- Determining factors: expansion tank capacity, system type and more

- Rationing of working pressure in apartment buildings

- What is the optimal pressure in a closed heating system

- Hydraulic tank maintenance rules

- We select the volume of the tank.

- Installing the expansion element

- Setting indicators in a new expansion tank of a membrane type

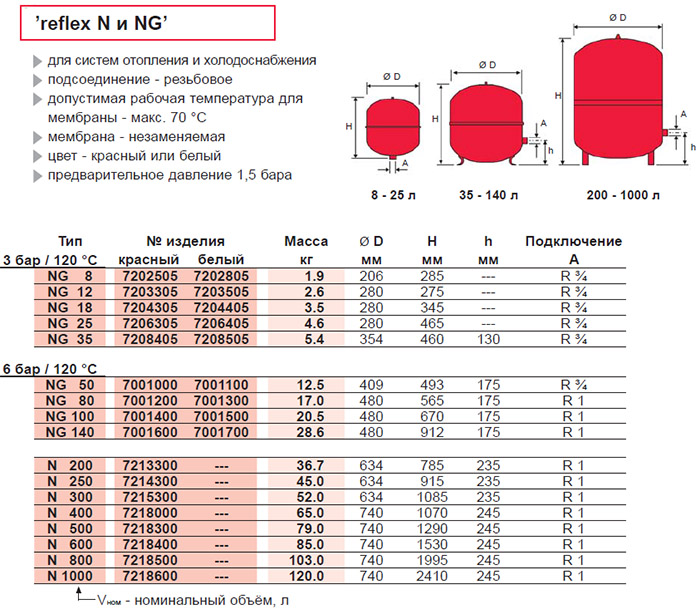

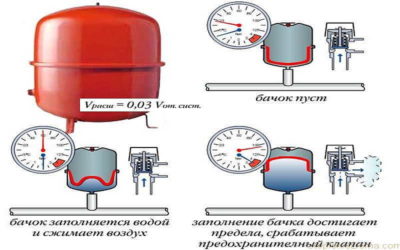

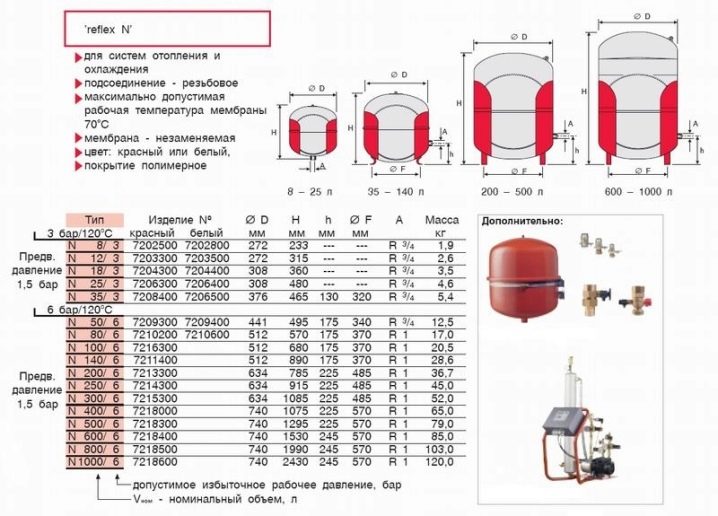

- Device and principle of operation

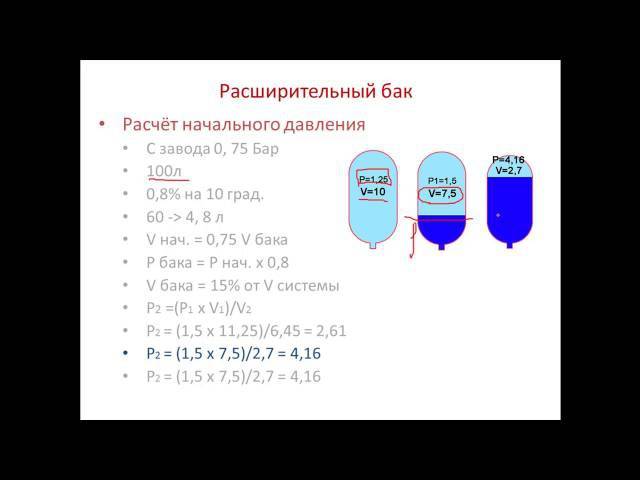

- Calculation of the volume of the expansion tank

- How does the expansion tank work and how is it arranged (regardless of the volume of the special tank - 100, 200 liters or less)?

