- Features of operation and installation of pellet boilers

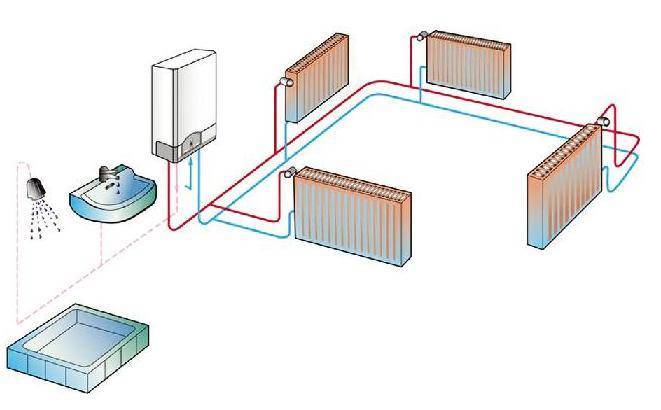

- Single-circuit and double-circuit heating boiler.

- Single-circuit boilers with hot water supply

- What is a heating boiler piping

- What pipe options can be used

- High-quality, but expensive copper products

- Budget steel products

- Durable and lightweight polypropylene piping

- Supply of heating and water pipes

- How and how to seal pipe joints

- Types of seals, sealing methods

- Sealing materials

- Do-it-yourself battery installation recommendations

- Selection of heating pipes

- Metal-plastic pipes

- Polypropylene pipes

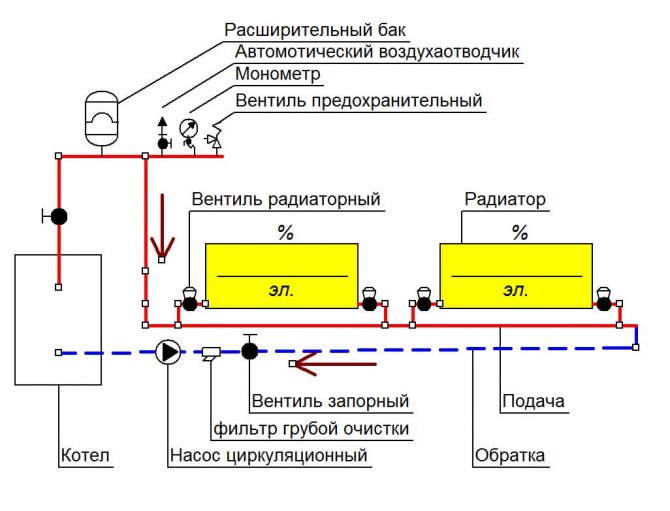

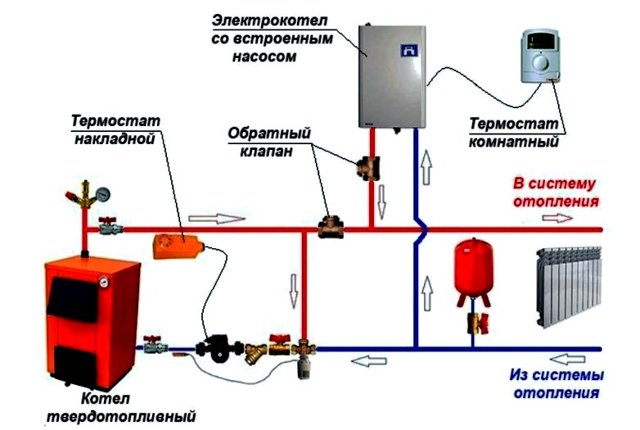

