- Main characteristics

- Where to put

- forced circulation

- natural circulation

- Mounting Features

- Principle of operation

- Classification

- Thermal collector "ground-water"

- "Water-water"

- "Air-water"

- Varieties of circulation pumps

- Why do you need a hot water pump

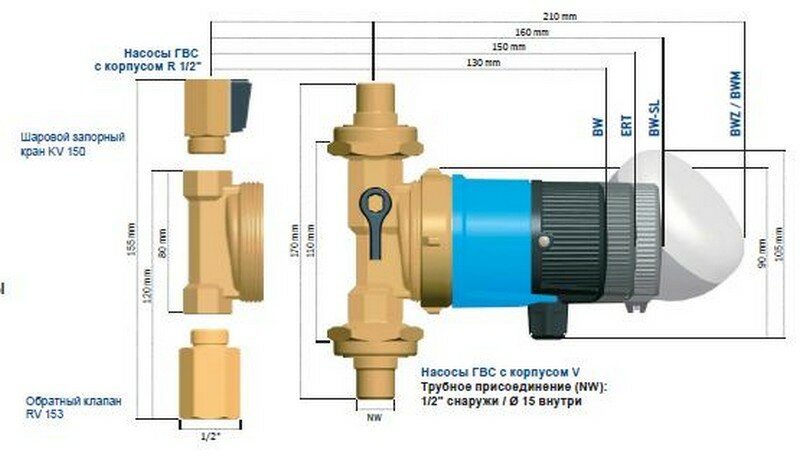

- What is the difference between circulation pumps for heating and hot water

- What to do if the DHW indicators in the pipes do not meet the standards?

- Where to complain?

- Required documents

- Making a claim

- Timing of the procedure

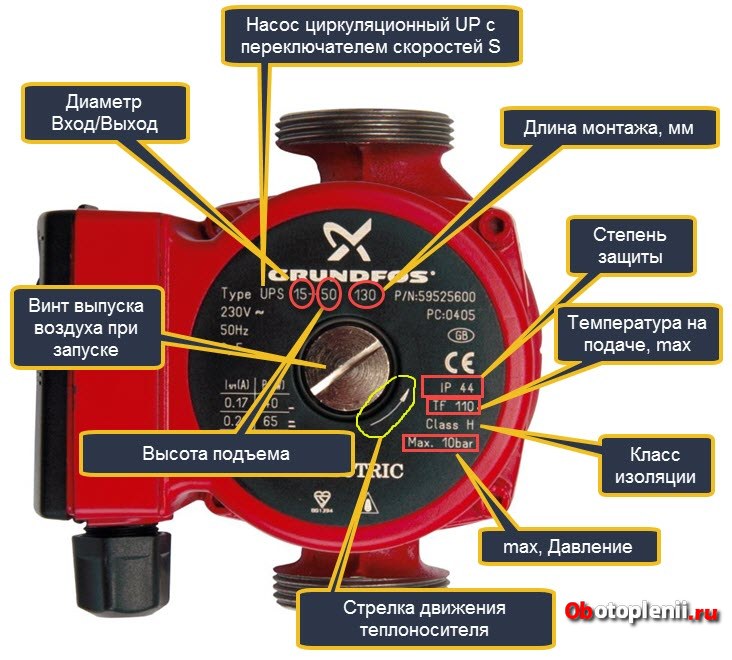

Main characteristics

When choosing a circulation pump for hot water or heating, you should pay attention to the following characteristics:

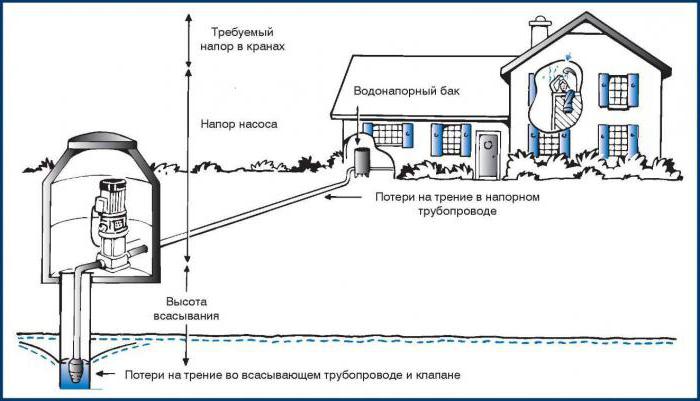

- productivity - the amount of liquid that the recirculating electric pump is able to pump per unit of time (m3 / hour or liter / min);

- head or pressure of the liquid medium created by the pump (meters of water column or Pa);

- power consumed by the recirculation pump (W);

- method of controlling the device (by means of a timer or a temperature sensor).