- Optimal Performance

- In an open system

- Closed

- Calculating pressure in two ways

- Consequences of instability in circuits

- What pressure in the boiler is considered normal

- EXPANSION TANK SETUP

Determining factors: expansion tank capacity, system type and more

The pressure in the heating system depends on several factors:

- Equipment power. Static is set by the height of a multi-storey building or by the rise of an expansion tank. The dynamic component is largely determined by the power of the circulation pump and, to a lesser extent, by the power of the heating boiler.

When providing the required pressure in the system, the appearance of obstacles to the movement of the coolant in pipes and radiators is taken into account.With prolonged use, scale, oxides and sediment accumulate in them. This leads to a decrease in diameter, and hence to an increase in resistance to fluid movement. Especially noticeable with increased hardness (mineralization) of water. To eliminate the problem, a thorough flushing of the entire heating structure is periodically carried out. In regions where the water is hard, clean filters for hot water are installed.

Rationing of working pressure in apartment buildings

Multi-storey buildings are connected to central heating, where the coolant comes from the CHP, or to domestic boilers. In modern heating systems, indicators are maintained in accordance with GOST and SNiP 41-01-2003. Normal pressure provides room temperature of 20-22 ° C at a humidity of 30-45%.

Depending on the height of the building, the following standards are established:

- in houses up to 5 floors high 2-4 atm;

- in buildings up to 10 floors 4-7 atm;

- in buildings above 10 floors 8-12 atm.

It is important to ensure uniform heating of apartments located on different floors. The condition is considered normal when the difference between the operating pressures on the first and last floor of a multi-storey building is no more than 8-10%

The condition is considered normal when the difference between the operating pressures on the first and last floor of a multi-storey building is no more than 8-10%.

During periods when heating is not needed, the minimum indicators are maintained in the system. It is determined by the formula 0.1(Нх3+5+3), where Н is the number of floors.

In addition to the number of storeys of the building, the value depends on the temperature of the incoming coolant. Minimum values have been established: at 130°C - 1.7-1.9 atm., at 140°C - 2.6-2.8 atm. and at 150 °C - 3.8 atm.

Attention! Periodic performance checks play an important role in heating efficiency. Control them during the heating season and in the off-season

During operation, control is carried out by pressure gauges installed at the inlet and outlet of the heating circuit. At the inlet, the value of the incoming coolant must comply with the established standards.

Check the pressure difference between inlet and outlet. Normally, the difference is 0.1-0.2 atm. The absence of a drop indicates that there is no movement of water to the upper floors. An increase in the difference indicates the presence of coolant leaks.

In the warm season, the heating system is checked using pressure tests. Typically, testing is provided by cold water pumped through. The depressurization of the system is fixed when the indicators fall within 25-30 minutes by more than 0.07 MPa. The norm is considered to be a drop of 0.02 MPa within 1.5-2 hours.

Photo 1. The process of pressure testing the heating system. An electric pump is used, which is connected to a radiator.

What is the optimal pressure in a closed heating system

Above, the heating of "high-rise buildings" is considered, which is provided according to a closed scheme. When arranging a closed system in private homes, there are nuances. Typically, circulation pumps are used that maintain the desired performance. The main condition for their installation is that the pressure created should not exceed the indicators for which the heating boiler is designed (indicated in the instructions for the equipment).

At the same time, it must ensure the movement of the coolant throughout the system, while the difference in water temperature at the outlet of the boiler and at the return point should not exceed 25–30 °C.

For private, one-story buildings, the pressure in a closed heating system in the range of 1.5–3 atm is considered the norm. The length of the pipeline with gravity is limited to 30 m, and when using a pump, the restriction is removed.

Hydraulic tank maintenance rules

A scheduled inspection of the expansion tank is to check the pressure in the gas compartment. It is also necessary to inspect the valves, shutoff valves, air vent, check the operation of the pressure gauge. To verify the integrity of the tank, an external inspection is carried out.

Despite the simplicity of the device, expansion tanks for water supply are still not eternal and can break. Typical causes are diaphragm rupture or air loss through the nipple. Signs of breakdowns can be determined by the frequent operation of the pump, the appearance of noise in the water supply system. Understanding principle of operation of a hydraulic accumulator is the first step to proper maintenance and troubleshooting.

We select the volume of the tank.

Understanding the main functions that it performs will help you choose an expansion tank.

The main task of the expander (as it is also called from the English “expanse” - to expand) is to take on the excess volume of coolant that is formed as a result of thermal expansion.

How much does it increase in volume of water as the main coolant when heated?

When water is heated from 10°C to 80°C, its volume increases by about 4%. We must also not forget that a closed expansion tank consists of two parts, one of which receives an excess of expanding coolant, and the other is pumped under pressure with gas or air.

