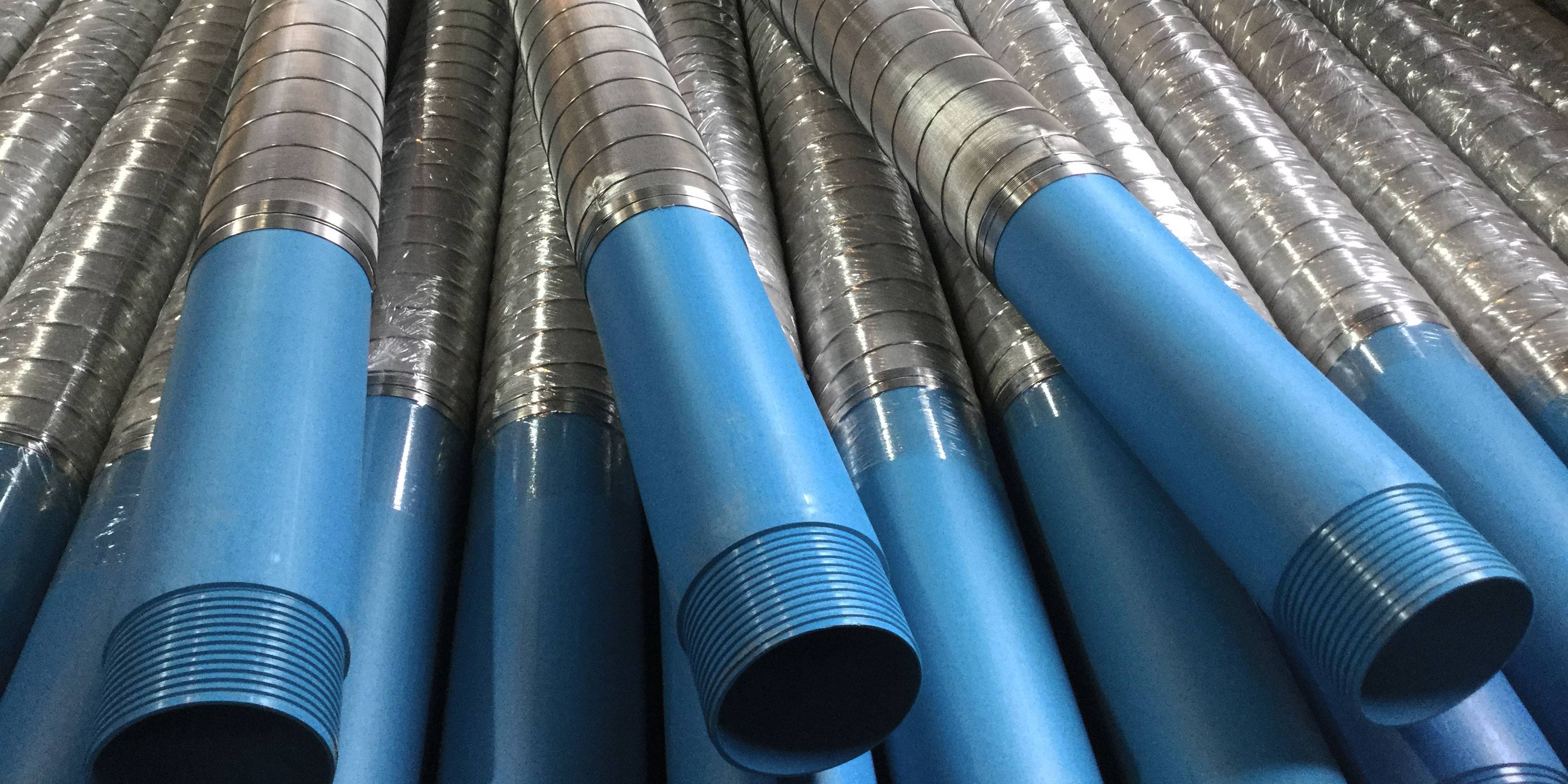

- 1. HDPE pipes (low pressure polyethylene)

