- The main criteria for choosing pipes

- Varieties of pipes made of propylene

- Various colors

- Structures of various types

- Varieties of multilayer pipes

- What should be the heating pipes

- Copper

- What are and what are better

- Which PPR pipes are suitable for which systems

- Which are easier to install

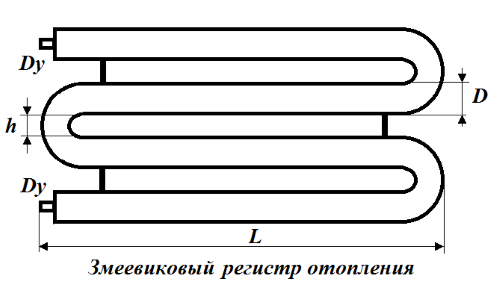

- Types of registers for installation

- Heating systems: their varieties and installation rules

- Advantages and disadvantages of different types of pipes for heating

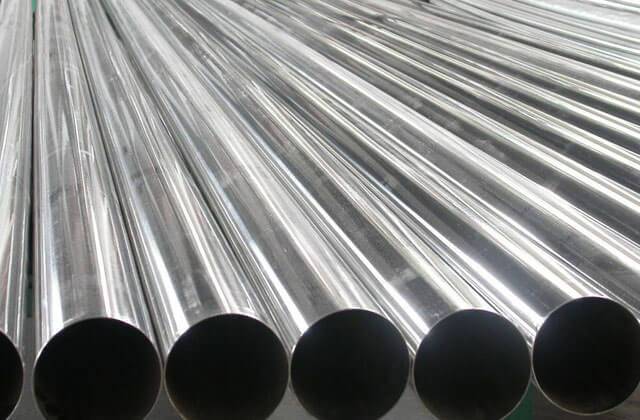

- metal pipes

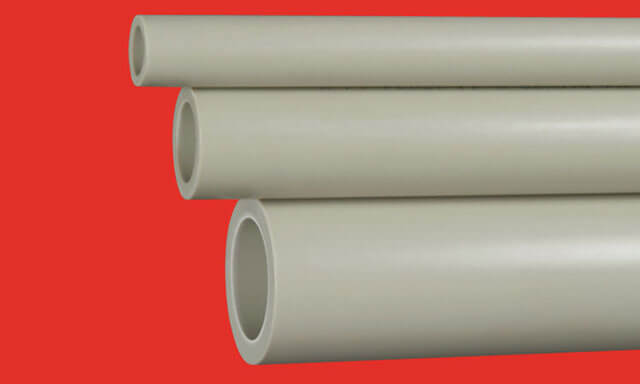

- Polypropylene pipes

- Cross-linked polyethylene (PEX) pipes

- Metal-plastic pipes

- Structural features

- Pipes for heating in the apartment. Keep everything warm! Pipes for heating: which is better and more reliable?

- Pipes or radiators: what to make heating from

- Which pipes are better to use for a heating system

- Steel

- What pipes to put on heating. Central

- No. 2. Scope of metal-plastic pipes

The main criteria for choosing pipes

The thermal capacity of an autonomous heating network depends not only on the brand of the boiler and the length of the radiator batteries, but also on the type of material of the pipeline fittings.

The thermal capacity of an autonomous heating network depends not only on the brand of the boiler and the length of the radiator batteries, but also on the type of material of the pipeline fittings.

Pipes for individual heating should be selected according to the following criteria:

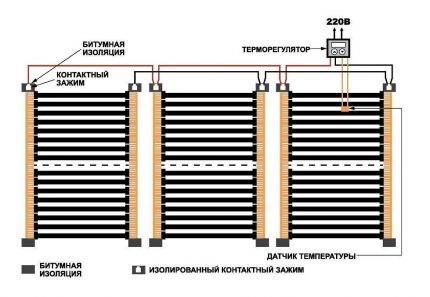

- Accounting for the type of pipeline laying.The installation of the wiring line is carried out in an open and closed (built-in) way, and in case of repair, the damaged area can be replaced without any special difficulties. The closed method is used for the “warm floor” heating system or when, according to the aesthetic requirements of interior design, the pipe wiring needs to be “hidden” in the wall or floor structure.

- Type of heating network. It can be an autonomous heat source or a centralized heating main with forced or natural circulation of the coolant.

- The indicator of the maximum temperature of the coolant. In regions with harsh climatic conditions, the heating circuit is designed for the maximum temperature of the coolant.