Considering the device of the expansion tank, it is recommended to select its volume as 10 - 12% of the volume of all water in the heating system of the house:

- in pipes;

- in heating appliances;

- in the boiler heat exchanger;

- a small initial volume of water that enters the tank itself with an initial temperature under pressure (the static pressure in the system is usually higher than the air pressure in the expander).

Installing the expansion element

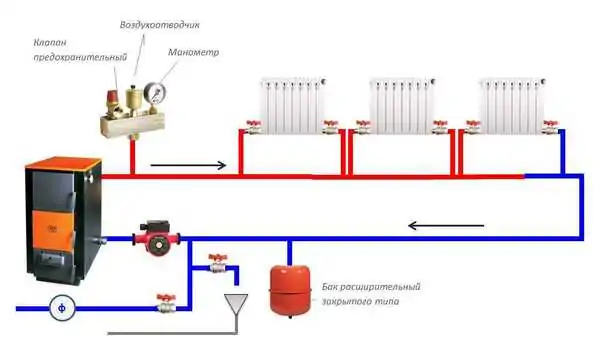

Device diagram

Boiler equipment is designed to operate at a certain pressure of water. This means that there must also be a certain pressure in the expansion tank for its normal operation. It is supported by air or nitrogen, which is filled with the case. Air is pumped into the tank at the factory. During installation, care must be taken to ensure that no air is released. Otherwise, the device will not function.

The pressure is monitored with a manometer. The running arrow of the device indicates that the air has come out of the expander. In general, this situation is not a serious problem, since air can be pumped through the nipple. The average water pressure in the tank is 1.5 atm. However, they may not be suitable for a particular system. In this case, the pressure must be adjusted independently.

Normal indicators - by 0.2 atm. less than in the system. It is strictly not allowed to exceed the pressure in the expansion tank compared to this indicator in the network. In such situations, the coolant that has increased in volume will not be able to enter the tank. The tank is connected to the pipeline through the connecting size.

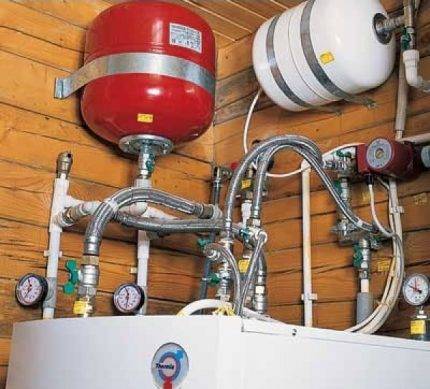

It is important not only to connect the expansion tank correctly, but also to choose the right place for its installation. Despite the fact that modern models can be mounted anywhere, experts advise installing this element of the system on the return line between the boiler and the pump

To ensure the maintainability of the structure, a ball valve is installed on the pipe through which the expander tank is connected. In the event of equipment failure, shut-off valves will allow it to be removed without pumping the coolant out of the system. During operation of the system, the valve must be open. Otherwise, the pressure will rise sharply in it, and it will leak at its weakest point.

Installation in a boiler room

In open systems with natural circulation of the coolant, tanks of other types are installed. Such a tank is an open container, usually welded from sheet steel. It must be installed at the highest point of the engineering network.

The principle of operation of such an element is very simple. As it increases in volume, the liquid is forced out of the pipes, rising along them with air. Cooling, the coolant returns to the pipeline under the action of gravitational forces and natural air pressure.

Setting indicators in a new expansion tank of a membrane type

The device is divided into two parts separated by a membrane. It exerts pressure on one of the halves, this is taken into account when setting up.

In most devices, factory values are entered, which are not always suitable for operation in certain conditions.

To change the indicators, a nipple is provided to which the plumber connects a compressor or a hand pump.

Attention! Many gauges show excess. To determine the actual pressure, add 1 atm. The initial indicator is made equal to that obtained in the cold system by adding 0.2 atm

The sum is the value of the static head divided by 10.For example, in a house 8 m high:

The initial indicator is made equal to that obtained in the cold system by adding 0.2 atm. The sum is the value of the static pressure divided by 10. For example, in a house 8 m high:

P = 8/10 + 0.2 atm.

Values are achieved by filling the tank with air through the spool.

Miscalculations can lead to one of two problems:

Tank overflow. Sometimes an indicator twice the static head is set in the air cavity. Turning on the pump will lead to a change in the number, but not more than 1 atm. With a larger difference, a disadvantage will result, due to which the compensator will begin to push the coolant out of the tank. This could lead to a serious accident.

