- Option #3 - steel

- Criterias of choice

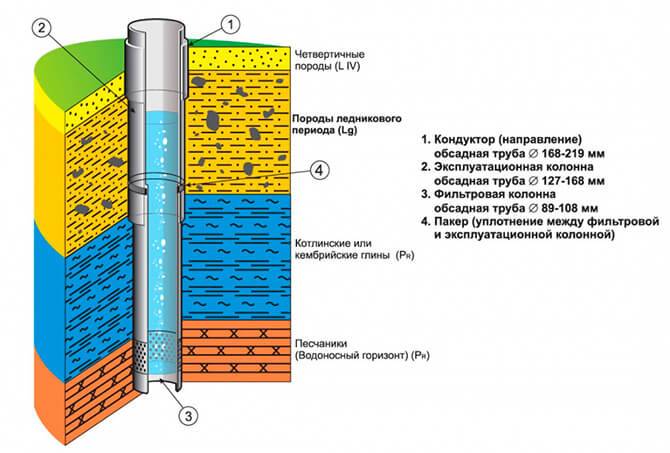

- Casing pipe sizing

- Well without plastic pipe

- What determines the flow rate of a well?

- Polymer pipes

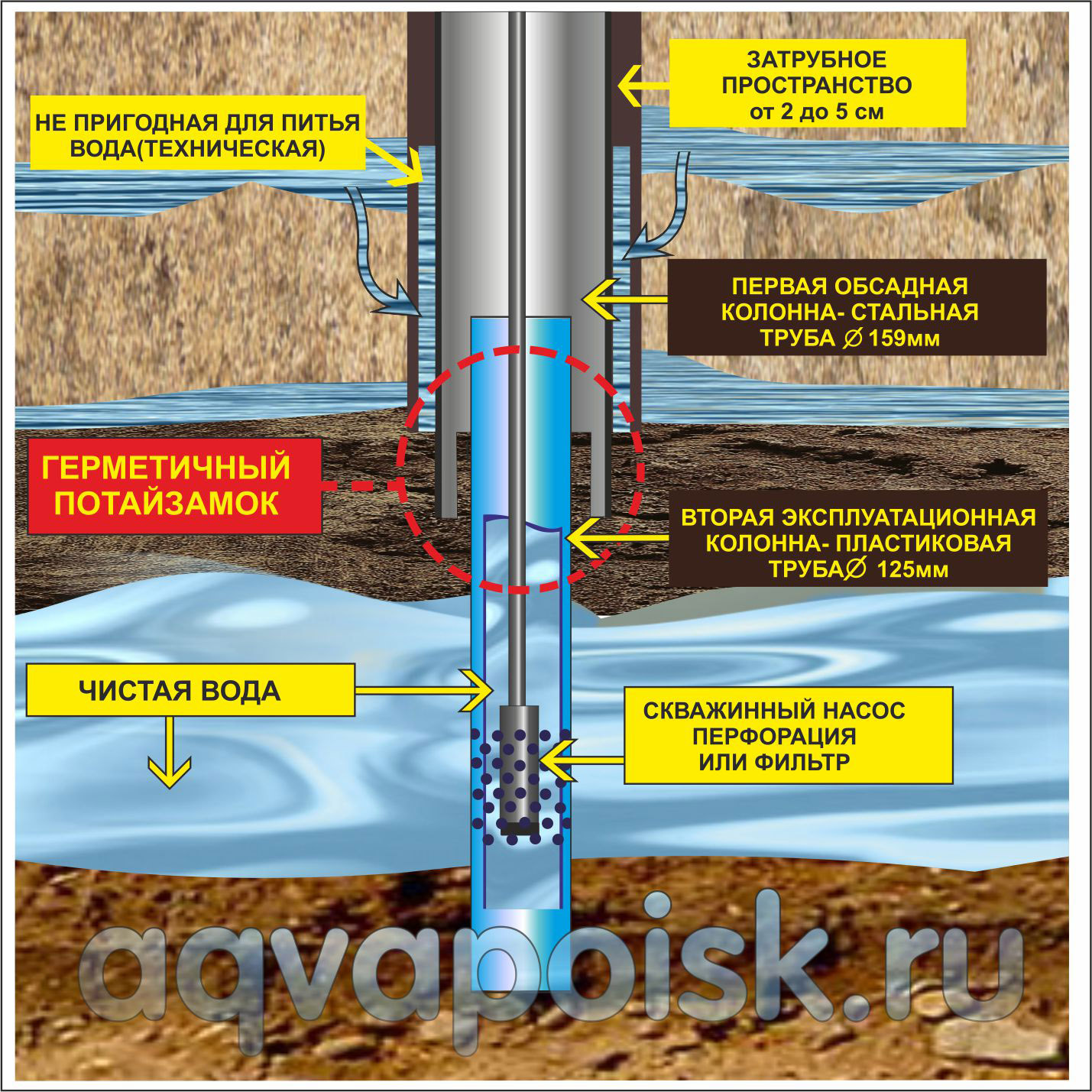

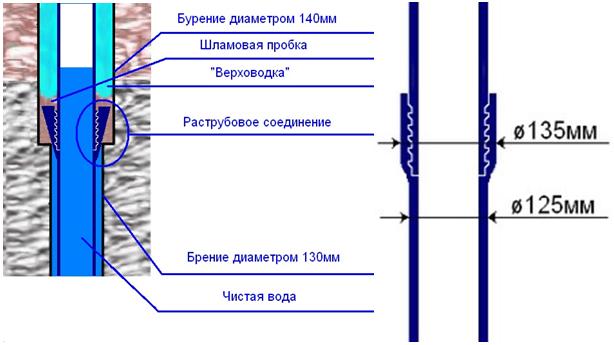

- How to case a well with a plastic pipe

- Types of casing pipes and rules for their use

- Plastic pipes for wells

- Pipes made of metals and alloys

- Asbestos-cement pipes

- Which pipe is better to use for a well

- Casing connection methods

- Well casing with plastic pipes

- Types of casing pipes

- Casing Selection Options

- Steel pipes for wells

- Dependence of the diameter of the production pipe on the dimensions of the pump ↑

Option #3 - steel

Black casing steel is a classic solution. The standard part with a wall thickness of 6 mm withstands the movement of any soil and will maintain its integrity for at least 50 years. Another advantage of steel elements is strength, which makes it possible to carry out work using a drilling tool during operation. Thus, in case of silting of the pipe, it can be cleaned. Among the disadvantages include instability to corrosion and, as a result, the appearance of rust in the water. As well as the high cost of such pipes.

Black steel is the best option for casing pipes. However, it is also one of the most expensive

If we talk about the feasibility of their use, then it is optimal to use steel casing for arranging wells for limestone and for deep structures. It is better not to install various variations of the type of stainless, galvanized and enameled pipes. Their use is justified by protection against corrosion and concern for water quality. However, over time, galvanized steel begins to release zinc oxide, which is dangerous for humans, into the water.