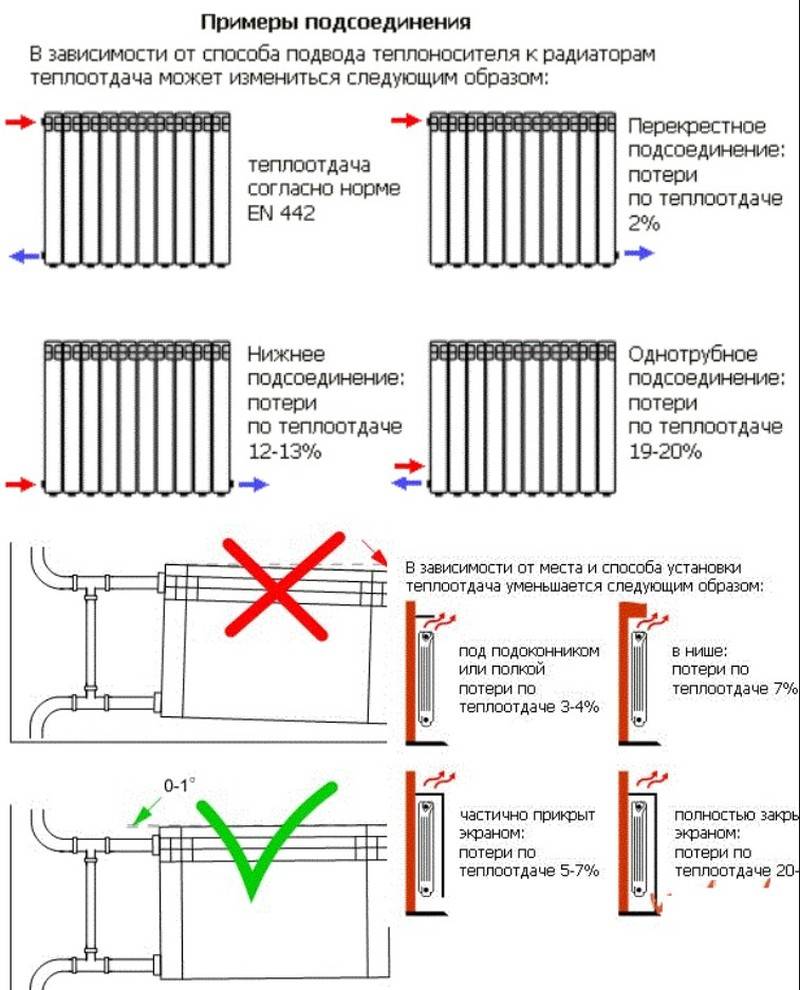

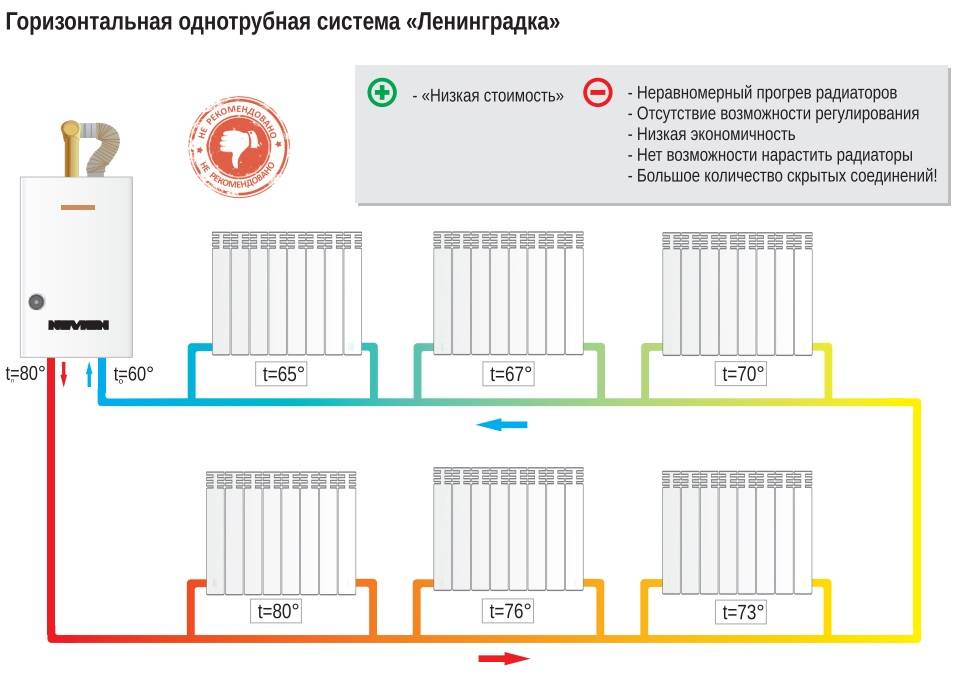

- piping configuration. The thermal system of a house with heating in one line in series from one heater to another is called a single-pipe system. The two-pipe configuration provides for the laying of heating pipes to the radiators of each room or room. The second configuration allows the inhabitants of the apartment to independently turn off the heating devices in each particular room.

According to these basic rules, the type of heating pipe is chosen for each particular private house or apartment.

Varieties of pipes made of propylene

Since products from this type of plastic are produced in a wide range, there are several types of classifications.

Various colors

The range of polypropylene pipes includes products of different colors. The most common mounting elements are white, green, gray and black.

As a rule, the shade of products is chosen arbitrarily and depends on the design of pipes and manufacturers (some enterprises traditionally produce pipes of the same color, for example, green).

When choosing polypropylene pipes, you should pay attention to the color of the products. This criterion is especially important if you plan to install an open system in living rooms or service rooms (bathroom, kitchen). The only exception is radical black plastic products.

As a rule, this color is an indicator of the maximum level of UV protection.

The only exception is radically black plastic products. As a rule, this color is an indicator of the maximum level of UV protection.

Structures of various types

According to the internal structure, all polypropylene pipes can be distinguished into two fundamental categories:

- single-layer, consisting of one layer of plastic;

- multilayer (reinforced) of several shells, which consist not only of plastic, but also of materials that reinforce the structure, creating a strong frame.

Reinforced structures are preferable to a single-layer one, since in this case the temperature elongation of the pipe is significantly reduced.