Since recirculation pumps pump small volumes of liquid that moves in heating pipes or water pipes at a low speed, such devices do not require high power and performance.So, to maintain the water temperature in domestic heating and water consumption systems, the length of which does not exceed 40–50 meters, a recirculation pump with a capacity of 0.2–0.6 m3 / h will be quite sufficient.

Grundfos pump with a capacity of 3.3 cu. m/hour

In terms of electricity consumption, pumps for a boiler room and hot water are also economical, since their power, depending on from the model is from 5 to 20 W. This is quite enough for the electric water pump to be able to provide efficient circulation through the hot water pipes in a private house.

In order to choose the right pump for this characteristic, you can be guided by the following recommendations when selecting recirculation equipment for heating and hot water systems of both a small residential building and a large cottage with several floors.

- If the pipes through which the pump must circulate the liquid medium are located at the same level, then we select equipment with a head value of 0.5–0.8 meters of water column.

- If the house has several floors, DHW recirculation must be provided at several levels of the pipeline, which means that the height to which the liquid must be raised should be taken into account.

In order to make the recirculation of the liquid medium more efficient in heating and hot water systems, pumps should be selected with a certain margin for the generated pressure.

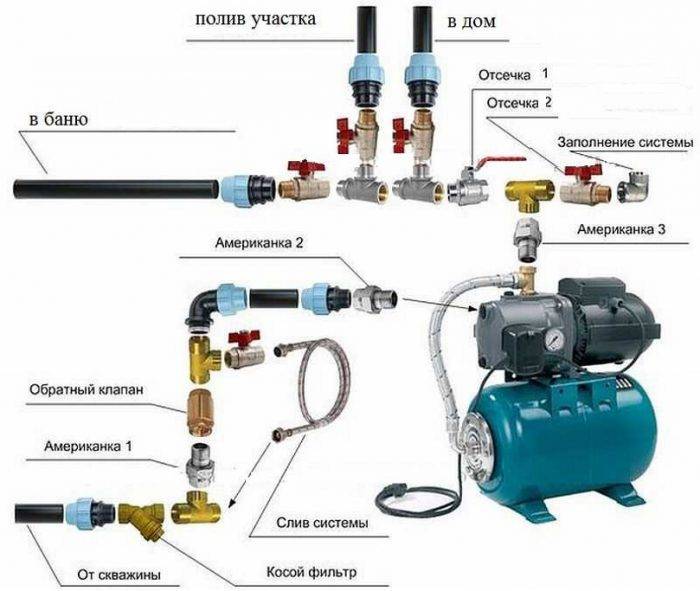

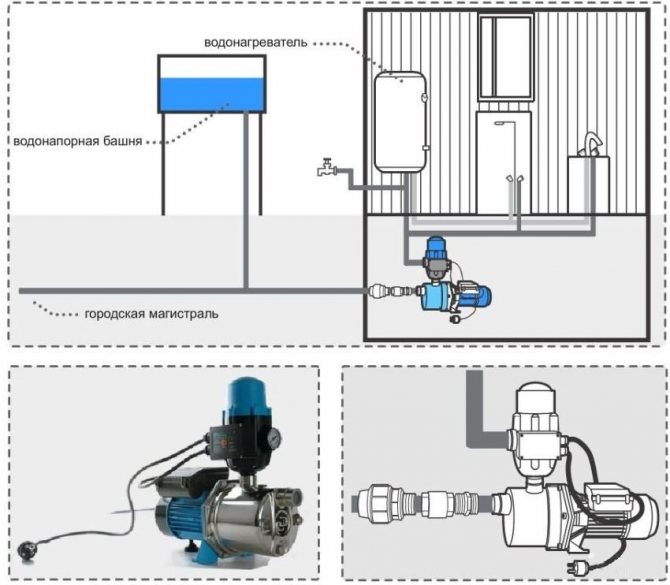

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C.There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