Enamelled parts are very sensitive to mechanical stress. It is practically impossible to install them without chips. Such damaged pipes will rust to holes much faster, because their wall thickness is less than that of ordinary steel ones. Stainless steel parts are resistant to corrosion and, accordingly, the absence of rust in water. Considering their cost, as well as the durability of black steel and the ease of filtering out rust particles, it becomes clear that overpaying here is most likely pointless.

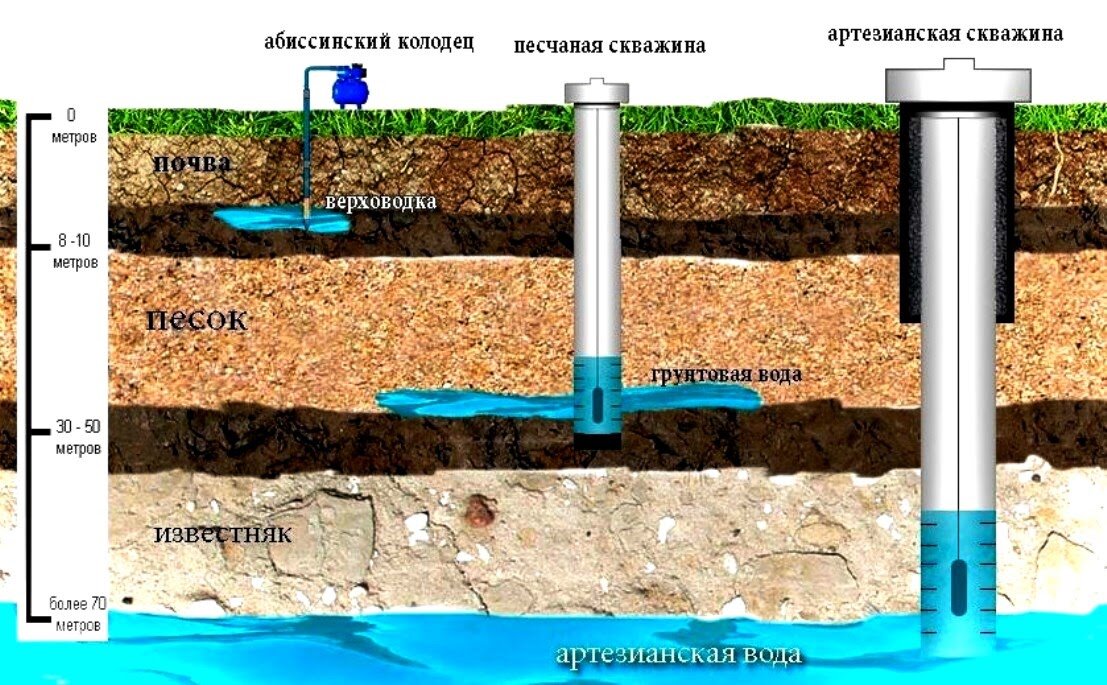

Criterias of choice

For arranging the casing, it is necessary to have the following information: the depth of the well, the volume of water supply, the diameter of the submersible electric pump, and the financial means of the consumer also influence the choice quite strongly. To determine which pipe is best for a well, consider several options for well sources for water supply.

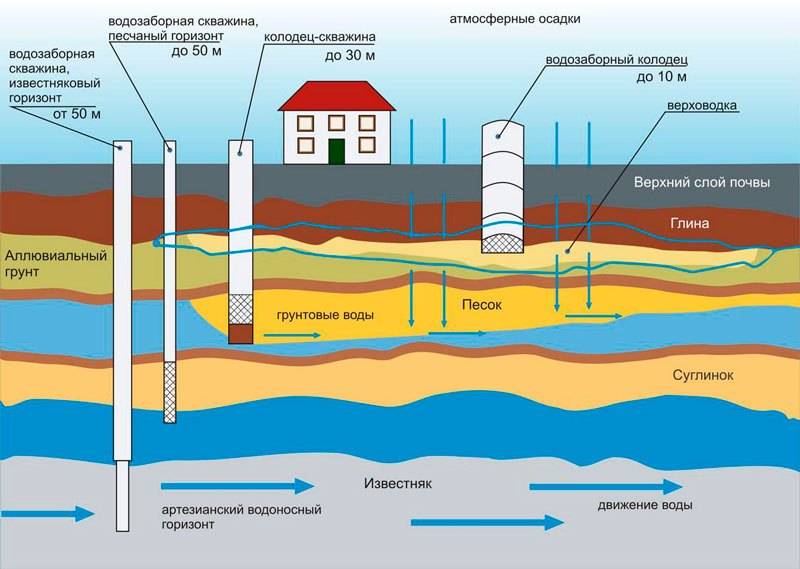

- For water intake using a submersible electric pump from a shallow well (up to 30 m) of the Abyssinian type, it is best to use a PVC-U polymer pipeline. Depending on financial capabilities, thin-walled products with a threaded socket connection or thick-walled products with versatile external and internal threads are chosen.

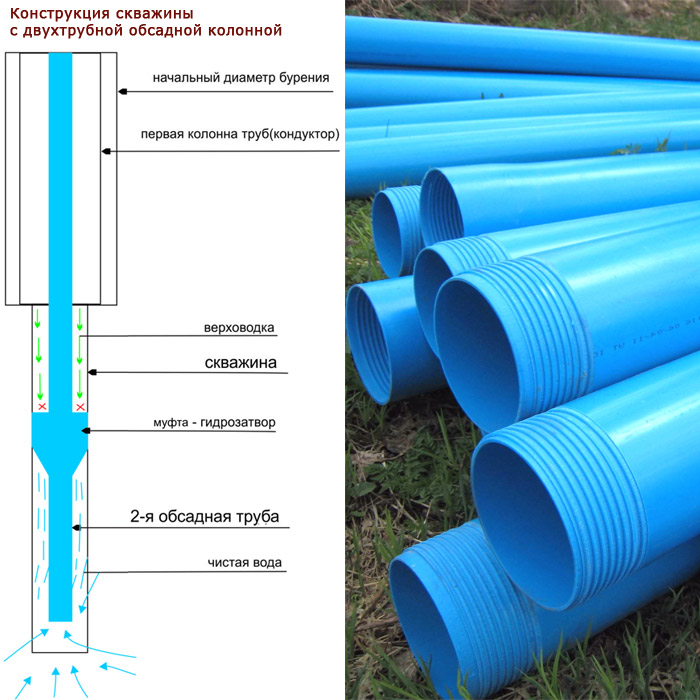

- For wells in sand up to 60 m deep, thick-walled PVC-U is a good option, with further depths up to 100 m, various methods with a double casing of polymers can be considered. A good option is to use a rigid pipeline made of PVC-U on the outside, and inside a shell made of flexible and less resistant HDPE.

- For depths above 100 m, it is rational to use a rigid metal casing, inside which an elastic HDPE or rigid PVC-U pipeline can be placed.

