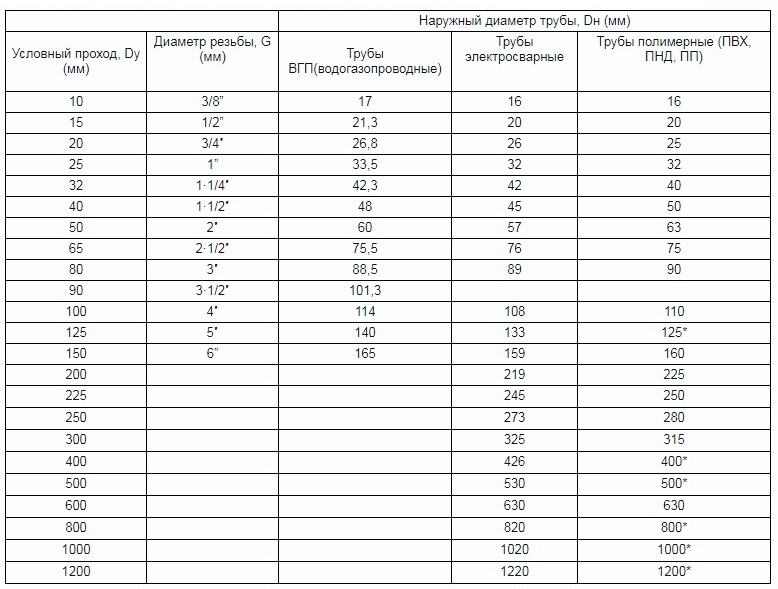

- Types of products used

- Disadvantages of polypropylene pipes

- Paint selection

- Benefits of using ITP

- Composition selection

- Alkyd enamel for heat pipes

- Heat resistant acrylic enamel

- Silicone and powder paints for metal

- The temperature in the apartment for the health of children

- Permissible levels of electromagnetic radiation

- Permissible levels of electromagnetic radiation in the radio frequency range (30 kHz-300 GHz)

