- Requirements for heating pipelines

- Steel

- How not to make a mistake

- Comparative price overview

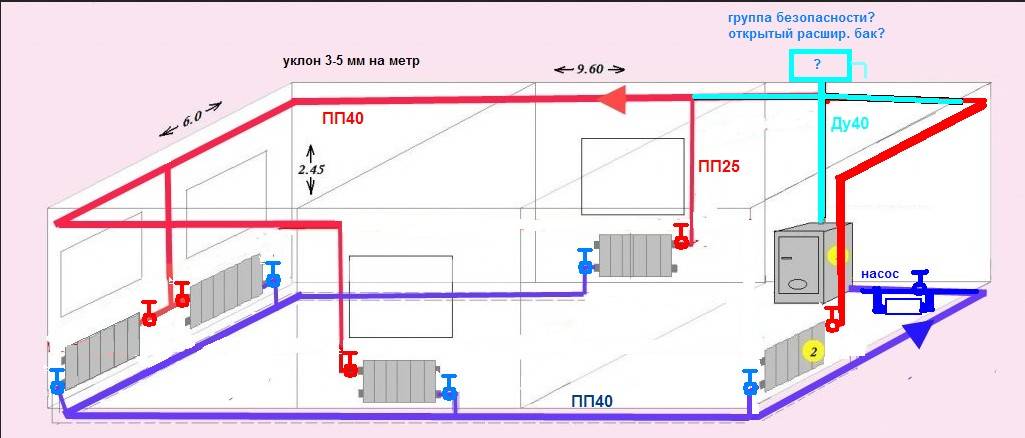

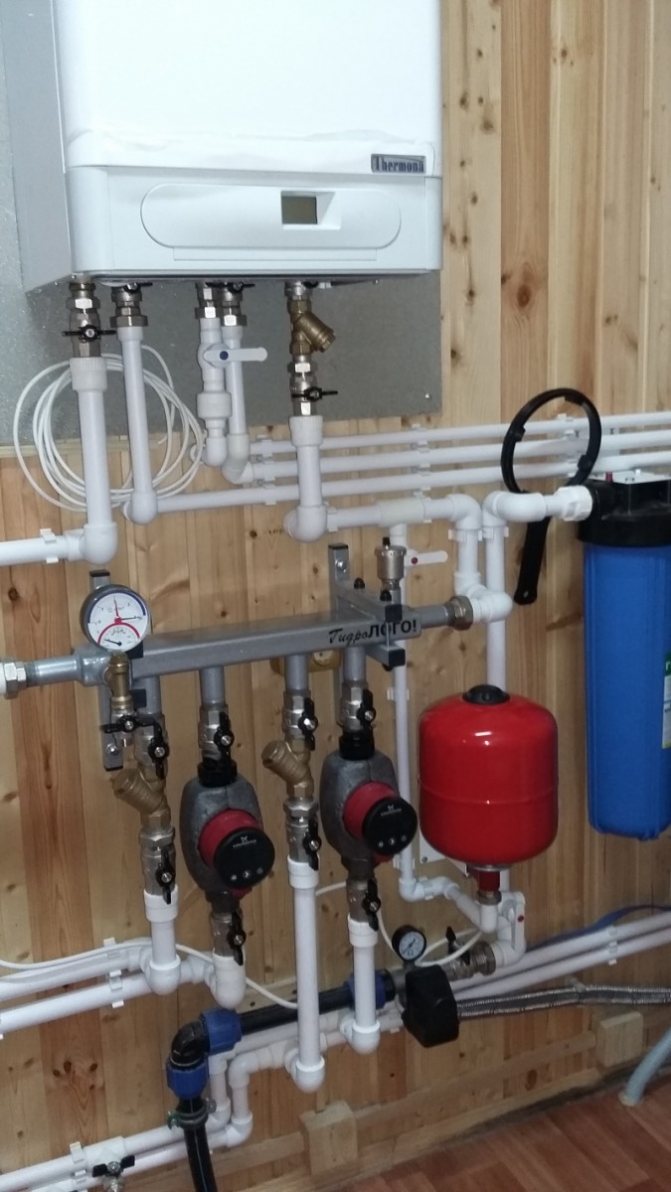

- No. 2. What to consider when choosing heating pipes?

