- Specifics of submersible pumping equipment

- Vibration pump + well: yes or no?

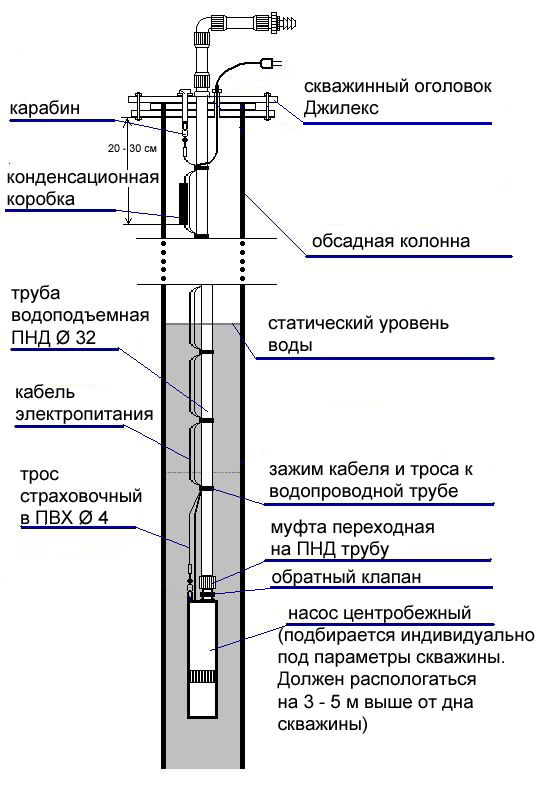

- Guidelines for choosing a centrifugal pump

- A few words about popular models

- Benefits of using asbestos cement

- Installation work

- Repair of asbestos-cement pipes

- Types of casing pipes for water wells

- Steel

- Plastic

- asbestos cement

- Installation of casing bored piles

- well drilling

- Types of casing pipes for a well

- Plastic casing products

- Advantages and disadvantages of asbestos pipes

Specifics of submersible pumping equipment

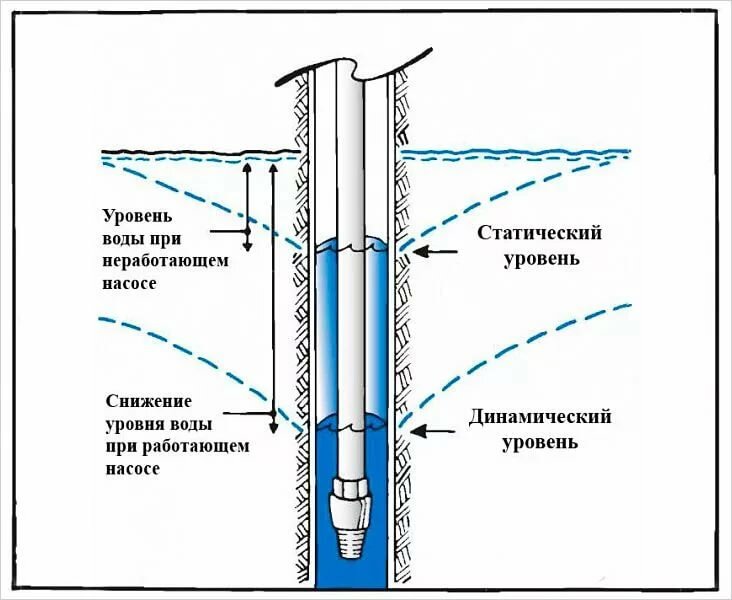

According to the type of device, centrifugal and vibration pumps are distinguished. In the first, a rotating disk with blades is used to supply water, and in the second, a special membrane that transfers water with the help of numerous vibrations. These design features are important because they affect well integrity in different ways.

Vibration pump + well: yes or no?

Is it possible to install a vibration pump in the well? These models are relatively inexpensive, easy to operate, and have performance that is suitable for a significant number of wells.

Many experts categorically object to the use of any vibration technique in the well shaft.However, owner reviews report that pumps of this type are used quite successfully without any damage to the structure. So, which pump - vibration or centrifugal - is better for a well?

The objections of experts are well founded. Prolonged vibration exposure almost always negatively affects the state of surrounding objects. The well is no exception.

Vibrations from a pump located next to the filter affect on the condition of the casing and the surrounding soil, which are gradually destroyed. Vibration can cause a significant acceleration of the processes of silting and sanding.

But it doesn't happen right away. Typically, wells successfully resist vibration for some time. Therefore, with the help of such a pump, it is possible to pump the well, and clean it, and successfully operate it without visible damage.

But destruction from vibration still occurs, although not too quickly. The constant use of a vibration pump can significantly reduce the life of the structure.

If necessary, the use of vibration models is quite acceptable, but only as a temporary option. But at the first opportunity, such a pump should be replaced with a safer centrifugal device.

Guidelines for choosing a centrifugal pump

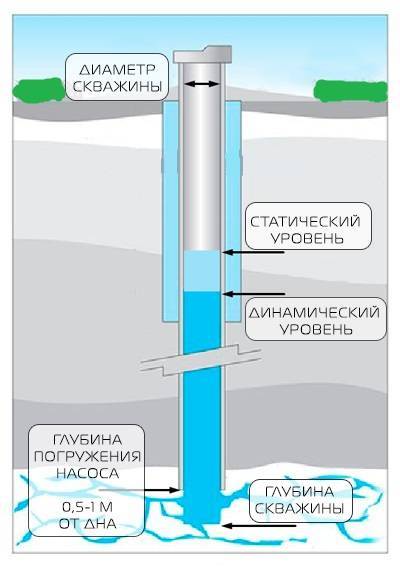

To do this, you need to carefully study the technical passport of the centrifugal device and find out several important points:

- what is the performance of the pump;

- whether its dimensions are suitable for the well;

- from what depth can he raise water;

- what are the features of its installation and operation;

- how and under what conditions warranty service is carried out, etc.