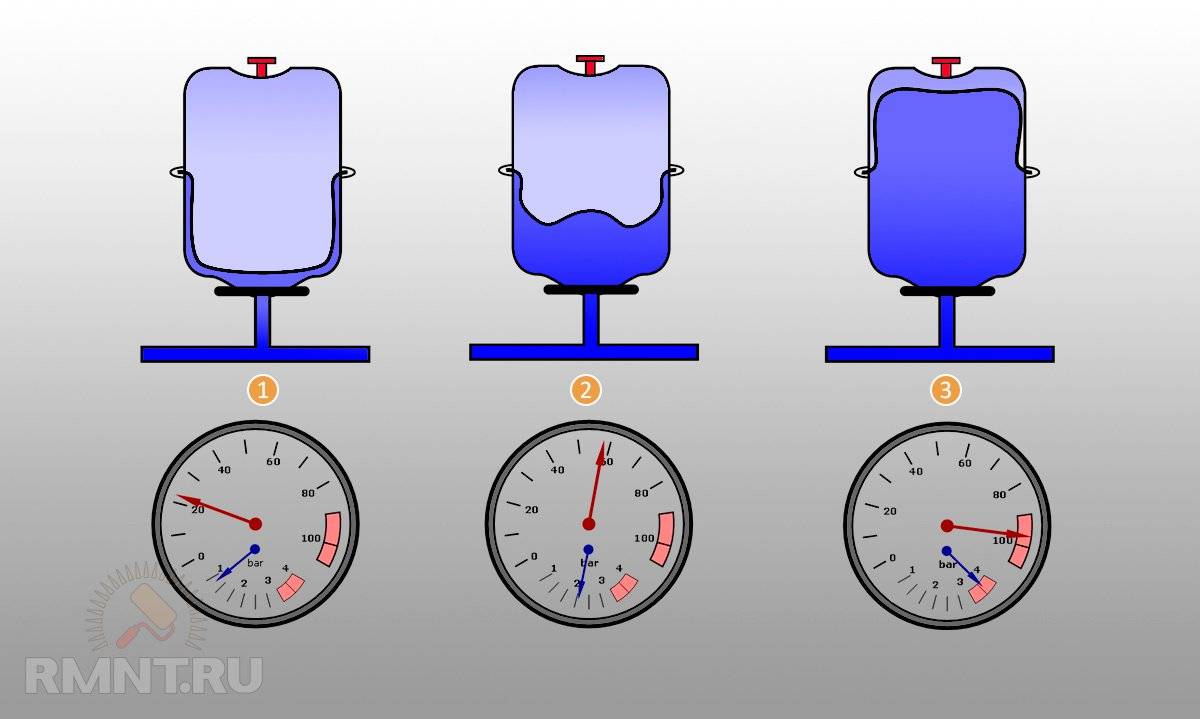

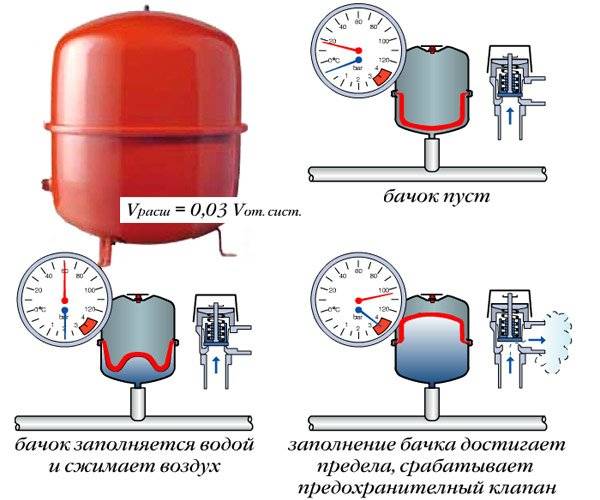

Photo 2. Pressure standards in the expansion tank: when it is empty, it is filled with water and when the filling of the device reaches the limit.

Getting an insufficient score. In a filled system, the working fluid will push through the membrane and fill the entire volume. Each time the heater is turned on or pressure is increased, the fuse may trip. The expander in such an environment will become useless.

Important! The initial setup must be done correctly to avoid problems. But even after the work of a good specialist, fuses may start to work. This is usually due to insufficient volume of the expansion tank.

Usually this is due to insufficient volume of the expansion tank.

The solution is to purchase a new device. It must contain at least 10% of the volume of the entire strapping.

Device and principle of operation

The body of the tank has a round, oval or rectangular shape. Made from alloy or stainless steel. Painted red to prevent corrosion.Blue-painted cisterns are used for water supply.

Sectional tank

Sectional tank

Important. Colored expanders are not interchangeable

Blue containers are used at pressures up to 10 bar and temperatures up to +70 degrees. Red tanks are designed for pressure up to 4 bar and temperatures up to +120 degrees.

