 40 atmospheres.

- The maximum coolant temperature is 130 degrees (for aluminum batteries - 110).

- Durable coating. Coloring is carried out in two stages: first, the product is completely immersed in a dye solution, after which a polymer layer based on epoxy resin is sprayed. Such processing not only gives the battery an aesthetic appearance, but also increases its tightness.

- Easy to transport and install. You can increase the number of sections on the spot.

Important! Some bimetal models have a single steel core and are not divided into sections. The advantage of such products is that they can withstand high pressure, are not subject to leakage.

Cons of bimetal

The difference between aluminum and bimetal radiators is that the heat transfer from bimetal is lower. The steel core significantly reduces this figure.

The cost of bimetallic batteries exceeds the price of aluminum ones by about 30%. The operating costs are also higher - the bimetal has a higher hydraulic resistance, so more energy will be needed to pump water.

Improper use of batteries causes corrosion of steel elements. This happens if, at the end of the heating season, water is drained from the system. Simultaneous contact with air and water creates conditions for steel rusting.

The narrow passage section of the iron pipe increases the risk of clogging and reduces the service life of the product.

Note! Steel and aluminum have different coefficients of thermal expansion, so after a while the radiator starts to make characteristic sounds. It poses no danger

Comparison of aluminum and bimetal radiators

- Externally, aluminum and bimetallic radiators are similar - they are metal rectangles with flat fins, painted in neutral tones. The number of sections for both is from 6 to 12. The average heat transfer from devices does not differ much - from 180 to 200 watts. But the use of devices has its own characteristics.

- Aluminum batteries are installed where maximum heat transfer is required at low pressure and good quality of the coolant, namely, in private homes. You can put bimetallic sections in an autonomous system, but this will be an unjustified waste of money.

- Bimetal devices were created taking into account the peculiarities of domestic centralized heating systems. The steel filling of the battery withstands frequent pressure drops in pipes, hydrodynamic shocks, and aggressive impurities in the coolant. Therefore, bimetallic radiators should be installed in the central heating system.

Finally. When buying radiators, it is better not to save money and choose appliances from well-known brands. If the production technology is not followed, the equipment will not last long

It is extremely important that experienced professionals carry out the installation, since the operation of the entire heating system and the heat in the house depend on the correct installation of the batteries.

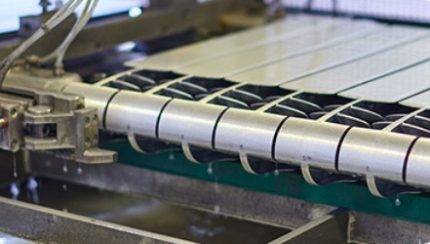

Classification of batteries by manufacturing technology

For the production of heating radiators, aluminum is not used in its pure form, but its alloys with silicon. Separate sections and whole products are obtained from blanks. The main metal processing methods are extrusion and casting.

Type #1 - extrusion

On production lines, the main tool for the manufacture of extrusion devices is a molding extruder, which literally squeezes out the required profile on metal blanks.

The disadvantage of the technology is the release of individual parts, subsequently connected by pressing. Of course, the seams on the structure make it vulnerable to pressure drops and untreated coolant.

Using extrusion, sections and manifolds are made.After the parts undergo pressing processing, it is not possible to change their size, therefore, during installation, the length of the finished products cannot be changed.

Extrusion models are the most inexpensive among aluminum models. They are characterized by a smaller area of working surfaces, which reduces the heat transfer of devices. The seams obtained as a result of pressing are gradually destroyed from contact with low-quality coolant.

The corrosion process is more active also because secondary aluminum is used as a raw material for extrusion, a characteristic feature of which is the presence of rapidly oxidizing impurities.

Type #2 - cast

Radiators produced by casting technology have higher performance. They are safer, stronger and more resistant to aggressive environments than extrusion counterparts, and, accordingly, more expensive. Aluminum is used for manufacturing (from 88%) and alloys with the introduction of silicon (up to 12%).