Usually consultants give quite professional recommendations when choosing such equipment. It should be remembered that many manufacturers indicate limiting rather than average characteristics for pumps, so you need to take into account some margin of operational life.

Directly in the marking of a domestic pump or in the technical passport of a foreign one, two numbers that are important for choosing are indicated. The first (in example 55) is the flow in l/min, the second (75) is the maximum head in meters

A few words about popular models

If the decision is made to use a vibration pump, most likely, “Kid” or “Brook” will be bought. These models are distinguished by good performance, resistance to breakdowns and quite affordable price.

They are easy to clean or repair with your own hands. But for permanent use, vibration technology is not suitable, it must be replaced as soon as possible.

Vibration pump "Kid" is a popular, but not very suitable choice for a well, since the vibrations of the device can cause its destruction

Among the popular brands of submersible centrifugal pumps, it is worth noting "Aquarius" and "Vodomet". They are very similar, but according to user reviews, Aquarius noticeably wins in quality and durability, although it costs more.

However, the Water Cannon also has its adherents. If you are lucky enough to get a well-assembled model, it will show quite decent results.

Submersible centrifugal pumps of the Aquarius brand have established themselves as reliable and durable equipment for the well, capable of coping with increased loads

Special well pumps will cost a substantial amount, but such costs will fully justify themselves over time.As an example of such a technique, it is worth noting the 3STM2 and 4STM2 models manufactured by TAIFU.

Benefits of using asbestos cement

Asbestos-cement products are gradually going out of fashion. The reasons why they are gradually being squeezed out of the market can be reduced to four main ones:

- Brittleness and tendency to delamination.

- They do not provide resistance to sand, so it is advisable to exclude their use in the presence of sandy impurities in the water.

- Pretty significant weight.

- Distrust of asbestos as a material with a poor environmental reputation. Although the threat comes only from the dust of exclusively amphibole asbestos.

There are many advantages to choosing an asbestos-cement pipe when arranging a well. These include:

- low cost;

- resistance to decay and resistance to corrosion. No special groundwater protection required;

- strength;

- low thermal conductivity, which makes it possible to refuse insulation;

- non-susceptibility to temperature changes, frost resistance;

- small, compared with metal structures, weight;

- durability of operation.

Casing of a well or well can also be done with asbestos-cement pipes

Casing of a well or well can also be done with asbestos-cement pipes

Asbestos-cement products during installation can only be connected by couplings, while each link is fastened as firmly as possible. Even having doubts about the environmental safety of asbestos cement, it is quite acceptable that it is used for irrigation and melioration. As the best option, asbestos cement is used when drilling in limestone soils.

Installation work

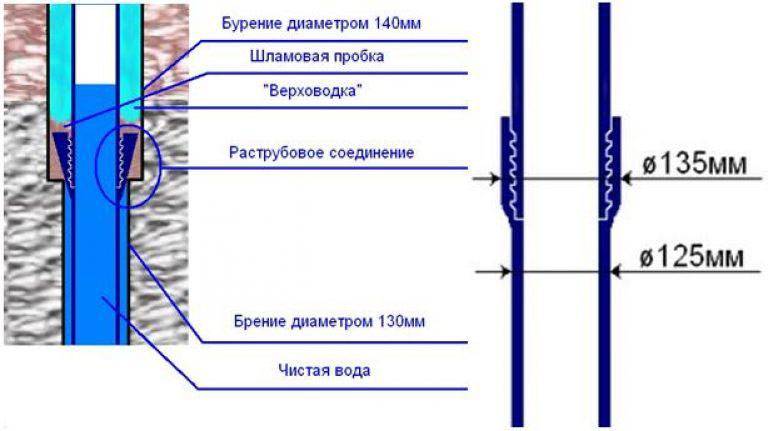

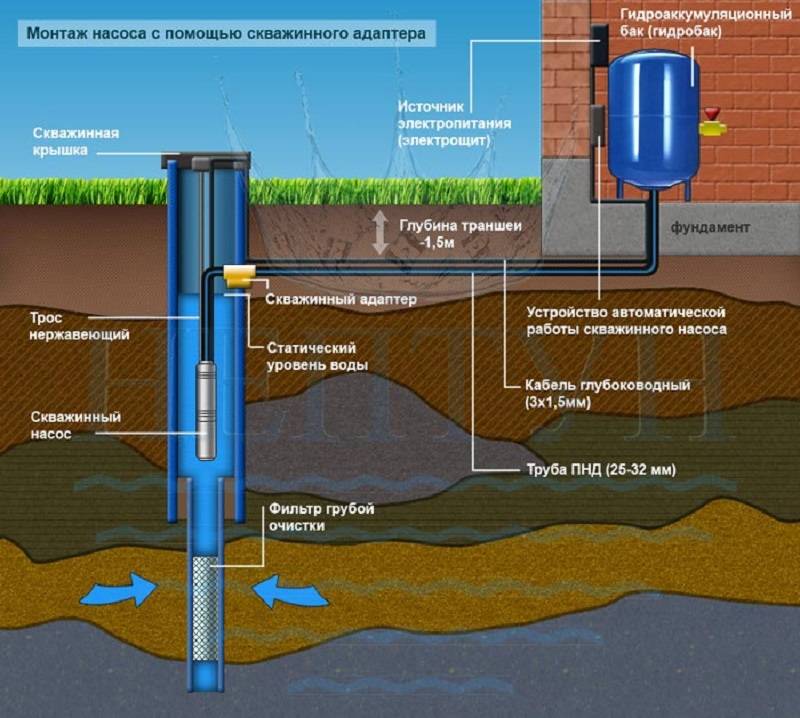

During the installation of the well, the soil is drilled with a drill, with a diameter smaller than that of the casing. Periodically, the drill is taken out to the surface for cleaning from the soil. At a depth of two meters, they begin to lower the casing.A well is drilled with casing until water appears. The pipe, if necessary, is increased in a convenient way.