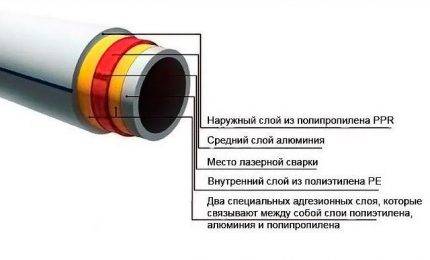

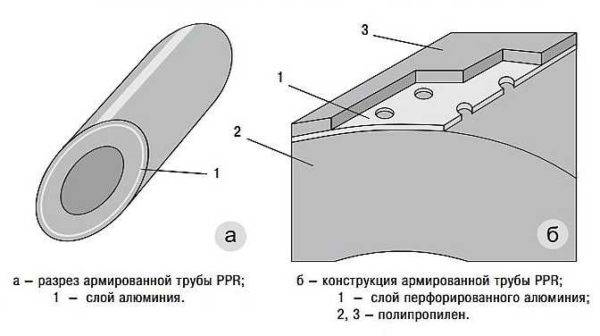

Varieties of multilayer pipes

There are several options for multilayer pipes. The most commonly used reinforcement is aluminum and fiberglass.

Schematic representation of a pipe reinforced with aluminum, with the designation of all layers, including adhesive ones. Similar products are obtained by modern laser welding.

Schematic representation of a pipe reinforced with aluminum, with the designation of all layers, including adhesive ones. Similar products are obtained by modern laser welding.

Pipes reinforced with a continuous sheet of aluminum foil.In the manufacture of such products, a smooth thin sheet of silver metal is applied to the outside of the polypropylene blank.

Before starting installation, such pipes must be cleaned by cutting off the foil at a distance of about 1 mm from the edge. Skipping this process adversely affects the quality of the seam, which will turn out to be loose and unreliable.

Mounting elements, reinforcement with perforated aluminum sheet. One of the layers of such pipes is foil with holes punched in it. As in the previous case, before using such parts, they should be cleaned.

It is important to note that perforated foil products have a high oxygen permeability coefficient, so they should not be combined with heating boilers or similar equipment. Pipes with a core reinforced with aluminum sheet

In this case, the products are reinforced in the middle or even the inner part, so that you can do without stripping before starting work.

Pipes with a core reinforced with aluminum sheet. In this case, the products are reinforced in the middle or even the inner part, so that you can do without stripping before starting work.

Parts reinforced with fiberglass. The core of the pipe is most often made from this durable material, while its inner and outer parts are made of polypropylene.

Pipes reinforced with fiberglass are well-deservedly popular. Such products are characterized by increased strength and rigidity, in addition, they can be used for welding without prior preparation.

Composite reinforcement.For greater strength in pipes, a middle layer is also made of a combined material, which combines polypropylene with fiberglass. Such pipes are also distinguished by high consumer properties and do not require stripping before use.

Despite the fact that the price of reinforced pipes is about 40% higher than single-layer pipes, they should be preferred for heating wiring. Multilayer products are highly reliable and durable, in addition, they have a more aesthetic appearance.

Despite the fact that the price of reinforced pipes is about 40% higher than single-layer pipes, they should be preferred for heating wiring. Multilayer products are highly reliable and durable, in addition, they have a more aesthetic appearance.

A variety of multilayer PP elements are pipes in which an additional layer of plastic is provided. Such products withstand high temperatures well, however, contact between the transported liquid and the reinforced layer is not ruled out.

In addition, coatings in such products are often glued together with glue, which under certain conditions can lead to delamination.

What should be the heating pipes

Of course, not only the efficiency of the entire heating system, but also its durability will depend on the quality of the pipes, since they are operated under conditions of increased load.

The first characteristic that determines the quality of a pipe is its long-term reliability.

In addition, no matter which pipes you choose for heating an apartment, they must be impervious to oxygen. This will avoid oxidation and corrosion of the pipes from the inside, and their premature wear.

The tightness of the connections directly affects not only the heating mode, but also its maintenance. If the pipe is strong enough, then the coolant will not be able to seep through it to the outside and will not spoil the heaters.Working temperature loads and strength of heating pipes depend on the raw materials used for their production.

Copper

In the question of which pipes are better to choose for heating, the answer is unequivocal - copper. This is a material that gives off heat better than others, is completely non-corrosive even in the most adverse conditions, and the service life of a copper pipeline with proper installation is 100 years or more.

Features of copper heat pipe:

- The ability of the line to withstand heating up to +500°C. Of course, the liquid in the system does not reach such a temperature, but the pipes always have a margin of safety for unforeseen situations.

- The strength of the walls is sufficient to withstand hydraulic shocks of various strengths.

- A feature of copper is the absence of reaction with oxygen and many chemicals. For this reason, plaque does not form on the inner walls even after 100 years.

Like steel, copper has excellent heat dissipation, but this is an advantage only when the network is indoors. In unheated areas, it is necessary to isolate the heat pipe with a heater.

The installation of copper pipes requires the participation of specialists: the segments are connected by soldering with capillary fittings and silver-containing solder.

The main disadvantage of a copper heat pipe is the very high cost of the components.

What are and what are better

By structure, polypropylene pipes are of three types:

- Single layer. The walls are completely made of polypropylene.

- Three-layer:

- reinforced with fiberglass - fiberglass threads are soldered between two layers of polypropylene;

- reinforced with foil - the design is similar.

Now briefly about why polypropylene pipes are reinforced. The fact is that this material has a high coefficient of thermal expansion. One meter of a single-layer pipe becomes 150 mm longer when heated by 100°C. This is a lot, although no one will heat them that much, but even at lower temperature deltas, the increase in length is no less impressive. To neutralize this phenomenon, compensation loops are installed, but this approach does not always save.