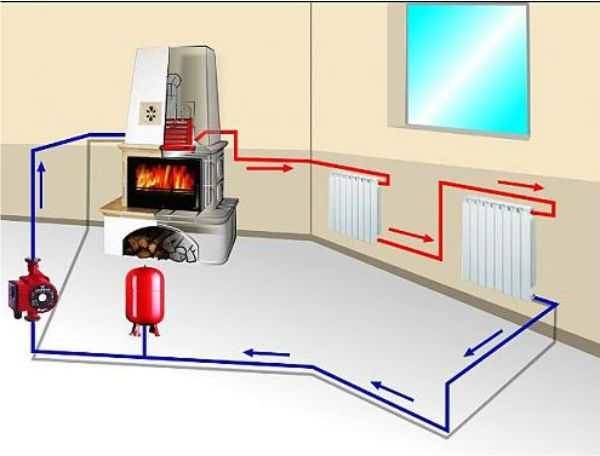

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer.However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

forced circulation

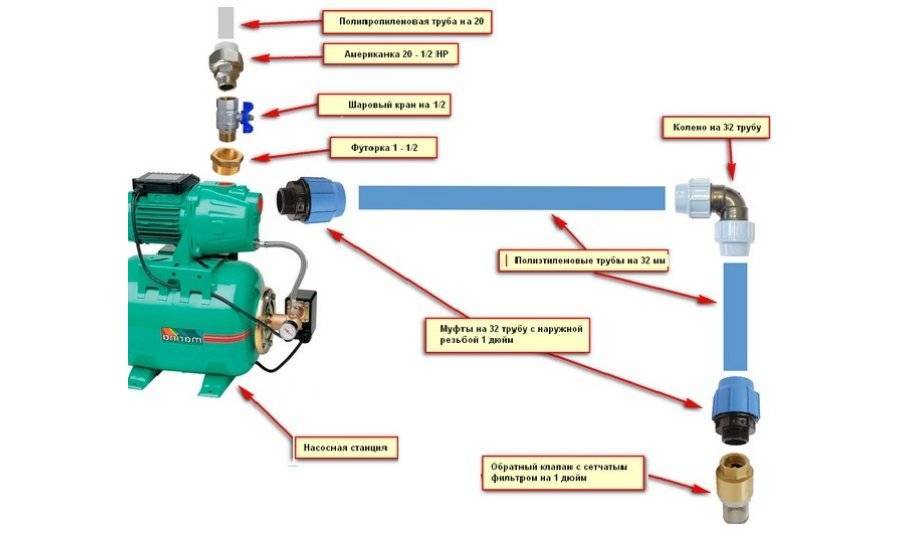

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

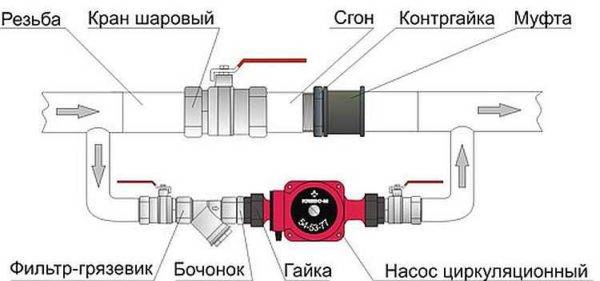

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation.In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow. There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

Principle of operation

All the space around us is energy - you just need to know how to use it. For a heat pump, the ambient temperature must be greater than 1C°. Here it should be said that even the earth in winter under snow or at some depth retains heat. The work of a geothermal or any other heat pump is based on the transportation of heat from its source using a heat carrier to the heating circuit of the house.

Scheme of operation of the device by points:

- the heat carrier (water, soil, air) fills the pipeline under the soil and heats it;

- then the coolant is transported to the heat exchanger (evaporator) with subsequent heat transfer to the internal circuit;

- the external circuit contains the refrigerant, a liquid with a low boiling point under low pressure. For example, freon, water with alcohol, glycol mixture. Inside the evaporator, this substance is heated and becomes a gas;

- the gaseous refrigerant is sent to the compressor, compressed under high pressure and heated;

- hot gas enters the condenser and there its thermal energy is transferred to the heat carrier of the house heating system;

- the cycle ends with the conversion of the refrigerant into a liquid, and it, due to heat loss, returns back to the system.