- The main criteria for choosing pipes

- What types of pipes are best. What to take anyway?

- No. 6. Copper pipes for heating

- The best pipes for a heating system

- FV Plast Phaser 20

- Dizayn Sirena PN-20

- Kalde Orange (3202-tfr-500000)

- Valtec PP-Fiber PN 20 Vtp.700.FB20.20

- Metal-plastic pipes - technical characteristics:

- Applications - coverage through technical features:

- Option #1 - Ferrous Metal Parts

- On a note:

- Choice of diameter and installation features

- plastic pipes

Requirements for heating pipelines

According to the norms of SNiP, the equipment used for the installation of heat supply systems must meet certain requirements:

- withstand a working pressure of 0.7-1.5 atm during the entire period of operation;

- maintain integrity during short-term water hammer at a pressure 1.5 times higher than the nominal (working);

- remain sealed at a coolant temperature of 90°C;

- have sufficient chemical resistance and UV resistance;

- be easy to install and maintain;

- have a service life of 25 years; and for pipelines laid in hidden structures (walls, concrete floors) - at least 40 years;

- the material used for their manufacture must not contain impurities harmful to human health;

- to protect against rapid clogging of the system, the inner surface of the pipelines must have an ideal smooth surface, for example, for steel products, the equivalent roughness can be 0.2 mm;

- the diameter of the pipeline must be sufficient to provide heat to each of the heated rooms.

Additional requirements are imposed on the pipelines used for the installation of underfloor heating systems. Such products should be enough flexible and elastic, easy to fit into loops without the formation of creases and keep the desired shape well.

Pipelines of heating systems must meet a number of requirements

Steel

Which is better, steel pipes for heating a private house or plastic? The advantages of metal products include high thermal conductivity and the ability to easily give off heat to the environment. Another indisputable advantage of metal pipes is increased strength, reliability, the ability to withstand even significant water hammer, mechanical stress and temperature changes.

When heated, the thermal expansion of the metal is negligible, so the likelihood of leakage at the junction of the pipes is minimal. In the event of their freezing, processing with a blowtorch or other source of open flame is allowed.

But there are many disadvantages of steel products. The first is susceptibility to corrosion. Even galvanized pipes will last no more than 25 years. In the first years of operation, there are no complaints about them. However, in the process of metal oxidation and the appearance of rust growths, the pipes begin to become clogged. As a result, their throughput is sharply reduced.A similar problem is a real scourge of steel products.

The service life of black steel products is short

The service life of black steel products is short

They are also quite complicated in installation - it is possible to bend metal only on special equipment when heated. Another disadvantage is high thermal conductivity. For this reason, it is not recommended to install metal pipes when installing an electric boiler.

Steel pipes stand slightly higher than similar plastic products. However, when choosing them, the cost and installation work should be taken into account. After all, metal welding requires considerable skills and expensive equipment.

An ideal option for installing heating and heating systems would be stainless steel pipes that can last almost forever. However, their use is limited due to the high price and complexity of installation.

How not to make a mistake

- Remember what the logo looks like, what font is used, what letters it has, what color they are written in, how many capital letters. In general, you need to study the logo and its spelling. Those who make fakes deliberately make some kind of mistake in the name, change / omit / double some letter. This is done so that it is impossible to make claims - the letter is different, another brand.

-

Next, you need to study the range, choose what you want to purchase. Then carefully study the color, the location of the markings. If the store offers you a product of the desired campaign of a different color, size, etc., but this is not on the official website, you are being sold a fake. Better to leave and look for another store.

- Please review product samples before purchasing. Pipes, fittings of normal firms have even walls (both external and internal). There should not be any sagging, depressions or other signs of poor-quality casting.

- Look at the cut of the pipe or fitting. The wall thickness must be the same. If these are reinforced products, then the reinforcing material is surrounded by polypropylene rings of the same thickness. If the difference is noticeable even "by eye", you should not take such products.

