- Coloring recommendations

- Video description

- Briefly about the main

- Paint for radiators

- Alkyd enamels

- Acrylic enamels

- Hammer enamels

- Powder paints

- Is it possible to paint the battery in the apartment with acrylic paint?

- Selection criteria

- acrylic enamel

- Paint thinner for radiators

- Characteristics of paints for radiators

- Types of paints

Coloring recommendations

First of all, it is worth noting that both solvent-based enamel and odorless radiator paint are not intended for painting on a hot surface. This is due not only to the danger of release of toxic substances from the heated surface, but also to the violation of the drying regime. Any paint should be applied and dried at an ambient and base temperature of +5 to +30 degrees.

But first, the radiator needs to be prepared for painting. If the old coating is solid, without cracks or damage, it is enough to lightly rub it with fine-grained sandpaper to improve adhesion to the new layer. Then clean from the resulting dust and degrease with white spirit or acetone.

Peeling paint and too thick a layer must be removed. This can be done quickly using firing, a drill with a special abrasive nozzle or a cord brush.

Removing the old coating

You can also use special gel washes that soften the paint layer, which after some time after applying the product is easily cleaned with a spatula.

Video description

The process of removing old paint from a cast-iron battery using a wash is shown in the video:

The next step is priming the surface. It is advisable to choose a composition for this on the same basis as the selected paint. For example, under alkyd enamel, radiators can be primed with GF-021, which has an anticorrosive effect.

You can start painting after the primer has dried. If it is done by hand, it is advisable to use two brushes: one curved on an elongated handle for hard-to-reach places and the second regular one for the front surface. Both should be with natural bristles.

Such a brush will allow you to get to the most difficult areas of the radiator.

They begin to paint from the inner surfaces, leaving the facade part for last. As a rule, a minimum of 2 passes is required to achieve a smooth and uniform surface. The second layer can be applied after the time specified in the instructions and necessary for complete drying.

Briefly about the main

Now you know everything about what should be the paint for radiators, which one is better to choose in this or that case. The choice should be made between acrylic and alkyd enamels, which have high heat resistance, environmental friendliness and abrasion resistance. Another worthy option is a silver coin made from aluminum powder and a special varnish. In order for the coating to serve for a long time without flaking or changing color, radiators should be carefully prepared for painting by removing the old layer and priming the surface.

Source

Paint for radiators

Now let's move on to the types of paint. Special paints for heating systems are alkyd and acrylic, there are also varieties of them - they are made on different bases.

Alkyd enamels

This group has a very wide range of shades, the smell is there, but not very strong, after a few hours it disappears. You can safely use them: they will not turn yellow and will not fade. But alkyd enamels for radiators come in different bases:

The manufacturer and its purpose must be indicated on the can of paint.

Acrylic enamels

Acrylic enamels, after drying, resemble a plastic coating. The effect is complete: both in appearance and to the touch. This paint is very good and washes well. But there are several types, with different properties. There are water-based, they are almost odorless. They are also called "acrylate enamels". But you need to look for heating systems intended for painting.

A good option is VD-AK-1179. But this paint must be applied to primed or previously painted metal. Drying time before applying the next layer is 2 hours, complete drying is 24 hours (the cost for a liter jar is about 600 rubles).

Manufacturers of paints for radiators and heating pipes

With a smell, but includes anticorrosive additives "Termakrill" of the ALP ENAMAL campaign. The declared temperature is up to +120 o C, it has anti-corrosion properties, it is suitable for painting any steel, including stainless, low-carbon and galvanized, aluminum and titanium alloys. Tinted in any shade. Drying time before applying the next layer at 20 o C - 20-30 minutes, complete drying - 2 days.

There are many other enamels of this class with different characteristics. Choose the option that suits you best.

Hammer enamels

This is a very interesting version of alkyd enamels, which allows you to achieve non-uniform coloring when using only one paint. Depending on the type of pigment, the surface may look like embossing, hammer blows and other effects. The heterogeneity of color hides defects and irregularities of the base very well. Base preparation is standard: removal of rust, old paint, cleaning to metal, degreasing to a “clean rag”. When applied to even and glossy surfaces, it is necessary to create a rough base (treat with sandpaper).

Hammer enamels give a very interesting effect that will hide many surface imperfections.