The same principle is used for refrigerators, so home heat pumps can be used as air conditioners to cool a room. Simply put, a heat pump is a kind of refrigerator with the opposite effect: instead of cold, heat is generated.

Do-it-yourself heat pumps can be designed based on three principles - according to the energy source, the coolant, and their combination. The source of energy can be water (reservoir, river), soil, air. All types of pumps are based on the same operating principle.

Classification

There are three groups of devices:

- water-water;

- groundwater (geothermal heat pumps);

- use water and air.

Thermal collector "ground-water"

A do-it-yourself heat pump is the most common and efficient way to generate energy. At a depth of several meters, the soil has one constant temperature and is little affected by weather conditions. On the external contour of such a geothermal pump, a special environmentally friendly liquid is used, popularly called "brine".

The outer contour of the geothermal pump is made of plastic pipes. They are dug into the ground vertically or horizontally.In the first case, one kilowatt may require a fairly large area of work - 25–50 m2. The area cannot be used for planting - only planting annual flowering plants is allowed here.

A vertical energy collector requires several wells of 50–150 m. Such a device is more efficient, heat is transferred by special deep probes.

"Water-water"

At great depths, the water temperature is constant and stable. The source of low-potential energy can be an open reservoir, groundwater (well, borehole), wastewater. There are no fundamental differences in the design for heating of this type with different heat carriers.

The “water-water” device is the least labor-intensive: it is enough to equip pipes with a heat carrier with a load and place them in water if it is a reservoir. For ground water, a more complex design will be required and it may be necessary to build a well for the discharge of water passing through the heat exchanger.

"Air-water"

Such a pump is slightly inferior to the first two and in cold weather its power decreases. But it is more versatile: it does not need to dig the ground, create wells. It is only necessary to install the necessary equipment, for example, on the roof of the house. This does not require complex installation work.

The main advantage is the ability to reuse the heat leaving the room. In winter, it is recommended to have another source of heat, since the power of such a heater can be significantly reduced.

Varieties of circulation pumps

The wet rotor pump is available in stainless steel, cast iron, bronze or aluminium. Inside is a ceramic or steel engine

To understand how this device works, you need to know the differences between the two types of circulation pumping equipment. Although the fundamental scheme of the heating system based on a heat pump does not change, two types of such units differ in their operation features:

- The wet rotor pump is available in stainless steel, cast iron, bronze or aluminium. Inside is a ceramic or steel engine. The technopolymer impeller is mounted on the rotor shaft. When the impeller blades rotate, the water in the system is set in motion. This water simultaneously acts as an engine cooler and lubricant for the working elements of the device. Since the “wet” device circuit does not provide for the use of a fan, the operation of the unit is almost silent. Such equipment only works in a horizontal position, otherwise the device will simply overheat and fail. The main advantages of the wet pump are that it is maintenance-free and has excellent maintainability. However, the efficiency of the device is only 45%, which is a small drawback. But for domestic use, this unit is perfect.

- A dry rotor pump differs from its counterpart in that its motor does not come into contact with the liquid. In this regard, the unit has a lower durability. If the device will work "dry", then the risk of overheating and failure is low, but there is a threat of leakage due to abrasion of the seal. Since the efficiency of a dry circulation pump is 70%, it is advisable to use it for solving utility and industrial problems.To cool the engine, the circuit of the device provides for the use of a fan, which causes an increase in the noise level during operation, which is a disadvantage of this type of pump. Since in this unit water does not perform the function of lubricating the working elements, during the operation of the unit it is periodically necessary to carry out technical inspection and lubricate the parts.

In turn, "dry" circulating units are divided into several types according to the type of installation and connection to the engine:

- Console. In these devices, the engine and housing have their own place. They are separated and firmly fixed on it. The drive and working shaft of such a pump is connected by a coupling. To install this type of device, you will need to build a foundation, and the maintenance of this unit is quite expensive.

- Monoblock pumps can be operated for three years. The hull and engine are located separately, but are combined as a monoblock. The wheel in such a device is mounted on the rotor shaft.

- Vertical. The term of use of these devices reaches five years. These are sealed advanced units with a seal on the front side made of two polished rings. For the manufacture of seals, graphite, ceramics, stainless steel, aluminum are used. When the device is in operation, these rings rotate relative to each other.