According to the design features, the tanks are produced:

- using a replaceable pear;

- with membrane;

- without separation of liquid and gas.

Models assembled according to the first variant have a body, inside of which there is a rubber pear. Its mouth is fixed on the body with the help of a coupling and bolts. If necessary, the pear can be changed. The coupling is equipped with a threaded connection, this allows you to install the tank on the pipeline fitting. Between the pear and the body, air is pumped under low pressure. At the opposite end of the tank there is a bypass valve with a nipple, through which gas can be pumped in or, if necessary, released.

This device works as follows. After installing all the necessary fittings, water is pumped into the pipeline. The filling valve is installed on the return pipe at its lowest point. This is done so that the air in the system can freely rise and exit through the outlet valve, which, on the contrary, is installed at the highest point of the supply pipe.

In the expander, the bulb under air pressure is in a compressed state. As water enters, it fills, straightens and compresses the air in the housing. The tank is filled until the water pressure is equal to the air pressure. If the pumping of the system continues, the pressure will exceed the maximum, and the emergency valve will operate.

After the boiler starts to work, the water heats up and begins to expand. The pressure in the system increases, the liquid begins to flow into the expander pear, compressing the air even more. After the pressure of water and air in the tank comes into equilibrium, the flow of fluid will stop.

When the boiler stops working, the water begins to cool, its volume decreases, and the pressure also decreases. The gas in the tank pushes the excess water back into the system, squeezing the bulb until the pressure equalizes again. If the pressure in the system exceeds the maximum allowable, an emergency valve on the tank will open and release excess water, due to which the pressure will decrease.

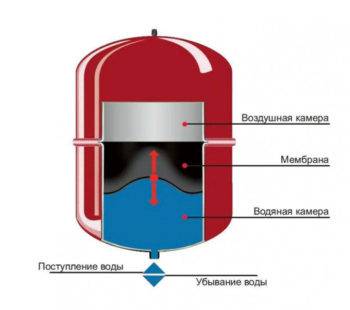

In the second version, the membrane divides the container into two halves, air is pumped in on one side, and water is supplied on the other. Works in the same way as the first option. The case is non-separable, the membrane cannot be changed.

Pressure equalization

Pressure equalization

In the third variant, there is no separation between gas and liquid, so air is partially mixed with water. During operation, gas is periodically pumped up. This design is more reliable, since there are no rubber parts that break through over time.

Calculation of the volume of the expansion tank

It is not difficult to ensure stable operation of the heating system, the main thing is to choose the right volume of the compensation tank. The calculation of the volume of the expander should be made taking into account the most intensive mode of operation of the gas boiler. At the first heating starts, the air temperature is not yet very low, so the equipment will work with an average load. With the advent of frost, the water warms up more and its quantity increases, requiring more additional space.

It is recommended to select a tank with a capacity of at least 10-12% of the total amount of liquid in the heating system. Otherwise, the tank may not be able to cope with the load.

It is recommended to select a tank with a capacity of at least 10-12% of the total amount of liquid in the heating system. Otherwise, the tank may not be able to cope with the load.

You can independently calculate the exact capacity of the expansion tank. To do this, first determine the amount of coolant in the entire heating system.

Methods for calculating the volume of water in the heating system:

- Completely drain the coolant from the pipes into buckets or other containers so that the displacement can be calculated.

- Pour water into the pipes through the water meter.

- The volumes are summed up: the capacity of the boiler, the amount of liquid in the radiators and pipes.

- Calculation by boiler power - the power of the installed boiler is multiplied by 15. That is, for a 25 kW boiler, 375 liters of water (25 * 15) will be needed.

After the amount of coolant has been calculated (example: 25 kW * 15 \u003d 375 liters of water), the volume of the expansion tank is calculated.

There are many methods, but not all of them are accurate and the amount of water that fits into the heating system can be much larger. Therefore, the volume of the expansion tank is always selected with a small margin

There are many methods, but not all of them are accurate and the amount of water that fits into the heating system can be much larger. Therefore, the volume of the expansion tank is always selected with a small margin

The calculation methods are quite complex. For one-story houses, the following formula is used:

Expansion tank volume = (V*E)/D,

Where

- D is the tank efficiency indicator;

- E is the expansion coefficient of the liquid (for water - 0.0359);

- V is the amount of water in the system.

The tank efficiency indicator is obtained by the formula:

D = (Pmax-Ps)/(Pmax +1),

Where

- Ps=0.5 bar is an indicator of the charging pressure of the expansion tank;

- Pmax is the maximum pressure of the heating system, on average 2.5 bar.