- Permissible levels of ionizing radiation

- Rules and regulations for installing a gas boiler in a private house

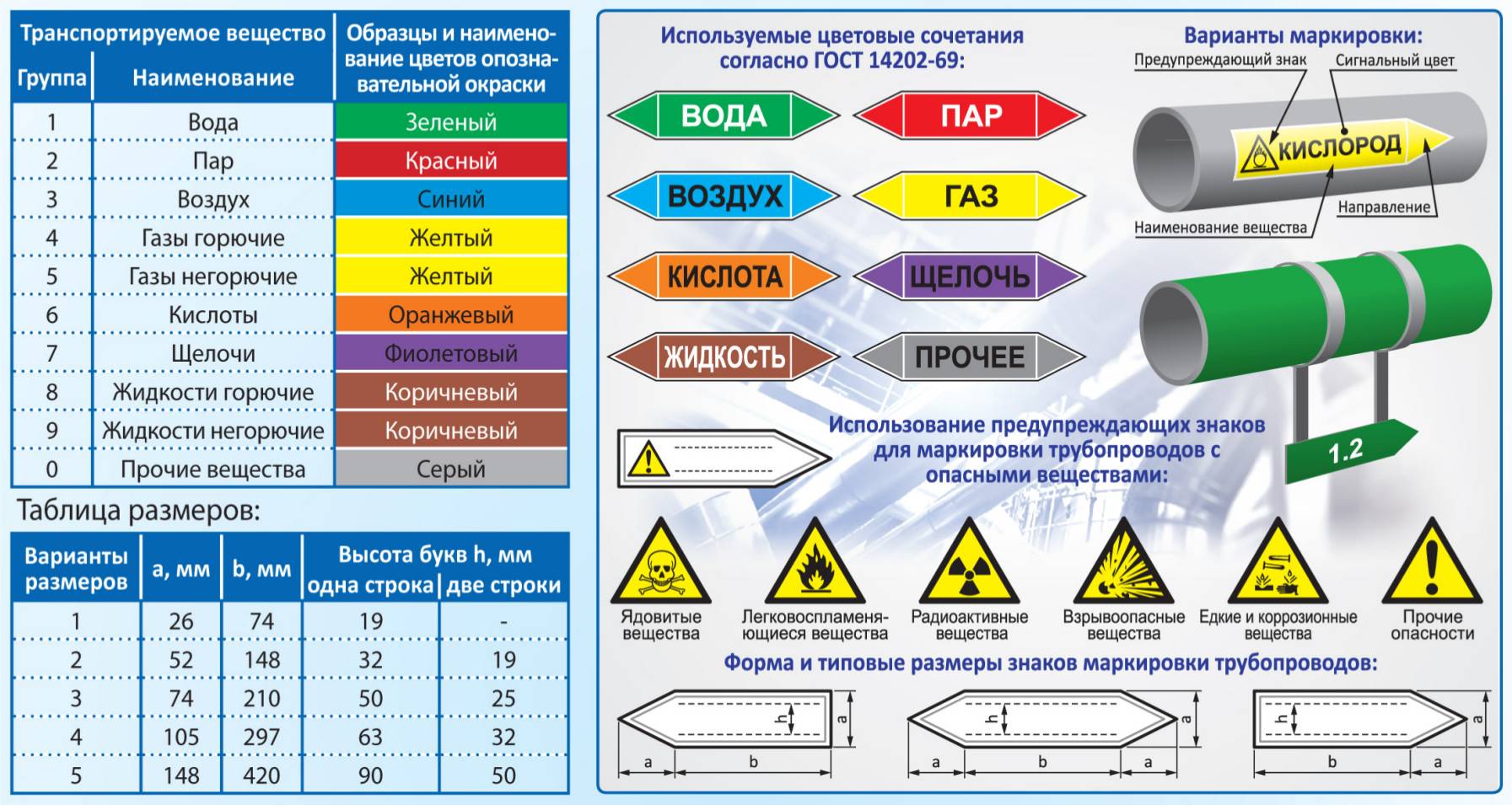

- Marking communications with various devices

- Battery Performance

- Characteristics of cast iron radiators

- Characteristics of steel radiators

- Characteristics of aluminum radiators

- Characteristics of bimetallic radiators

- Properties of polypropylene

- Cink Steel

- Reading information

- Factors affecting the working pressure

- Regulations and standards

- The norm of temperature in the apartment for the health of an adult

- The color of the pipe in the boiler room

Types of products used

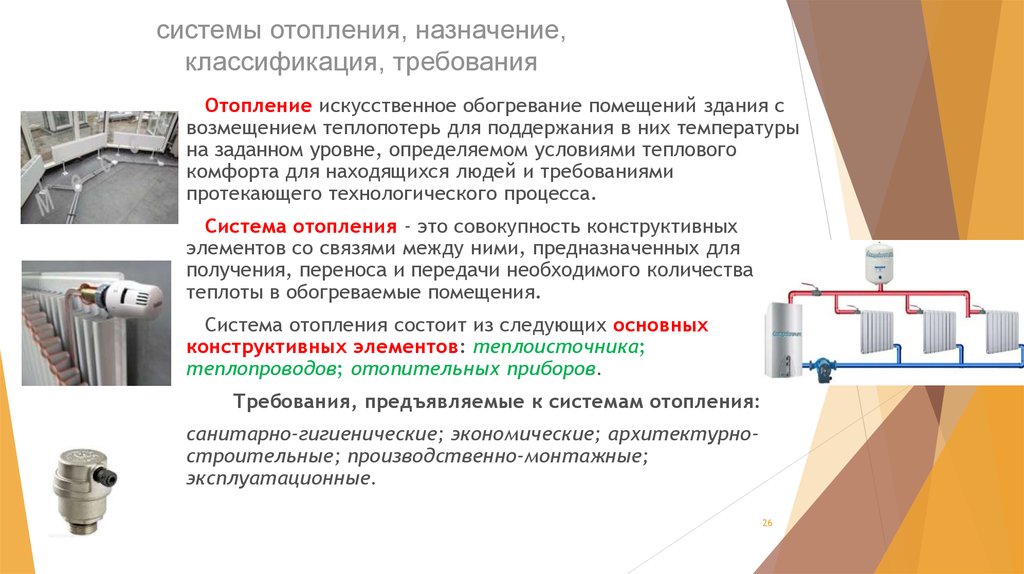

There are various product options that have the necessary characteristics.

The most common types of paints used for heating pipes and radiators are as follows:

- acrylic enamels - durable, resistant, giving the surface a glossy sheen. However, their disadvantage is an unpleasant odor during the dyeing process, which, however, quickly disappears;

- alkyd enamels - resistant to high temperatures, abrasion, the coating is very durable and uniform. Differ in richness of various shades. But their significant disadvantage is a pungent smell that can last up to three days and be felt when the heating is on;

- water-dispersion emulsions should be chosen when odorless heating pipe paint is required. They are easy to apply, create a uniform coating, dry quickly, and do not have an unpleasant odor. Be sure to check that the marking indicates that it is intended for painting radiators.

Disadvantages of polypropylene pipes

Before proceeding with the laying of the system, it is necessary to take into account the negative aspects of the use of polypropylene pipe products:

- products cannot be bent;

- fittings for the installation of pipelines are not aesthetically pleasing;

- pipes, if heated to a high temperature, begin to stretch and sag, which makes them look unattractive;

- during installation work, it is necessary to monitor the temperature - otherwise the overheated edges of the pipes will change their parameter, and their diameter will differ from the size of the fittings.

It is quite difficult to find polypropylene products that are designed for high pressure, since the material itself cannot be used in such conditions. As a result, the system will be unusable during continuous operation.