The casing pipe in its composition has such elements as:

1. The first cleaning filter in the form of a stainless mesh or wire.

2.Filter at the bottom of the gravel, protects the water from dirt particles that are at the bottom of the structure.

3.head outside to protect against dirt from the street. If you ensure a tight connection of the head, there will be a guarantee of creating a negative pressure, which contributes to the flow of water. Sometimes the head is cemented to give tightness.

Repair of asbestos-cement pipes

In principle, their technology is exactly the same as that of cast-iron counterparts. The easiest option is to apply a rubber band, which is secured with wire or clamps. You can also use a bandage soaked in a cement mixture for this. True, you have to wait until the lining dries.

If the place of the defect is responsible or the material moves under pressure inside the pipeline, then the best option is to dismantle part of the pipeline and install a new section. Fortunately, asbestos-cement pipes are easy to process. You can cut them, for example, with an ordinary hacksaw for metal.

As you can see, asbestos-cement pipes have not yet lost their positions. This is especially true in areas where stringent fire safety requirements must be taken into account. We add that these products are by far the cheapest option with decent technical characteristics.

Scopes of asbestos-cement pipes, novelties with high operational characteristics. Video:

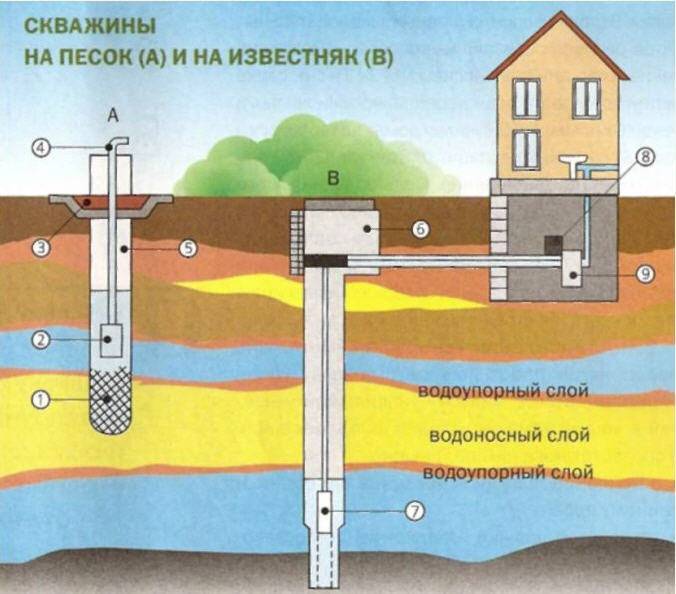

Types of casing pipes for water wells

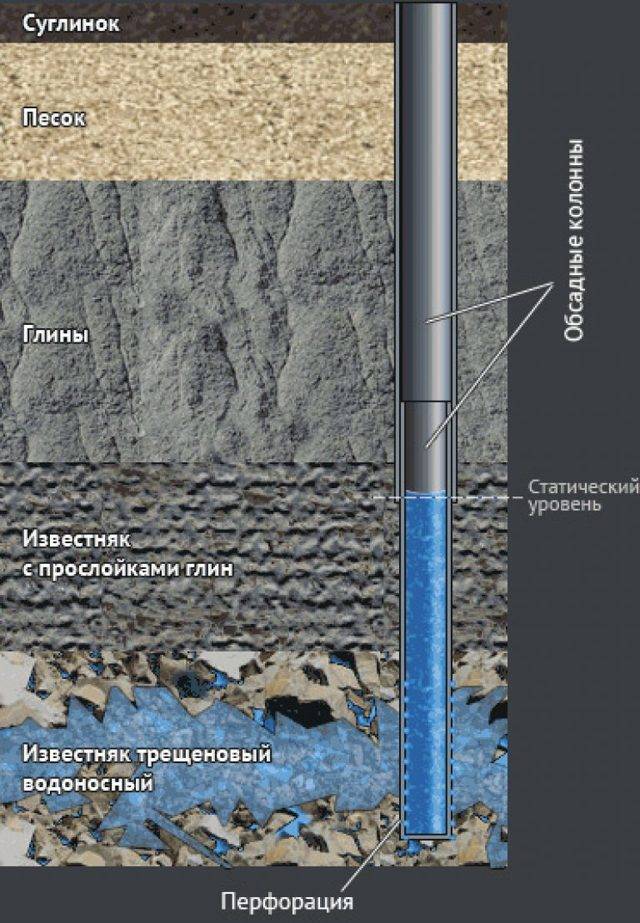

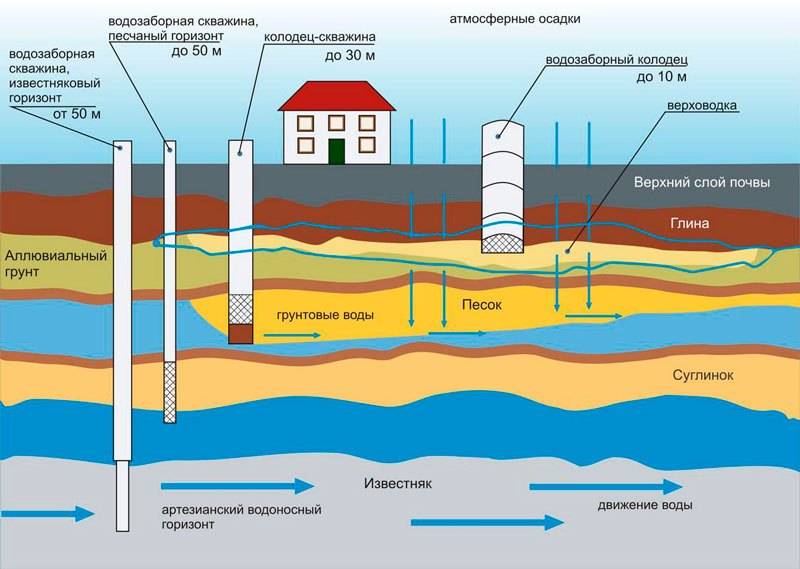

Today, the following raw materials serve as the material for the production of casing: metal, plastic, asbestos cement. Each has advantages and disadvantages over the others. Detail:

Steel

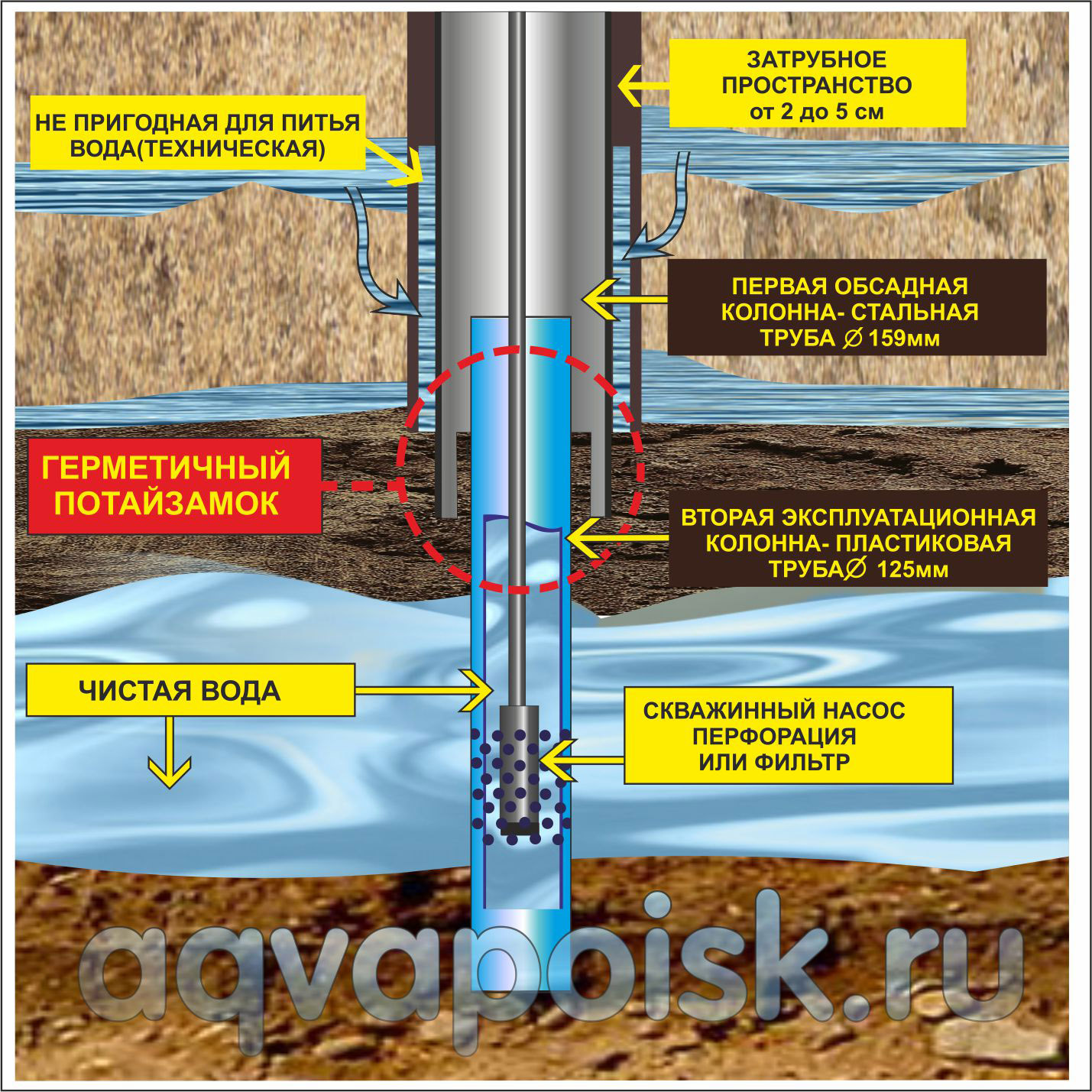

Metal casing pipes are presented in the following options: enamel, galvanized, stainless steel, traditional steel. The unifying advantage is rigidity. Such pipes are not threatened by movements and soil pressure, vibration, therefore, the well will serve the owners for a long time. The manufacturers give a guarantee 50 years. In addition, the depth of the well can be any - in length and diameter. But there are nuances of each type:

- Traditional steel is easily corroded. Flaking metal poses a threat to health and pumping equipment that is not protected by multi-stage filters.

- Enamelled well casing must not be subjected to rough cleaning, chips during installation. This will also lead to rust.

- Galvanizing over time is capable of releasing substances harmful to human health into the water. In addition, it is soft and is able to deform from ground movements.

Stainless steel is expensive. Actually, any metal will cost the owners a round sum, so you need to choose the best one in terms of its qualities.

Nevertheless, owners of deep wells should think about installing metal structures. Having paid once and subjecting the autonomous water supply to regular maintenance, you can not worry about anything.