- D \u003d (2.5-0.5) / (2.5 + 1) \u003d 0.57.

For a system with a boiler power of 25 kW, an expansion tank with a volume of (375 * 0.0359) / 0.57 \u003d 23.61 liters is required.

And although the double-circuit gas boiler already has a built-in tank of 6-8 liters, but, looking at the results of the calculations, we understand that the stable operation of the heating system without installing an additional expansion tank will not work.

How does the expansion tank work and how is it arranged (regardless of the volume of the special tank - 100, 200 liters or less)?

The main function of this device is to maintain pressure in the system that supplies water to a private house or cottage. In most cases, closed membrane-type devices are used for water supply. expansion water supply tank of this type - This is a container with a rubber membrane built into it, which, in turn, divides the expansion (storage) tank, regardless of what the volume is - 100 liters or less, into two cavities - one of them will be filled with water, and the second is air. After the system is started, the electric pump will fill the first chamber. Naturally, the volume of the chamber in which the air will be located will become smaller. According to the laws of physics, with a decrease in the volume of air in the tank (again, regardless of whether the volume of the tank is 100 liters or less), the pressure will increase.

When the pressure reaches a certain level with a subsequent increase, the pump turns off automatically. It can only be activated again if the pressure drops below the set value. As a result, water will begin to flow from the water chamber of the tank (separate container).A similar mechanism of action (its constant repetition) is automated. The pressure indicator is controlled by a special pressure gauge, which is installed on the device. It is possible to change the initial settings.

The main functions of an expansion tank built into an autonomous water supply system (as a special container) are as follows.

A membrane expansion tank (special container) installed in the water supply system of a private house or cottage performs several functions at once:

- Ensuring stable pressure in the event that at a certain moment the pump is not functioning.

- The container protects the water supply system of an honest house or cottage from a likely hydraulic onslaught, which may occur due to a sharp change in voltage in the network or if air enters the pipeline.

- Saving under pressure a small (but strictly defined) amount of water (that is, this device, in fact, is a storage tank for water supply).

- Maximum reduction of wear of the water supply system of a private house.

- The use of an expansion tank allows you not to use the pump, but to use the liquid from the reserve.

- One of the most important purposes of this kind of devices (in this case we are talking exclusively about membrane expansion tanks) is to ensure that the most clean water is supplied to residents of a private house.

Optimal Performance

There are generally accepted averages:

- For a small private house or apartment with individual heating, pressure ranging from 0.7 to 1.5 atmospheres is sufficient.

- For private households in 2-3 floors - from 1.5 to 2 atmospheres.

- For a building of 4 floors and above, from 2.5 to 4 atmospheres are recommended with the installation of additional pressure gauges on the floors for control.

Attention! To carry out calculations, it is important to understand which of the two types of systems is being installed. Open - heating system in which the expansion tank for excess fluid interacts with the atmosphere

Open - a heating system in which the expansion tank for excess fluid interacts with the atmosphere.

Closed - hermetic heating system. It contains a closed expansion vessel of a special shape with a membrane inside, which divides it into 2 parts. One of them is filled with air, and the second is connected to the circuit.

Photo 1. Scheme of a closed heating system with a membrane expansion tank and a circulation pump.

The expansion vessel takes in excess water as it expands when heated. When the water cools and decreases in volume, the vessel makes up for the deficiency in the system, preventing it from breaking when the energy carrier is heated.

In an open system, the expansion tank must be installed in the highest part of the circuit and connected, on the one hand, to the riser pipe, and on the other, to the drain pipe. The drain pipe insures the expansion tank from overfilling.

In a closed system, the expansion vessel can be installed in any part of the circuit. When heated, water enters the vessel, and the air in its second half is compressed. In the process of cooling the water, the pressure decreases, and the water, under the pressure of compressed air or other gas, returns back to the network.

In an open system

In order for the excess pressure on the open system to be only 1 atmosphere, it is necessary to install the tank at a height of 10 meters from the lowest point of the circuit.

And in order to destroy a boiler that can withstand a power of 3 atmospheres (the power of an average boiler), you need to install an open tank at a height of more than 30 meters.

Therefore, an open system is more often used in one-story houses.

And the pressure in it rarely exceeds the usual hydrostatic, even when the water is heated.

Therefore, additional safety devices, in addition to the described drain pipe, are not needed.