- Advantages of HDPE

- Disadvantages of HDPE

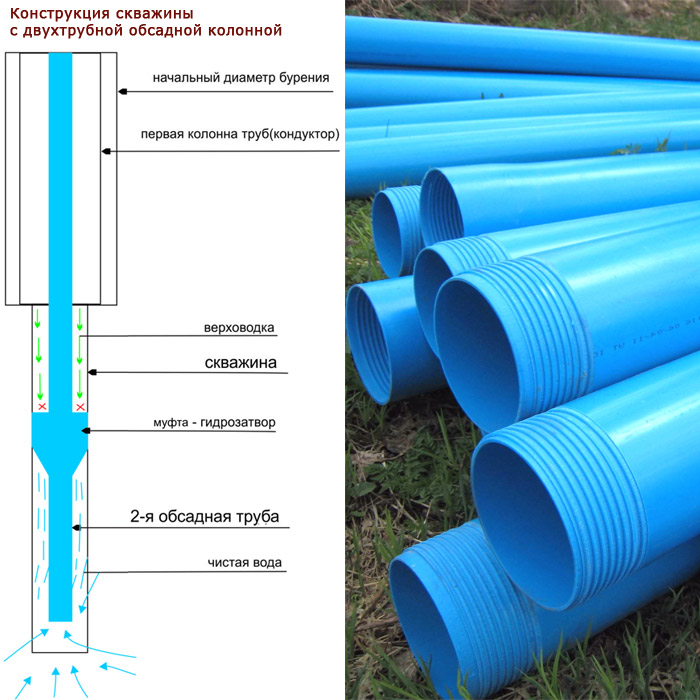

- Well casing designs recommended for private water supply

- Benefits of using asbestos cement

- Types of casing pipes for wells

- Metal pipes

- Asbestos cement pipes

- Plastic pipes

- Calculation of pipe diameter for well casing

- Casing connection methods

- Types of casing pipes for a well

- Plastic casing products

- General points to be considered

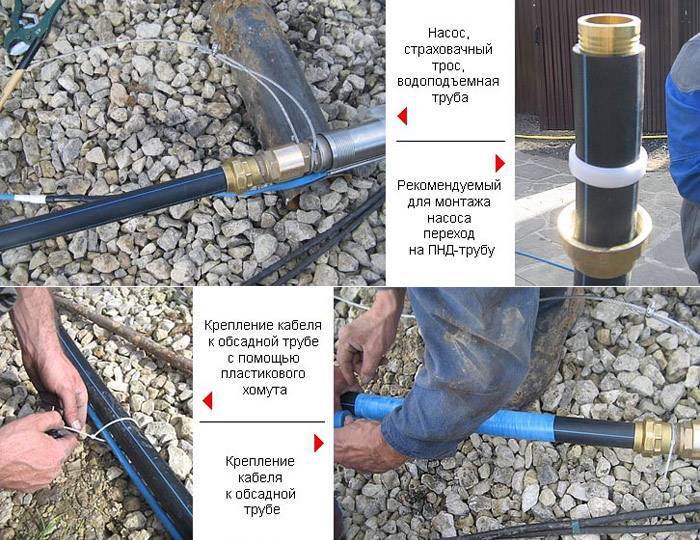

- Fixing wells with pipes

- Well before operation. Trial

- Steel casing pipes

- Application for water wells

- Types of materials and their characteristics

- Metal casing pipes

- Polymer pipes

- Disadvantages of PVC pipes:

- Rolled steel casing pipes

- Advantages of rolled steel pipes:

- Galvanized casing pipes

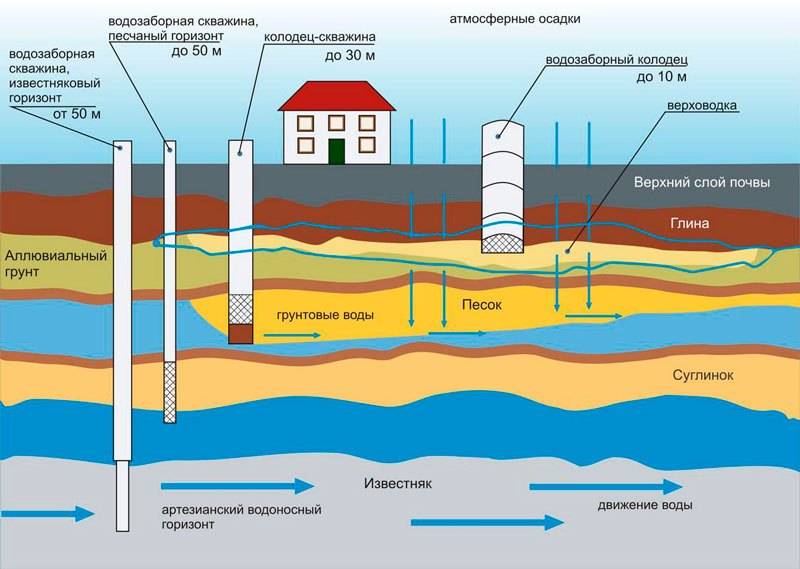

- Definition and purpose of the casing

- Conclusions and useful video on the topic

1. HDPE pipes (low pressure polyethylene)

Polyethylene was discovered by German chemists at the beginning of the last century. After targeted development, LDPE (High Density Polyethylene) was invented. But due to its softness and low strength, it was impossible to use it for the pipeline.

In 1953, Karl Ziegler created a catalyst that produced low-pressure (high-density) polyethylene, which is characterized by high rigidity and strength. Developments in this promising direction continued, and after 20 years, several more catalysts were discovered, which made it possible to produce even more advanced polymers.

Modern HDPE has a density of over 0.94 g/cm. The weak branching of molecular bonds provides high tensile strength of this material.

In Russia, HDPE pipes have been used for drilling private wells for water for more than 20 years. Previously unfamiliar material is now used in 95% of artesian wells.

Advantages of HDPE

- Are not subject to corrosion;

- Frost resistance up to -70 ° С;

- Projected service life of at least 50 years;

- The threaded connection ensures the tightness of the joints;

- Environmentally friendly material does not pollute water and the environment.

Disadvantages of HDPE

- The material is elastic, the modulus of elasticity is 900 MPa (rolled steel 2.06 • 10 5 );

- Strong ground pressure collapses the pipes, so they can only be used using a two-pipe design as an internal casing string.

Attention: the point about the environmental friendliness of the material applies exclusively to pipes from primary raw materials. Recycled plastic is cheaper, but causes irreparable harm to water quality

Secondary raw materials are obtained by recycling used containers, both food and non-food: bottles, canisters, boxes, syringes, corks. Types of plastic are not sorted, crushed into granules, and all together go to the production of secondary HDPE.

It is important for the Systems for Home company to always provide only high-quality services. We never use recycled pipes