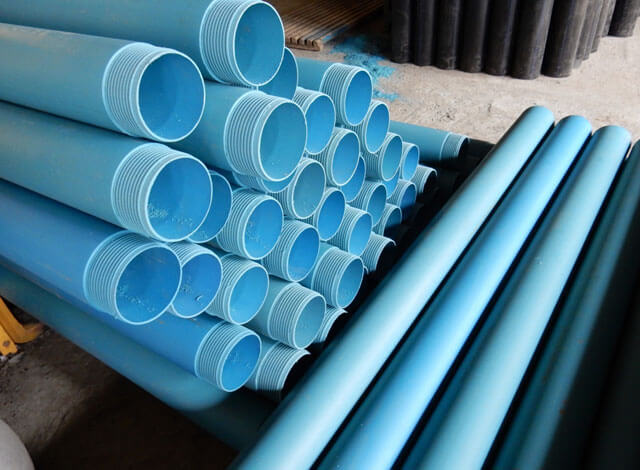

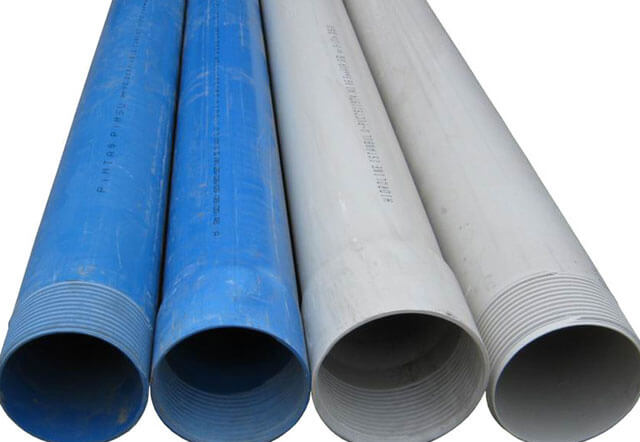

Rice. 14 Appearance of PVC-U pipes

- In any case, when choosing a single-pipe or two-pipe casing, one should take into account the composition of the soil, geological factors, and the level of groundwater. It does not hurt to listen to the reviews of highly qualified specialists on the issue of casing.

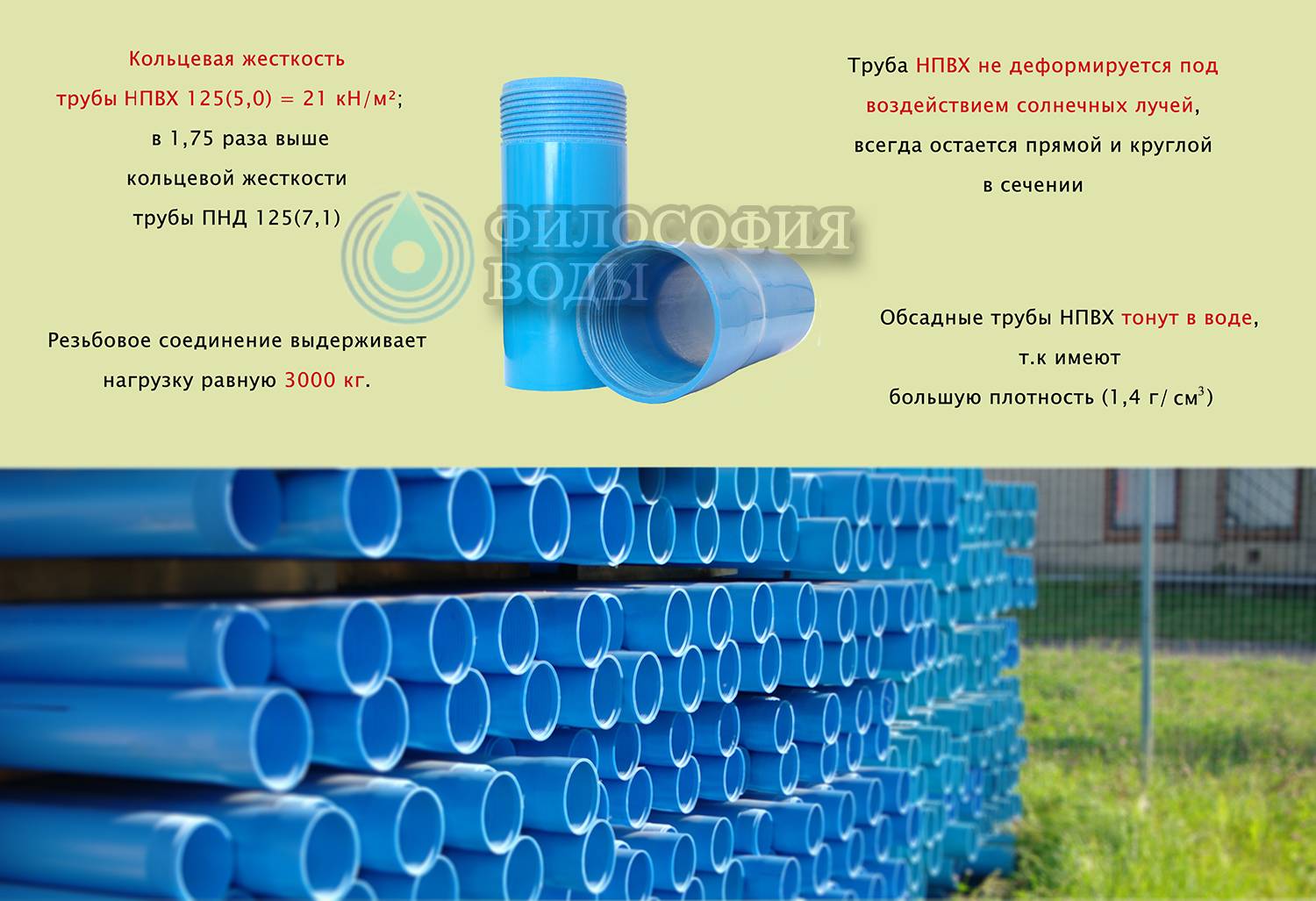

- When buying HDPE products, you should be careful due to the fact that recycled technical polyethylene and food primary material are sold in the distribution network. Their main easily distinguishable difference is the color: the pipe from the secondary granule usually has a dark blue or deep blue color, sometimes there is a green tint. HDPE products made from primary raw materials, in accordance with GOST, have a bright blue or light blue color.

- Another criterion for determining a low-quality HDPE product is the smell of plastic. Un can be reminiscent of the aroma of confectionery, detergents, washing powder, etc. - all this indicates the material of manufacture from recycled granules. Pure primary polyethylene is odorless and can be used in drinking water systems without harm to human health, while polyethylene from recycled materials can be used in water intake systems for technical needs.

- When choosing the diameter of the string, they are guided by the flow rate (productivity) of the source and the dimensional parameters of the electric pump; with large volumes of water intake, they try to increase the diameter of the casing string. The pump is selected in such a way that its diameter is not less than 5 mm of the inner size of the wellbore, if a soft HDPE pipeline is used or water intake is carried out at great depths, a larger inner diameter of the column is selected, taking into account the deformation of the channel when squeezed by soil.

- The quality of a PVC-U threaded connection is determined as follows - a pipe is screwed into another or its branch pipe by three turns and then one of the parts is moved to the sides - a large backlash indicates a weak fastening. Such a connection has low tightness, and if it is necessary to dismantle the casing and remove the string from the wellbore, the thread will most likely be torn off.