Production takes place as follows. The molten metal enters the molds for casting, where it acquires a given profile. The parts that have received the design configuration are cooled, processed and checked for leaks. The walls of the blanks are treated on all sides with an anti-corrosion compound.

After the next cooling and drying, the almost finished sections are painted with a protective polymer enamel with the addition of epoxy resins. Finishing stage - assembly and testing

Various manufacturers are experimenting with casting technology, resulting in new types of radiators. Suppose Faral Trio has released a line of dual-channel radiators that have not lost strength and do an excellent job with burst pressures of more than 55 atm.

And the Italian Raden radiators have vertical fins of 6 rows, due to which there is an increase in heat transfer.

If you want the heating system to be equipped with really reliable and protected devices, pay attention to anodized batteries. These are radiators made of aluminum coated with a durable oxide film, which has two purposes - protection and decoration.

The oxidation process several times increases the resistance of the metal to corrosion and other negative changes or reactions to the poor quality of the liquid circulating through the instrument channels.

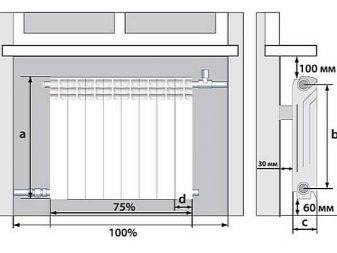

Features of mounting radiators

If the system is mounted horizontally, air will be difficult to bleed

When installing batteries yourself in a private house or cottage, the following rules and regulations should be observed:

- radiator length - 55-75% of the width of the window opening;

- distance to the wall - 30-50 mm, to the floor - from 100 mm, from the window sill - from 50 mm;

- batteries should be mounted under the window, not far from the door - in places with the highest air circulation;

- the central axis of the radiator coincides with the central axis of the window, the recommended deviation is 20 mm.

When installing a radiator, sealant is required

When installing a radiator, sealant is required

When installing bimetallic or aluminum radiators, the packaging is not removed from them until the end of work in order to avoid accidental damage. With natural circulation of fluid in batteries, it is permissible to mount up to 12 sections, with artificial circulation - up to 24. In addition to radiators, you will need:

- sealant;

- sealing tape;

- torque wrench;

- thermostats and valves;

- fasteners (brackets);

- shanks of different sizes.

Mayevsky crane for air release

Mayevsky crane for air release

Thermostats, shut-off valves and a Mayevsky crane are installed on the batteries, through which air is released. Brackets are attached to the walls according to the level, radiators are hung on them. They should be tight, not wobble. Then the plugs are unscrewed, with a single-pipe system they mount a bypass with a valve, with a two-pipe system - a drive with a valve. Pipes are connected with spurs with a torque wrench so as not to overdo it when tightening the nuts (the torque limit is indicated in the instructions for the fasteners). A weak connection is fraught with leaks. The joints are sealed with a sealant or sealant.

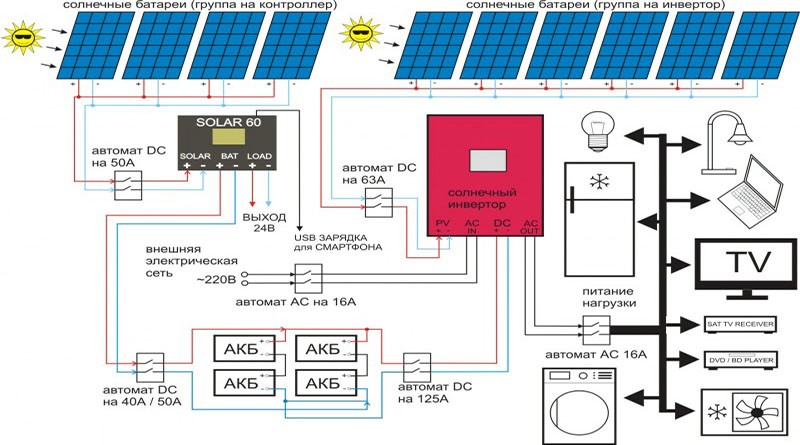

Connection methods

According to SNiP, radiators can be connected in a side, bottom or diagonal way. The most common is the side connection, in which the inlet and outlet pipes are located on one side of the battery. With a bottom connection, connect the input to the bottom fitting on one side, and the output to the bottom fitting on the other side. In this case, heat transfer is reduced by 10-15%. The most advantageous is the diagonal connection, when the inlet is connected to the upper fitting on one side, the outlet is connected to the lower fitting on the other side.