In general, you should have a positive impression of the quality of the products. Only if all the "tests" are passed, you can buy.

Comparative price overview

In construction, plumbing stores you can buy heating pipes that are made from different materials:

- Copper. The average price for 1 meter (diameter 20 mm) is 250 rubles. Permissible temperatures of the working fluid - up to 500 degrees Celsius. They transmit stray currents, which is a disadvantage.

- Polypropylene. The average price for 1 meter is 50 rubles. Suitable for liquid temperatures up to 95 degrees. They don't oxidize. Cannot withstand strong water hammer.

- Metal-plastic. The average price for 1 meter is 40 rubles. The temperature maximum is up to 150 degrees. The term of active operation is 15 years.

Prices vary depending on the diameter, wall thickness, fame of the manufacturer.

Copper pipes for heating

No. 2. What to consider when choosing heating pipes?

There are no universal pipes that would function equally well in different rooms. To select the best pipes for heating, i.e.

the most optimal and suitable in specific conditions, it is necessary to take into account the following factors:

- temperature and pressure in the system, which largely depend on what kind of heating is used, individual or centralized. In individual systems, the pressure rarely exceeds 2-3 atmospheres, and in centralized systems it can rise to 16 atmospheres;

- type of pipe laying, outdoor or hidden;

- total area of heated housing;

- design capacity of the boiler and type of fuel (for private houses);

- pipeline operating conditions. This refers to the presence of unheated premises in certain areas;

- the possibility of repair.

All characteristics of pipes depend on the material of their manufacture - this is the most important parameter that must be considered when choosing.

The main criteria for choosing pipes

In order to reasonably and correctly select pipes for a home heating system, the following items are taken into account:

- type of installation of the pipeline complex - surface or hidden (internal);

- estimated pressure power - an assessment of the range from basic to the maximum possible indicators;

- type of heating system - autonomous or central communications with gravity or forced circulation of the heating composition;

- the maximum temperature for which the coolant is designed;

- configuration features of heating equipment - one-pipe or two-pipe complex.

Only knowing all these factors, they begin to choose the type of material that will most effectively manifest itself in the specific specified conditions.

What types of pipes are best. What to take anyway?

They have almost the same performance, but stainless, while a little cheaper.

If funds permit, it is best to consider one of these options.

Among plastic pipes, metal-plastic and reinforced polypropylene ones have a clear leadership.

Metal-plastic pipes are flexible and great for heating

But polypropylene pipes are an opportunity to save money and not lose quality, but you have to install the system with care

In special circumstances, other materials will be more suitable:

- For work in extreme conditions (strength tests, pressure surges, temperature changes) - choose steel, galvanized pipes or stainless pipes (which means will allow).

- The cheapest pipes are polypropylene.

- The easiest way to mount it yourself is plastic pipes on compression fittings.

- And for warm floors, they are suitable (in order of increasing price) - polyethylene, metal-plastic and corrugated stainless steel.

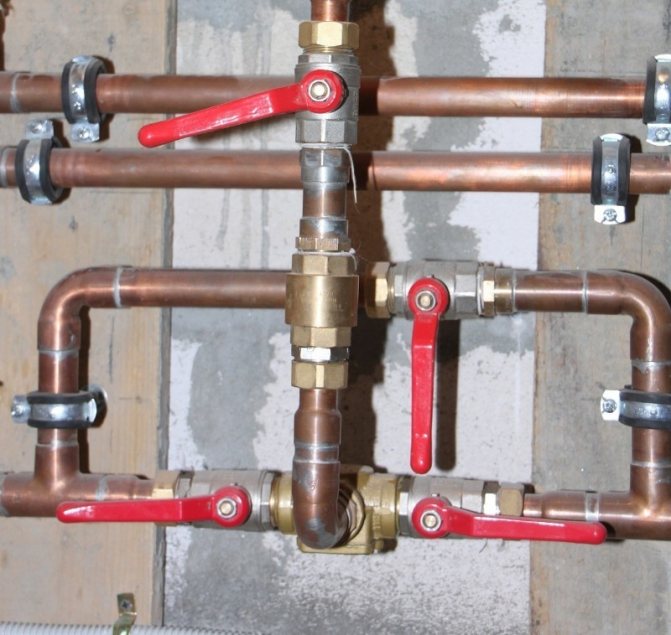

No. 6. Copper pipes for heating

Let's continue the study of metal heating pipes. Copper pipes began to be used as early as the 17th century and are still actively used, despite the appearance of cheaper options.