Types of expansion joints for polypropylene pipes

Manufacturers found another solution - they began to make multilayer pipes. Between two layers of pure propylene, they lay fiberglass or aluminum foil. These materials are not needed for reinforcement or any other purpose, but only to reduce thermal elongation. If there is a layer of fiberglass, the thermal expansion is 4-5 times less, and with a layer of foil - 2 times. Compensation loops are still needed, but they are installed less frequently.

On the left is a fiberglass reinforced pipe, on the right is a conventional single-layer

Why is reinforcement made with both fiberglass and foil? It's about the operating temperature range. Those with fiberglass can withstand temperatures up to 90°C. This is sufficient for domestic hot water, but not always enough for heating. Foil-reinforced polypropylene pipes have a wider temperature range - they withstand heating of the medium up to + 95 ° C. This is already enough for most heating systems (except for those in which solid fuel boilers are installed).

Which PPR pipes are suitable for which systems

Based on the foregoing, it is clear which polypropylene pipes better for heating - reinforced with foil, if high-temperature operation of the system is expected (from 70 ° C and above).For low-temperature heating systems, products reinforced with fiberglass can be used.

Any PPR pipes are suitable for cold water supply, but the most rational solution is ordinary single-layer pipes. They cost quite a bit, and the thermal expansion in this case is not so big, one small compensator for plumbing in an average private the house is enough, but in the apartment, with a small length of the system, they don’t do it at all, or rather they make it “L”-shaped.

An example of a polypropylene plumbing

For laying the DHW system, it is best to take polypropylene pipes with a fiberglass reinforcing layer. Their qualities are optimal here, but can also be used with a foil layer.

Please note that the presence of compensators is required

Which are easier to install

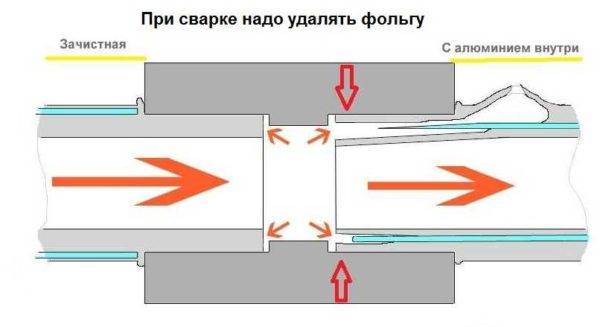

When deciding which polypropylene pipes are better, pay attention to such a parameter as the complexity of installation. All types are connected by welding, and for turns, branches, etc.

fittings are used. The welding process itself is identical for all types, the difference is that in the presence of aluminum foil pre-treatment is required - it is necessary to remove the foil to the soldering depth.

It looks like external reinforcement of a polypropylene pipe with foil

In general, there are two types of aluminum reinforcement - external and internal. With the outer, the foil layer is close to the outer edge (1-2 mm), with the inner, the reinforcing layer is approximately in the middle. It turns out that it is filled with almost the same layer of polypropylene on both sides. In this case, the preparation for welding also consists in removing the outer layer of propylene to the entire depth of welding (and the foil too). Only under these conditions can the required strength of the seam be achieved.All this preparation takes a lot of time, but the most unpleasant thing is that in case of an error we get a very unreliable connection. The most dangerous option is when water seeps into the foil. In this case, polypropylene will sooner or later collapse, the connection will flow.

Foil-reinforced pipes must be welded correctly

Based on these data, it can be concluded that, if conditions permit, it is better to use single-layer or fiberglass-reinforced polypropylene pipes. Adherents of aluminum reinforcement say that the foil further reduces the amount of air that enters the system through the walls. But the foil is often made perforated and it does not necessarily go in a continuous strip, covering the entire diameter of the pipe. Often it has a longitudinal gap. After all, its task is to reduce the amount of thermal expansion, and even strips of more stable material cope with this task.

Types of registers for installation

The most commonly used products are cast iron, steel and aluminum. The most common aluminum Their advantages are as follows:

- resistant to corrosion;

- have a minimum weight;

- long period of use;

- no joints and joints from welding;

- high heat dissipation.

In the manufacture of aluminum registers, monolithic casting is used. Such products are most often installed in residential and office premises. If you need heating in production, it is better to install registers made of steel or cast iron, as they are more durable. Heating systems can be either stationary, in which the coolant is heated by a boiler, or mobile. In such registers, special protection against accidental electric shock is installed.Steel heating registers are not characterized by high heat transfer, but they significantly benefit from budgetary cost, ease of processing and a large selection of sizes.

Stainless steel registers are also used, but they have low heat transfer, so they need a lot of pipes to make them, which is quite expensive. In heating systems, where all wiring is made of copper pipes, registers are installed from a similar material. They have the highest heat dissipation. It is 4 times higher than steel. Copper has a high ductility, so it is easy to bend it in the right places. Welding is required only at the connection points of the different parts. Copper registers have quite serious drawbacks - these are the high cost and the need to comply with the terms of use. In order for copper registers to serve for a long time, the following conditions must be observed:

- there should be no solid particles in the coolant;

- there should not be other metals incompatible with copper in the system;

- grounding is installed in the system to prevent corrosion;

- since the metal is very soft, special protection is needed for the registers.

Cast iron registers are massive and heavy, so you need to install strong racks under them. Cast iron is a very brittle metal and can be damaged by a strong impact. Because of this, cast iron registers need protection in the form of casings, which significantly reduces heat transfer and increases their price. Installing them is quite difficult. Cast iron is a chemically neutral material, and he does not care what coolant is in the radiator.

The most budgetary and reliable material for registers is steel.