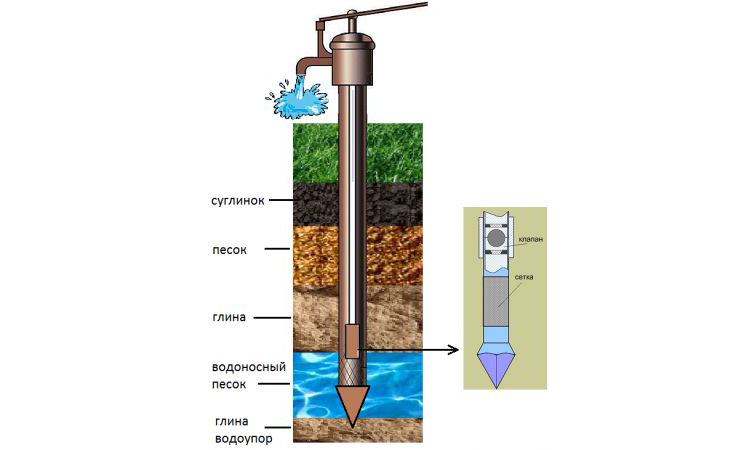

Rice. 15 Downhole filters and cone plug

Casing pipe sizing

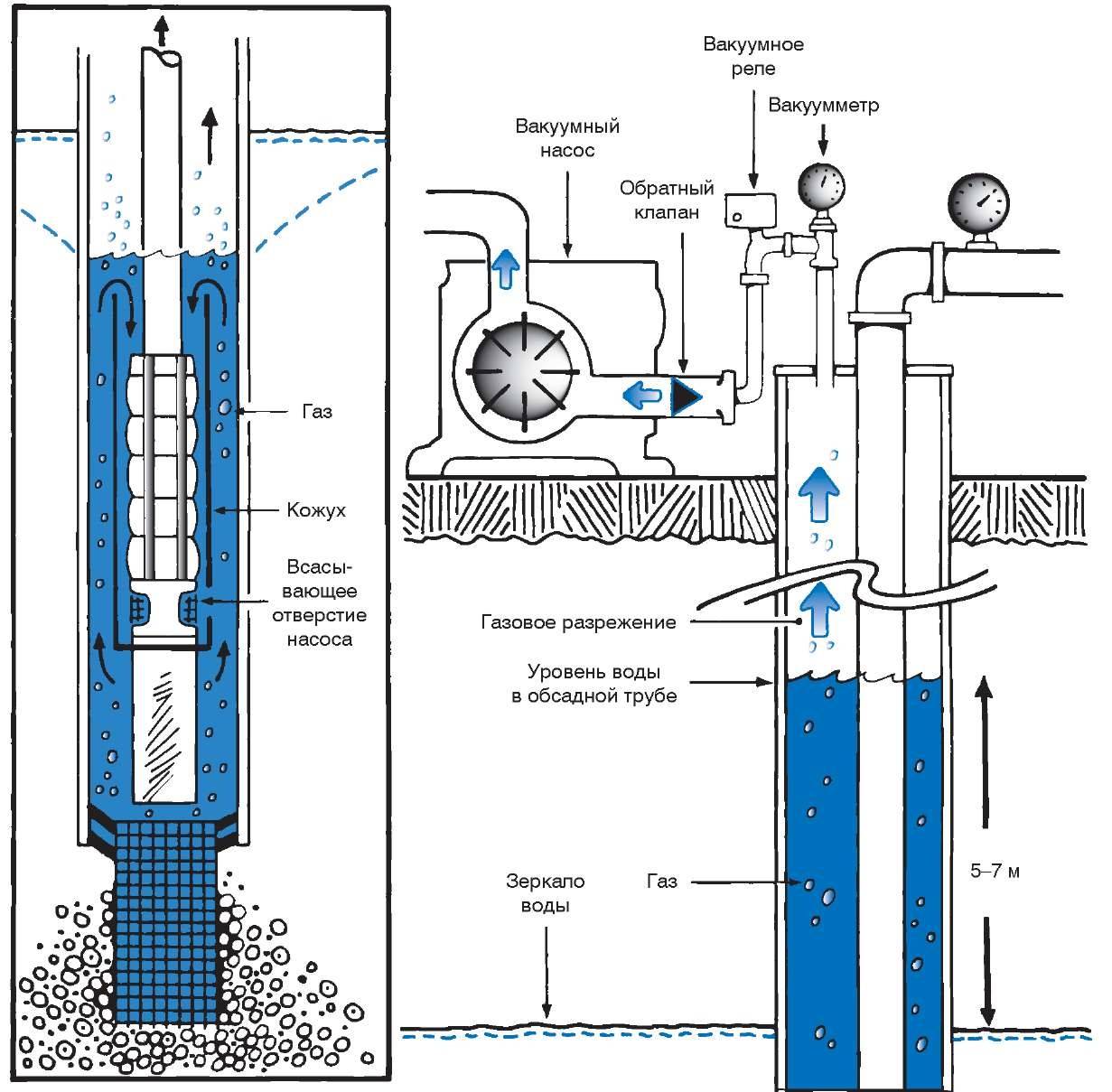

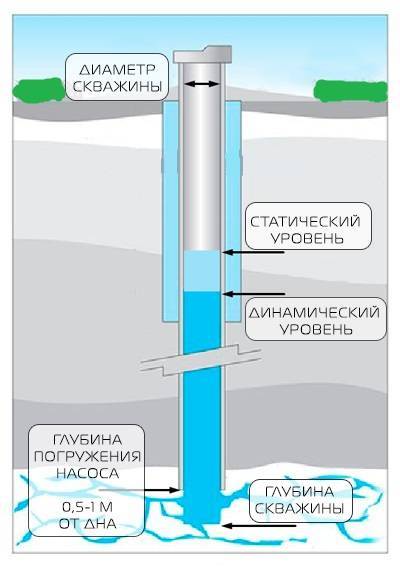

The calculation of the required diameter must begin with determining the need for the amount of water for the normal functioning of the economy. After that, a pump of the appropriate capacity is selected. For wells, submersible pumps placed inside the casing or external centrifugal pumps can be used.

In the second case, the factor taken into account is the larger the diameter of the casing, the higher the well flow rate, which is associated with the area of the filtering surface.

For the first case, the diameter of the submersible pump is of decisive importance, the gap between it and the casing must be at least 5 mm. Thus, the casing pipe for the well must have an internal diameter determined by the ratio:

Din = dnas +10 (mm), where

Din is the inner diameter of the casing;

dus is the diameter of the pump.

For example, for the case where the pump size is 95 mm, the inside diameter of the casing will be 95 + 10 = 105 mm. Considering that for such pipes the wall thickness is usually 6 mm, the calculated pipe diameter will be 105 + 6x2 = 117 mm. The nearest standard size according to GOST 632-80 is 127 mm.