Advantages:

- durability compared to the life of buildings. Copper pipes and fittings do not lose their qualities for 100 years or more;

- resistance to corrosion, high tightness, lack of ability to pass air and accumulate deposits on the inner surface, therefore, over the years, the throughput of pipes does not decrease;

- high thermal conductivity;

- resistance to temperature extremes (operating temperature range from -200 to +500С) and pressure surges in the system;

- aesthetic appearance.

The main disadvantage is the high price. Not only is the material itself expensive, but also the main manufacturers are concentrated outside the country.

If we take into account the durability of the material and the absence of problems in the next 100 years, then the cost does not look like such a significant drawback. If the issue of choosing heating pipes does not rest on the budget, then copper pipes will be the best option.

The installation process is specific, so it is better to seek help from professionals.

In order for the heating system to serve for many years, it is better not to combine copper pipes with unalloyed steel pipes. The latter will rust very quickly. If such a combination cannot be avoided, then let the steel pipes be in front of the copper pipes in the direction of water movement.

The best pipes for a heating system

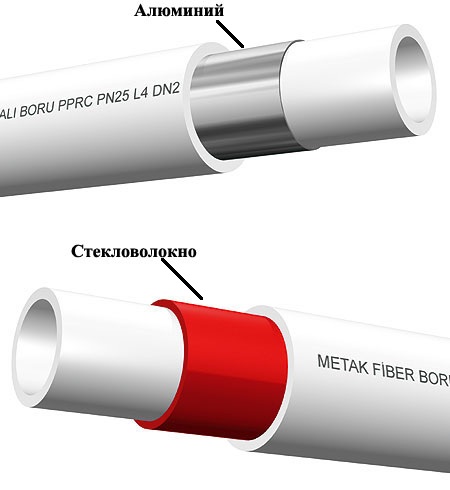

The heating system should not change its performance under the influence of high temperatures and pressure, and have a low thermal linear expansion. It must be taken into account that the coolant can be not only chemically neutral water, but also antifreeze. Pipelines must be chemical resistant. All these requirements are met by reinforced polypropylene pipes for heating, reinforced with aluminum foil or composite fiberglass.

The experts analyzed the products of 11 domestic and foreign brands. According to the test results, 4 best brands were selected, the products of which comply with the current SNiPs. They are able to ensure trouble-free operation of the heating system.

FV Plast Phaser 20

Universal pipes of the Czech company Faser for water and heat supply with an outer diameter of 20 mm. It is recommended for transportation of the heat carrier heated up to the temperature of 95ºС. The walls with a thickness of 3.4 mm are reinforced with fiberglass.

The monolithic construction turns polypropylene into a composite material and allows it to withstand pressures of 20PN. The inner surface is PP-R polypropylene, which provides high hygiene and low resistance to heat carrier flow. Supplied in 4 m long whips, making transport easy and convenient.

Advantages:

- High bending stiffness;

- Low linear expansion under thermal exposure;

- Does not need stripping when welding during installation;

- Resistance to aggressive substances;

- Low roughness of internal walls.

Flaws:

Lack of products in specialized stores.

The minimum linear expansion allows to reduce the distance between the supports. This simplifies installation and reduces costs.

Dizayn Sirena PN-20

A company from Turkey produces polypropylene pipes for heating a private house from raw materials of European and Russian production. PP-R 100 is used, which is safe for human health.

During installation, socket welding with a soldering iron is used. The recommended heat carrier temperature is 95ºС. High strength characteristics allow to withstand a pressure of 20PN.

It is supplied in 4 m long whips. It is produced at the Russian plant in Alabuga, the quality of the products complies with the current SNiPs.