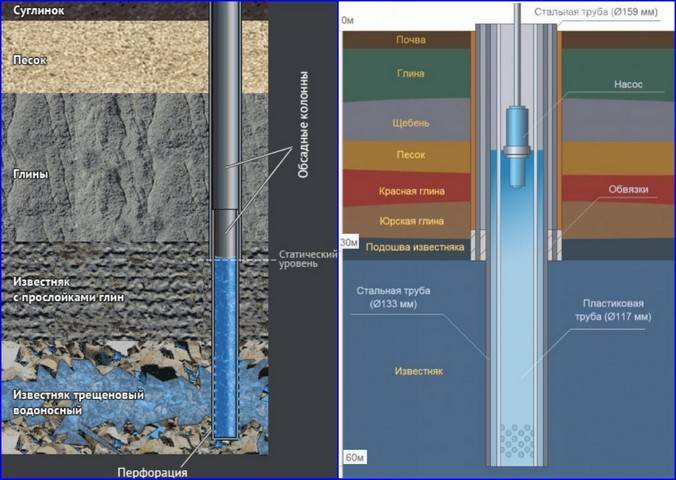

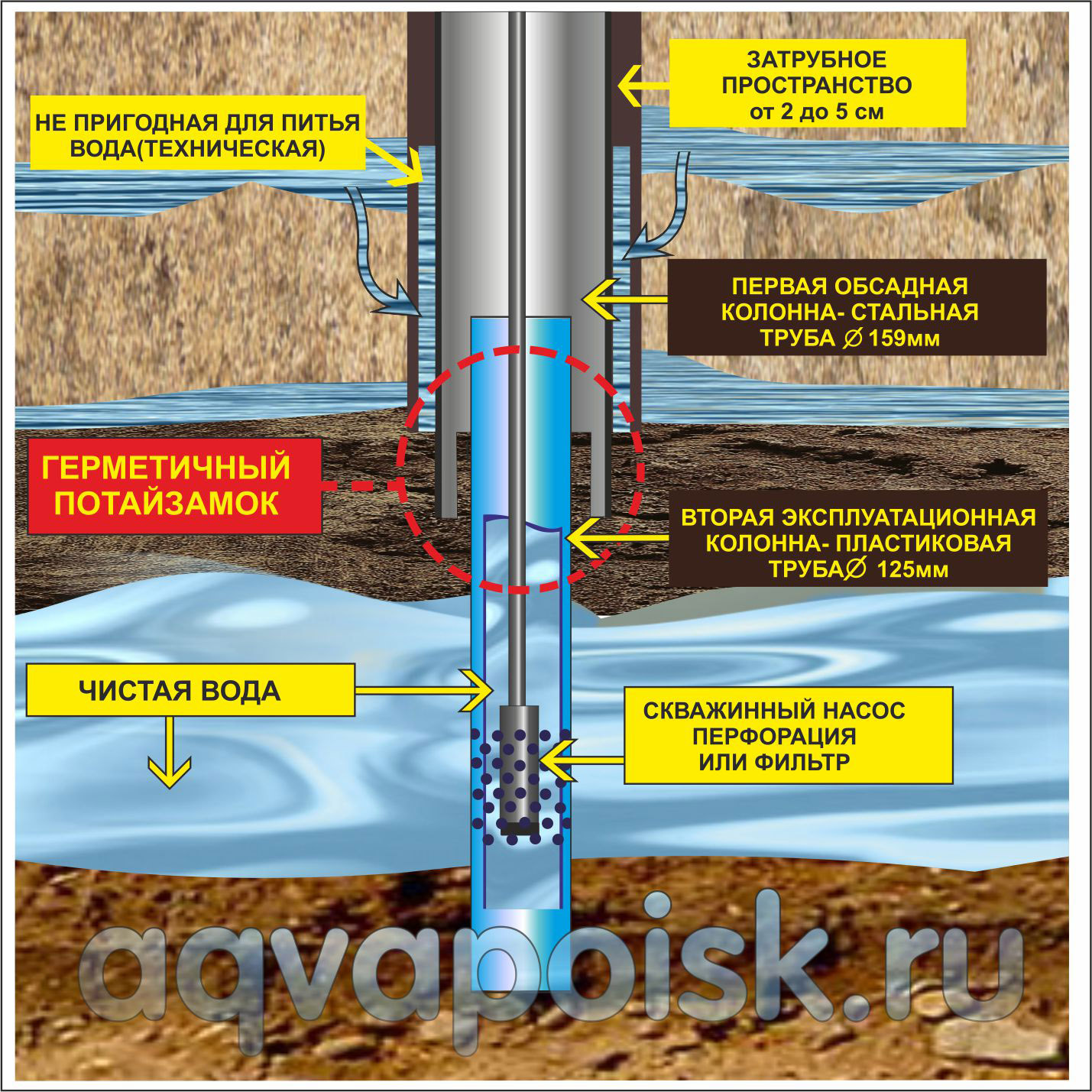

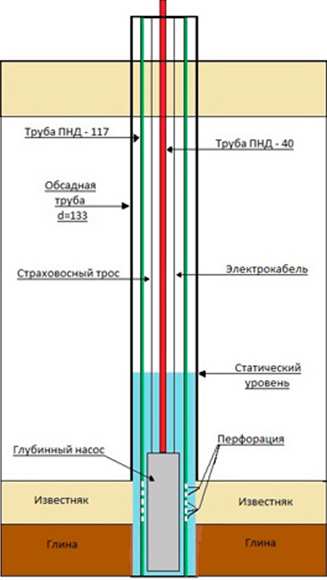

Well casing designs recommended for private water supply

- Steel conductor with a diameter of 133 mm with an inner pipe made of HDPE with a diameter of 117 mm.

- External casing made of steel pipe with a diameter of 159 mm, internal casing made of HDPE with a diameter of 125 mm.

In the case of using pipes manufactured in accordance with GOST and intended for water drilling, the service life of such a design is more than 50 years.

Benefits of using asbestos cement

Asbestos-cement products are gradually going out of fashion. The reasons why they are gradually being squeezed out of the market can be reduced to four main ones:

- Brittleness and tendency to delamination.

- They do not provide resistance to sand, so it is advisable to exclude their use in the presence of sandy impurities in the water.

- Pretty significant weight.

- Distrust of asbestos as a material with a poor environmental reputation. Although the threat comes only from the dust of exclusively amphibole asbestos.

There are many advantages to choosing an asbestos-cement pipe when arranging a well. These include:

- low cost;

- resistance to decay and resistance to corrosion. No special groundwater protection required;

- strength;

- low thermal conductivity, which makes it possible to refuse insulation;

- non-susceptibility to temperature changes, frost resistance;

- small, compared with metal structures, weight;

- durability of operation.

Casing of a well or well can also be done with asbestos-cement pipes

Asbestos-cement products during installation can only be connected by couplings, while each link is fastened as firmly as possible. Even having doubts about the environmental safety of asbestos cement, it is quite acceptable that it is used for irrigation and melioration.As the best option, asbestos cement is used when drilling in limestone soils.