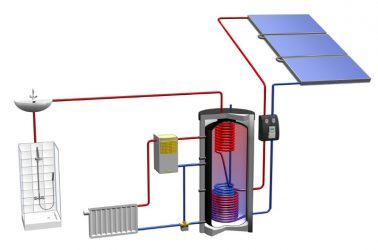

Powder paints

This is a modern method of painting, according to which aluminum is painted. bimetallic and steel radiators. At home, it is difficult to implement. It's a matter of technology. Powder paint is dry and sprayed from a special gun. It costs about $40-60, but you can find an organization that rents equipment.

The painted part (prepared and cleaned) is given a negative potential, the powder is positive. To "charge" the part, a diesel engine is needed, which can deliver fractions of an ampere at a voltage of 25-30 kV.

Due to the potential difference during spraying, the powder is evenly distributed over the surface of the part. Then the applied coating requires polymerization: the creation of conditions under which the applied powder turns into a single hard coating.

Powder coating gives a durable and smooth finish, but it is a complex process.

Most often, this condition is heating to certain temperatures.The heating temperature can vary from 170-200 o C to 350 o C. At a low polymerization temperature, it may be enough to heat the part with an ash gun, but at a high temperature, the part is placed in a special oven (used costs about $ 60), where it is gradually heated . There are also compounds that polymerize with ultraviolet radiation. Everything is simpler here: in a closed space, an ultraviolet lamp is turned on and the part is kept for a certain period of time.

In any case, it is quite difficult to create such conditions at home. If there is a need for powder coating, you can contact a specialized auto repair shop, maybe they have similar equipment, and they will agree to paint your radiators.

As you can see, the choice of colors is quite wide. The only type that is not advised is oil paints. In fact, they have already outlived themselves. But if you like them, you can use them.

Is it possible to paint the battery in the apartment with acrylic paint?

The process of painting a heating battery is often accompanied by the question of whether it is possible to paint the battery with acrylic paint. Can hot batteries be painted? What is the best paint and varnish for a heating radiator?

Painting a heat exchanger is often an indispensable part of a renovation, although it can be just a design move to bring bright colors into a home. They are also tinted and, as the current top painted layer wears out, or they are simply painted with patterns on top of the existing one. Regardless of the type and scope of work, it is better to approach the choice of means responsibly.

Selection criteria

There are quite a few requirements for all types of coatings for heating radiators.The paint product must be resistant to high temperatures, at the level of 90-100 ° C, serve as a metal protection against corrosion, fit well on the surface, not change color over time and be non-toxic. Modern hardware stores offer a wide selection of paints and emulsions of all possible colors and shades. Most people are accustomed to the fact that the heating radiator should be white, but some seek to turn such an ordinary item into an original interior detail. After all, this beautifully painted item can become a highlight, a harmonious detail of any, even the most elaborate interior.

Some experts believe that color affects performance. Dark colors increase the heat dissipation of the device, while light colors reduce it slightly. Now the choice of coatings is very large: there are separate products specifically for radiators, you can also use various enamels, heat-resistant varnishes, water-based paints.

However, each type of coverage has its pros and cons. So before buying, you need to carefully analyze everything.

acrylic enamel

The main advantage of acrylic enamel is a very high temperature resistance to yellowing, it is 100 ° C, in some - up to 120 ° C; at home, it will not turn yellow, since heating radiators simply do not heat up to such temperatures. Their main operating mode is 40-60°C. Also, this enamel is considered to be quite resistant, which allows you to preserve the decorative appearance of the painted device for a long time. A plus in the piggy bank of the positive characteristics of the acrylic coating is the fairly quick drying of the applied layer, 2-3 hours. More accurate information is usually indicated on the paint can.

Some are interested in the question of whether it is possible to paint hot batteries. Answer: Acrylic agent allows you to paint even warm radiators.

A feature of these enamels is that they are produced on organic solvents. So, during the staining process, a slight characteristic smell of the solvent is released, which, however, evaporates rather quickly. However, thanks to this component, the paint acquires a beautiful glossy sheen when it dries. But, having dried, the color can slightly change the shade. Acrylic usually darkens as it dries. This enamel has excellent mechanical resistance, UV resistance and impermeability to steam. In addition, they are endowed with water-repellent abilities and are resistant to cold after complete solidification.