Advantages:

- Service life exceeds 50 years;

- Low price;

- Easy installation;

- Low flow resistance;

- Wide range of fittings.

Flaws:

Lack of reinforcement.

Kalde Orange (3202-tfr-500000)

Kalde has been producing polypropylene pipes and components at its factories in Turkey since 2002 and is the leading exporter of these products in its country, supplying them to European markets.

The Orange line is made from European-made polypropylene. Fiberglass is used for reinforcement, which increases strength and reduces linear expansion. It is recommended for heating systems of cottages with a maximum heat carrier temperature of 75ºС.

Advantages:

- Wall thickness 8.3 mm;

- Stable section geometry;

- Easy installation;

- Wear resistance.

Flaws:

The maximum pressure in the system is 10PN.

Valtec PP-Fiber PN 20 Vtp.700.FB20.20

Valtec produces a full range of sanitary equipment for heating systems, offers the best technical support to customers. The PP-Fiber PN 20 series is distinguished by effective glass fiber reinforcement, a wall thickness of 2.8 mm and the ability to transport a coolant heated to +90ºС. The maximum allowed pressure in the system, when using pipes of this series, should not exceed 20PN.

Advantages:

- Low linear expansion at high temperatures;

- Easy installation;

- Good elasticity;

- Guaranteed for taps up to 10 years.

Flaws:

Overcharge.

Metal-plastic pipes - technical characteristics:

- outer diameter 16-63 mm;

- wall thickness 2-3 mm;

- aluminum layer thickness 0.19-0.3 mm;

- the weight depends on the diameter, for example, one meter of a metal-plastic pipe with a diameter of 16 mm weighs 105 grams, and if the diameter is 63 mm, then the weight of one meter is 1224 grams;

Metal-plastic pipes withstand pressure:

- operating pressure 10 bar (at 95 °C);

- operating pressure 25 bar (at 25 °C);

- bursting pressure 80 - 94 bar (at 20 °C);

Metal-plastic pipes withstand temperatures:

- constant load +95°С;

- short-term load — up to +110°С;

- at a temperature of -40 ° C freeze;

- with manual bending, the minimum bending radius is 80-125 mm (depending on the outer diameter);

- when bending with a pipe bender - 45-95 mm (depending on the diameter);

- coefficient of linear expansion 1/°C - 0.26 x 10-4;

- thermal conductivity of metal-plastic pipes (the amount of heat that the material is able to pass through a square meter per second) W / m * K - 0.43;

- oxygen diffusion 0 g/m3 (does not let air through);

- service life: a) 25 years at 95°C; b) 50 years at 20°C;

- throughput is 1.3 times higher than that of steel.

The advantages of pipes made of metal-plastic

For anyone who decides to purchase this material, operational characteristics are much more important than technical ones. First the positives:

- ecological cleanliness;

- resistance to the formation of rust, stones or other deposits;

- the ability to maintain a newly acquired shape after bending;

- the possibility of profiling to wrap around the structural elements of the building;

- easy and quick assembly that does not require many tools;

- minimum waste;

- flexibility allows you to save on connection elements;

- low resistance to fluid flow due to the absence of roughness;

- compatibility with other materials;

- light weight for easy transportation;

- high levels of sound insulation;

- antistatic;

- resistance to condensate and freezing (metal-plastic withstands triple freezing);

- do not change the quality of the transported liquid;

- high maintainability;

- aesthetic appearance without painting.

All the advantages of metal-plastic pipes are obtained due to the unique design. The inner polyethylene layer makes it possible to bend the product. Aluminum provides rigidity and prevents oxygen diffusion. The absence of oxygen prevents rust from forming in boilers and radiators.

Flaws

When choosing and buying metal-plastic pipes, negative characteristics are just as important to consider as positive ones:

- with a hidden pipeline, threaded fittings cannot be used;

- metal-plastic does not tolerate ultraviolet rays;

- when freezing with water, the system will certainly burst, although they are suitable for installing an external pipeline. In this case, high-quality insulation is necessary.