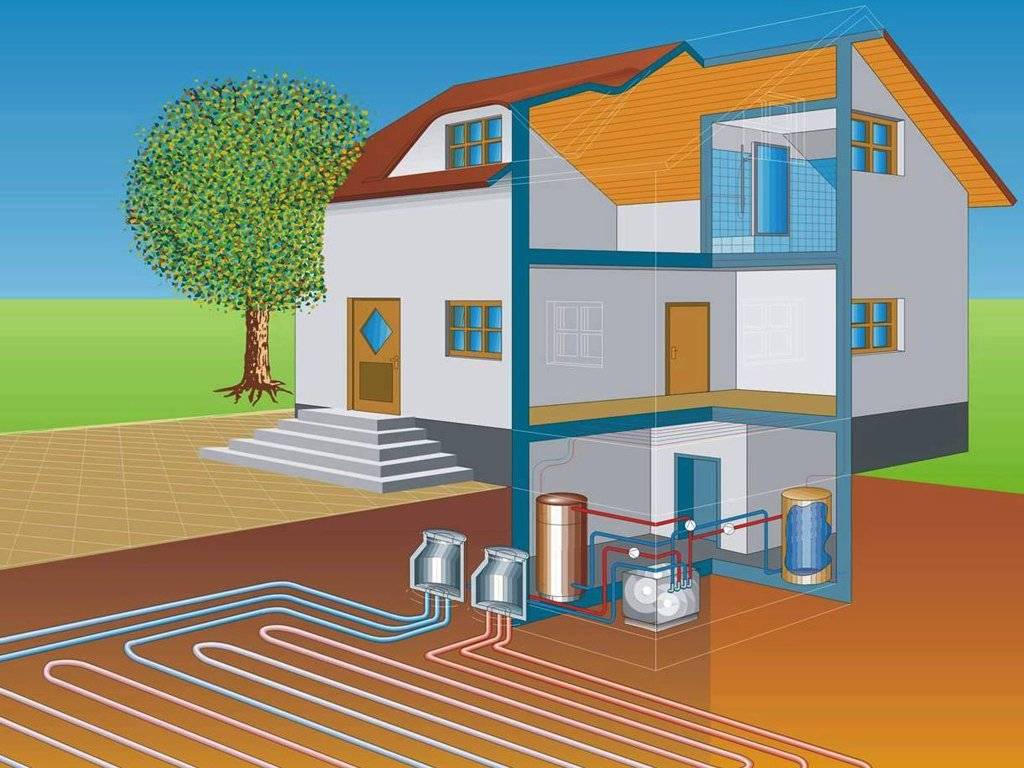

Heating systems: their varieties and installation rules

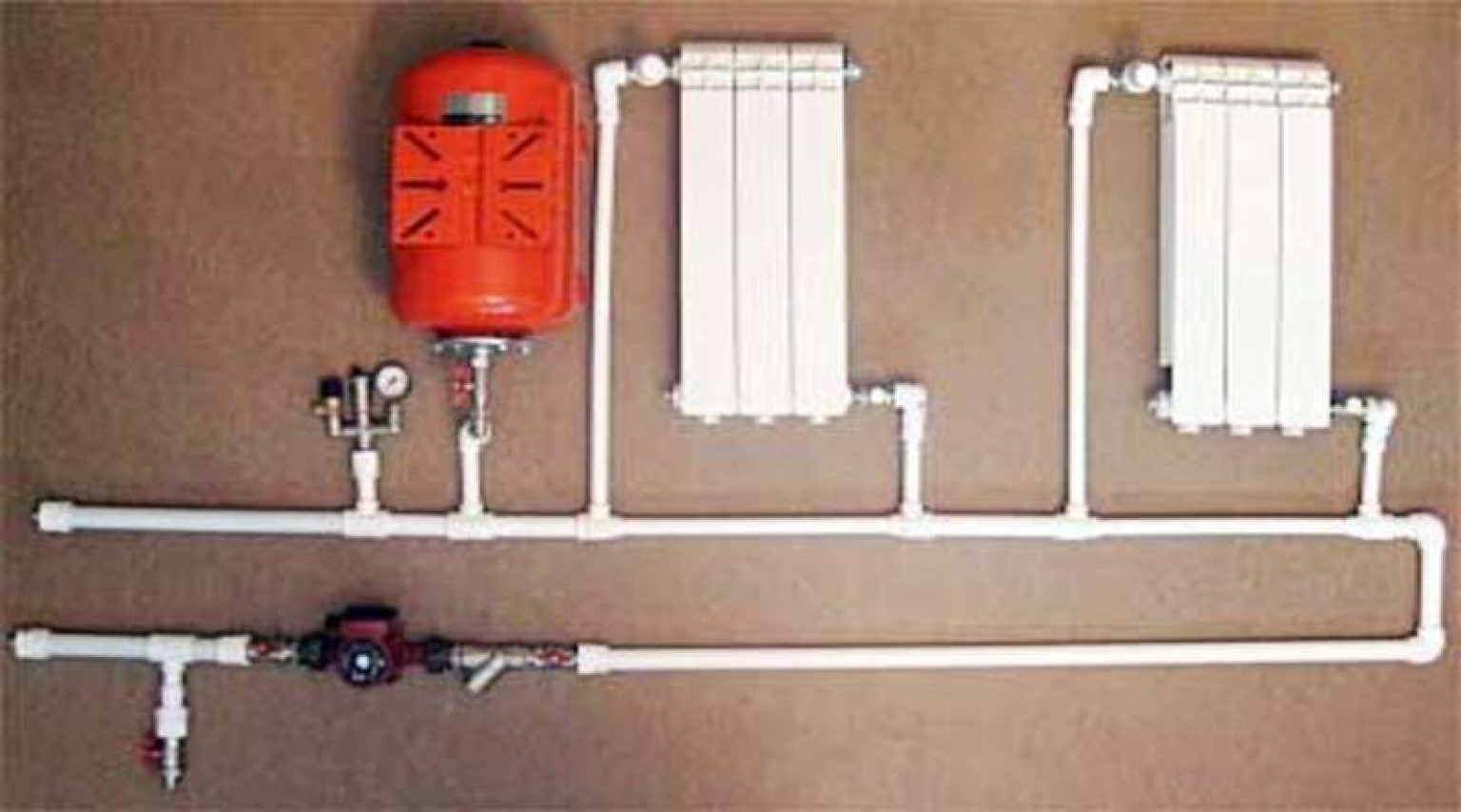

Before starting the installation of the heating system in the house, you should first decide how the coolant (in most cases it is water or non-freezing antifreeze liquid) will circulate through it. Because both the choice of the heating boiler and the choice of pipes directly depend on this step.

At the moment, there are the following types of boilers used for heating private houses:

- gas - one of the most popular, run on natural gas;

- solid fuel - also very popular, can run on various types of solid fuels (coal, firewood, peat);

- liquid fuel (diesel) - less popular than the rest and run on liquid fuel (usually diesel fuel);

- electric - optimal in the absence of gas, because they work on electricity;

- combined - universal and can operate on different types of fuel.

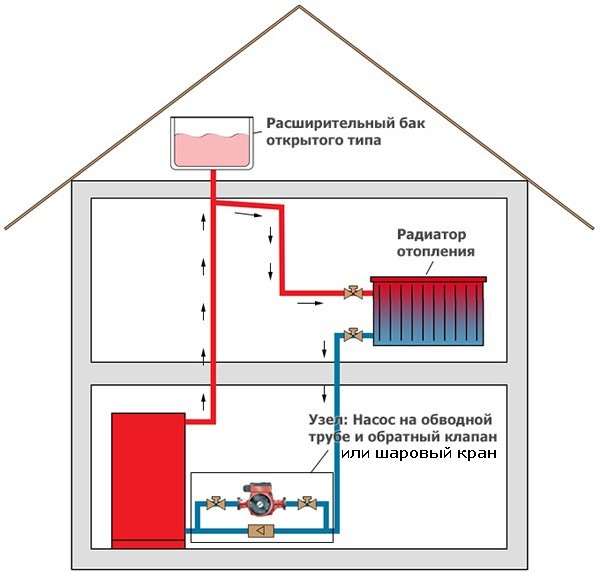

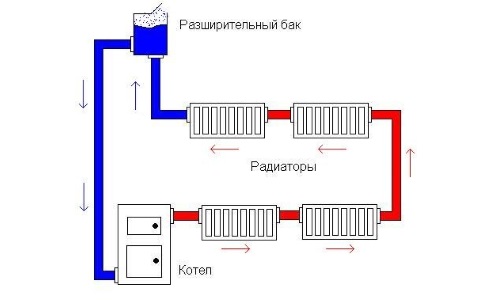

As a rule, the following variant of the division of heating systems is generally accepted:

- with natural circulation, in which the coolant moves due to the temperature difference: hot water rises, and gradually cools down, naturally falls down;

- with forced circulation, in which the movement of the coolant occurs due to the connected circulation pump.

The first option allows the heating system to work only at the expense of a gas boiler, without additional installations. But, at the same time, its installation will require complex calculations, calculations and compliance with the necessary slopes and a strictly defined distance between the pipes.

In this regard, the forced circulation heating system has a number of advantages and is considered more efficient. A pump installed separately or built into the boiler provides the necessary pressure in the system, regardless of the presence or absence of a slope, the length of communications. Yes, and in this case, you can install heating pipes of small diameter, which gives additional opportunities for interior design.

The generated pressure in a heating system with natural circulation is usually 1.5 - 2 bar, and in a system with forced circulation - 2 - 4 bar.