However, another important factor must be taken into account. The life cycle of such products is approximately 10 years and there comes a time when the casing needs to be changed. It is not always possible to extract the old casing string due to its dilapidation and laboriousness of the operation, besides, this requires special equipment.

To avoid such problems, usually the initial wells are performed taking into account the repair size. This means that instead of the calculated 127 mm, they put pipes of the next size from the homologous series, which is 140 mm. When repairing, it remains just to insert a new casing into the old one, pump the well and live in peace until the next repair.

Well without plastic pipe

It is possible to drill an artesian well without the use of plastic if there are pressure horizons. For example, if after drilling a well, water has risen into steel pipes, and the pump will also stand in a steel casing pipe. But even in this case, it is desirable to plant limestone because it is a kind of rock: it can become limp, it will begin to fill up the trunk ...

It is possible to drill an artesian well without the use of plastic if there are pressure horizons. For example, if after drilling a well, water has risen into steel pipes, and the pump will also stand in a steel casing pipe. But even in this case, it is desirable to plant limestone because it is a kind of rock: it can become limp, it will begin to fill up the trunk ...

This is not such a big nuisance, but we want a hassle-free design.

In places where limestone is interlayered with clay, it is always necessary to plant limestone, because the clay will tint the water, and then completely tighten the well.In such cases, the area with clay is covered with a solid pipe, and perforations are made in the area of the water carriers.

In general, there can be many designs of a water well, and they all depend on the geology of the area, where it is needed, and where it is not. So you can't choose how to do with or without plastic. Plastic is not a luxury, HDPE pipe is a necessity. If in your case you need to supply HDPE, but you refuse, then you will have to lower a more expensive steel pipe.

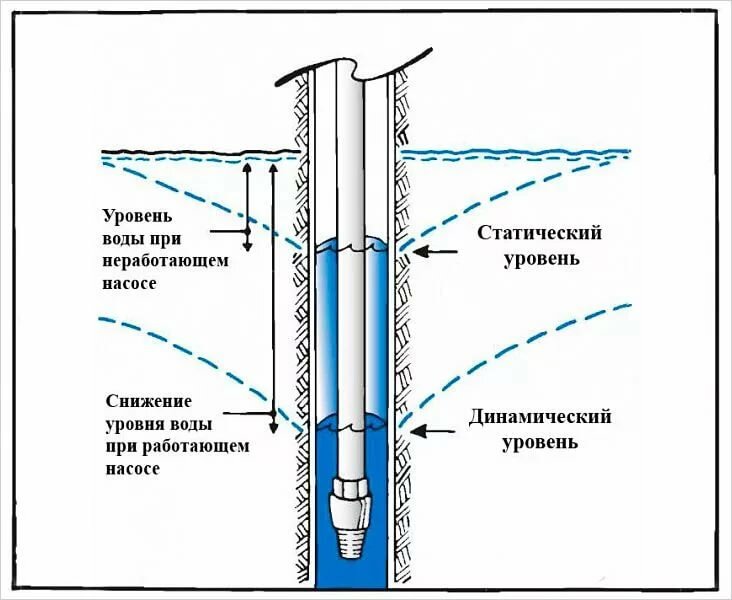

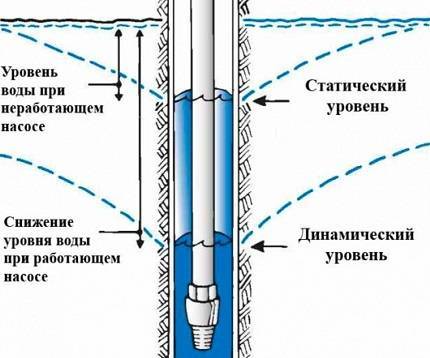

What determines the flow rate of a well?

The key parameter that determines the well flow rate is the saturation of the aquifer, and not the casing diameter at all. Here it is worth giving a simple example.

The flow rate of a well and a well with a large pipe diameter dug on the same path can be about 1 cubic meter of water per hour, while the second well with a smaller casing diameter will already bring 1.5-1.8 cubic meters of water per hour.

What is the reason for such a difference if the second well has a smaller pipe diameter? It's all about its depth: it is this well that has sufficient depth and reaches the aquifer, while it works stably and brings the largest amount of water.

Another misconception regarding pipes of small diameter is their great propensity for rapid silting, and therefore difficult maintenance.

You should not be afraid of this, because the rate of silting is determined, first of all, not by the diameter of the pipe, but by the quality of the bottomhole and the correctness of the further operation of the well. It is also not true that sediment can be buried in such a pipe. In fact, even after 10-12 months of inactivity, getting the pump out of the well is not difficult.

Polymer pipes

Recently, these products have become increasingly popular.

Advantages of plastic pipes:

- quite a long service life, subject to careful installation and operation of products;

- chemical neutrality of products - plastic does not react with most aggressive environments that threaten the well, and is not subject to corrosion;

- no need to install additional rust filters (in connection with the previous paragraph);

- products have significantly less weight than metal ones, which facilitates the assembly of the structure, maintenance and replacement of elements;

- such pipes are relatively inexpensive;

- a large size range of manufactured products, which makes it possible to select pipes of the required parameters for each well;

- the ability to use pipes in the construction of wells of any type and size, although they are most often used when drilling tunnels in a sandy environment with a depth of about 50-60 m;

- ideal for the construction of filter columns.

Cons of products:

- low resistance to mechanical stress, as a result of which the pipes must be carefully installed, avoiding damage to the surface; in addition, under the influence of aggressive external factors, damage to the well is possible;

- impossibility to clear the silted area with the help of drilling rigs.

How to case a well with a plastic pipe

When creating an autonomous water supply, it is possible to use three types of polymer pipes:

- PVC (made from unplasticized polyvinyl chloride);

- HDPE (low pressure polyethylene is used);

- PP (polypropylene).

Without going into details, the general advantages of using plastic pipeline structures are noted:

- low cost;

- light weight;

- durability of operation;

- ease of installation;

- tightness;

- resistance to corrosion and exposure to aggressive chemicals in soils.

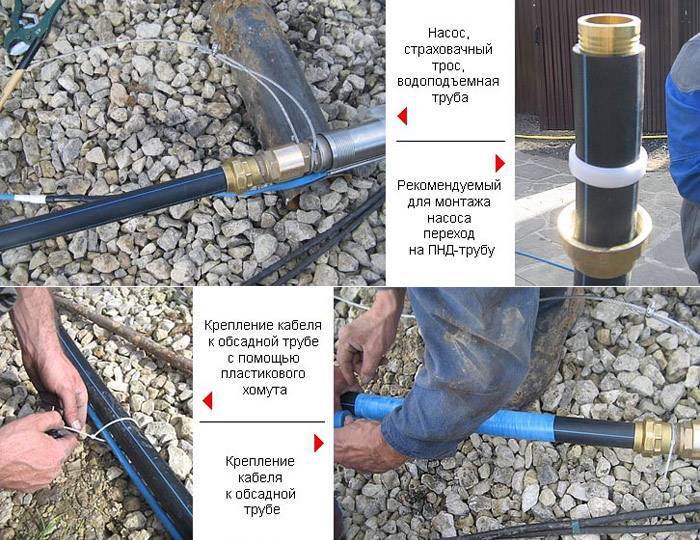

Polymer products can be used for casing both as an independent element and in combination with a steel structure. A well cased with a plastic pipe is mounted in the same way as the others. As the casing pipe is lowered into the drilled area, the next elements are connected to it by a threaded connection. To achieve greater reliability of the connection, it is additionally sealed, for which special rubber seals are installed. This procedure is repeated until the complete casing of the well is completed. The lower edge is not brought to the bottom by about half a meter, so that a free flow of water is ensured, regardless of the time of year.