Metal-plastic pipes are supplied in bays. The length of the pipe in the bay varies from 50 to 200 meters. You can buy any length, starting from a meter.

Applications - coverage through technical features:

- internal systems of cold and hot water supply, heating of apartments, houses and cottages;

- floor heating systems, sports grounds, swimming pools;

- transportation of gaseous and liquid substances (including caustic and poisonous) in industry, agriculture and transport;

- compressed air supply;

- air conditioning systems;

- protection of electrical wires and cables;

- construction and repair of river and sea vessels, railway cars;

- systems of watering, irrigation, collection of water from wells and wells.

A sufficiently long service life and an optimal ratio of cost and quality have allowed metal-plastic pipes to establish themselves as a successful alternative to metal and plastic products. After all, metal-plastic combined the positive qualities of both of these materials.

Increasingly, when creating plumbing and heating systems in residential buildings, metal-plastic pipes are used.

However, in order to make the right choice, it is important to know not only the features of the structure and operation of pipes consisting of a composite material, but also the pros and cons of these products.

Option #1 - Ferrous Metal Parts

Not so long ago, steel pipes were practically the only choice for the vast majority of heating systems. Today they continue to be used.Steel performs particularly well in self-contained gravity systems where large diameter pipes are needed. The advantages of such pipes include:

- high thermal conductivity;

- small linear expansion;

- resistance to high pressure;

- strength;

- ability to withstand high temperatures;

- affordable cost.

Among the shortcomings, it is worth paying attention to the complex installation, which is impossible without the use of special equipment. Only a person with the necessary training may work with it.

Pipe dimensions also complicate the installation process. It is best done before finishing work, as welding can very easily damage floor and wall coverings. Another “minus” is that the metal is susceptible to corrosion, which is why it is strongly not recommended to use it for laying hidden pipelines.

Steel pipes are the ideal solution for self-contained gravity systems where large diameter pipes need to be used.

On a note:

- The PN marking indicates the allowable working pressure (bar) at a maximum temperature of 20°C and a service life of 50 years at a minimum design factor.

- Polypropylene pipes can be used for underfloor heating, but polypropylene is not used for laying underfloor heating on the Belarusian market, as there are solutions that are no less reliable, but more convenient to install (cross-linked polyethylene pipes, metal-plastic pipes).

- It is possible to use PN20 and EVO pipes for central heating, but it must be taken into account that in this case it will be necessary to compensate for the linear expansion of the pipe at high temperatures and pressure.There is a more convenient solution for installation - use other types of PP pipes - reinforced, which will be discussed below.

Multilayer / reinforced pipes (combined) - pipes made of several layers of different materials, one of which acts to stabilize (strengthen) the pipe and protect it from oxygen penetration.

Such pipes provide reliability and durability to plumbing structures and withstand temperatures up to +95°C. Most often they are used for hot water supply and heating. The secret is that reinforced pipes provide a 100% oxygen barrier, and the linear expansion of such pipes is several times lower than that of all-plastic pipes made of polypropylene. Reinforced pipes are slightly more expensive than single-layer pipes, but for those who want to save money, the difference in price can be the price of comfort both during installation and operation of the pipeline.

There are three types of reinforced polypropylene pipes, depending on the reinforcement material:

Thus, for the installation of hot water supply and heating distribution, the ideal solution is a pipe reinforced with basalt fiber, but the use of pipes stabilized by aluminum will be no less reliable. The question of choice is only in the ease of installation.

Understanding the structure of polypropylene pipes and the fundamental differences between them will help you not only choose which product is best for solving water supply problems, but also allocate funds most efficiently when planning repairs.

Today, on the Belarusian market, you can find polypropylene pipes and fittings from a large number of manufacturers:

- Wavin Ekoplastik (Czech Republic)

- PRO AQUA (Russia)

- Heisskraft (Russia)

- RVC (Russia)

- Valfex (Russia, Turkey)

- Valtec (Russia, Italy)

- Lammin (Russia)

- Firrat (Turkey)

- Hakan (Turkey)

- Kalde (Turkey)

- And many others. others

You can get lost among the assortment, so we recommend that you listen to your plumber / installer and common sense.