Its main advantages include the absence of high temperatures and pressure, as well as the possibility of using thin metal or flexible corrugated foil pipes. But, despite this, this system also has disadvantages. So, due to the strong noise and overall dimensions of such pipes, mounting and installing them in the wall may not always be possible.

After you have managed to determine the type of heating system to be installed and choose the most suitable option, you should familiarize yourself with some points that are important to consider when installing it.

So, the rules for installing heating systems are as follows:

It is necessary to observe the recommended distance between communications and not install additional objects (stop valves, strainer) between the boiler and the safety group (pressure gauge, relief valve, automatic air vent).

In a network with a forced heating system, a strainer can be installed in front of the pump.

Pipes should be selected based on the type of boiler.

Different types of pipes can be combined, but it is necessary to carefully study their marking and manufacturer's recommendations.

When connecting a large number of radiators, double-circuit wiring should be done and pipes of large diameter should be installed.

It is important to provide for the installation and removal of pipes to remove combustion products, if this is required by the design of the boiler.

Now we will tell in detail about what pipes for heating are, what main characteristics and properties they possess.

Advantages and disadvantages of different types of pipes for heating

Each material for the manufacture of pipes has its own characteristics, which means advantages and disadvantages.

metal pipes

Metal pipes are the oldest version of pipeline elements, and to this day are actively used both for heating private houses and for creating urban communications.

Since iron is highly susceptible to corrosion, galvanized pipes or their corrosion-resistant steel grades should be used.

The widespread use of these products at present is partly due to the observance of traditions in the design of heating circuits, but it also has a rational explanation.