According to SNiP, radiators can be connected in a side, bottom or diagonal way. The most common is the side connection, in which the inlet and outlet pipes are located on one side of the battery. With a bottom connection, connect the input to the bottom fitting on one side, and the output to the bottom fitting on the other side. In this case, heat transfer is reduced by 10-15%. The most advantageous is the diagonal connection, when the inlet is connected to the upper fitting on one side, the outlet is connected to the lower fitting on the other side.

You can connect in series and in parallel. The first method implies a closed system in which the inlet pipe of one battery is the outlet for another. If there are no bypasses, in order to repair one battery, you need to turn off the entire system. Bypass - a tube connecting the input and output of each battery. In parallel, each radiator is connected to the main pipe.

Sectional or monolithic bimetallic radiators

At first, bimetal products were always assembled from several sections.However, any sectional radiator can suffer from a coolant that damages the joints and reduces the life of the devices. In addition, joints are always a potentially dangerous place, which is more prone to leakage due to increased pressure in the system. Therefore, they came up with a new technology, according to which a solid steel or copper collector is made, and an aluminum shirt is “put on” on top of it. Such radiators are called monolithic.

The device section of the bimetallic radiator.

Now let's try to find out which bimetallic radiators are better - sectional or monolithic. According to the technical characteristics, the advantage of the latter is obvious.

- The term of work is up to 50 years (for sectional ones - up to 20-25 years).

- Working pressure - up to 100 bar (for sectional - up to 20-35 bar).

- Thermal power per section - 100-200 watts (on the same level as sectional models).

But the price of monolithic devices is somewhat higher than sectional ones. The difference can be up to one fifth. And one more nuance: models with a solid core cannot be modified by removing unnecessary or adding additional sections, but at the same time they are available in various sizes both in height and in length. Therefore, it is not difficult to choose a radiator with the required power.