Important! For normal operation of an open system, the boiler is installed at the lowest point, and the expansion tank is at the highest point. The diameter of the pipe at the inlet to the boiler must be narrower, and at the outlet - wider

Closed

Since the pressure is much higher and changes when heated, it must be equipped with a safety valve, which is usually set to 2.5 atmospheres for a 2-story building. In small houses, the pressure can remain in the range of 1.5-2 atmospheres. If the number of storeys is from 3 and above, the boundary indicators are up to 4-5 atmospheres, but then the installation of an appropriate boiler, additional pumps and pressure gauges is required.

The presence of a pump provides the following advantages:

- The length of the pipeline can be arbitrarily large.

- Connection of any number of radiators.

- Use both serial and parallel circuits for connecting radiators.

- The system operates at minimum temperatures, which is economical in the off-season.

- The boiler operates in a sparing mode, since the forced circulation quickly moves the water through the pipes, and it does not have time to cool down, reaching the extreme points.

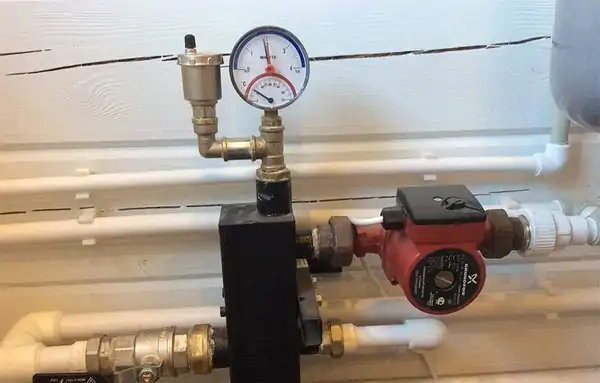

Photo 2. Measurement of pressure in a closed-type heating system using a pressure gauge. The device is installed next to the pump.

Calculating pressure in two ways

Before you buy a tank, you need to calculate its volume.In practice, decisions are made in the following order:

- design. At this stage, a decision is made about which rooms will be heated and which not, diagrams are drawn and the volume of the system in liters is calculated;

- boiler selection. Based on the volume of the system and the area of heated premises, a heater is selected. For 15 liters of coolant, one kilowatt of heater power is required;

- determination of the required volume of the expansion tank.

Now consider several different methods for calculating the pressure in the expansion tank of a sealed heating system.

Option number 1.

For this we need the following quantities:

- system volume (OS);

- tank volume (OB);

- the maximum allowable value of the pressure gauge scale for this system (DM);

- water expansion - 5%.

By the time you have to do the calculations, you already know how many liters the system holds. The required volume of the tank is calculated by dividing the capacity of the circuit in liters by ten. Although this is an approximate calculation, it is very working.

Calculate pressure air in the expansion tank heating systems in another way:

Air vent

Option number 2.

It's good that we live in a world of fierce competition. To ensure that the client is satisfied with the purchase and does not have any problems with operation, boiler manufacturers indicate in the product passport the required pressure of the heating expansion tank. If for some reason this cannot be found out, then this value can be calculated, knowing what the readings of the pressure gauge should be in the operating mode of the system.

The latter with one hundred percent probability can be found in the technical documentation or on the boiler.Then, 0.2-0.3 atmospheres should be subtracted from the working pressure. What is it for? If the pressure in the tank is greater than the operating pressure in the system, then the coolant will not be squeezed into the tank. He simply will not be able to do this as an even greater force acts on him from the side of the tank. And if there is not enough air in the tank, then there will be difficulties with the return of the coolant to the system.

Consequences of instability in circuits

Too little or too much pressure in the heating circuit is equally bad. In the first case, part of the radiators will not effectively heat the premises, in the second case, the integrity of the heating system will be violated, its individual elements will fail.

Proper piping will allow you to connect the boiler to the heating circuit as necessary for the high-quality operation of the heating system

An increase in dynamic pressure in the heating pipeline occurs if:

- the coolant is too hot;

- the cross section of the pipes is insufficient;

- the boiler and pipeline are overgrown with scale;

- air jams in the system;

- too powerful booster pump installed;

- water supply occurs.

Also, increased pressure in a closed circuit causes incorrect balancing by valves (the system is overregulated) or a malfunction of individual valve regulators.

To control the operating parameters in closed heating circuits and to automatically adjust them, a safety group is set:

The pressure in the heating pipeline drops for the following reasons:

- coolant leakage;

- pump malfunction;

- breakthrough of the expansion tank membrane, cracks in the walls of a conventional expansion tank;

- malfunctions of the security unit;

- water leakage from the heating system into the feed circuit.

Dynamic pressure will be increased if the cavities of the pipes and radiators are clogged, if the trapping filters are dirty. In such situations, the pump works with an increased load, and the efficiency of the heating circuit is reduced. Leaks in connections and even rupture of pipes become a standard result of exceeding pressure values.