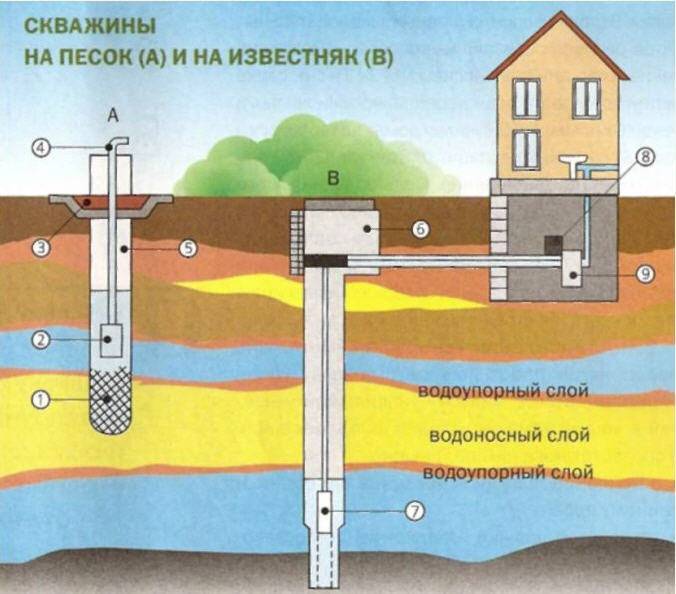

Types of casing pipes for wells

Each of them has a number of advantages and disadvantages, which determines the intended purpose. If it is not clear which pipes are best for wells of a particular depth, read on or contact a specialist.

Metal pipes

There is another classification here. Products are divided into types, and there are:

- cast iron or steel;

- enamelled;

- galvanized;

- from stainless steel.

It is impossible to say unequivocally which casing pipe for a well is better, because each type is used depending on the climate, soil characteristics, the depth of the aquifers, and other factors.

The most popular type of metal casing pipes are steel. Steel is applicable for the device of artesian wells when the depth reaches the level of occurrence of limestone aquifers. Not sure which pipe to choose for a well? Steel is a versatile material that is suitable for any type of source and purpose. The advantages are:

- Long period of operation.

- High bearing capacity with small dimensions.

- Immunity to external mechanical influences and deformations.

- Resistance to abrasion, the ability to clean the source from bottom sediments.

You will have to pay for all the listed requirements for casing pipes. High cost and high weight are the minutes of metal casing for wells. During operation, a metallic taste appears in the water. It is difficult to mount the pit on your own due to the large specific gravity.

Asbestos cement pipes

This is a low cost material. It is resistant to salts.Asbestos cement has been used for many years in the construction of hydraulic structures. The list of main benefits is as follows:

- The appearance of foci of corrosion is excluded.

- Permissible operating period - 65 years.

- The cost is affordable, always available.

But there are a number of disadvantages, and the first of them is that such casing pipes are not used for arranging an artesian well. Besides:

- Complicated installation, the need for special equipment.

- The material is fragile, afraid of mechanical shocks, which complicates transportation.

- Flange connection or butt-to-butt joint is provided, which does not guarantee tightness.

- Regular maintenance required. A coating appears on the surface, which will have to be removed.

Well casing diameter and wall thickness varies, but the range presented has a smaller range of applications than metal or plastic.

Plastic pipes

ND polyethylene, PVC and polypropylene continue to squeeze metal and concrete competitors out of the market. Popularity was provided by competitive advantages, of which there are many:

- Extended service life.

- Absolute inertness in relation to salts and other chemical elements.

- The appearance of foci of corrosion, decay is excluded.

- Low specific gravity allows you to perform work without construction equipment.

- A threaded connection is provided to achieve absolute tightness.

- Ease of transportation, storage, use due to low weight.

To understand which pipe is better to use for a well if the budget is limited, add low cost to this list.The disadvantage is the restriction on the depth of the well, which cannot exceed 60 meters. Otherwise, everything depends on the selected wall thickness and section geometry.

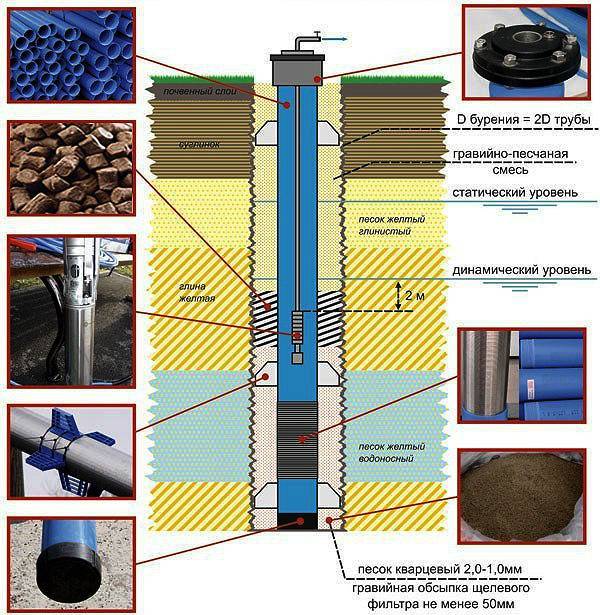

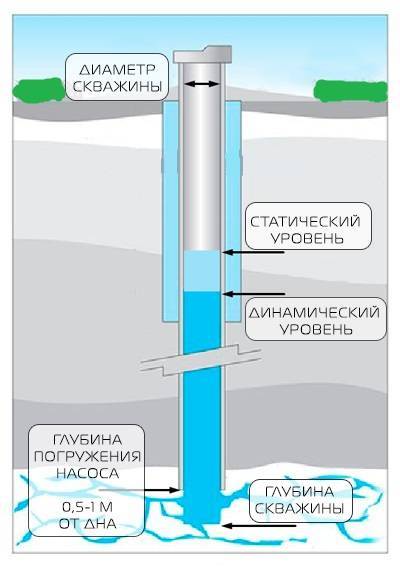

Calculation of pipe diameter for well casing

When calculating the planned flow rate, we must not forget that it directly depends on the diameter of the casing pipes. In other words, the supply of water is greater in that source; the project provides for a larger diameter of pipes for a water well for the device.

But this is not the only factor influencing the choice. The parameters of the pumping equipment that is planned to be installed are taken into account. On average, to pump 4 cubic meters of water, you will need a pump with a body diameter of about 8 cm. There must be a margin of 5 mm on each side.

This is the distance from the pump to the inner surface of the casing. Therefore, in this case, 2 times 5 mm must be added to 80 mm. It turns out that for the implementation of the task, a casing pipe with a diameter of 100 mm is required.