Polymeric pipes are prepared before connection - a chamfer is removed on the socket, seals are installed if necessary

Polymeric pipes are prepared before connection - a chamfer is removed on the socket, seals are installed if necessary

The use of sewer pipes for the well is allowed. Naturally, not if the water is intended exclusively for drinking. A source built to receive technical water, for irrigation and melioration, may well be equipped in a similar way. This is in no way a violation of sanitary and hygienic standards. And sewerage with autonomous water supply equipment must be provided for. Sewer disposal should be responsibly disposed to avoid water pollution.

The well can be built without casing. True, for many specialists the existence of such water supply facilities seems mythical. The collapse of the walls of the source will put it out of action in the shortest possible time.And restoration will require a lot of money, time and effort.

Types of casing pipes and rules for their use

The determining criteria for choosing casing pipes is the length of the wellbore, the design pressure of the soil. Based on this, you can install plastic, metal or asbestos-cement structures. Each type has its own advantages, disadvantages and requirements for installation and operation.

Plastic pipes for wells

Made from polypropylene, PVC or HDPE. Must comply with GOST 2248-001-84300500-2009. They do not collapse under the influence of moisture, but the plastic case is less resistant to mechanical damage than the metal one. It is possible to form a wellbore entirely from polymeric water pipeline, but only with the right choice of model.

How to choose a good plastic pipe for a well:

- The design pressure in the lower part of the barrel should not exceed 16 atm. An alternative is to install check valves every 10-15 meters of the well to normalize the pressure.

- For HDPE, diameters from 90 cm, wall thickness - from 7 cm.

- Polypropylene is rarely used because of the high cost. For structural rigidity, models PN25 or higher must be used.

- Connection method - threaded coupling (couplingless) or welded. The latter is rarely used for a well.

At low temperatures, the polymer loses its plasticity, which can lead to damage due to external pressure. This also complicates the maintenance of the system at low temperatures. Installation in regions with an average winter temperature of -10°C is not recommended.

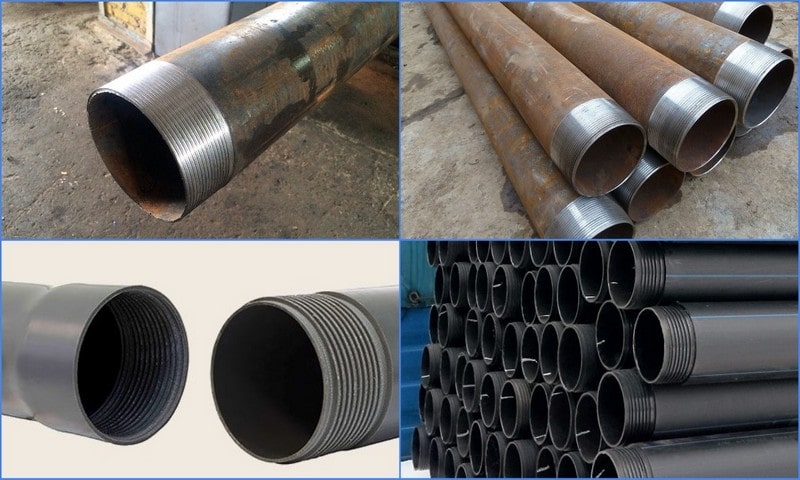

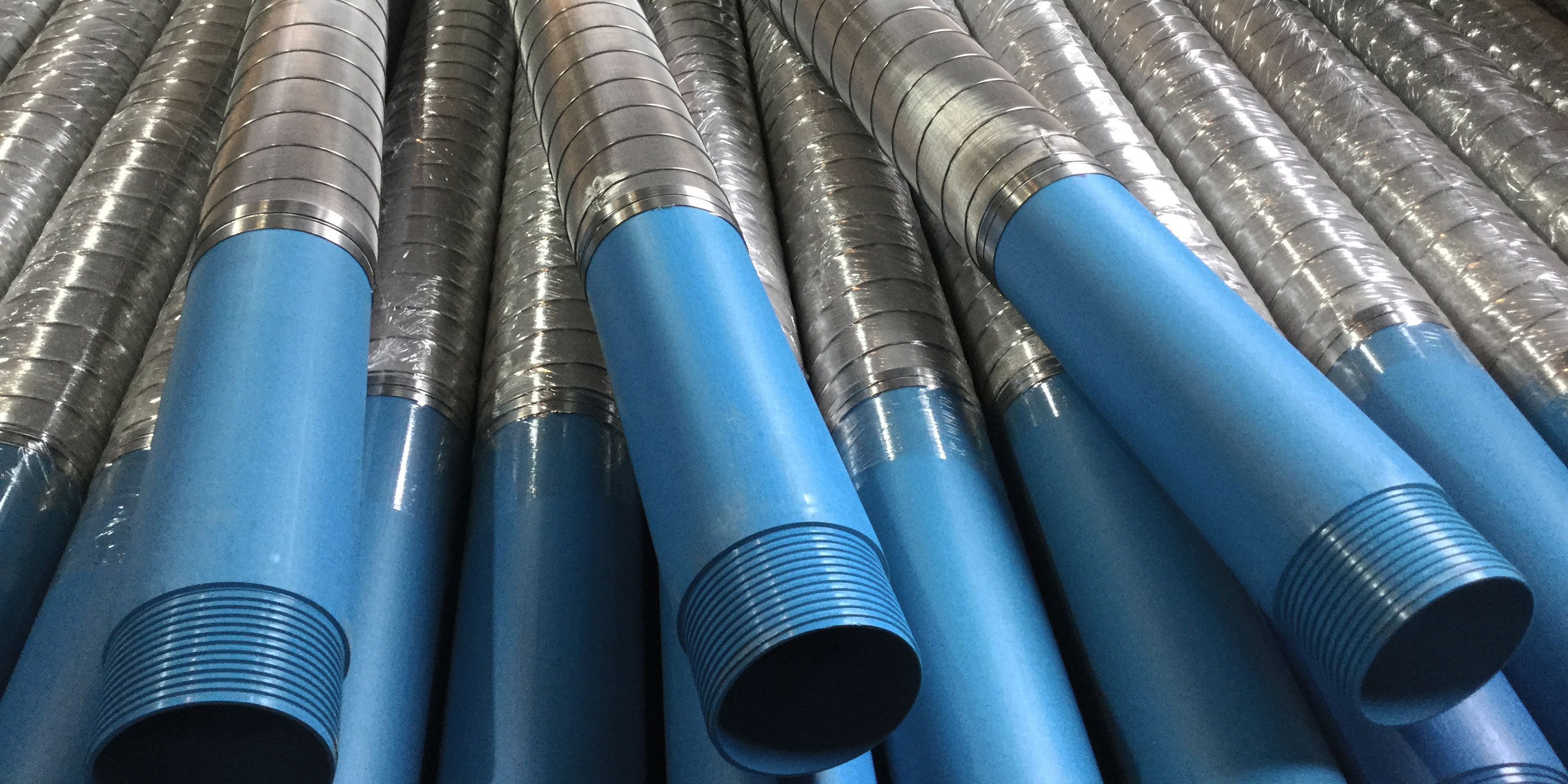

Pipes made of metals and alloys

More often, iron (steel) pipes are used for drilling a borehole. The reason is the availability of the material, relatively simple processing, resistance to mechanical stress. Disadvantages - gradual destruction due to corrosion, large mass, which complicates installation. The latter requires a special technique.