Advantages of using metal (steel, cast iron, copper) heating pipes:

- ease of installation of the pipeline;

- resistance of products to elevated temperatures;

- resistance to mechanical stress of any kind;

- good thermal conductivity;

- the ability to use a minimum of fasteners due to the inherent rigidity of the metal;

- plasticity of pipes, which makes it possible to bend products;

- a wide range of fittings - connecting, corner, etc.;

- resistance to high internal pressure in the heating system;

- the ability to use pipes from different metals;

- durability and reliability of the assembled structure (for steel pipes - up to 50 years, for copper pipes - over 100 years).

Cons of metal products:

- heavy weight, in some cases not giving the opportunity to work alone;

- the need to weld elements, requiring a qualified welder or skills in working with a welding machine;

- installation of a metal pipeline takes more time;

- roughness of the inner surface of the pipes, which means the possibility of sedimentation;

- the threat of corrosion of elements, requiring the avoidance of hidden pipe laying;

- the need to periodically paint products to avoid external damage;

- large heat losses in cold rooms.

Polypropylene pipes

Advantages of pipelines made of polypropylene pipes:

- smooth inner surface, virtually eliminating the possibility of blockages;

- light weight, allowing installation without any extra effort, including alone, and in addition, safe for houses built on shifting soils;

- no threat of corrosion, so such pipes can be laid in the walls in a closed way;

- there is no need for coloring products;

- while maintaining the desired temperature level, the pipeline will last at least 20 years;

- the design is easy to wash and clean;

- low cost of production - for the same money it is possible to equip a pipeline of much greater length than from metal.

Disadvantages of such pipes:

- you need a special welding machine to connect structural elements;

- pipes cannot be bent; fittings must be used;

- maximum temperature threshold - 70°C (short-term - up to 90°C);

- instability to mechanical influences;

- sagging in extended sections (during installation, use more fasteners).

Cross-linked polyethylene (PEX) pipes

The advantages of such products:

- high operating temperature threshold for plastic - up to 90 ° C;

- increased density of the material of manufacture, providing good mechanical stability and protection against leaks;

- pipes made of this material can be bent when heated and bent back in the same way (memory effect);

- smoothness of the inner surface, preventing the formation of blockages;

- small expansion coefficient that does not require the installation of compensators;

- light weight, which makes it possible to freely assemble the pipeline;

- ease of installation (press fittings are used);

- durability of products - the service life of such a pipeline is at least 50 years.

There are no drawbacks to such pipes; they can be used both for installing the pipeline as a whole, and in combination with other materials.

Metal-plastic pipes

Such pipes combine the best properties of metal and polymer products: a smooth inner surface, metal reinforcement that provides strength, and an outer layer that does not require painting.

Product disadvantages:

- high cost of associated fittings;

- freezing deformation - such pipes must be used in houses for permanent residence, otherwise the unused pipeline will become unusable during the winter.

The choice of pipes for the installation of heating systems is practically unlimited, and the quality of the assembled circuit depends primarily on the correct decision of the designer and the conscientious implementation of all stages of the system assembly.

Structural features

Most often, radiators are made of smooth steel pipes. Welding of smooth pipes is registered and serpentine. Registered pipes can have 2 types of pipe connections - this is a column and a thread. Column - the connection of each pipe to each other on both sides with the help of jumpers. When connecting the "thread" jumpers are installed alternately, then on one side, then on the other. This ensures a serial connection, and the coolant flows around all the pipes in turn.

The heater radiator can be welded not only from round, but also from square pipes. They are not much different, but they are more difficult to work with and have higher hydraulic resistance. Although such radiators are much more compact.

The area of contact between the metal and air in this case is much larger, which increases heat transfer. Such heating registers do not look very presentable, but they heat the room well, despite the temperature outside the window.

Pipes for heating in the apartment. Keep everything warm! Pipes for heating: which is better and more reliable?

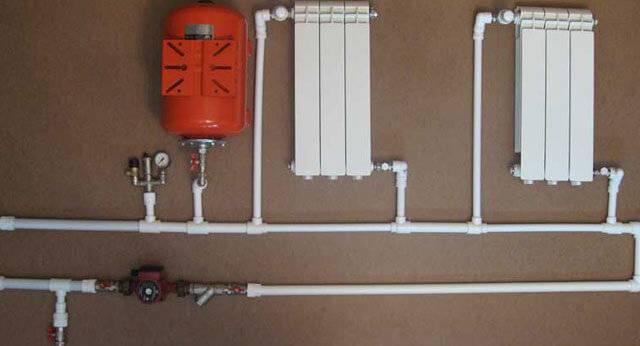

In the heating system, pipes perform the task of transporting the coolant from the distribution unit or boiler to heating devices (radiators).

For the efficient operation of the heating system, it is necessary to select the right pipes, based on their installation features, material, and cost of products.

Pipes or radiators: what to make heating from

Some pipes for space heating (without heatsinks) is not enough for the following reasons:

- radiators provide heating in places where cold air enters (under window openings);

- radiators look aesthetically pleasing, organically fitting into the design of the room;

- pipes are not capable of heating by thermal convection;

- the cost of installation (welding) of heating systems from pipes is comparable to or exceeds the price of a system of panel or cast-iron radiators similar in terms of thermal power.

In residential and public buildings, it is better to install radiators that perform the function of heating the room, and pipes perform a transport function - they bring the coolant to the radiator and take it back to the system.

A register heating system without radiators is used in industrial premises of large areas, where superheated steam is used as a heat carrier.