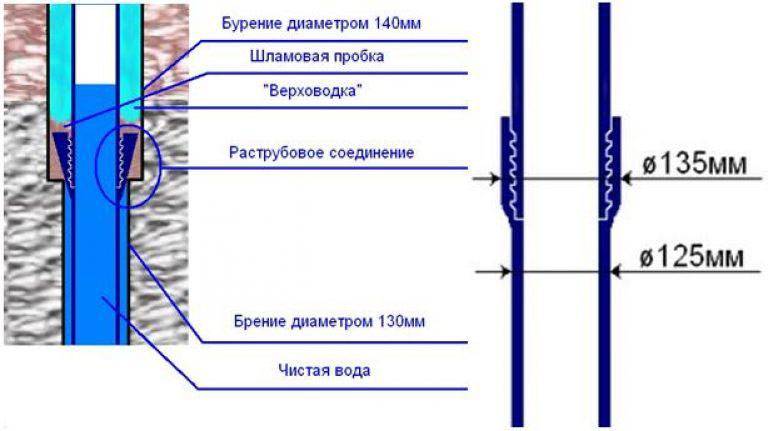

Casing connection methods

Often, casing pipes consist of segments that are interconnected in one of the three indicated ways.

- Welding.

- Fittings, thread.

- Trumpet.

In order to find out which connection method is better, let's remember what the main function of the casing is. That's right, sealing. Therefore, threading is the best connection method. When welding, everything depends mainly on the work of the welder, but there will be many seams, which means that there is a high probability that at least one of them will be of poor quality. Moreover, welds are a kind of catalyst for the appearance of rust, so the life of the structure is reduced.When the tightness of the weld is broken, the pipe may move, as a result of which earth may enter the column and block access to the submersible pump.

Threaded connection

The socket is not reliable from a physical point of view, because when installing pipes, you will not be able to control the process, and subsidence can occur after a few years of operation.

Types of casing pipes for a well

The specific type of casing communications is selected individually, for each specific section, the following is taken into account:

- well depth,

- ground structure,

- cost of consumables.

It is not always possible to make the bypass pipe one-piece - very often several sections have to be joined together. Experts recommend using threaded well pipes. Thanks to the threaded connection, the sections are securely fixed to each other. The use of butt or coupling joints is highly undesirable, since soil can penetrate into the pipe through the joints and the submersible pump may fail.

Steel pipe for a well

Steel pipes have been used in well drilling for a long time. They are known for their reliability and durability. A steel pipe with a wall thickness of about 5 mm can last more than 40 years without any complaints. In some cases, well drilling is only possible using steel products.

The disadvantages of steel casing pipes should also be noted. The metal is constantly in contact with water, which leads to its gradual corrosion. As a result of this natural process, the incoming water may contain rust impurities. Although, in principle, this problem is solved by installing a water filter. Another disadvantage is the high cost.This is especially noticeable in recent years, due to the rise in price of metal products.

Asbestos-cement casing pipes

Asbestos cement pipes are also very common for well construction. Their popularity is due to their low cost and availability. The service life of such pipes is more than 60 years.

In fairness, the disadvantages of asbestos-cement pipes should also be listed. First of all, it is a lot of weight and thick walls. For the installation of such pipes, it is necessary to use larger diameter drills and lifting equipment. This leads to an increase in the cost of the well. Also, the installation of such products should be carried out by organizations specializing in this, since the joining of pipe sections to each other has a number of features.

During installation, it is necessary to exclude the possibility of gaps in the joints. Not all specialists can perform such work with high quality, because the design has butt joints. Some sources contain information that asbestos fibers contain a dangerous element - chrysotile, which over time can lead to a deterioration in the health of people using water from such a well. However, the effect of asbestos-cement products on humans has not been fully elucidated.