They are diluted with water, but when dried, as can be seen from the names, they do not acquire a characteristic sheen. Often these products cost more than glossy enamel, but they better hide dents and other small surface defects that appear when coated with glossy paint. It takes about 10 hours to completely dry the battery, painted with acrylic emulsion.

So if you decide to paint the batteries with acrylic paint, choose which option suits you best and paint.

This is interesting: Do-it-yourself drywall lift - drawings and diagrams

Paint thinner for radiators

Of course, the new paint for radiators will lay down tightly and evenly only if the old coating from the radiators is completely removed.In order not to waste time manually scraping metal or peeling it off with a drill and a brush, you can use special gel washes. Such a composition is applied to the surface of the radiator and left for a certain time. When the paint softens, it is simply scraped off with a spatula.

You can apply a paint remover with an old brush with natural bristles or a spatula made of metal or wood. Among the various types of washes, there are aerosol types of washes. In order not to damage adjacent surfaces, all nearby objects are covered with a film before spraying the composition.

Manufacturers indicate the exposure time of various formulations on the packaging. After a predetermined period, the old coating becomes soft enough that it can be removed without difficulty.

Although the wash contains chemically active components, they do not damage metal and wooden objects, as well as skin. But still, it is better to use gloves when working. Residues of the composition from the radiator can be washed off with plain water.

conclusions

As it became clear, the range of types and colors of dyes for radiators is very extensive. When buying, you will need to choose the color and type of paint - matte, semi-gloss or gloss

In addition, it is important to decide which paint you want to buy - alkyd enamel or acrylic. The last step is to select a manufacturer.

Characteristics of paints for radiators

On packaging containers with compositions intended for decorative finishing of heating devices, there should be a mark “Paint for radiators”. Regardless of what components it consists of, it must have the following qualities:

- heat resistance;

- environmental friendliness;

- moisture resistance;

- abrasion resistance;

- good thermal conductivity.

Let's analyze each point.

In order for the coating not to peel off, crack or change color, it must calmly withstand an increase in the temperature of the base to at least 80 degrees. Better - more, as the batteries can get very hot.

Application result for heating pipes paints with low heat resistance

The environmental friendliness of the paint means the absence of volatile toxic substances in its composition, which are released when heated. It doesn't have to be unscented radiator paint: it can smell as it dries. The main thing is that after drying, the release of volatile substances stops.

Moisture and abrasion resistance are the characteristics that will allow you to wash batteries without fear of damaging the coating.

The higher the thermal conductivity of the paint, the less it will affect the efficiency of the heater and its heat transfer. The thickness of the coating layer is also important here. It is noticed that painting in 2-3 layers does not prevent the release of heat, but each subsequent layer reduces heat transfer by 1%. This is one of the reasons why it is recommended to peel off the thick old coating before restoring the batteries.

One cleaning method is to soften the old paint with a blowtorch and remove it with a spatula.

It is also desirable that the composition has anti-corrosion properties, but this is not a mandatory option subject to pre-treatment with special means.

In the conditions of painting directly in place, odorless, quick-drying radiator paint is preferable. Its use will allow you not to move out of the house during the repair.Compositions with a pungent odor are best used under the condition of good ventilation and the absence of people and animals nearby.

In addition to technical requirements, there are also aesthetic ones related to the color of the coating and its texture. They are all different. If you are satisfied with the white color of the heater - namely, this base color is mainly presented in stores - use the paint according to the instructions. But before buying, make sure that it does not contain chalk, which will soon turn yellow from high temperatures. It is better to pay more, but to get paint with titanium white.

If you want to paint the batteries in the color of walls or other interior elements, you can achieve the desired shade by mixing the base composition with tinting paste. Moreover, it is better to tint it on special equipment, which is available in any large hardware store of the corresponding profile.

