- What well pumps to buy

- Arrangement of a well for water supply at home

- Which well pump is better to buy

- Stages of work on installing the pump in the well

- What material should the impeller be made of?

- What to pay extra attention to when choosing a pump for a well

- Stages of work on installing the pump in the well

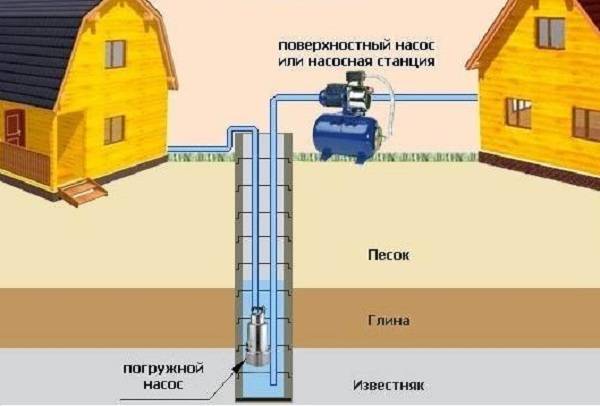

- Installation of a surface pump ↑

- Rules for mounting a deep pump ↑

- Pumping stations - "monsters" of automation

What well pumps to buy

Based on the above information, the following options are possible, taking into account the depth of immersion and the required pressure:

1. For watering the garden: GLP-36-11 from GRINDA;

2. For a country house located far from the well: NVT-360/10P from Caliber;

3. For a small family living in a house with several water points: XHSm1500 and NSB-130 from LEO;

4. For the average family: PW-175EA from Wilo; SBA 3-45 A from Grundfos; Jumbo 50/28 Ch-24 from JILEX;

5. For a large family (perhaps a cottage): Acuaplus from ESPA; Hydrojet JPB 6/24 from Grundfos; ASP2-25-100WA from Aquario;

6. For a house with a jacuzzi, swimming pool and many other taps: 5500/5 Inox and 6000/5 Comfort from GARDENA; SPm 4 04-0.75A from LadAna.

The above options are approximate, since when buying this household appliance, you must additionally take into account many options.

Updated: 21 August 2016

Arrangement of a well for water supply at home

Uninterrupted operation of the well requires compliance with the installation of certain conditions:

- The depth of the future well should vary from 8 to 20 meters. But as a rule, the level is not higher than 6 meters in depth.

- It is necessary to provide a main line for supplying water to the house.

- At the bottom of the well, it is necessary to install a pumping station that will pump water.

- Piping and tank installation are some of the most time-consuming and skill-intensive processes.

In addition, it is recommended to pay due attention to the quality of the materials from which the well will be assembled for the water supply of a private house. Experts recommend buying reinforced concrete rings with a diameter of at least 1.5 - 2 meters

Reinforced concrete pipes can serve as an alternative.

In no case should metal be used, as over time it will begin to oxidize, and even water filters will not help get rid of the unpleasant taste of rust.

Which well pump is better to buy

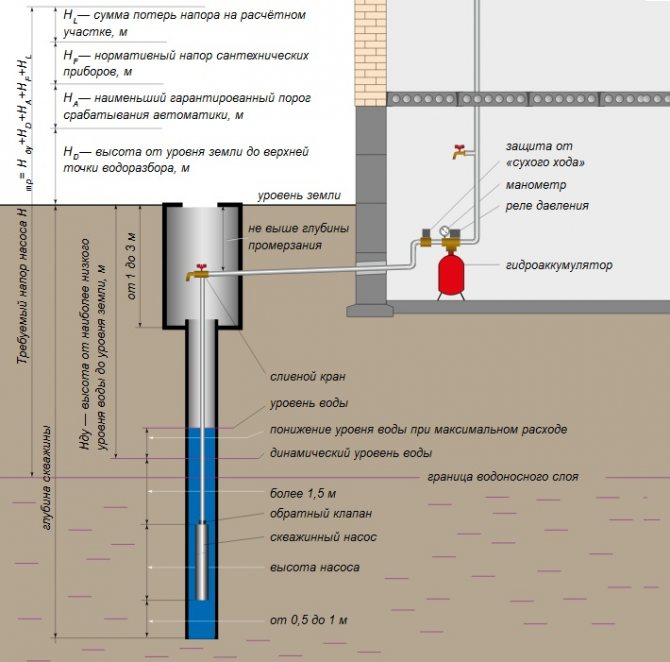

When choosing, it is necessary first of all to take into account the type and characteristics of the well in which the pump will be installed. The main characteristics include static and dynamic water levels, flow rate, bottom bottom mark, as well as the exact diameter of the hole. The depth of immersion, the required power and pressure of the pump depend on these indicators.