The pressure parameters will be lower than expected for normal functionality if an insufficiently powerful pump is installed in the line. He will not be able to move the coolant at the required speed, which means that a somewhat cooled working medium will be supplied to the device.

The second striking example of a pressure drop is when the duct is blocked by a tap. A symptom of these problems is the loss of pressure in a separate pipeline segment located after the coolant obstruction.

Since all heating circuits have devices that protect against overpressure (at least a safety valve), the problem of low pressure occurs much more often. Consider the reasons for the fall and ways to increase blood pressure, which means to improve the circulation of water in heating systems of open and closed type.

What pressure in the boiler is considered normal

The value of this indicator in the heating system depends on the purpose of the mains and the heat sources used. For example, for a high-rise building, a pressure of 7–11 atmospheres (atm) is considered normal, and for an autonomous line of a two-story private cottage, depending on the design of the boiler heat exchanger, a value of up to 3 atm will be acceptable.

The value depends on the equipment and the strength of the coil in which the coolant is heated. Modern domestic gas units are equipped with durable heat exchangers that can withstand 3 atmospheres.Manufacturers of solid fuel equipment recommend not to exceed 2 atm.

The given values show the maximum value for which the boiler is designed. You don't need to use it in this mode at all. Moreover, when heated, the pressure rises. An average value will suffice, which will ensure the required performance of the unit and radiators.

To determine the operating value, the recommendations of the manufacturers of the boiler used and the installed heaters are taken into account. All of them are reduced to indicators from 0.5 to 1.5 atm. The value of the pressure of the autonomous system, which is within these limits, is considered normal!

Pressure fluctuations that occur during operation in heating mode will have less effect on nodes and devices at a lower value. Operation at 2 or more atmospheres will require additional load, as well as periodic operation of a closed expansion tank and a safety valve.

EXPANSION TANK SETUP

The second thing to pay attention to when the pressure drops in the heating system is the correct operation of the expansion tank. As you know, liquids increase their volume when heated. Water, for example, at a temperature of 90 degrees has an expansion coefficient of 3.59%

Therefore, so that excess pressure is not created in the heating system, expansion tanks are used. When the liquid is heated, the excess volume must enter the expansion tank, thereby stabilizing the pressure, and when the water cools, it leaves the tank, filling the system. Thus, the pressure in the heating system during the operation of the boiler is maintained within acceptable limits.In double-circuit boilers, expansion tanks are already installed in the boiler itself.

Water, for example, at a temperature of 90 degrees has an expansion coefficient of 3.59%. Therefore, so that excess pressure is not created in the heating system, expansion tanks are used. When the liquid is heated, the excess volume must enter the expansion tank, thereby stabilizing the pressure, and when the water cools, it leaves the tank, filling the system. Thus, the pressure in the heating system during the operation of the boiler is maintained within acceptable limits. In double-circuit boilers, expansion tanks are already installed in the boiler itself.

As you know, liquids increase their volume when heated. Water, for example, at a temperature of 90 degrees has an expansion coefficient of 3.59%. Therefore, so that excess pressure is not created in the heating system, expansion tanks are used. When the liquid is heated, the excess volume must enter the expansion tank, thereby stabilizing the pressure, and when the water cools, it leaves the tank, filling the system. Thus, the pressure in the heating system during the operation of the boiler is maintained within acceptable limits. In double-circuit boilers, expansion tanks are already installed in the boiler itself.

The incorrect operation of the expansion tank may be indicated by the fact that when heated, the pressure rises sharply, even an emergency discharge of water through the safety valve is possible, and when it cools, the pressure gauge needle drops down to such an extent that you have to feed the system. In this case, you need to adjust the operation of the expansion tank.

The manual for the boiler says what is the air pressure should be in the expansion tank.Therefore, for the correct operation of the tank, this pressure must be set. For this:

1. Let's turn off the water supply and return valves.

2. Find a drain fitting on the boiler,

open it up and drain the water.

3. Find a nipple on the expansion tank, like on a bicycle wheel, and bleed all the air.

4. Connect the car pump to the expansion tank and pump it up to 1.5 bar, while water can come out of the drain fitting.

5. Let's release the air again.

6. If a hose from the boiler fits the tank, disconnect it, you need to pour all the water out of the tank.

7. Attach the hose back.

8. We inflate the expansion tank with pressure according to the instructions for the boiler

(in our case it is 1 bar).

9. Close the drain fitting.

10. Open all taps.

11. We fill the heating system with water at a pressure of 1-2 bar.

12. Turn on the boiler and check. If, when the water is heated, the pressure gauge needle is within the green zone, then we did everything right.