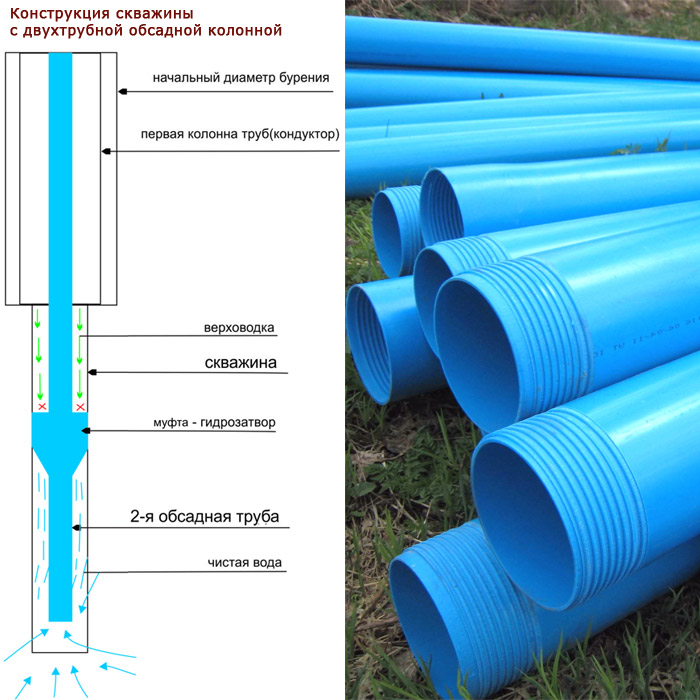

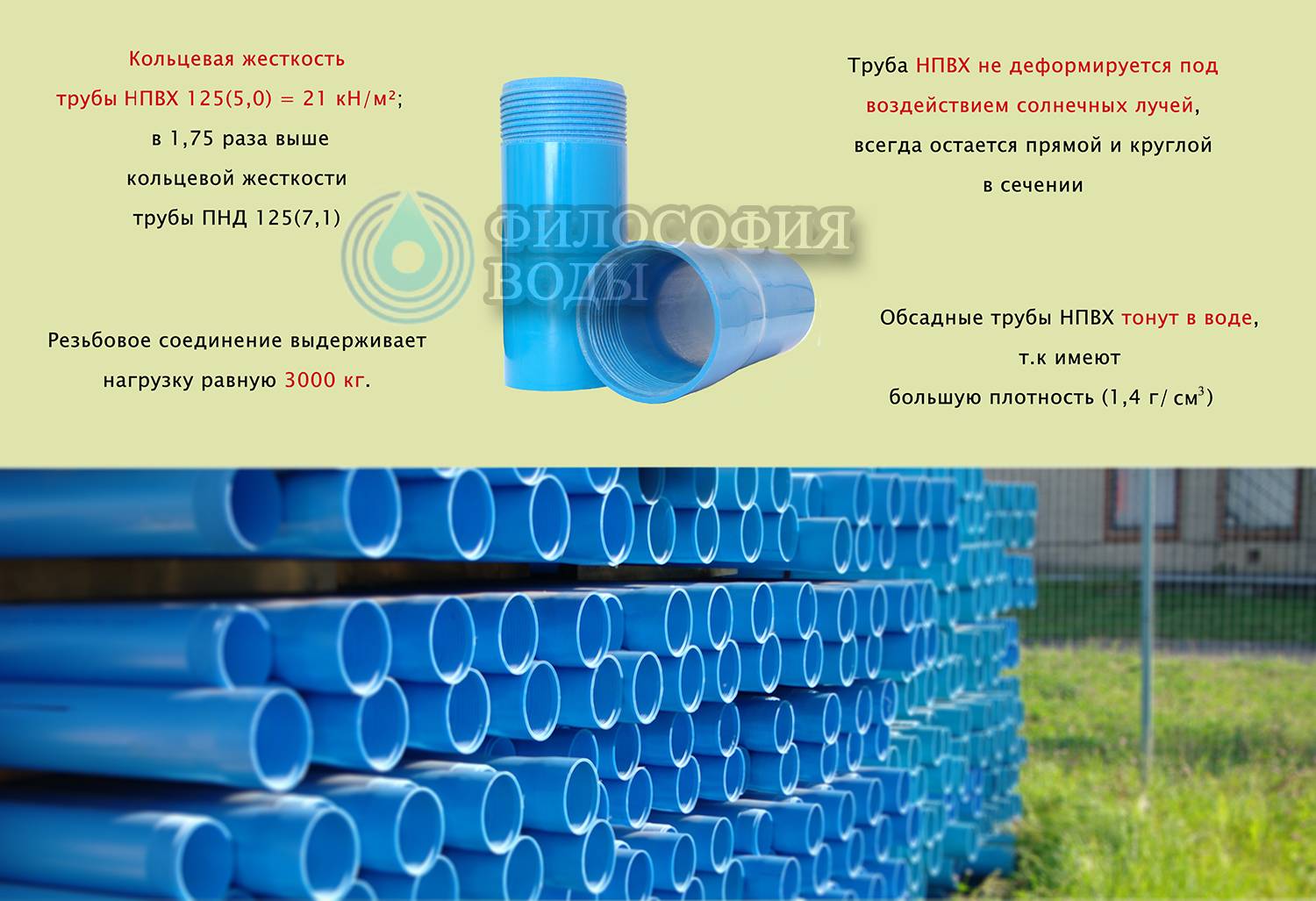

Plastic

All modifications of pipes made of this material - HDPE, PVC, polypropylene - combine several advantages - ease of installation, environmental friendliness, non-corrosion and reasonable price.