The choice of instrument is also influenced by the quality of the drilling of the well. Holes made by site owners on their own may not be durable, often subject to sanding and even collapse.Therefore, to pump out water in such conditions, you will need a productive apparatus equipped with a water filtration system.

One of the important indicators of the functioning of the pump is its performance. For a family of three to four people, the approximate daily water consumption is about 70 liters.

We recommend focusing on an indicator of at least 2.1 cubic meters / hour when choosing a borehole pump for private use. On average, it is achieved due to the operation of an engine with a power of about 750 watts.

Speaking about the design features of the device, it is necessary to note the material of manufacture of the connected hose. Made of soft rubber, this element tends to collapse during operation, blocking the flow of water

Therefore, you should pay attention to models equipped with a plastic hose.

Stages of work on installing the pump in the well

If it is decided with the question of how to choose a pump for a well, it remains to find out how to install it. The installation of a surface pump is fundamentally different from the installation of a deep one.

If the pump is not used all year round, but only during the summer season, its installation is quite simple. The mechanism itself is installed near the well. Water is poured into the body. The suction hose is lowered into the water.

The hose must be equipped with a strainer that protects the device from solid particles and silt, as well as a check valve that prevents the outflow of water when the pump is turned off. The supply pipe of the unit is connected to the water supply using a fitting.

Installation of a surface pump can be done even by an ordinary summer resident, there is nothing complicated about it

With constant use of the pump, you need to take care of the insulation of the unit and the water supply. A shallow pit for a pump (caisson) is equipped near the well; it must be insulated for cold weather. If possible, the unit is installed in a nearby room. But not in a residential area, otherwise the noise from the pump will disturb the residents of the house.

The water main is laid to a depth below the freezing level of the soil by 30 cm. In preparation for winter, the well cover is also insulated. When installing a surface pump, one should take into account its remoteness from the source. Further than 12 meters, it is not advisable to install the mechanism.

Before installing the pump in the well, a pipeline must be connected to it. What it will be depends on the installation depth of the unit and the goals set. The maximum pressure of the mechanism must not exceed the maximum pressure for the installed pipes.

If the pump will be used only for filling containers and watering the garden, then it is advisable to use a regular hose. It connects to the pump through a plastic sleeve. For regular use, the pump is installed permanently and removed only for preventive measures or in the event of a breakdown.

When lowering the deep pump into the well, it is necessary to proceed with extreme care

Pipes in this case are taken metal or plastic. Having attached the pipes, fix the cable of the mechanism. It is best to secure the cord to the pressure pipe using staples and some slack. This option will protect the cable from damage and make it easier to lower the pump.

A nylon cable is passed into special eyes, to the ends of which a spring suspension is attached. After the preparatory work, the pump is installed in the well.To reduce pressure losses in the pipeline, sharp turns and bends in the pipeline should be avoided.

For the device of automatic uninterrupted water supply of houses, pumping stations are used. This automated process includes a pump, flow and pressure switch, expansion tank, check valve and control system. Such a station is good because the pump turns on automatically when the tap is opened and turns off when it is closed.

Installation of a pumping station in a pit (caisson) is the best option that will protect equipment from external influences

The whole process is automated and does not require constant attention. The main thing is that the power supply is uninterrupted, and the water level in the well does not fall below critical. Complete with a finished pumping station is a detailed instruction for its installation and operation.

What material should the impeller be made of?

This structural element in submersible pumps can have the following design:

Plastic. The main advantage of plastic impellers is their resistance to corrosion. Otherwise, it is less durable than stainless steel, cast iron or bronze. Conceptually, plastic components are made in relatively inexpensive models designed for clean water, and in fecal-type devices. Sometimes some sellers recommend buying a pump made of plastic, arguing that it is light in weight. However, you should not “be led” by such advertising, since in fact you will lower the device into the water once and will not constantly drag it back and forth, so the weight is not important here.

Stainless steel.The best material for the manufacture of an impeller or auger, as it is not subject to corrosion and is quite durable. On average, the pump impeller lasts about 10 - 12 years (depending on the manufacturer). However, stainless steel devices are more expensive than plastic ones.

Cast iron. Almost the same strength as stainless steel, but slightly worse in corrosion resistance. However, due to the cost below stainless steel, it has the same popularity as its steel counterpart.

There are also devices with aluminum and bronze screws, but they are an order of magnitude more expensive than those made of stainless steel, and they are about the same in quality and durability, so buying them for home use is not profitable.

If you want to purchase a device for pumping clean water from a well or pool, then take it with an impeller made of cast iron or stainless steel. For pumping out a drain pit or a sewer well, plastic models are better, since plastic still better withstands the influence of aggressive environments.