Professional tinting allows you to get exactly the right tone

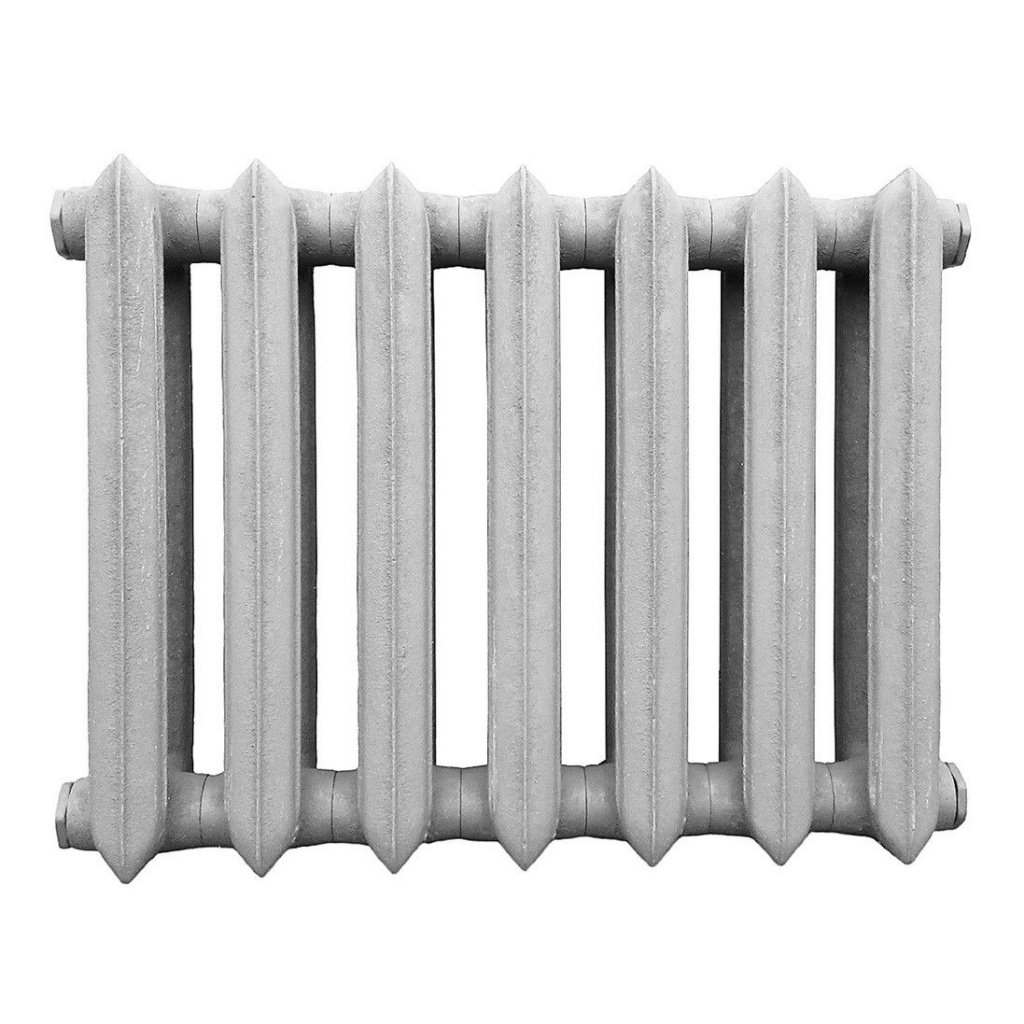

As for the texture, battery paint is glossy, semi-matte and matte. The former retain color brightness longer, but reveal all surface defects. Matte on the contrary - mask them. Therefore, it is matte compositions that are usually used for decorating cast iron products that initially have a rough surface with metal influxes, dents and other irregularities.

Repairing a leaking battery is very difficult.

Types of paints

What paint paint radiators? You are very lucky if you have modern powder-coated radiators at your disposal - it lasts for decades without peeling and hardly changing its color.Such paint covers aluminum, bimetallic and steel radiators of various designs. To give special strength, the coloring is subjected to procedures that make it stronger and more durable. The longest service life is characterized by multi-stage painting.