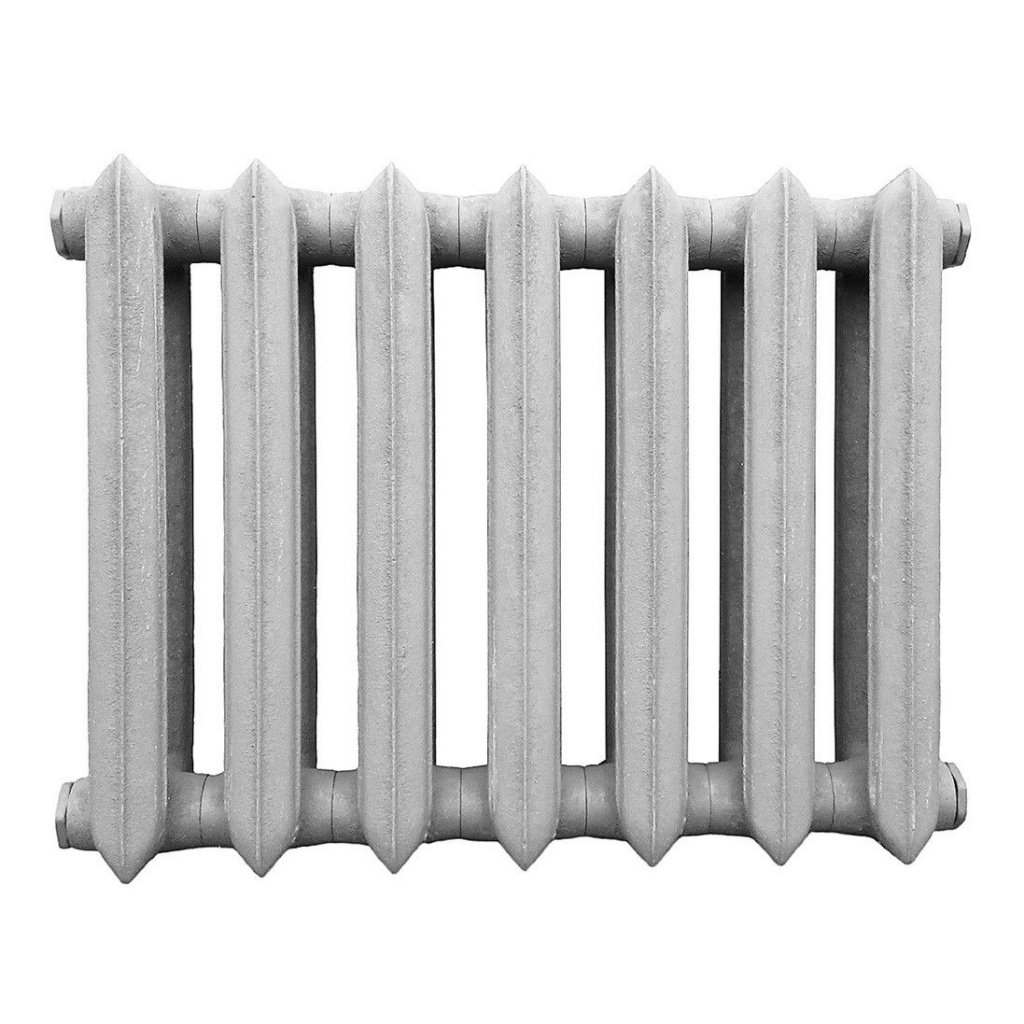

2 Aluminum radiators

It is generally accepted that aluminum radiators are very efficient, which is why they are so widely used for space heating. And for a long time, this system has really proven itself on the positive side. Many choose them for external data, as they really look more aesthetically pleasing than bulky cast-iron models.In addition, they are quite light.

For the manufacture of these devices, two technologies are used:

- extrusion method;

- casting method.

In the first case, an aluminum profile and a special press are used in the manufacture, with the help of which individual parts are formed. In the future, the structure is assembled and ready-made sections are obtained to make them airtight, special gaskets are used, as well as reliable and high-quality insulation.

Aluminum tends to heat up quickly, and the heat that comes from the appliance moves to the ceiling with the help of convection air flow. The thermal power of each sectional compartment is approximately 110-120 W, and the depth varies from 70 to 110 mm. The weight of the structure is 2 kg. The maximum temperature regime at which such a radiator can function normally is 90 degrees.

Comparison of classic bimetal and aluminum

Each material has its own characteristics. Aluminum perfectly enters into various chemical reactions. Such a battery consists of several sections, which are fastened together with nipples. To achieve maximum tightness, the joints are insulated with gaskets. Inside there are ribs that significantly increase heat transfer. But bimetallic devices have a compact core, which increases the likelihood of pipe clogging.

If we compare these two heating devices in terms of heat transfer, then aluminum products win. The main difference is that each section is capable of generating up to 200 watts of valuable energy. The main percentage of heat enters the room in the form of waves, and the rest is distributed by the convection method.

Already 8 minutes after turning on the system, the room will be well warmed up. Aluminum structures function when the pressure is in the range from 6 to 20 atmospheres. This indicator is not enough for central heating, since radiators do not withstand sudden changes. Aluminum are sensitive to water hammer, because of which they can simply burst and fill the room with hot water.

The working pressure of the bimetal reaches 40 atmospheres. This indicator is quite enough for the system to cope with the shutdown and abrupt opening of the valves on the pumps. They are often installed in multi-storey buildings, where there is a high probability of water hammer.

Consumers should definitely pay attention to chemical resistance. Aluminum cannot boast of optimal parameters, as it quickly reacts with coolant impurities, which makes it simply impossible to avoid corrosion.