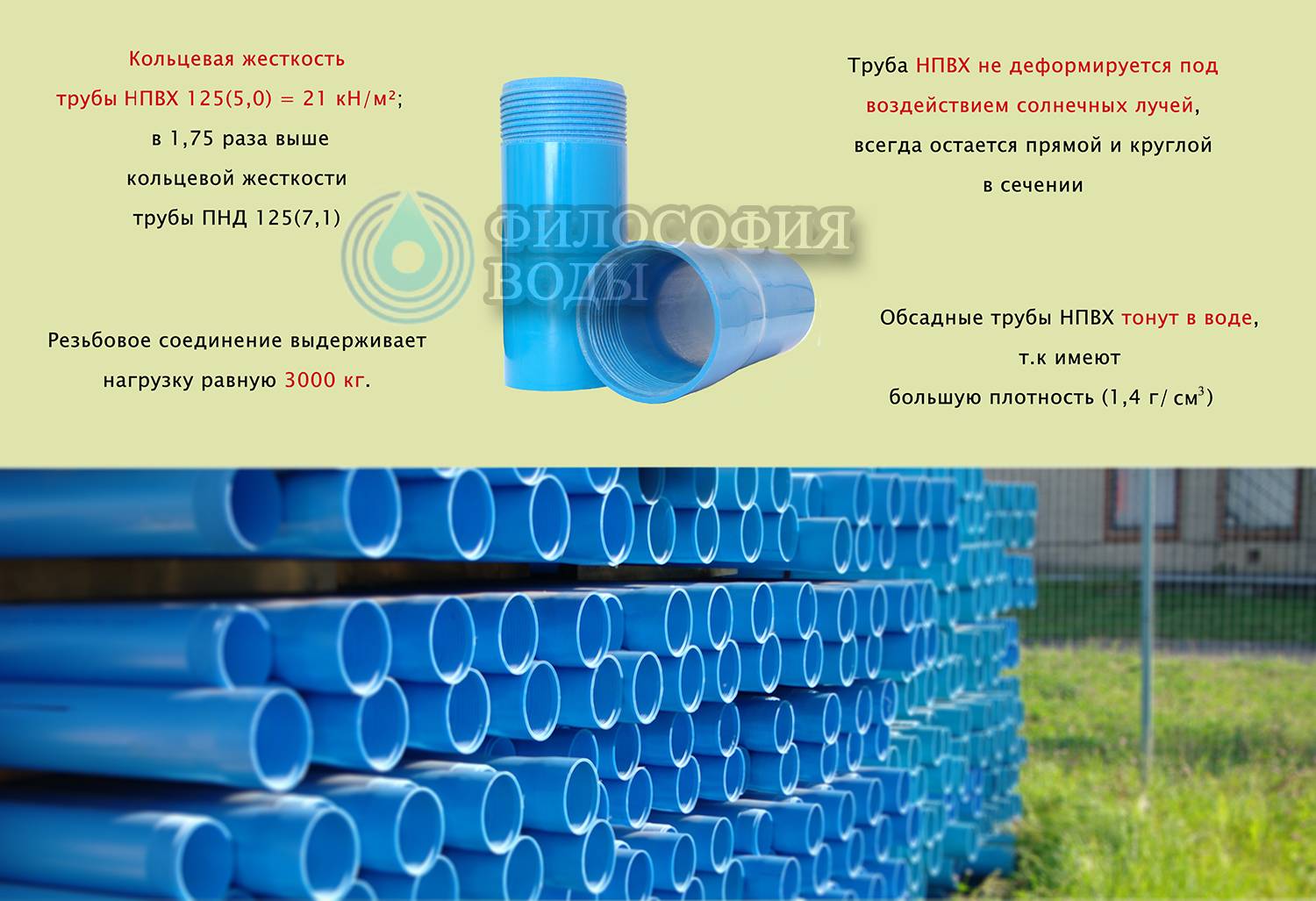

Plastic casing products

The most modern material for wells is plastic. Plastic pipes for a well are lightweight compared to steel or asbestos-cement pipes. In addition, the price for them is not so inaccessible compared to metal. Simple installation and high tightness of connections allow us to conclude that plastic pipes are now the main material used for drilling wells.

A polyethylene pipe for a well can be operated for more than 50 years. Plastic is resistant to corrosion and is neutral when interacting with aggressive chemicals. Deposits do not form on the walls of plastic pipes, and repair of plastic products is an extremely rare need.

PVC pipes for wells can be of two main types:

- uPVC,

- HDPE.

Plastic pipes for HDPE wells are low-pressure polyethylene products. They are easy to install and environmentally friendly. Like all plastic pipes, they are not afraid of internal deposits, they are able to bend if necessary, taking a given shape.

Therefore, builders try not to install HDPE pipes in wells, recommending the installation of PVC-U pipes. Although HDPE products are quite suitable for laying sewers, gas pipelines and water pipes. HDPE pipes do not have a threaded connection, but are joined together by a flange or coupling connection.

Pipes plastic UPVC are made of unplasticized PVC. The material is highly durable. In terms of strength, PVC-U pipes can be compared with their steel counterparts.

UPVC products have a higher allowable stress, yield strength and density compared to HDPE.

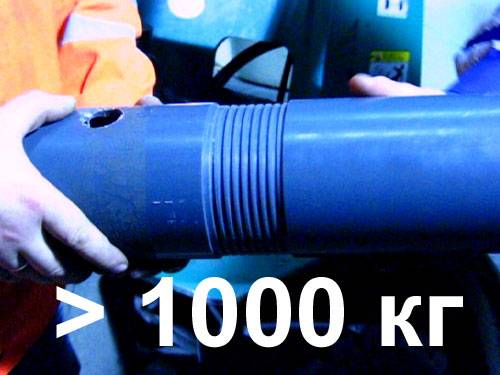

For example, a PVC-U pipe with a diameter of 125 mm, being immersed to a depth of 30 meters, is able to withstand a load of more than 5 tons. Such products can be installed in almost any soil. PVC-U pipes differ from HDPE pipes by the presence of a threaded connection.

Only after carefully studying the types of casing pipes, make a decision on the choice of a particular material.

Consider your abilities and needs

General points to be considered

The market offers a variety of pipes made of three types of material:

- become;

- asbestos cement;

- plastic.

But among them it is difficult to find a universal option that is suitable for any well.

The conditions under which drilling will be carried out vary, so for each specific situation, you need to look for the best option. When choosing which pipe to use for a well, a number of factors should be taken into account:

- drilling depth;

- drilling technology;

- well diameter;

- soil structure.

The fact is that the soil is heterogeneous and has some mobility, so the casing pipes experience significant loads from the outside and inside.

That is why it is very important to decide from which aquifer it is supposed to extract water. The possibility of sewage penetration into the pipe and the level of the upstream water carriers should also be assessed.

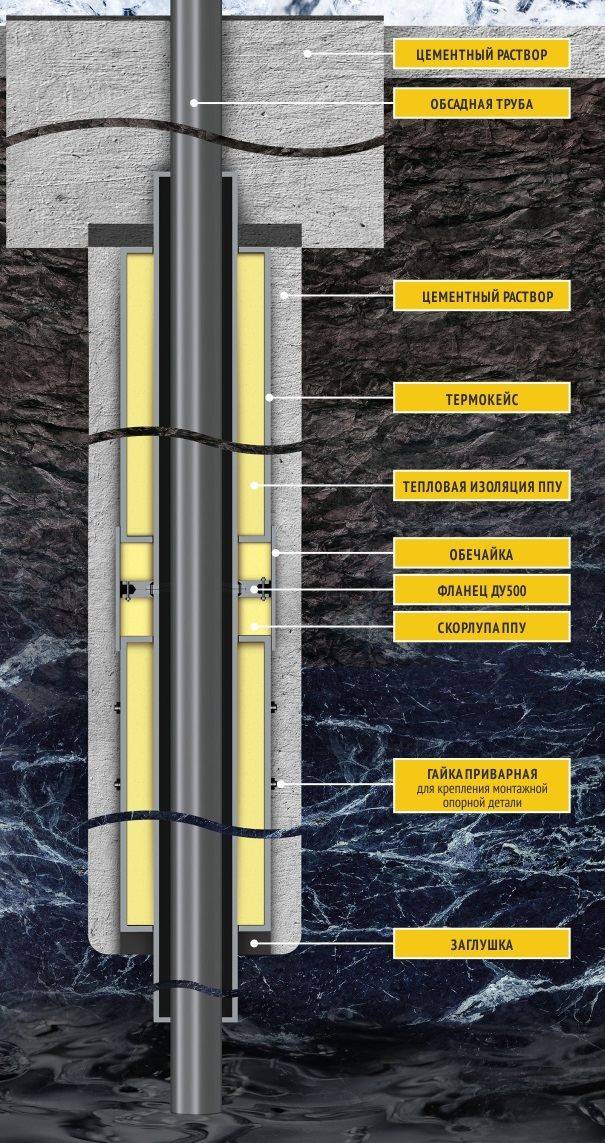

Fixing wells with pipes

Casing pipes are special pipes manufactured in industry with a clear purpose of its use, which is to prevent collapse of insufficiently stable rocks in the walls of various wells.