Also on sale there are more powerful devices with two rotors. This dual circuit allows you to increase the performance of the device at maximum load. If one of the rotors exits, the second one can take over its functions.This allows not only to enhance the operation of the unit, but also to save energy, because with a decrease in heat demand, only one rotor works.

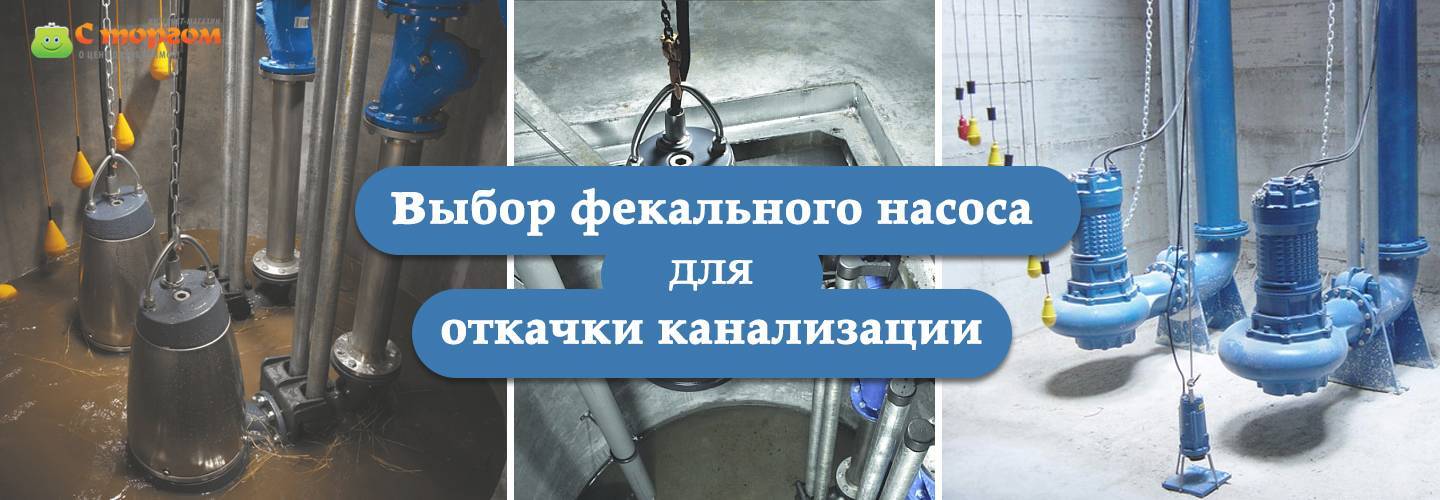

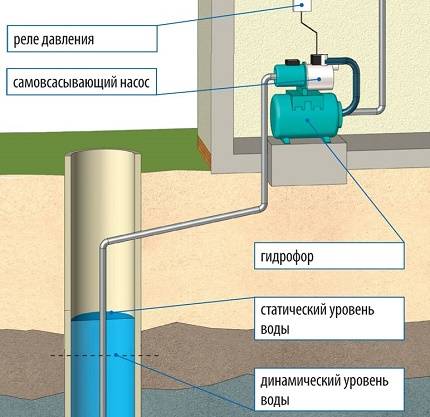

Why do you need a hot water pump

The DHW circulation pump is designed to create pressure and constant circulation of water in domestic water supply systems. After opening the tap, you have to wait a long time until the water becomes hot, and the farther from the DHW inlet the draw-off point is located, the more time is needed for this. The pressure in the system does not always meet even the minimum requirements, preventing you from washing normally.

DHW circulation pumps are installed for the following purposes:

- Ensure stable pressure in the system - for this, hot water is diverted into a special buffer tank, after which it is supplied under pressure to water supply points.

- Ensure an instant supply of hot water - the circulation pump for hot water supply is connected to a closed pipeline. Water is constantly in motion. Due to circulation, the cooled liquid is mixed with the heated one. As a result, immediately after opening the tap, hot water is supplied to the consumer.

The parameters of domestic water supply make it necessary to install hot water in both private and multi-apartment buildings.

What is the difference between circulation pumps for heating and hot water

The use of a circulation pump in a hot water supply system has its own characteristics that differ from the use of stations in water heating circuits. For this reason, the circulation equipment for each system is not interchangeable.