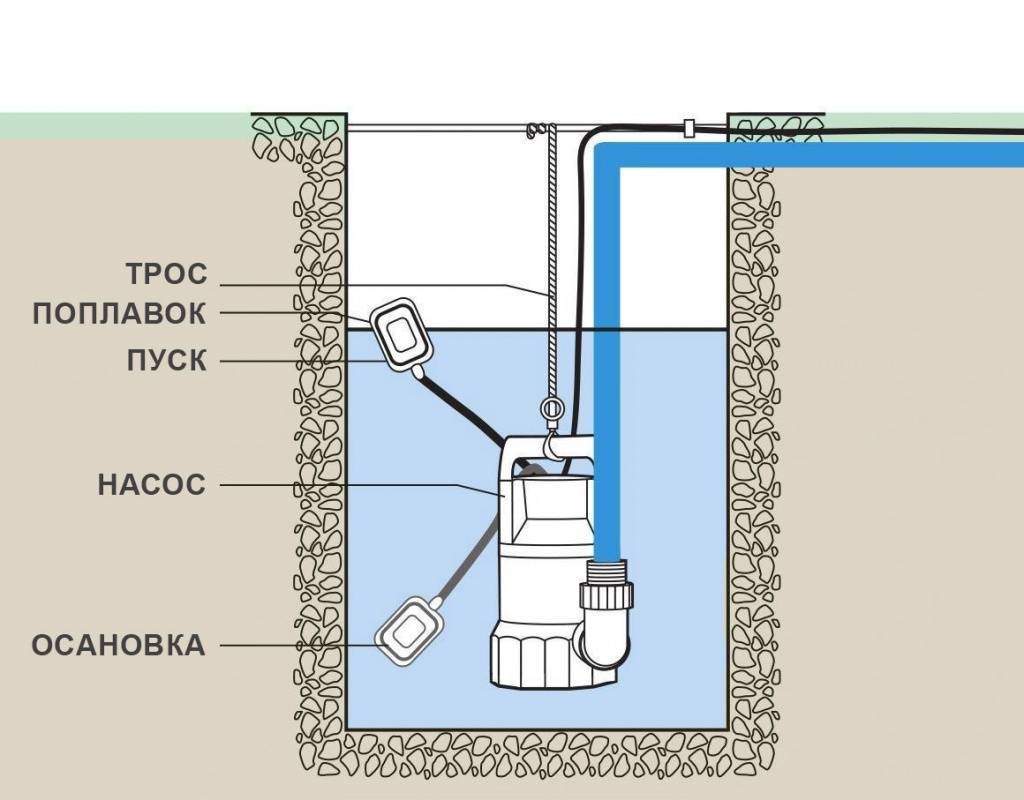

What to pay extra attention to when choosing a pump for a well

An important criterion is the price of the equipment. Today it is not a benchmark of quality. There are a huge number of well pumps on the market, especially from domestic manufacturers, which do an excellent job of their functions, because they are adapted to Russian operating conditions. Their cost is much lower than that of foreign analogues.

It is necessary to pay attention to whether the pumps are equipped with an automation system. It makes it possible to extend the life of the units. Although its presence is a price increase

Therefore, manufacturers offer simple systems such as the float switch above. Or more complex in the form of blocks that are responsible for dry running, overheating of the electric motor

Although its presence is a price increase. Therefore, manufacturers offer simple systems such as the float switch above. Or more complex in the form of blocks that are responsible for dry running, overheating of the electric motor.

And the third criterion is the material from which the devices are made. Preference is better to give stainless steel, not plastic

Stages of work on installing the pump in the well

If the question of how to choose a pump for a well is decided, it remains to find out how to install it. The installation of a surface pump is fundamentally different from the installation of a deep one.

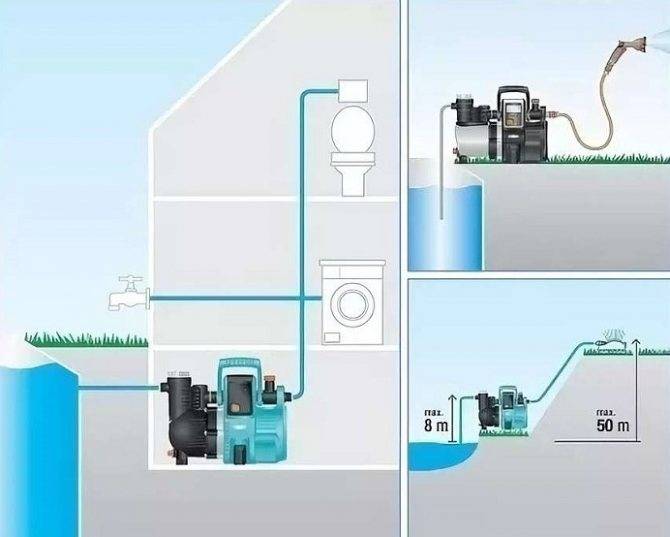

Installation of a surface pump ↑

If the pump is not used all year round, but only during the summer season, its installation is quite simple. The mechanism itself is installed near the well. Water is poured into the body. The suction hose is lowered into the water.