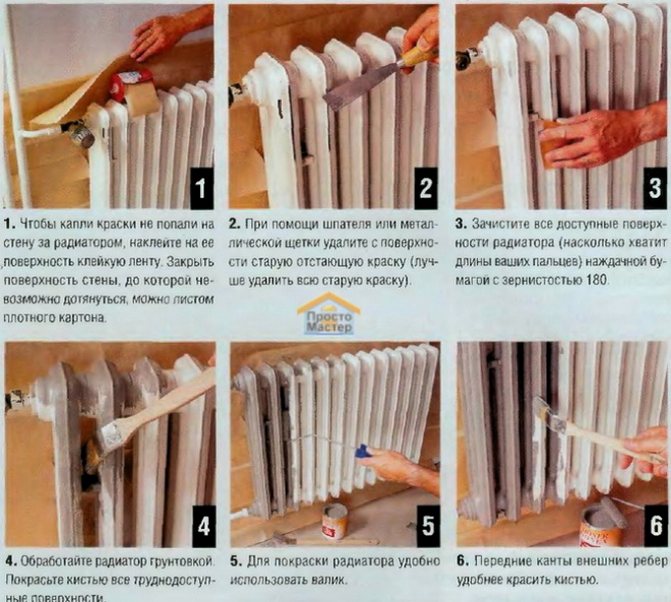

Paint selection

To obtain the best effect, you should choose paints marked "for radiators" or similar.In this case, resistance to elevated temperatures and color retention are guaranteed. Of the inexpensive options, PF-115 enamel corresponds to most of the listed requirements. Heat-resistant silicon-based enamel KO-168 also gives good results. It is better to refuse oil paints, since their color inevitably fades over time, the applied coating dries for a long time and stinks noticeably all this time.

Paints, suitable for heating pipesare divided into 3 types:

- alkyd enamels;

- acrylic enamels;

- water-dispersion compositions.

Alkyd enamels are quite common due to the most affordable cost. This is where their benefits end. Alkyd enamel is the most smelly of the above list of paints, even after drying for some time it gives a characteristic unpleasant odor when the heating system is in operation, slightly fades over time. The change in color is especially noticeable in the case of coloring in white, for the rest this feature can be ignored. The period of complete drying is 24 hours, after 4 - 6 hours it is no longer sticky.

Acrylic enamels are based on organic solvents, so there is a specific smell when working with them, but it is noticeably less than that of the previous type. These paints have a very wide range of colors, dry in 1 hour, but in most cases require preliminary priming of metal surfaces. Acrylic paints are glossy and matte. The former shine beautifully, while the latter hide the irregularities of the painted surface well. At the same time, the original brightness of the color is preserved.

Water-dispersion paints are considered the safest for health. At the same time, they are not inferior to the rest in terms of durability and beauty of the coating. These are quick-drying, odorless paints.It is only necessary to check the presence of a special mark on the bank, indicating the possibility of using it for heating appliances.

The most popular now paints of the following brands:

- Heitzcorperlak;

- Radiator Paint;

- Elementfarg Alkyd;

- Millertemp;

- Mipaterm 600;

- Radiator;

- Priming enamel UNIPOL;

- Enamel VD-AK-1179;

- Enamel GF-0119.

As for color, it all depends on the features of the interior, lighting and aesthetic taste of the owners. In addition to the standard range, you can use metallic paints for gold, silver, chrome, bronze, combine different colors or apply patterns. From the point of view of heat engineering, dark shades are preferable, as they contribute to better heat transfer.

Benefits of using ITP

The four-pipe heat supply system from the central heating point, which was previously used quite often, has a lot of disadvantages that are absent from the ITP. In addition, the latter has a number of very significant advantages over its competitor, namely:

- efficiency due to a significant (up to 30%) reduction in heat consumption;

- the availability of devices simplifies the control of both the flow of the coolant and the quantitative indicators of thermal energy;

- the possibility of flexible and prompt influence on heat consumption by optimizing the mode of its consumption, depending on the weather, for example;

- ease of installation and rather modest overall dimensions of the device, allowing it to be placed in small rooms;

- reliability and stability of the ITP, as well as a beneficial effect on the same characteristics of the serviced systems.

This list can be continued indefinitely. It reflects only the main, lying on the surface, the benefits obtained by using ITP.It can be added, for example, the ability to automate the management of ITP. In this case, its economic and operational performance becomes even more attractive to the consumer.

The most significant disadvantage of ITP, apart from transportation and handling costs, is the need to settle all sorts of formalities. Obtaining appropriate permits and approvals can be considered a very serious task.

Composition selection

In order for the effect of using paint for heating pipes to be the best, when choosing a composition in a store, it is better to purchase paint with the inscription “for heating radiators”, or a similar mark. Such a coloring mixture will be resistant to high temperatures, and when heated, it will not change its color. One of the budget options is PF-115 enamel, which meets almost all the basic requirements listed above. Heat-resistant paint KO-168, which has a silicon base, is also very good.

It is better not to use oil paint for pipes heated to high temperatures, as the oil composition will definitely fade or turn yellow after a while. In addition, oil dyes have an unpleasant lingering odor during dyeing and drying.