However, there are significant disadvantages:

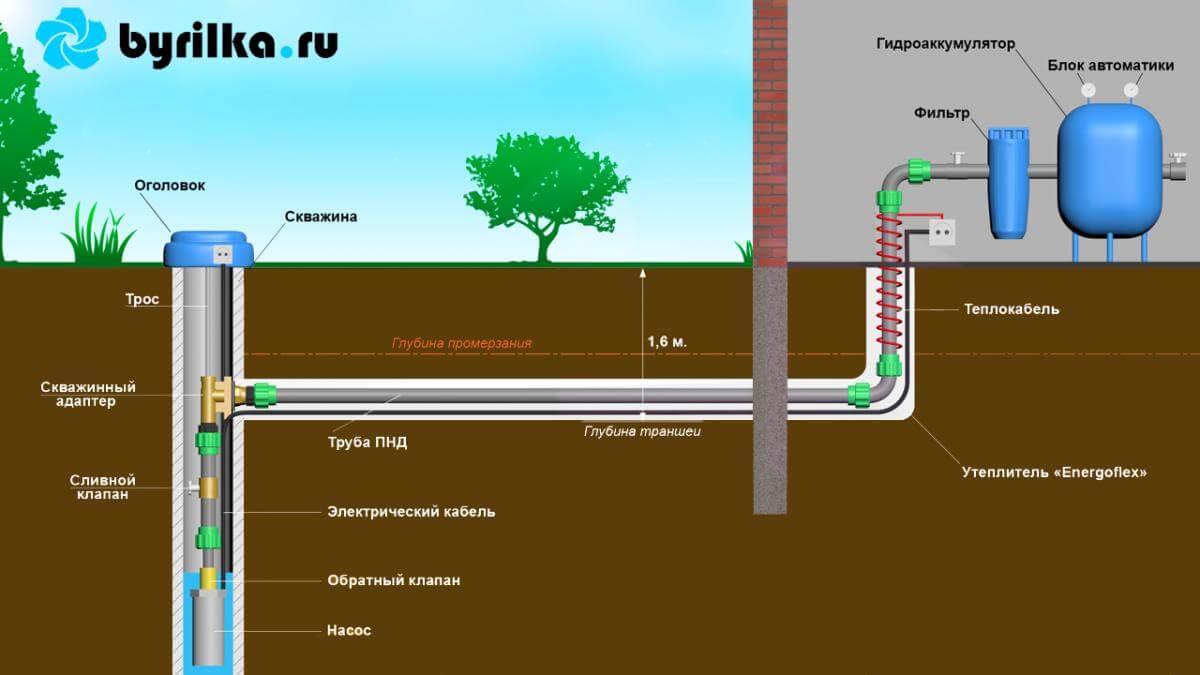

- Plastic casing is powerless against soil movements - it will break.It is also deformed in severe frosts - a heating cable is required.

- Depth for plastic pipes matters - they are usually installed in shallow mines. If, nevertheless, the owners decide to make a casing in a well of considerable depth. That without threaded or coupling connections is indispensable. And they lose their integrity over time. Hence the problems - pollution of drinking water, deformation of the entire casing, destruction of the walls of the mine.

- As a rule, plastic pipe casing is used in tandem with steel pipes. It turns out a double benefit - the strength of the well and the purity of the resource. Naturally, the price goes up.

asbestos cement

Pipes made using concrete pouring technology are classic in their use for wells, septic tanks, wells. They have a large diameter, are resistant to corrosion, and have an unlimited service life. But they lose their popularity due to the fragility of the material. Besides:

- These are rather heavy structures and construction equipment cannot be dispensed with without installing such a casing in a well. Naturally, this will affect the final result of payment.

- Concrete is able to absorb dirt and is not so easy to clean. To do this, you will have to drain the well completely and spend several days on work. All chips and other defects are eliminated immediately.

- Regular preventive maintenance is carried out only by specialists with knowledge of the features of an asbestos-cement pipe. Otherwise, the service life due to inaccurate action is reduced significantly.

- Depending on the wall thickness, asbestos cement pipes can be expensive. Therefore, the price, unlike the cost of the metal, does not always justify the quality of the casing.

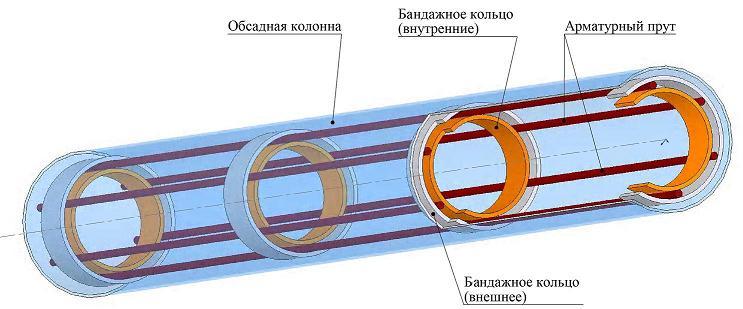

Installation of casing bored piles

Installation and arrangement of the pile foundation is carried out directly on the construction site. In principle, the do-it-yourself installation technology of such a design is quite simple: it is necessary to lower the pipe into the well, reinforce it and concrete it. In length, such structures can be up to thirty meters with a diameter of up to one and a half meters, although with the improvement of technical support, the length can be doubled, and the cross section increased to 3.5 m. With such parameters, the bearing capacity of bored supports will be 500 tons.

In most cases, the structure is buried by 5–12 m with a diameter of 25–40 cm. Do-it-yourself assembly of metal structures is carried out according to the following scheme:

- A well is filled with concrete mortar per meter;

- tamping of the solution is carried out;

- the casing gradually rises to the level when the concrete drops by 35 - 40 cm;

- this process must be repeated until the rod is completely filled with mortar.

The walls of the leader casing wells during drilling, they become rough and loose due to collapsed soil, so a gap is formed between the hole and the metal structure, which is compacted with mortar, and concrete, in turn, seeps into the soil structure and makes it more durable. This technology has one disadvantage, and it is that you cannot control the density of the concrete pour inside the long shaft. This minus can lead to erosion by groundwater of unset areas of the mixture, if such, of course, will be.