Which pipes are better to use for a heating system

When choosing pipes for a heating system, the following parameters must be considered:

- Correspondence of the material to the temperature and pressure of the coolant.

- Ease of laying and installation.

- Cost of material and labor.

- Appearance (aesthetics).

- Life time.

Heating pipes are distinguished by the materials from which it is made. Materials are divided into two large groups: metal and plastic (polymer).

Metal:

- of steel;

- from galvanized steel;

- stainless steel;

- from copper.

Plastic:

- from polypropylene;

- from cross-linked polyethylene;

- from metal-plastic.

Steel

The material of the pipe is black steel. They are measured segments of solid-rolled or electric-welded tubular products. For heating, pipes with a wall thickness of 2.8 -3.2 mm are used.

Photo 1.Heating steel pipe connected to a radiator. The product is made of black steel.

Pros:

- Mechanical strength, resistance to temperatures and pressures, which significantly exceed the parameters of most domestic central and individual heating systems.

- The thermal expansion of steel pipes is minimal compared to polymer pipes and is 6 mm per 10 meters of length (when heated from 20°C to 90°C).

- Corrosion resistance. In closed heating circuits, there is practically no oxygen, which causes oxidation and destruction of the metal.

- Low cost compared to other materials.

Minuses:

- It is difficult to hide a steel pipe in a plaster gate, so they are laid openly in plastered rooms. Needs some decorative painting.

- The complexity of installing a steel system. Welding (electric or gas) is required, labor-intensive plumbing operations for threading, assembling joints are required. The installation process is messy and is done before the finishing work.

- When buying a pipe, you need to check it for compliance with GOST requirements, due to the high risk of acquiring a low-quality stale pipe or Chinese counterfeit. Poor quality material may have a discrepancy in steel composition or wall thickness, which affects durability.

- In central heating systems, they can become clogged with deposits that narrow the useful clearance, reducing the flow and heat transfer of the coolant.

What pipes to put on heating. Central

The normal mode of central heating systems is as follows:

Central heating differs from autonomous circuits in that deviations from normal modes are possible in it.It's simple: the more complex any system, the more likely it is that something will go wrong during its operation.

Here are some of the most realistic scenarios I've personally encountered:

- When the circulation in a large circuit stops abruptly or, conversely, when a discharged heating system is filled with a small amount of air, a water hammer occurs in it: at the front of the water flow, the pressure briefly rises to values 4-5 times higher than the nominal ones;

- Incorrect switching of shut-off valves on the route or in the elevator unit can lead to the fact that when testing the heating main for density, the pressure in the circuit rises to 10-12 kgf / cm2;

- In some cases, the operation of a water-jet elevator with a removed nozzle and a muffled suction is practiced. Usually this configuration is going to be in extreme cold with a lot of heat complaints and is a temporary alternative to increasing the diameter of the nozzle. From a practical point of view, this means that water is supplied to the radiators directly from the supply line of the heating main.

.

Within the current temperature schedules supply temperature at the lower peak of winter temperatures should reach 150C. In practice, the coolant cools somewhat on the way from the CHP to the consumer, but still remains heated noticeably above the boiling point. Water does not evaporate just because it is under pressure.

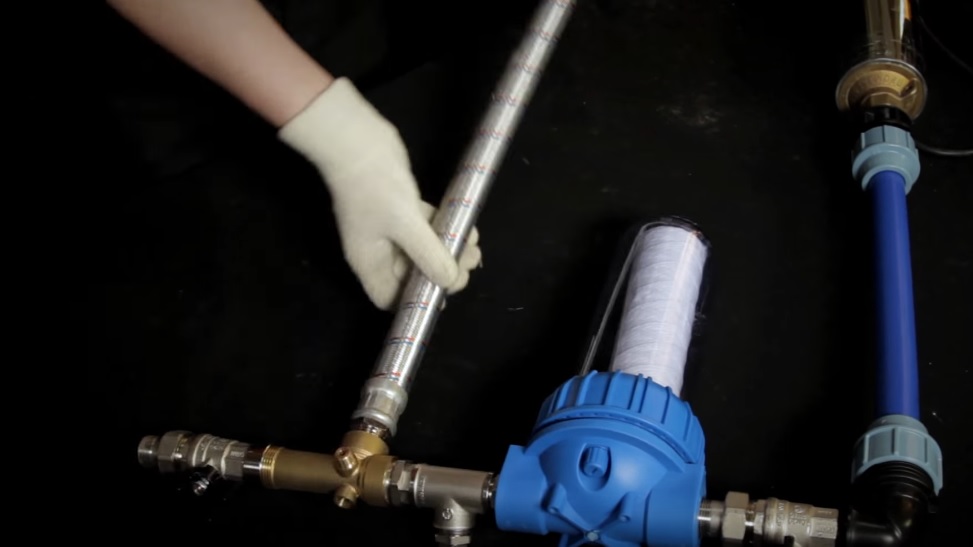

No. 2. Scope of metal-plastic pipes

The properties of metal-plastic pipes make it possible to use them almost everywhere in civil and industrial construction. Without fear, they can be used in such areas:

- cold and hot water supply in apartments and private houses;

- heating systems;

- sewerage systems;

- arrangement of irrigation systems;

- water intake systems from wells and wells;

- compressed air supply;

- transportation of certain chemically aggressive liquids

Since the installation is carried out without welding, such pipes are installed in places where it is forbidden to carry out welding work.

Do not use such pipes in rooms where nearby objects are located that can heat up to a temperature of 150C and above, as well as in rooms with a high level of fire danger.