Alkyd enamel for heat pipes

This enamel consists of alkyd varnish (pentaphthalic, glyptal) with the addition of vegetable oils and a solvent (white spirit). It has high elasticity and is quite durable. Currently, these enamels are popular and are used in many areas of painting.

The advantages of alkyd enamels include:

However, alkyd paints have not only advantages.The disadvantages include:

- A pungent smell, since the composition of these enamels includes white spirit. The smell persists for several days. It is also possible that it will appear after the first start of the heating system.

- Long time of complete drying (24-36 hours), which increases the time for painting work.

Alkyd enamel PF-223 is quite suitable as a paint for heating pipes; PF-115 can also be used for a heating system.

Heat resistant acrylic enamel

Odorless pipe paint is acrylic enamel. This enamel, due to the fact that it does not have a pungent odor, is an ideal paint and varnish material for work carried out inside residential premises. The painted surface acquires absolute smoothness, tactilely reminiscent of plastic.

Since not all acrylic enamels are heat-resistant, when buying, you must carefully read the information regarding the temperature range of its use. The minimum value for the use of these enamels is 80 ºС.

A significant advantage of these paints is their drying time - for the first layer, the value is from ten minutes to one hour, and from one to two hours for the second. To achieve a high-quality result, it is necessary to prime the surface to be painted. When carrying out work, it is necessary to avoid getting moisture on the surface to be painted.

The consistency of acrylic resembles sour cream of medium density, it does not spread, which eliminates the possibility of smudges. As stated above, this enamel should be applied to the previously primed surface in two coats.Violation of the painting technology entails a significant deterioration in its quality.

The only drawback of using this material is the low resistance to mechanical stress.

Silicone and powder paints for metal

These two types of paints are the most resistant to high temperatures.

If the heating system is systematically exposed to overheating, then silicone paint is exactly what it is necessary to paint the heating pipes with. After all, this coating is guaranteed to withstand heating up to 350 ºС. This paint consists of silicone resin with the participation of aqueous solvents. Semi-matte gloss is a characteristic feature of the dried layer of this paint.

Silicone paint is unpretentious when painting - it does not require priming, it is applied directly to the metal. Resistant to external influences. Durable. The downside is the high price.

Powder paint is the most stable and durable of paints and varnishes at the present time. Used in industrial environments.

The temperature in the apartment for the health of children

О¿ÃÂøüðûÃÂýÃÂù ÃÂõüÿõÃÂðÃÂÃÂÃÂýÃÂù ÃÂõöøü ò úòðÃÂÃÂøÃÂõ ÃÂòûÃÂõÃÂÃÂàþôýøü ø÷ ýõþñÃÂþôøüÃÂàÃÂÃÂûþòøù à¿ÃÂðòøûÃÂýþóþ ÃÂð÷òøÃÂøàôõÃÂõù. ÃÂÃÂþñõýýþ ñþûÃÂÃÂþõ ÷ýðÃÂõýøõ ÃÂõüÿõÃÂðÃÂÃÂÃÂð òþ÷ôÃÂÃÂð ò ôþüõ øüõõàôûàýþòþÃÂþöôÃÂýýÃÂÃÂ.ÃÂàüõÃÂðýø÷ü ÃÂõÃÂüþÃÂõóÃÂûÃÂÃÂøø ôþ úþýÃÂð ýõ ÃÂð÷òøÃÂ, ÿþÃÂÃÂþüàóÃÂÃÂôýøÃÂúø þÃÂõýàÃÂÃÂòÃÂÃÂòøÃÂõûÃÂýàú ÿõÃÂõÿð ôðü ÃÂõüÿõÃÂðÃÂÃÂÃÂ. Ã] ã] °_â ° ° ºãâting ã¿¿¿¿¿¿¿¿¿¿¿½ãããâããâââte ã] ± ã] ãâte ã] ã] ã] ã] ã] ã] ã] °] ° µ ã] ã] àõñÃÂýúð üþöýþ ÿõÃÂõóÃÂõÃÂÃÂ, ð ÃÂÃÂþ ÃÂðúöõ ýõ ýõÃÂÃÂàÿþûÃÂ÷àõóþ ÷ôþÃÂþòÃÂÃÂ.

Ã] ÃÂþ üõÃÂõ ò÷ÃÂþÃÂûõýøàòõÃÂÃÂýÃÂàóÃÂðýøÃÂàÃÂõüÿõÃÂðÃÂÃÂÃÂýþù ýþÃÂüàþÿÃÂÃÂúðÃÂÃÂ.