Rust appears after the pH level exceeds 8 units.

As a result of a chemical reaction, hydrogen is released, which is fraught with an explosion and fire. That is why you need to regularly bleed air from the system.

The main difference is that the bimetal lasts much longer. In production, the steel core is coated with a thick layer of anti-corrosion agent. Some manufacturers use high-quality stainless steel pipes, due to which the battery lasts more than 30 years.

Comparison of devices

Comparison of devices

Types of bimetallic radiators

There are two main types - sectional and monolithic. Below we will tell you more about them and help you figure out which one is best for you.

Sectional radiators

They are assembled from several sections. Often performed in the form of a "layer cake" of heating plates. This discovery allows to significantly increase the area of heat exchange with the environment. But there is a big drawback: any coolant destroys the joints of the components. The result is a relatively short service life.

Sectional heaters consist of several parts

Monolithic radiators

They also have a large heat exchange area, so they are in no way inferior to sectional heaters. Gives out one section of about 100-200 watts. Monolithic radiators are manufactured according to a fundamentally new technology: the body is cast as a whole, and then processed by pressure. A layer of aluminum is applied over the steel frame under pressure.

Monolithic heaters are one piece

The advantage of monolithic radiators is obvious. The service life is twice as high and is not 25 years, like sectional ones, but 50. But at the same time, they cost about a fifth more. Their disadvantage is that they do not make it possible to add additional sections and thereby adjust the power.

If you think about the question of which heating battery is better for apartments in high-rise buildings, then the answer is unequivocal - monolithic. The point is a large pressure drop due to altitude.

Tips & Tricks

To make the right choice in favor of aluminum or bimetallic radiators, it is worth considering the recommendations of experts.

If the required radiator power is incorrectly calculated, in the future this may lead to the creation of an uncomfortable microclimate in the room. Overheating of the room leads to stuffiness, to get rid of which you will have to constantly open windows or doors.And also if the surface of the heater gets too hot, this leads to a decrease in the level of humidity in the room, burning oxygen, as a result of which health deteriorates. Even furniture suffers from incorrectly selected power, which can deteriorate with strong temperature fluctuations.

Batteries are installed in such a way that at least 20 cm of free space is left around its edges

This distance is necessary to ensure normal air convection.

The installed battery in a niche should have 20% more than the calculated power.

If the room has two or three windows, then it is advisable to install a separate radiator under each of them than to choose a long model.

When buying a heating structure, you should pay attention to its technical passport. It should indicate such characteristics as the permissible temperature of the water in the heater, the maximum pressure, and others.

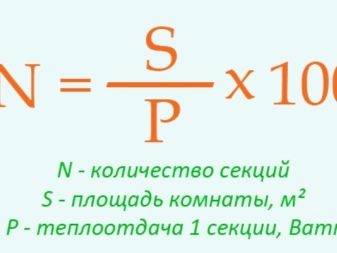

- The correct number of sections for a heating radiator is easily calculated using an online calculation. To do this, you need to have such information as: the lowest possible temperature outside the window, the size of the room, the power of one section of the battery.

- Before proceeding with the installation of the battery yourself, it is necessary to make a plan for the placement of not only the device itself, but the entire heating system. Unlike cast iron batteries, aluminum and bimetallic radiators are installed on the wall using special brackets.

- Both types of radiators can be attached using special racks on the floor if the walls of the room are made of plasterboard, for example.

- The plastic film should not be removed from the battery until it is fully installed, so as not to damage the surface.

After installation, it is important to ensure the tightness of the threaded connections. Fum tape is used for sealing.

Experts say that the amount of marriage when choosing heating radiators is 0.5-0.9%

The main thing is to choose a company that has proven itself in the Russian market. Most of the brands under which aluminum and bimetallic batteries are produced are mainly produced in China. The number one brand in the world for the production of radiators is Global, the only company that has not moved its production to China. Among the companies specializing in the production of radiators, one can also note Rommer, which manufactures heating batteries suitable for Russian conditions.

How to choose a radiator, see the following video.