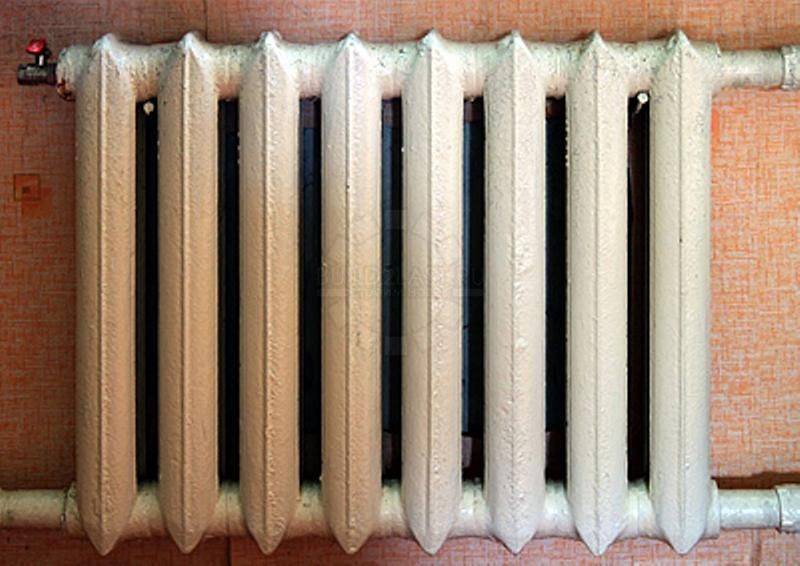

Painting batteries is needed not only to give a neat appearance to the radiator, but also to protect it from the environment.

If the house has ordinary cast-iron accordion batteries or old steel batteries, then they need to be tinted periodically. The paint quickly turns yellow, begins to crumble, exposing the metal and creating all the conditions for the formation of corrosion centers. Therefore, the paintwork needs to be updated. It may also be needed during repairs - what if you decide to paint the batteries in different colors and adapt them to your interior design?

What paint paint radiators? There are many types of paints:

- water-dispersion - do not emit an unpleasant odor and dry quickly;

- acrylic - they smell of solvents and give gloss;

- alkyd - resistant durable, characterized by long drying;

- oil - not the most worthy option for painting batteries;

- heat-resistant silver - an excellent option for painting heating appliances;

- silicone aluminum - excellent in all respects, but very expensive;

- canned automotive enamels are a reasonable heat-resistant option.

The water-dispersion composition for radiators is completely safe, as it dissolves with water.

Water-based paints are good because they do not have a strong solvent smell, since their base is ordinary water.They are fast drying and are well suited for painting radiators. On some varieties there are marks indicating the possibility of painting heaters.

You don't like matte radiators and want them to shine? Then we recommend that you turn your attention to modern acrylic enamels. They give excellent gloss and have a long service life.

Their disadvantage is the smell of the solvent, so the premises after painting will need to be ventilated.

Alkyd paints are the most durable. They are resistant to temperature loads, well resist abrasion, do not change their color for a long time. Some of them withstand heating up to +150 degrees without turning yellow for many years. Despite the obvious advantages, such paints have one striking drawback - the strong smell of the solvent. It manifests itself not only at the stage of painting, but also when starting the heating system.

Some consumers note that after drying, the unpleasant odor disappears, but appears already at the first start of heating, disappearing after 1-2 days. During these periods, it is recommended to carefully ventilate the rooms in which the painted batteries are located.

Oil paints are not very well suited for heating radiators, so they have been practically not used recently. They have a strong solvent smell, dry and stick for a very long time, and the dyes used in them turn yellow over time. In addition, after a year or two, such a painting will begin to peel off and fall off, exposing the metal of the heating devices. We do not recommend using this paint for painting heating radiators.

Radiators painted with silver look very attractive, but the main thing here is that the surface of the battery is even, without bumps and depressions, otherwise the impression will be smeared.

Heat resistant silver is an excellent choice for painting batteries silver. It contains heat-resistant varnish and powdered aluminum. Tserebrianka advantages:

- withstands heating up to +200 degrees;

- does not change color;

- almost does not peel off and does not fall off.

The disadvantage is a rather strong smell, so after painting the batteries, the rooms must be ventilated.

Silicone-aluminum paints have the highest resistance to high temperatures. They fit well on any surface, forming a strong and reliable connection. The surface is smooth and plastic, the painting does not peel off even after several years of operation. The payoff for such excellent performance is high cost - you have to pay for advantages and durability.

Autoenamels are also suitable for painting heating radiators. They are resistant to temperatures up to + 80-100 degrees and form a shiny glossy surface that does not change color under the influence of temperature loads.