The well for the foundation of pipes is reinforced only in the upper part, while the reinforcement cage is buried in fresh concrete by 1.5 - 2 m. Along with the casing, a dry method is also used, suitable for stable and dense soils that withstand the load without destroying the walls. The frame is installed in the well with your own hands, and then the mortar mass is filled. If bored wells are sunk into weak watery soils without casing, then their walls must be reinforced with clay coating, the density of which should be at least 1.2 g / m3.

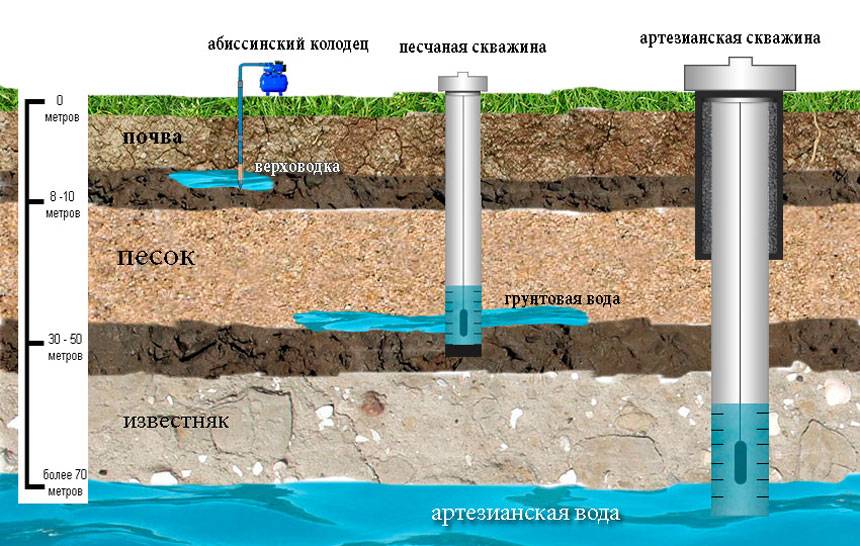

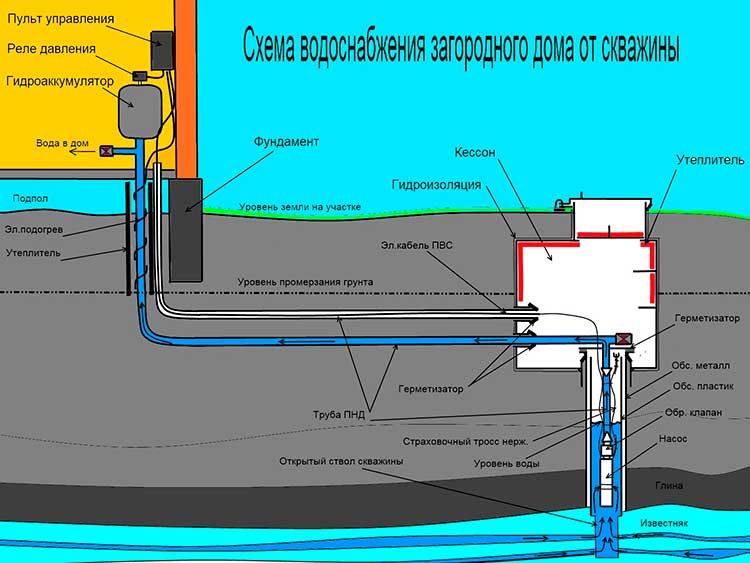

well drilling

When installing a well using steel pipes, driven technology is used, but it is not suitable for arranging a plastic well - the polymer material is not designed for shock loads. Therefore, a plastic conduit is lowered into a pre-prepared well.

Paste a VALID AdSense code in Ads Elite Plugin options before activating it.

At the first stage, a small pit should be dug with a diameter of 1 m and a depth to the freezing point of the soil. Then, in the center of the pit, using an extendable hand drill, a hole is made to the bottom of the sandy aquifer, which is usually located about 6 - 8 meters from the surface.

Since the upper layers of the soil are quite loose rocks, drilling should not be any particular problem.

In the process of work, it is important to monitor the verticality of drilling, so it is better to work with one or two assistants. The filtration section of the Abyssinian well must be located in a sandy aquifer, so the hole for the pipe should be made until the drill rests on dense clay that holds water in the above ground layers

After the hole is made, a plastic pipe with a conical plug is lowered into it. Sections are built up using polymer couplings with rubber seals for sealing, or, if the pipe material allows it, a solder connection is used.

When the filter section enters the aquifer, the well begins to fill with water. After the appearance of water, it is recommended to swing and rinse the well (by installing a check valve and a pump) and leave it alone for a day so that the water is filtered.

You can find advice to spend this day of waiting to concrete the area near the exit of the pipes to the surface, but you should not rush if the well is designed to provide drinking water to the house. After the water is filtered, it is necessary to take a sample and send it to the laboratory for analysis, the results of which will make it clear whether the water after additional purification can be used for drinking, or other technologies will have to be used to raise water from deeper aquifers.

If it is supposed to take water from a street well all year round, it is advisable to insulate the part of the pipe that lies above the freezing point of the soil with a foamed polymer heat insulator. For convenience and aesthetics, the area near the pipe is concreted, decorated, a manual rocking chair and / or a protective “house” for an electric pump are installed.

Video on the topic "Do-it-yourself Abyssinian well from plastic pipes":

People are building houses or acquiring dachas where there is no central water supply yet. But drilling a well or well is an expensive service.There is a way out of this situation: you can make an Abyssinian well by equipping your own water source with everything you need. It is not difficult to create it with your own hands, given the elementary rules and requirements.

Types of casing pipes for a well

The specific type of casing communications is selected individually, for each specific section, the following is taken into account:

- well depth,

- ground structure,

- cost of consumables.

It is not always possible to make the bypass pipe one-piece - very often several sections have to be joined together. Experts recommend using threaded well pipes. Thanks to the threaded connection, the sections are securely fixed to each other. The use of butt or coupling joints is highly undesirable, since soil can penetrate into the pipe through the joints and the submersible pump may fail.