So, in order to fix the well with the help of columns, casing pipes are immersed in the well, after which the annulus is cemented.

Due to the presence of casing pipes in the well, the well is completely protected from complex stresses, namely:

- External pressure, which is formed by rocks;

- Internal pressure resulting from the flow of working agents through the pipes;

- Longitudinal stretching;

- Bending that may occur under its own weight;

- Thermal elongation, the probability of which in some cases is very high.

All this is tested by pipes, thereby protecting the well and ensuring its integrity.

Before the casing pipes are driven inside the well, the internal diameter of the well is determined using a caliper, and the volume of cement slurry required for cementing the annulus is calculated.

This process is mandatory, since it is thanks to the quality of the cement slurry and its pouring that success in mining will be determined. After all, cement mortar not only provides complete tightness of the well, but also is an excellent protection for pipes from exposure to aggressive environments, such as salt solutions and groundwater. When the process of casing the well with pipes is completely completed, the well is left to "rest" for a period of 16 to 24 hours. This is done so that the cement is completely frozen. However, the rate of setting of the solution can be controlled by applying various chemicals. So, the hardening time can either be increased or decreased.

Also, a very important point is the fact that during the preparation of cement mortar for fixing wells, pipes do not use fresh water. This is due to the fact that cement on fresh water does not provide proper sealing of the well due to the formation of a loose boundary layer. The reason for the formation of such a layer is the interaction of excess fresh water in solution with rocks. A much higher quality of the interaction of cement with clay, for example, is provided by a saturated aqueous salt solution.

During the casing of the wellbore with pipes, a sufficiently concentrated solution of sodium chloride is used to flush the wells before cementing, as well as during the displacement of cement. In the latter case, for the correct distribution of cement in the annulus, the velocity of the supplied saturated salt solution must be at least 1.2 m/s.

Well before operation. Trial

The casing of the wellbore is considered completed only after the well test, which involves two stages.

The first stage is carried out immediately after the cement mortar has hardened. If the well is not deep, then the string is tested at a pressure 2-3 times greater than the pressure that the working agent has directly during development. The strength test of deep wells is carried out at a pressure of 600-1000 MPa.

The second stage of testing oil wells in the pipe and under the casing string after the cement shoe is drilled out. In this case, the optimal pressure for testing is one that is equal to twice the pressure of the working agent.

Carrying out all the necessary tests allows you to determine in time the presence or absence of damage and all sorts of malfunctions that could harm the well, and eliminate them in time.

Thus, a well, formed with all the subtleties, is a durable and strong tool for oil production.

Steel casing pipes

Black steel casing pipes have earned a positive reputation through the test of time.They are durable, not subject to corrosion, so they do an excellent job with any depth of the well. They can be used both when drilling sand wells to a depth of more than 20 m, and when drilling artesian wells.

Of course, such pipes are not protected from rust for the entire service life. But it will not appear immediately, but in 20-30 years, and then in such quantity that any filter can easily filter it out.

If you will use black steel casing, the recommended diameter is 133 or 152 mm (depending on the diameter of the pump used and the complexity of the well design) with a wall thickness of 6 mm.

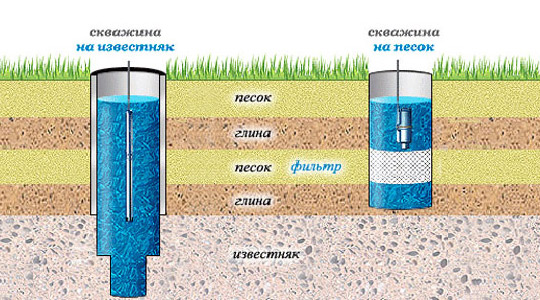

Application for water wells

When drilling water wells, three types of casing pipes are used: plastic, steel and asbestos-cement. In order to save money and simplify installation, it is recommended to use a plastic casing (PVC or PVC-U).

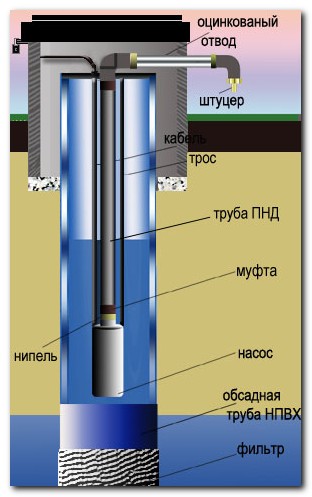

Installation of a casing pipe is carried out when arranging water wells to any depth. Casing immersion is performed upon completion of cavity drilling. Compound pipes are used, joined by means of a threaded connection.

The diameter of the casing pipe and the well itself is selected based on the required productivity of the source. The cross section of the casing must be such that it can accommodate a drainage pump. The lower sections of the casing string are made of perforated products, the openings of which are blocked by a mesh filter.

There is a lot of controversy about which pipes for casing water wells are better to use - steel, asbestos-cement or plastic.The key disadvantage of metal products is the tendency to corrosion, which can cause a characteristic taste of rust and the presence of sediment in the water, for the purification of which you will have to buy expensive filtering equipment, and the iron products themselves are much more expensive than their counterparts.