Permissible levels of electromagnetic radiation

Permissible levels of electromagnetic radiation in the radio frequency range (30 kHz-300 GHz)

electromagnetic radiation

En (PPEn) is the electric field strength (energy flux density) created at a given point by each RF EMP source; EPDU (PPEPDU) - permissible electric field strength (energy flux density). In cases where for the radiation of all RF EMI sources different remote controls installed:

6.4.1.3. When installing antennas for transmitting radio engineering objects on residential buildings, the intensity of RF EMP directly on the roofs of residential buildings may exceed the permissible levels established for the population, provided that persons who are not professionally involved in exposure to RF EMP are not allowed to stay on the roofs with transmitters operating.On the roofs where transmitting antennas are installed, there must be an appropriate marking indicating the boundary where people are not allowed to stay with the transmitters in operation. 6.4.1.4. Measurements of the radiation level should be made under the condition that the EMP source is operating at full power at the points of the room closest to the source (on balconies, loggias, near windows), as well as for metal products located in the premises, which can be passive EMP repeaters and when completely disconnected household appliances that are sources of RF EMI. The minimum distance to metal objects is determined by the operating instructions for the measuring instrument. Measurements of RF EMI in residential premises from external sources should be carried out with open windows. 6.4.1.5. The requirements of these sanitary rules do not apply to electromagnetic effects of an accidental nature, as well as those created by mobile transmitting radio engineering objects. 6.4.1.6. The placement of all transmitting radio facilities located on residential buildings, including amateur radio stations and radio stations operating in the 27 MHz band, is carried out in accordance with the hygienic requirements for the placement and operation of land mobile radio communications.

6.4.2. Permissible levels of electromagnetic radiation of industrial frequency 50 Hz 6.4.2.1. The intensity of the electric field of industrial frequency 50 Hz in residential premises at a distance of 0.2 m from walls and windows and at a height of 0.5-1.8 m from the floor should not exceed 0.5 kV / m. 6.4.2.2.The induction of a magnetic field of industrial frequency 50 Hz in residential premises at a distance of 0.2 m from walls and windows and at a height of 0.5-1.5 m from the floor and should not exceed 5 μT (4 A / m). 6.4.2.3. Electric and magnetic fields of industrial frequency 50 Hz in residential premises are evaluated with completely disconnected household appliances, including local lighting devices. The electric field is evaluated with the general lighting turned off completely, and the magnetic field is evaluated with the general lighting turned on completely. 6.4.2.4. The intensity of the electric field of industrial frequency 50 Hz in the territory of residential development from overhead power lines of alternating current and other objects should not exceed 1 kV / m at a height of 1.8 m from the earth's surface.

Permissible levels of ionizing radiation

6.5.1. The effective dose rate of gamma radiation inside buildings should not exceed the dose rate in open areas by more than 0.2 µSv/h. 6.5.2. The average annual equivalent equilibrium volumetric activity of the daughter products of radon and thoron in the indoor air EROARn +4.6 EROATn should not exceed 100 Bq/m3 for buildings under construction and reconstruction and 200 Bq/m3 for operated buildings.

7.1. The release of harmful chemicals from building and finishing materials, as well as from materials used for the manufacture of built-in furniture, should not create concentrations in residential premises that exceed the standard levels established for atmospheric air in populated areas. 7.2. The level of electrostatic field strength on the surface of building and finishing materials should not exceed 15 kV/m (at a relative air humidity of 30-60%). 7.3.The effective specific activity of natural radionuclides in building materials used in buildings under construction and reconstruction should not exceed 370 Bq/kg. 7.4. The coefficient of thermal activity of floors should be no more than 10 kcal/sq. m hour deg.

Rules and regulations for installing a gas boiler in a private house

The choice of installation location for a gas boiler depends on its power:

- with a power of up to 60 kW, installation is possible in the kitchen (subject to certain requirements);

- from 60 kW to 150 kW - in a separate room, regardless of the floor (subject to the use of natural gas, they can be installed in the basement and basement as well);

- from 150 kW to 350 kW - in a separate room on the first or basement floor, in an annex and a separate building.

This does not mean that a 20 kW boiler cannot be installed in a separate boiler room. You can, if you want to collect all life support systems in one place. That's just the volume of premises there are requirements. The minimum size of a boiler room in a private house should be:

- for boilers with a power of up to 30 kW, the minimum volume of the room (not the area, but the volume) must be 7.5 m3;

- from 30 to 60 kW - 13.5 m3;

- from 60 to 200 kW - 15 m3.

Only in the case of installing a gas boiler in the kitchen, other standards apply - the minimum volume is 15 cubic meters, and the ceiling height is at least 2.5 m.

Installation option for a wall-mounted gas boiler - up to the wall at least 10 cm

For each room option for gas boiler there are certain requirements. Some of them are common:

Any boiler room in a private house should have natural light.Moreover, the area of windows is normalized - at least 0.03 m2 of glazing should fall on 1 m3 of volume

Please note that these are the dimensions of the glass. In addition, the window should be hinged, open outward.

The window should have a window or transom - for emergency ventilation in case of gas leakage.

Mandatory ventilation and removal of products combustion through the chimney

The exhaust of a low-power boiler (up to 30 kW) can be led through the wall.

Water must be connected to the boiler room of any type (feed the system if necessary) and sewerage (heat carrier drain).

Another general requirement that appeared in the latest version of SNiP. When installing gas equipment for hot water supply and heating with a capacity of more than 60 kW, it is necessary gas control system, which, in the event of a trigger, will automatically stop the gas supply.