How to choose a metal pipe for a water well:

- Steel grade - ST.20 or higher.

- It is recommended to use seamless patterns. Welded ones are more likely to be damaged if the seam is made poorly.

- Wall thickness - from 5 mm.

- Connection - threaded coupling. Welding complicates maintenance (replacement of damaged sections).

Steel casing pipes should be recommended according to GOST-8732-78 (solid-drawn) or GOST-10705-80 (electrowelded seam). For the manufacture of carbon low-alloy steel is used. The use of galvanized steel products is not recommended. The reason - when in contact with the soil, the effect of "stray currents" appears - electrochemical corrosion. The use of additional protective equipment will increase the budget.

Asbestos-cement pipes

The rare use of asbestos-cement pipelines is due to their relative fragility and insufficiently reliable socket connection. Installation is also difficult due to the large mass of asbestos cement. To increase strength, thick walls are made, which leads to an increase in weight. Installation is possible only with the use of special equipment.

However, they do not corrode, and with prolonged temperature exposure, they retain their shape and integrity. The neutral composition does not enter into chemical reactions with the environment, does not affect the water in the well. The service life of asbestos-cement pipes is up to 70 years.

Which pipe is better to use for a well

Having made a decision regarding the creation of an autonomous water supply system, you will have to face a difficult choice: which pipe is better to use for arranging a well? The choice of casing pipe is determined by several circumstances:

- soil structure;

- well diameter;

- drilling depth;

- the location of the aquifer;

- the chosen drilling technology;

- the possibility of penetration of waste and surface water (perched water);

- the level of the higher aquifers.

The choice is relatively small, the designs are made of the following materials:

- asbestos cement;

- metal;

- polymers.

When choosing a casing pipe to protect the well from depressurization, i.e., ingress of water from the upper layers, which, as usual, is not of the best quality, and penetration of sand and other polluting rocks from the outside, care should be taken:

- about the strength and durability of operation, the reliability of the barrier to the collapse of the walls of the well;

- that the selected material does not affect, in contact with water, a change in its chemical composition and a decrease in quality.

The choice of a tube for casing a well depends on the type of soil, the depth of water and other factors.

The choice of a tube for casing a well depends on the type of soil, the depth of water and other factors.

Deciding which pipe is better to choose for a well should be based on specific conditions, and not be guided solely by general considerations.

Casing connection methods

Often, casing pipes consist of segments that are interconnected in one of the three indicated ways.

- Welding.

- Fittings, thread.

- Trumpet.

In order to find out which connection method is better, let's remember what the main function of the casing is. That's right, sealing. Therefore, threading is the best connection method.When welding, everything depends mainly on the work of the welder, but there will be many seams, which means that there is a high probability that at least one of them will be of poor quality. Moreover, welds are a kind of catalyst for the appearance of rust, so the life of the structure is reduced. When the tightness of the weld is broken, the pipe may move, as a result of which earth may enter the column and block access to the submersible pump.

Threaded connection

The socket is not reliable from a physical point of view, because when installing pipes, you will not be able to control the process, and subsidence can occur after a few years of operation.

Well casing with plastic pipes

So, the well is drilled and cased with a steel pipe to the limestone, the water is in the limestone and does not rise into the steel pipes. You cannot lower the downhole pump into bare limestone (because it will get stuck), so it is pre-lined with an HDPE pipe and then a pump is placed in this pipe. Previously, metal pipes were used for limestone casing, but they are expensive, today the competition has gained rampant proportions and, in pursuit of the best price, everyone has switched to plastic pipes.

When casing limestone, it is customary to bring a plastic pipe several meters above the water so that it does not surface.

There is a widespread myth that if you bring a plastic pipe under the top, then this provides additional protection from groundwater in the event of through corrosion of a steel pipe. We have to disappoint you: this will not work in most cases. If a steel pipe rusts, then water will get into the annulus, from there into the limestone, and then into your house.If the steel rusts very much, then the plastic will be squeezed by clays. But sometimes such a well design is implemented when the plastic pipe is not lowered to the bottom, but a kind of pocket is made in limestone, where the plastic will be covered with clays. This will protect the well from perched water even in the case of through corrosion of steel.

Some drilling organizations offer to put a packer in the well, which looks like a winding on a plastic pipe, it is designed to close the space between plastic and steel and ensure tightness. But while the pipe is lowered with winding into the well, this winding will loosen, break and there will be no sense from it. But the main thing is that no one will ever understand whether the packer is out of order or not, because the water will still be clean and transparent.

There are more complex options for packers, but this is additional money, additional time for their installation, and now all companies are on the path of extreme cost reduction and no one will do this for free.

And now the most popular: many drilling organizations say that by installing a plastic pipe, you will only drink water from it. They just throw this pipe down the well and it hangs out there. There is water in it, but there is also water between the plastic and steel pipes. It's not supposed to talk about it, you won't know it anyway. This is how most drillers work without proper experience.

Naturally, if the steel rusts, then the top water will be in your tap.

Types of casing pipes

Since the well is reinforced with these products, it is especially important when designing, redevelopment or repair of a well to correctly select not only the material from which the pipe is made, but also the parameters of the element - the diameter and wall thickness.

Since the casing industry segment is quite well developed, there are many sizes of products on the market. In the Russian Federation, the assortment pipes are regulated by GOST conditions 632-80, other countries have their own systems, which must be checked when purchasing elements from abroad.

Casing Selection Options

There is no single true standard for drilling. The well organization method is determined on an individual basis.

Many indicators are taken into account: the structure of the soil, the height of groundwater and aquifers, the parameters of pumping equipment, water quality, the diameter and depth of drilling.

Any drilling company will offer its own version of the project and recommend, in their opinion, the best type of pipe. The final decision on the choice of casing string is made by the customer.

The performing organization, first of all, defends its own interests, so their decision is not always objective. Some contractors specialize in any one type of downhole system device and try to "impose" a profitable option for them.

The only right decision is to decide in advance which pipe to choose and use for the well, comparing all the pros and cons, and after that, apply for the development and implementation of the project.