The hose must be equipped with a strainer that protects the device from solid particles and silt, as well as a check valve that prevents the outflow of water when the pump is turned off. The supply pipe of the unit is connected to the water supply using a fitting.

Installation of a surface pump can be done even by an ordinary summer resident, there is nothing complicated about it

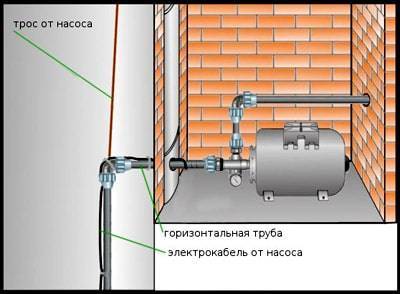

With constant use of the pump, you need to take care of the insulation of the unit and the water supply. A shallow pit for a pump (caisson) is equipped near the well; it must be insulated for cold weather. If possible, the unit is installed in a nearby room. But not in a residential area, otherwise the noise from the pump will disturb the residents of the house.

The water main is laid to a depth below the freezing level of the soil by 30 cm. In preparation for winter, the well cover is also insulated.When installing a surface pump, one should take into account its remoteness from the source. Further than 12 meters, it is not advisable to install the mechanism.

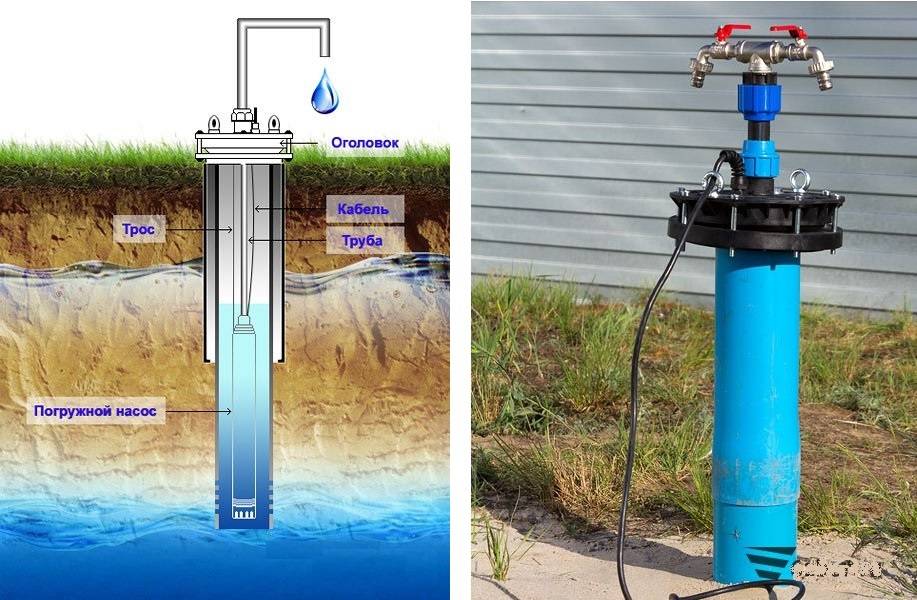

Rules for mounting a deep pump ↑

Before installing the pump in the well, a pipeline must be connected to it. What it will be depends on the installation depth of the unit and the goals set. The maximum pressure of the mechanism must not exceed the maximum pressure for the installed pipes.

If the pump will be used only for filling containers and watering the garden, then it is advisable to use a regular hose. It connects to the pump through a plastic sleeve. For regular use, the pump is installed permanently and removed only for preventive measures or in the event of a breakdown.

When lowering the deep pump into the well, it is necessary to proceed with extreme care

Pipes in this case are taken metal or plastic. Having attached the pipes, fix the cable of the mechanism. It is best to secure the cord to the pressure pipe using staples and some slack. This option will protect the cable from damage and make it easier to lower the pump.

A nylon cable is passed into special eyes, to the ends of which a spring suspension is attached. After the preparatory work, the pump is installed in the well. To reduce pressure losses in the pipeline, sharp turns and bends in the pipeline should be avoided.

Pumping stations - "monsters" of automation

For the device of automatic uninterrupted water supply of houses, pumping stations are used. This automated process includes a pump, flow and pressure switch, expansion tank, check valve and control system.Such a station is good because the pump turns on automatically when the tap is opened and turns off when it is closed.

Installation of a pumping station in a pit (caisson) is the best option that will protect equipment from external influences

The whole process is automated and does not require constant attention. The main thing is that the power supply is uninterrupted, and the water level in the well does not fall below critical. Complete with a finished pumping station is a detailed instruction for its installation and operation.