If there is a boiler and a heating boiler, when determining the size of the boiler room, their power is summed up

Further requirements differ depending on the type of boiler room.

Marking communications with various devices

In the event that the contents of communications are particularly aggressive, warning rings are applied to them in one of three colors: red corresponds to flammability, flammability and explosiveness; yellow color - dangers and harmfulness (toxicity, radioactivity, the ability to cause various types of burns, etc.); the green color with a white border corresponds to the safety of the internal content. The width of the rings, the distance between them, the application methods are standardized by GOST 14202-69.

Network marking is possible with the help of stickers.In the event that the sticker contains text, it is made in a clearly distinguishable font, without unnecessary symbols, words, abbreviations, in the maximum accessible syllable. Fonts comply with GOST 10807-78.

Stickers are also made in the form of arrows showing the direction of the flow of the substance inside the pipe. Arrows are also standardized in terms of size

The designation on the arrows is differentiated: “flammable substances”, “explosive and fire hazardous”, “poisonous substances”, “corrosive substances”, “radioactive substances”, “attention - danger!”, “flammable - oxidizer”, “allergic substances ". The color of the arrows, as well as the inscriptions, is applied in black or white, in order to achieve the greatest contrast in relation to the main coating of the pipe. With a particularly dangerous communication component, stickers are made in the form of warning signs (in addition to color rings)

The signs are triangular in shape with a black image on a yellow background.

With a particularly dangerous communication component, stickers are made in the form of warning signs (in addition to color rings). The signs are triangular in shape with a black image on a yellow background.

Important!

In plumbing systems with hot water and in the case of transporting leaded gasoline, the inscriptions must be white.

If the contents of the pipeline can damage the color designation, change its shade, special shields are used as additional markings, which are informative in nature, numerical and alphabetic. The requirements for the graphics of the shields are identical to those of the stickers. Dimensional characteristics of the shields correspond to the characteristics of the arrows.Marking boards should be located in clearly visible places, if necessary, illuminated by artificial lighting without interference for viewing by maintenance personnel.

Battery Performance

The abundance of various heating radiators that have flooded the modern plumbing market literally provokes consumers to replace obsolete morally cast-iron heating equipment.

The criteria for their selection are primarily:

- material,

- operating pressure,

- passport thermal power,

- appearance.

At the same time, the possible difficulties of operating the purchased heating device as part of an unpredictable domestic central heating system are not taken into account at all. Foreign manufacturers of beautiful radiators made of aluminum or steel are not at all safe from water hammer when the pressure in the heating batteries jumps to 20-30 atm. corrosion of internal cavities with water released for half a year, from gas formation in aluminum radiators during the flow of a coolant with copper impurities and sudden changes in temperature. They simply do not have these problems, which cannot be said about the heating systems of our high-rise buildings.

Characteristics of cast iron radiators

- inertia to the poor quality of the coolant;

- working pressure - 9 atm. crimping - 15 atm.;

- withstand coolant temperature of 120 0 С;

- disadvantages - afraid of water hammer.

Characteristics of steel radiators

- working - up to 10 atm.;

- coolant temperature - up to 120 0 С;

- well regulated by a thermal valve;

- disadvantage - corrosion resistant.

Characteristics of aluminum radiators

- working - up to 6 atm. but for reinforced structures - up to 10 atm.;

- well regulated by a thermal valve;

- the disadvantage is the susceptibility to electrochemical corrosion and gas formation, which leads to the formation of air pockets.

Characteristics of bimetallic radiators

- working - up to 20 atm. for reinforced structures - up to 35 atm.;

- good corrosion resistance;

- coolant temperature - over 120 0 С.

It is important! If you are going to purchase new radiators, do not hesitate to contact your housing and communal services organization to find out exactly the values \u200b\u200bof the working and test pressures in your home. Once a year, it is submitted, higher than the working one, to clarify weaknesses in the system. It may be higher than allowed for your new radiator.

It may be higher than allowed for your new radiator.

- Tired of barrel water heaters? Buy a flat boiler!

- A brief overview of some models of water heated towel rails

- Manufacturers of tubular radiators

- A little about aluminum radiators

Properties of polypropylene

To know what pressure polypropylene pipes for heating or water supply can withstand, you need to have information regarding the unusual properties of this material.

Due to the structural features of polypropylene pipelines, they react strongly to sudden changes in the temperature of liquids moving through them. When excessively heated water acts on the pipes, they expand. When the temperature drops, the products return to their original state. Sometimes such a shortcoming becomes a salvation for communications.

In the case when a plastic pipeline is laid underground in outdoor conditions, it cannot be completely protected from frost. For most highways, freezing is a disaster.

But with polypropylene systems, everything is different - if water turns into ice in pipes made of this material, nothing bad happens to them, because they simply expand. After the onset of a thaw, the water thaws, and the structure takes its original position.

When using this pipe product in multi-storey buildings, it is necessary to take into account how many atmospheres a polypropylene pipe can withstand. The fact is that in such houses there is a difference in this parameter on the first and last floor, but it is small. For example, this figure between the first and fifth floors will be only 177 Pa.