The differences between circulation pumps are as follows:

Performance - heating pumps have a larger power reserve, which is simply meaningless for domestic hot water. If necessary, you can put circulation equipment for heating systems on water, but not vice versa. Some manufacturers offer dual pumps with two electric motors specifically for this purpose. The module is simultaneously connected to DHW and heating.

Case - another difference between models for heating, from pumps for domestic hot water, is the material of the case. In stations for hot water supply, the structure is made of brass, covered with a heat-insulating casing from above. Cast iron appliances are installed for heating.

Heat carrier temperature

If you pay attention to the technical characteristics of the pumps, you will notice that DHW equipment can be operated at a liquid operating temperature of not more than 65 ° C. In heating systems, the coolant is heated up to 90-95°С

Despite the external similarity, pumping equipment for heating and hot water systems is not interchangeable. The exception is "twin pumps" offered by many leading European manufacturers.

What to do if the DHW indicators in the pipes do not meet the standards?

If the water does not meet the standards, then the consumer has the right to apply to the responsible department with a requirement to promptly eliminate the shortcomings and recalculate utility bills.

The regulations and features of filing a complaint are established by Government Decree No. 354.

Where to complain?

Upon the fact of revealed violations or suspicions of violations, the consumer contacts the emergency dispatch service of the Criminal Code. Features of the procedure:

- the appeal is recorded in written or oral forms (by phone);

- the appeal is registered, the consumer reports the full name, address, nature of the violations;

- the dispatcher informs the full name, position, time and registration number of the application;

- in case of awareness of the causes of the violation, the dispatcher informs the consumer about the timing of the elimination;

- if necessary, the day of temperature measurement is set.

On the appointed day, the specialist arrives at the address indicated by the owner of the dwelling. The temperature is measured and an act is drawn up in at least 2 copies. One copy remains with the measurer, the second is provided to the consumer. If the act confirmed the consumer's assumptions about the provision of low-quality services, then he has the right to file a complaint with the Management Company.

Required documents

The only document that must be attached to the claim is the act of measuring the temperature of hot water, as it confirms and establishes the grounds for the consumer's appeal. To file a complaint, it is enough to provide your personal data. These include your name, address, and contact information.

Some features of the drafting of the act are regulated by clause 10 of Government Decree No. 354. If violations during the audit are not confirmed, then this information is also reflected in the document.

Making a claim

The claim is drawn up on a sheet of A4 format in written or printed text. In the document, the consumer expresses a requirement to measure, eliminate identified violations and recalculate utility bills.

In the header on the right, the details of the responsible and applicant parties are indicated:

- position and full name of the head of the management company;

- name of the management company;

- Full name of the applicant, full address of the residential facility in which the violation is suspected;

- phone number in city or federal format.

The name of the document is indicated in the middle - “Claim” or “Statement”. The body of the statement lists:

- reference to clause 2.4 of SanPin, indicating that the temperature of hot water cannot be lower or higher than the established limit;

- measurement indicators in degrees, as well as the circumstances of independent or professional measurement;

- if necessary, the requirement to conduct a measurement, prepare an act on the number of participants in the audit;

- requirements for the elimination of identified violations and recalculation of payments.

At the end, the document is dated and certified by the signature of the applicant. If a claim is sent with a requirement for preliminary measurement, then this should be indicated in the appropriate wording. For example: “I ask you to measure hot water at the address (address), draw up an act on the fact of the measurement and hand over one copy to me.

In case of identified violations, I ask you to take measures to eliminate them and recalculate payments. If the results of a qualified check are already known, then it is necessary to refer to the act provided by the measurer.

Download a claim form to the Criminal Code for low hot water temperatureDownload a sample claim to the Criminal Code for low hot water temperatureWe do not recommend completing the documents yourself. Save time - contact our lawyers by phone:

8 (800) 350-14-90

Timing of the procedure

Based on clause 108 of Government Decree No. 354, the dispatcher or employee accepting an application from the consumer, during the registration period, undertakes to transfer information to the resource supplying organization in order to notify the user of the time and date of the check.

The set time for measurement cannot exceed 2 hours from the moment of fixing the appeal. Elimination of violations is carried out as soon as possible, which allow technical conditions.