One of the first polypropylene pipes and fittings on the Belarusian market in the world for almost two decades is the Czech brand Wavin Ekoplastik. The market was flooded with a large number of cheaper analogues, however, the Wavin Ekoplastik brand does not lose its popularity both at large construction sites and among private sector installers.

When purchasing polypropylene pipes, pay attention to the compliance of the system with building codes, the availability of quality certificates, and the guarantees provided by the plant. And, of course, choose a reliable supplier of polypropylene pipes, with a proven track record.

A good supplier follows all laws, observes the conditions of transportation and storage, has all the necessary certificates and guarantees, and will easily advise you when choosing a product. You will not get a marriage or a fake from him and you will be sure of your order.

Select pipes and fittings from a reputable manufacturer and supplier, and ALWAYS follow the installation and operation requirements specified in the technical instructions.

Choosing the best pipes and fittings from the best manufacturer in the world cannot protect you from leaks and system failure if you do not follow the installation and operating instructions!

Choice of diameter and installation features

All PVC pipes for heating, without exception, are prone to thermal expansion.If the installation of the pipeline is not done correctly, then due to stress in the material, leaks appear at the fittings, in extreme cases, the pipeline is deformed.

The value of the linear expansion of plastic pipes (mm) can be determined by the formula: R = a / (b-c), in which:

- a - coefficient. linear expansion by material;

- b is the operating temperature of the pipeline;

- c - temperature during installation of the system.

To reduce the negative effect of thermal expansion of pipes on the heating system, rigid fasteners should not be used to fix the pipeline on the wall. Clips used to fasten pipes must have a sliding clip.

It is also important to install the clamps at the correct distance from each other (50-60 cm). to avoid bending and pinching fasteners. Such installation will give the pipeline the possibility of free lengthening and shortening, which will ensure that there is no increased stress in the material.

Such installation will give the pipeline the possibility of free lengthening and shortening, which will ensure that there is no increased stress in the material.

A few words about which diameter is better to choose. Plastic pipes have a minimum roughness coefficient, the smoothness of their inner walls provides high throughput and no pressure loss during circulation coolant, which allows the use of products with a smaller diameter than steel counterparts.

The following calculation allows you to determine which pipes by diameter you need to choose:

- We calculate the required power of the heating system for a particular room: the norm is 1 kW per 10 m2 of the room.

- We multiply the resulting value by a safety factor of 1.2.

- According to the table, we determine the required diameter.

The diameter directly depends on the circulation rate of the coolant. The optimal speed is 0.4-0.55 m / s, it is from this value that it is necessary to build on when designing a heating system.

Keep in mind that it is contraindicated to use pipes whose diameter is larger than the calculation showed, since in this case the speed of water movement decreases, and the products of increased diameter themselves are much more expensive than standard 16-20 mm.

plastic pipes

By themselves, plastic pipes for heating are not strong enough and efficient, but technology has improved this product. Plastic pipes reinforced with fiberglass or aluminum foil have collected all the best qualities of metal-plastic and plastic pipes.

Advantages of plastic pipes:

- Lightweight material and easy installation.

- Attractive design for outdoor mounting.

- Non-susceptibility to internal salt deposits, ensuring a constant flow of water.

- Low heat dissipation, which retains the heat of the water as much as possible all the way from the boiler to the radiator.

- The minimum number of threaded connections, reducing the likelihood of leakage.

- No rust.

- Low price of the product compared to pipes made of other materials.

Disadvantages of plastic pipes:

- Strong thermal expansion, due to which they can be deformed at temperatures above +95 C. This can be avoided by installing temperature compensators or using reinforced plastic pipes.

- Lack of flexibility, due to which you have to use special angles that are inconvenient during installation and not quite aesthetic in appearance.

- The sizes of plastic pipes and fittings are usually large.

- The connection of a plastic and metal pipe poses a danger to the tightness of the system and does not withstand low temperatures.

The quality of a heating system made of plastic pipes is highly dependent on the level of professionalism of the installer.