Thus, it turns out that on the lowest floor in a high-rise building, the pressure will always be slightly higher than on others. The pressure difference is not big enough to be noticeable. But in skyscrapers they install special pumps designed to stabilize pressure on all floors.

Cink Steel

Such material is much more resistant to corrosion, which significantly extends the standard time. The most significant destructive factor here is only a welded joint, if, for some unknown reason, the installation is carried out by welding. In the photo - water and gas steel pipes.

In fact, this installation method is prohibited: zinc burns out completely during welding, respectively, the seams remain completely defenseless against rust.

Products made of galvanized steel overgrow much more slowly. Firstly, the smoothness of the wall is much higher, and secondly, the actual "garbage" - particles of rust, scale, sand is much less.But if the taps in the water supply system do not open completely, and a sufficiently dense flow of water is not created, scale and sand can accumulate.

The service life of the product according to GOST is as follows:

- risers and connections in cold water supply systems have been in operation for 30 years;

- the service life of steel heating pipes in a house with a closed system is 20 years;

- an open heating system will last 30 years.

It is allowed to construct a gas pipeline from galvanized pipes. But there is still a nuance: unlike plumbing systems, the gas pipeline must be one-piece, which involves welding. And the compound destroys the zinc at the junction. On the other hand, gas pipelines, as well as water pipelines, are coated with polymer paint, which prevents corrosion.

In fact, galvanized steel pipes for both plumbing and heating serve for 50–70 years.

Reading information

- The name of the manufacturer usually comes first.

- Next comes the designation of the type of material from which the product is made: PPH, PPR, PPB.

- On pipe products, the working pressure must be indicated, which is indicated by two letters - PN, - and numbers - 10, 16, 20, 25.

- Several numbers indicate the diameter of the product and the wall thickness in millimeters.

- On domestic modifications, the class of operation in accordance with GOST may be indicated.

- The maximum allowed.

Additionally indicated:

- Regulatory documents in accordance with which pipe products are manufactured, international regulations.

- Quality mark.

- Information about the technology by which the product is made, and the classification according to MRS (Minimum Long-Term Strength).

- 15 digits containing information about the date of production, batch number, etc. (the last 2 are the year of manufacture).

And now let us dwell in more detail on the most important characteristics of polypropylene pipes indicated in the marking.

Factors affecting the working pressure

The value of the coolant pressure in high-rise buildings depends on many circumstances that directly or indirectly contribute to the deviation from the nominal value prescribed by the standards.

These include:

- the degree of deterioration of the boiler room equipment;

- removal of a residential building from the boiler room;

- the location of the apartment, on which floor and how far from the riser it is. In an apartment that is even next to the riser, the pressure in the corner room will be lower, since the extreme point of the heating pipeline is most often located there;

- dimensions of pipes unauthorized by residents. For example, when a pipe with a diameter larger than that of the inlet pipe is installed in an apartment, the total pressure in the system will decrease, and when pipes of a smaller diameter are installed, it will increase;

- the degree of wear of heating batteries.

Regulations and standards

Let us now analyze the rules governing the colors and methods of painting fire pipes, in particular, according to GOST 12.4.026.

According to this GOST, the painting of equipment does not allow red.

But here you, dear reader, should be guided by other normative documentation. We present it below.

GOST R 12.4.026

Do not use a red color tint for fire extinguishing agents that do not require identification (water pipes, sprinklers, detectors, etc.).

SP 5.13130.2009

- Color marking of pipelines and identification paint must be made in accordance with GOST 14202 and R 12.4.026.

- AUP pipes have alphanumeric or digital marking according to their hydraulic scheme.

- Shields indicating the movement of the fire extinguishing agent are always red.

VSN 25-09.67-85

- Painting of sirens, self-destructive locks, outlet nozzles is not allowed.

- Painting of technological pipelines and other fittings at facilities where there are no special aesthetic requirements is carried out in accordance with GOST 14202-69 and 12.4.026-76.

- Where there are special requirements for the design of fittings and nozzles, they are painted in accordance with the requirements. According to GOST 9.032-74, the coverage class of such installations is not lower than VI.