Asbestos cement casing pipes are a budget solution, the disadvantages of which are a large wall thickness, which reduces the useful volume of the well, as well as dubious sanitary suitability (there are studies indicating that asbestos cement is a carcinogen).

In general, asbestos-cement products can be used for casing wells under the following conditions:

- when arranging an artesian well (such a pipe cannot have perforations, which makes it impossible to equip a filter column in sand wells);

- in the presence of a hygienic certificate for the product.

In terms of performance, plastic casing is best suited for water wells. Such products are easy to install, cheap, resistant to corrosion and durable (service life up to 50 years).

Plastic casing for water wells

For the manufacture of plastic casing pipes, four types of materials can be used:

- PVC - polyvinyl chloride;

- nPVC is an unplasticized variety of polyvinyl chloride;

- HDPE - low pressure polyethylene;

- PP - polypropylene.

The most popular are products made of PVC-U. Unlike standard PVC products, PVC-U pipes are classified as pressure pipes - they have greater mechanical strength and resistance to deformation, which allows them to be used in wells up to 300 m deep.

PVC and UPVC plastic casing pipes for water wells are produced in the following sizes:

- Diameter 90 mm, wall thickness 5 mm;

- DU 110, thickness 6.3 mm;

- DU 125, thickness 7.6 mm;

- DN 140, thickness 10 mm;

- DU 165, thickness 12 mm.

Most often, pipes with a diameter of 90 and 125 mm are used, since most modern borehole pumps are produced for this size.

Pipe sections (length 3-12 meters), depending on the design features, can be joined into the casing in two ways - using a thread or a socket. The threaded connection, which is easy to assemble with your own hands, provides the greatest reliability and tightness of the casing, however, threaded products are more expensive than analogues with a socket.

The leading domestic manufacturer of PVC and PVC-U polymer casing pipes is Cormell, which supplies the market with products of all common sizes. In addition to the Cormell company, the products of the SPT, Bix and Omega companies have also proven themselves well.

Types of materials and their characteristics

Metal casing pipes

Structures based on metal columns are the most reliable and have been proven over many years of use. Steel pipes with a diameter of 133-159 mm are installed in individual wells, but the wall thickness can be different

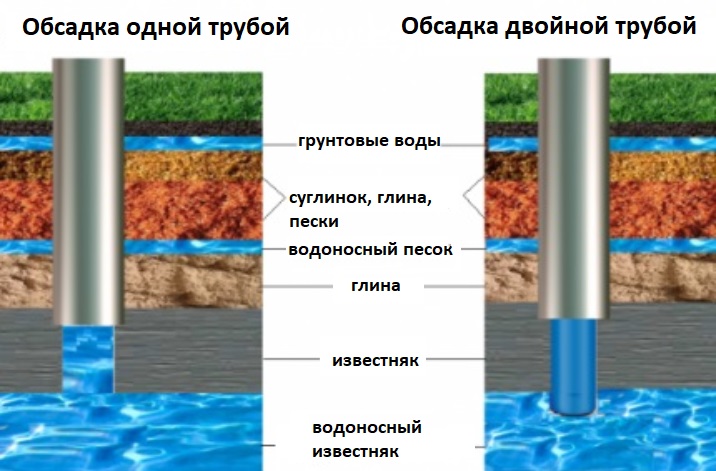

When choosing a drilling company and design, it is important to pay close attention to this. For the well to work for more than 50 years, the pipe wall thickness must be at least 4.5 mm - photo 1

Polymer pipes

Disadvantages of PVC pipes:

- Soil movements and interlayer pressure lead to column flattening, wells fail and cannot be repaired;

- The thread does not withstand the load and, when twisted, cracks in the intra-threaded connection. And such a connection becomes not hermetic;

- Unplasticized polyvinyl chloride tends to dry out and crack over time, so there is no need to talk about reliability and durability;

- The caisson is attached to the PVC-U casing through a clamping sleeve, so the caisson often jumps off, which complicates the installation work.

The advantage of PVC-U pipes is only one - the pipes do not corrode.

HDPE pipes - low pressure polyethylene.

The HDPE pipe is less durable, it is installed with an additional inner pipe in a two-pipe design (metal + HDPE or PVC-U + HDPE).

Rolled steel casing pipes

Advantages of rolled steel pipes:

- Structural strength (suitable for shallow and deep wells);

- Reliable assembly among themselves;

- Steel, when in contact with water, does not emit harmful elements;

- High maintainability – high strength allows cleaning and re-drilling.

Galvanized casing pipes

In contact with water and soil, the pipe walls are more resistant to corrosion. Galvanized pipes can be installed in a well for individual water supply. But such pipes are used less frequently than steel pipes due to the difference in price.

A stainless steel pipe is similar in merits to a pipe made of rolled steel, but has a very high cost. Stainless steel does not corrode and therefore lasts a very long time. There is almost no demand due to the high price.

Definition and purpose of the casing

Let's look at what a well casing is.This is a pipeline assembled vertically from pipes, where all the elements are hermetically connected, and each of them has a reinforced casing.

Casing:

- Ensure the integrity of the water intake pit.

- They protect the source from shifts in soil layers, rock falls.

- Do not allow dirty groundwater to seep inside.

- Provide water intake from clean aquifers.

- Protects the pump installed inside, cable and transfer hose.

- They do not allow the natural pressure of the soil to "seal" the well.

The pipe for the well can be made from various types of materials. In any case, all elements must be connected during installation into a single integral hermetic structure.

Conclusions and useful video on the topic

Comparison of the quality of a threaded connection on PVC-U pipes:

Overview of steel pipes with welded and threaded connections:

Checking the strength characteristics of metal and plastic pipes:

From the foregoing, the conclusion suggests itself: for a year-round home, where a well is the only permanent source of drinking water, it is important to ensure the stability and reliability of the water system. The best option is a two-pipe column made of steel and plastic

The polymer is suitable for a shallow mine when arranging a "seasonal" well

The best option is a two-pipe column made of steel and plastic. The polymer is suitable for a shallow mine when arranging a "seasonal" well.

Are you looking for a suitable pipe option for arranging a well? Or have you already made your choice? Please leave comments on the article and ask your questions. The feedback form is located below.