Steel pipe for a well

Steel pipes have been used in well drilling for a long time. They are known for their reliability and durability. A steel pipe with a wall thickness of about 5 mm can last more than 40 years without any complaints. In some cases, well drilling is only possible using steel products.

Steel pipes have been used in well drilling for a long time. They are known for their reliability and durability. A steel pipe with a wall thickness of about 5 mm can last more than 40 years without any complaints. In some cases, well drilling is only possible using steel products.

The disadvantages of steel casing pipes should also be noted. The metal is constantly in contact with water, which leads to its gradual corrosion. As a result this natural process, the incoming water may contain rust impurities. Although, in principle, this problem is solved by installing a water filter. Another disadvantage is the high cost. This is especially noticeable in recent years, due to the rise in price of metal products.

Asbestos-cement casing pipes

Asbestos cement pipes are also very common for well construction. Their popularity is due to their low cost and availability. The service life of such pipes is more than 60 years.

In fairness, the disadvantages of asbestos-cement pipes should also be listed.  First of all, it is a lot of weight and thick walls. For the installation of such pipes, it is necessary to use larger diameter drills and lifting equipment. This leads to an increase in the cost of the well. Also, the installation of such products should be carried out by organizations specializing in this, since the joining of pipe sections to each other has a number of features.

First of all, it is a lot of weight and thick walls. For the installation of such pipes, it is necessary to use larger diameter drills and lifting equipment. This leads to an increase in the cost of the well. Also, the installation of such products should be carried out by organizations specializing in this, since the joining of pipe sections to each other has a number of features.

During installation, it is necessary to exclude the possibility of gaps in the joints. Not all specialists can perform such work with high quality, because the design has butt joints. Some sources contain information that asbestos fibers contain a dangerous element - chrysotile, which over time can lead to a deterioration in the health of people using water from such a well. However, the effect of asbestos-cement products on humans has not been fully elucidated.

Plastic casing products

The most modern material for wells is plastic. Plastic pipes for a well are lightweight compared to steel or asbestos-cement pipes. In addition, the price for them is not so inaccessible compared to metal. Simple installation and high tightness of connections allow us to conclude that plastic pipes are now the main material used for drilling wells.

A polyethylene pipe for a well can be operated for more than 50 years.Plastic is resistant to corrosion and is neutral when interacting with aggressive chemicals. Deposits do not form on the walls of plastic pipes, and repair of plastic products is an extremely rare need.

PVC pipes for wells can be of two main types:

PVC pipes for wells can be of two main types:

- uPVC,

- HDPE.

Plastic pipes for a HDPE well, this is low pressure polyethylene products. They are easy to install and environmentally friendly. Like all plastic pipes, they are not afraid of internal deposits, they are able to bend if necessary, taking a given shape.

Therefore, builders try not to install HDPE pipes in wells, recommending the installation of PVC-U pipes. Although HDPE products are quite suitable for laying sewers, gas pipelines and water pipes. HDPE pipes do not have a threaded connection, but are joined together by a flange or coupling connection.

Pipes plastic UPVC are made of unplasticized PVC. The material is highly durable. In terms of strength, PVC-U pipes can be compared with their steel counterparts.

UPVC products have a higher allowable stress, yield strength and density compared to HDPE.

For example, a PVC-U pipe with a diameter of 125 mm, being immersed to a depth of 30 meters, is able to withstand a load of more than 5 tons. Such products can be installed in almost any soil. PVC-U pipes differ from HDPE pipes by the presence of a threaded connection.

Only after carefully studying the types of casing pipes, make a decision on the choice of a particular material.

Consider your abilities and needs

Advantages and disadvantages of asbestos pipes

Asbestos-cement pipes have a number of advantages.They are fairly easy to mount, are reliable and robust, are not exposed to aggressive environmental influences and can be located deep underground without the need for replacement.

In addition to these properties, they have a relatively long service life than metal pipes. For example, metal products that do not have corrosion resistance need to be repaired for 5-10 years, because formations occur under the influence of corrosion and the inner diameter narrows, which causes a decrease in the pressure of water circulating through pipes, and also reducing the rate of heat.

Periodic cleaning does not solve the issue, because the rust that has accumulated on the walls inside the pipes is not removed and after some time again affects the throughput of the system, reducing the water pressure.

In addition, the inner surface of asbestos pipes is not subject to overgrowth under the influence of water flow, so the initial water pressure is provided for many years.

So, asbestos pipes have the following advantages:

- absolute inertness to the adverse effects of corrosion, including corrosion as a result of stray currents, since asbestos is a dielectric;

- a wide range of various sizes and a relatively low cost;

- resistance to elevated temperatures - products can withstand temperatures up to 2000C;

- slight linear expansion when heated;

- incombustibility, asbestos pipes are fireproof;

- frost resistance, when water passing through pipes freezes, products are not damaged;

- simple machining and easy installation with couplings;

- slight hydraulic resistance due to the smoothness of the inner walls;

- lack of overgrowing, due to which asbestos pipes retain the throughput of the system throughout the entire operation.

However, in addition to all the advantages of asbestos pipes, there are also some disadvantages:

- they are not allowed to be used in systems where there is a temperature above 3000C, under the influence of such a high temperature, the pipes may crack;

- when using asbestos pipes as a chimney that removes combustion products, they are covered with soot from the inside and absorb condensate;

- as a result of the low thermal conductivity of asbestos, a low chimney draft is formed;

- asbestos products are quite fragile, so you should be extremely careful when transporting them, as well as during installation. In addition, measures should be taken to provide additional protection against ground subsidence, which can lead to unwanted fractures;

- asbestos products have low resistance to sand. An excellent option in this case are plastic pipes in comparison with asbestos and ceramic products.