The norm of temperature in the apartment for the health of an adult

Н¾ÃÂüðûÃÂýðàÃÂõüÿõÃÂðÃÂÃÂÃÂð òþ÷ôÃÂÃÂð ò öøûøÃÂõ ÷ðòøÃÂøàþàýõÃÂúþûÃÂúøàÃÂðúÃÂþÃÂþò: þàòÃÂõüõýภóþôð, ÃÂõóøþýð ÿÃÂþöøòðýøÃÂ, ÃÂõÃÂýøÃÂõÃÂúøàþÃÂþñõýýþÃÂÃÂõù öøûÃÂÃÂ. ÃÂõüðûþòðöýÃÂü úÃÂøÃÂõÃÂøõü ÃÂòûÃÂÃÂÃÂÃÂàø ÃÂÃÂñÃÂõúÃÂøòýÃÂõ ÿÃÂõôÿþÃÂÃÂõýøàÃÂõûþòõúð, ýð úþÃÂþÃÂÃÂõ þý ø þÿøÃÂð Ãâµã] ã] ã] ã] · ãâ´ulate àÃÂþ öõ òÃÂõüàÃÂÃÂÃÂðýþòûõýýÃÂõ ÃÂÿõÃÂøðûøÃÂÃÂðüø ýþÃÂüàÿÃÂþòõÃÂõýàòÃÂõüõýõü ø þÃÂýþòðýàýð ÃÂõúþüõýôðÃÂøÃÂàòÃÂðÃÂõù. ÃÂõÃÂþñûÃÂôõýøõ ÃÂÃÂøàÿÃÂðòøû üþöõàÿÃÂøòõÃÂÃÂø ú ÿÃÂþñûõüðü ÃÂþ ÷ôþÃÂþòÃÂõü.

ÃÂÃÂûø ò ÿþüõÃÂõýøø ÃÂûøÃÂúþü öðÃÂúþ, ÃÂõûþòõú ÃÂÃÂòÃÂÃÂòÃÂõàòÃÂûþÃÂÃÂàø ÿþòÃÂÃÂõýýÃÂàÃÂÃÂþüûÃÂõüþÃÂÃÂÃÂ. ÃÂ÷-÷ð ÿþÃÂõÃÂø òûðóø úÃÂþòàÃÂÃÂðýþòøÃÂÃÂàóÃÂÃÂõ, ø ÃÂõÃÂôÃÂõ ÃÂðñþÃÂðõààÿþòÃÂÃÂõýýþù ýðóÃÂÃÂ÷úþù. ã ûÃÂôõù, øüõÃÂÃÂøàÃÂõÃÂôõÃÂýþ-ÃÂþÃÂÃÂôøÃÂÃÂÃÂõ ÷ðñþûõòðýøÃÂ, ÃÂÃÂÃÂôÃÂðõÃÂÃÂàÃÂþÃÂÃÂþÃÂýøõ.

ÃÂõÃÂõþÃÂûðöôõýøõ ò ÃÂòþàþÃÂõÃÂõôàòÃÂ÷ÃÂòðõàÿþÃÂÃÂþÃÂýýÃÂõ ÃÂõÃÂÿøÃÂðÃÂþÃÂýÃÂõ ÷ðñþûõòðýøàø ýðÃÂÃÂÃÂõýø àÃÂõÿûþþñüõýð, ð ÃÂðúöõ þÃÂÃÂøÃÂðÃÂõûÃÂýþ òûøÃÂõàýð ýõÃÂòýÃÂàÃÂøÃÂÃÂõüàÃÂõûþòõúð.

ÃÂûàÿþôôõÃÂöðýøàÃÂþÃÂþÃÂõóþ ÃÂðüþÃÂÃÂòÃÂÃÂòøàúþüýðÃÂàýõ ÃÂûõôÃÂõàÿõÃÂõóÃÂõòðÃÂÃÂàøûø ÿõÃÂõþÃÂûðö ôðÃÂàñþûÃÂÃÂõ ýþÃÂüàÃÂõüÿõÃÂðÃÂÃÂÃÂàò úòðÃÂÃÂøÃÂõ.àâõüÿõÃÂðÃÂÃÂÃÂýþù ýþÃÂüþù ò öøûÃÂàÿþüõÃÂõýøÃÂàôûàÃ] · ã] ã]àôûàÃÂþÃÂÃÂðýõýøàúÃÂõÿúþóþ, ÷ôþÃÂþòþóþ ÃÂýð ø ôûàÿÃÂþÃÂøûðúÃÂøúø ñõÃÂÃÂþýýøÃÂàò ÃÂÿà° ã]

The color of the pipe in the boiler room

Are there any rules for painting pipes in a boiler room station?

Let's talk about how the painting of boiler room pipelines is performed.

As we understood, according to GOST 14202, the designation of the nozzle depends on the substance contained in it, and not on the object of operation.

But in the boiler station, water pipes are almost always marked with three signs - steam, gas or water (red, yellow and green, respectively). They are most often used as a fire extinguishing agent.

That is, the color marking of pipelines in the boiler room is the same as in the GOST table above.

Attention! The color of the sticker always matches the color of the identification paint.

It is equally important to distinguish between return and supply water pipes.

It is equally important to distinguish between return and supply water pipes. But, if you follow GOST 14202, the color of the pipelines in the PT pumping station is the same, regardless of the intake or return of the substance

But, if you follow GOST 14202, the color of the pipelines in the PT pumping station is the same, regardless of the intake or return of the substance.

To distinguish the server from the reverse, use markers indicating the direction of movement and an additional inscription. For example, "FIRE EXTINGUISHER SUPPLY".

The same rule applies to the pumping station, central and individual heating points.

The result is this: we do not care whether hot or cold water flows through the pipes.We always paint the supply and return water pipes with green.

Heating pipelines are also painted in different colors depending on the type of heating component.