When making a decision, you should take into account the main parameters for choosing a riser pipe:

- Manufacturing material.This parameter determines the budget for installation work, the bearing capacity for reservoir loads, maintainability and longevity of the well.

- The method of joining the elements of the column. The choice of method depends on the pipeline material, drilling depth and casing diameter. In any case, the connection must be completely sealed, otherwise the water quality will deteriorate over time, and the pump and the well as a whole will fail.

- Pipe diameter. The calculation of the value is made taking into account the maximum possible water consumption per day.

The larger the diameter of the supply pipeline, the higher the productivity of the well.

Steel pipes for wells

Steel structures are the most reliable, but at the same time, the most expensive structures for a well. A steel pipe can withstand any load, well protects water from pollution and has a long service life, more than 50 years.

A well with a steel pipe is easy to clean without any damage. These types of pipes are great for any pump design.

If a large depth of the well is assumed, the soils are quite complex, then professionals advise using steel pipes.

Advantages of steel products:

- high strength;

- reliability in use;

- long service life.

Steel pipes are able to withstand any load and therefore they are perfect for the extraction and supply of artesian water.

The disadvantage is the high cost.

In addition to conventional steel products, the industry currently produces galvanized, enameled steel models and stainless steel products.

Enameled products are difficult to install without damage and deformation. Violation of the enamel leads to rapid corrosion of the material.

The use of galvanized structures during long-term use, according to experts, can cause contamination of drinking water with zinc oxide, which is harm to health person.

Due to the fact that steel products are very expensive, manufacturers are currently looking for replacements for expensive steel alloys. In some cases, black steel structures are used. But over time, due to the use of this type of product in water, rust can form. In these cases, the owners can use a filter to purify the water.

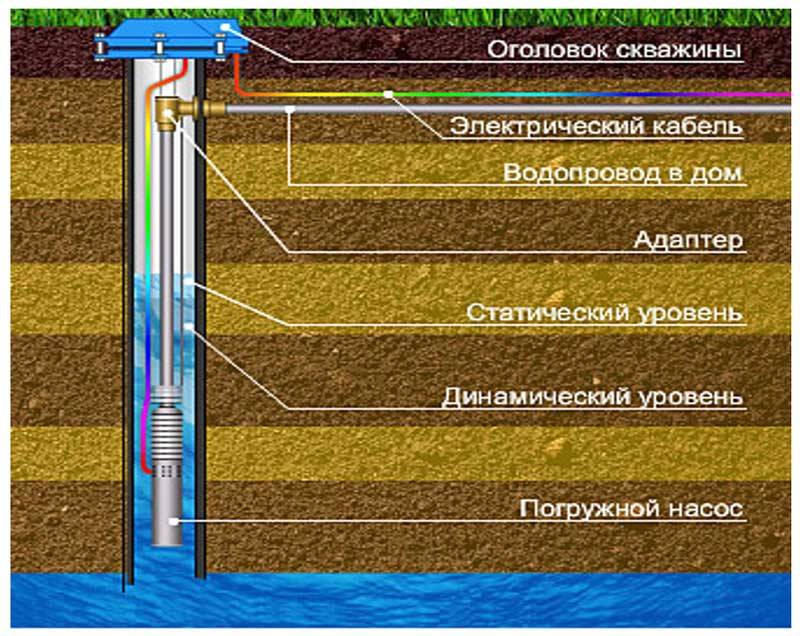

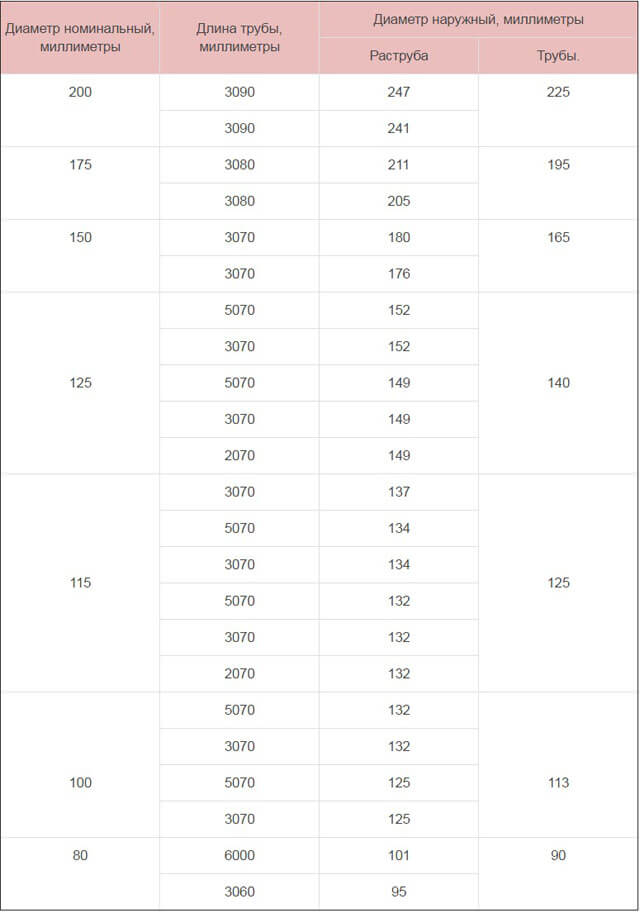

Dependence of the diameter of the production pipe on the dimensions of the pump ↑

The diameter of the well for water directly depends on the type and size of the pump, and vice versa, the choice of pumping equipment is carried out in accordance with the dimensions of the casing string.

If the water mirror is close to the surface, then self-priming surface pumps can be used for water intake, which are often bundled with hydraulic accumulators and are called pumping stations.

When using a pumping station, the diameter of the water well depends on the diameter of the riser pipe or hose that goes down. As a rule, in this case, a 50 mm casing is sufficient to ensure the normal operation of the water supply system.

The minimum diameter of deep well pumps is 3 inches (76 mm). The installation of such devices can be carried out already in a 90 mm casing pipe. However, for domestic needs, in most cases, 4-inch units are used, which are cheaper and have higher performance. For their normal placement, a production string of at least 110 mm is used.

The distance between the hull and the casing wall should not be less than 2 mm along the entire radius. At the same time, for vibratory submersible pumps, this criterion is more stringent, since direct contact with the production string may result in destruction of the structure.

To accurately determine the diameter of the pipe for a well pump, you can use a simple formula:

D(casing) = D(pump) + clearance + wall thickness

Thus, for a 3-inch unit, the minimum diametral hole size will be:

D=76+4+5=85mm

Based on this, a column of 90, 113 or 125 millimeters (in accordance with the table above) is suitable for such devices.

For 4" (102 mm) submersible pumps, the allowable casing size will be different accordingly:

D = 102 + 4 + 5 = 111 mm

According to the table, we select the required dimensions: 113, 125 or 140 millimeters.

On the one hand, a small-diameter well is difficult to maintain and tends to quickly silt, on the other hand, drilling and arranging too large bore holes is financially unprofitable. Sometimes it is very difficult to find the most rational solution on your own. In this case, it will not be superfluous to take the help of specialists.