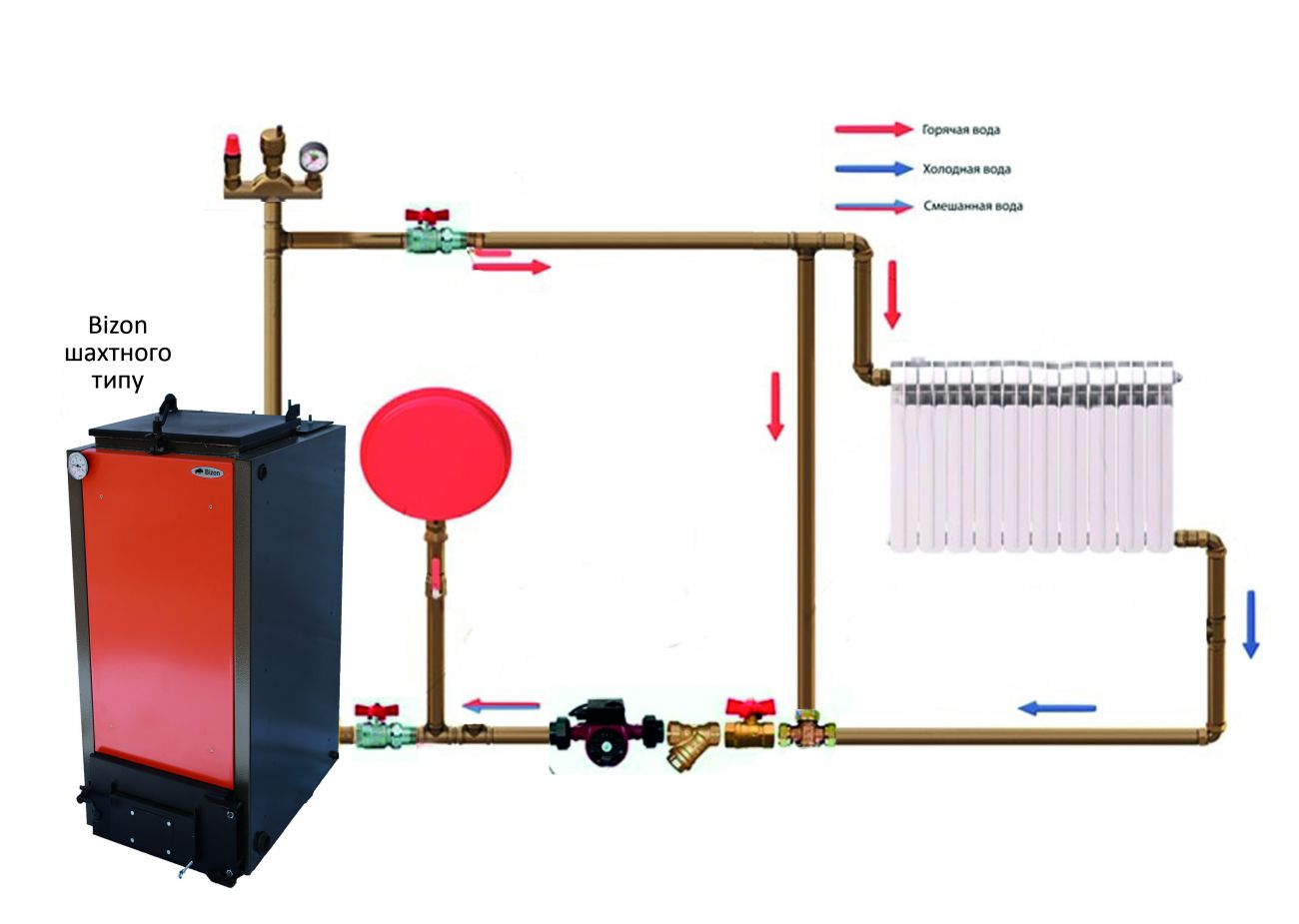

- Nuances and strapping options for different types of boilers

- Gas equipment

- Electric heater

- Solid fuel models

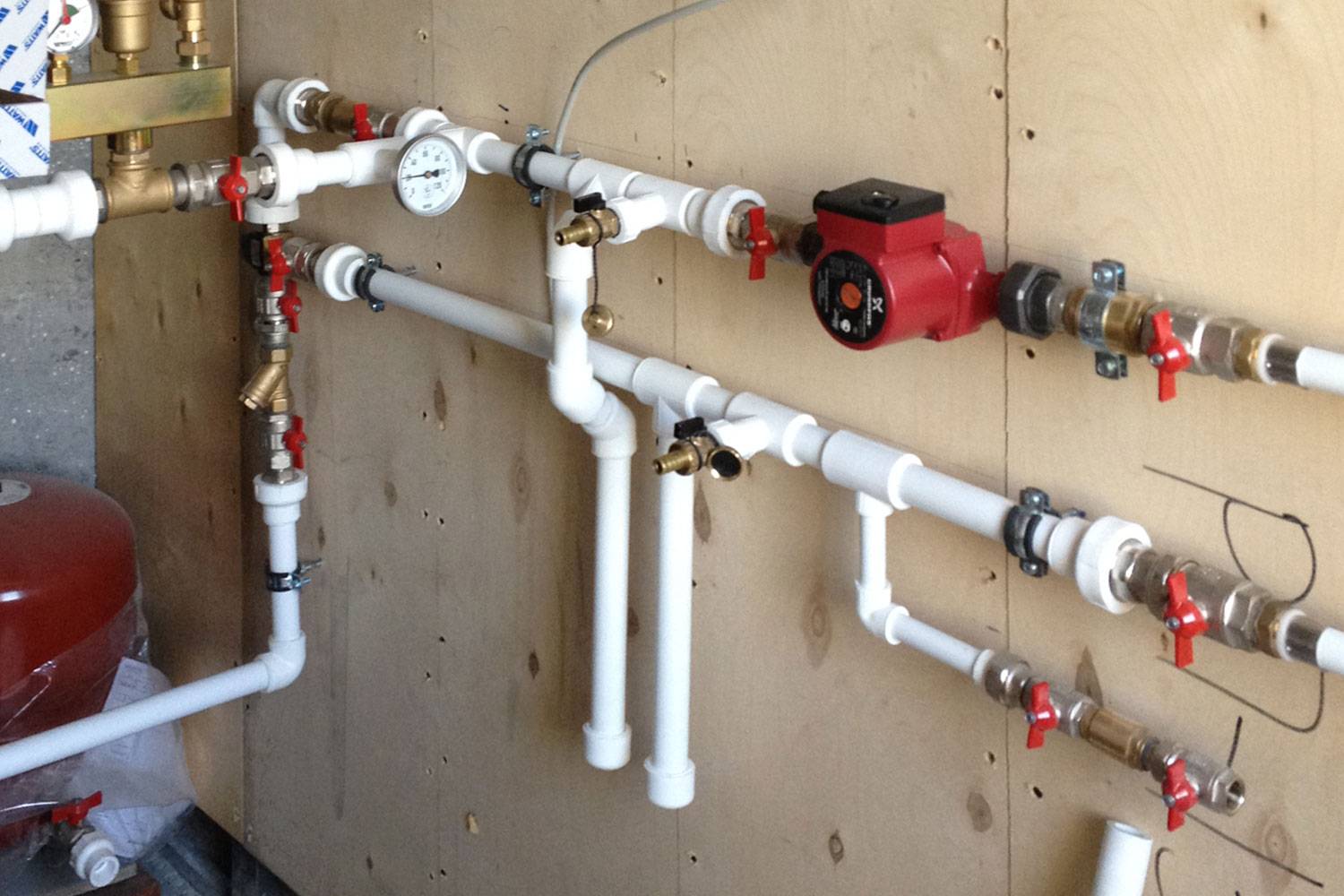

- Heating system from polypropylene pipes

- Single pipe

- Two-pipe

- Collector

Features of operation and installation of pellet boilers

Although pellet boilers are classified as solid fuel equipment, they are an order of magnitude better than traditional units that burn wood or coal, because:

- dry pellets burn, giving off much more heat, which significantly increases the efficiency of the unit;

- in the process of work, a minimum amount of fuel combustion products is produced;

- loading pellets into the bunker is carried out much less frequently than when using firewood or coal.

This effect is achieved due to the special design of the equipment, as well as through the use of highly efficient pyrolysis combustion processes. An important point in the operation of a pellet boiler is the moisture content of the fuel, which should be less than 20%. If this requirement is not met, the capacity of the equipment will subsequently decrease and condensed moisture will enter the system. And this can very soon lead to serious damage to the equipment.

There are combined pellet boilers in which there are two fireboxes: one for burning pellets, the other for conventional solid fuels. The efficiency of such units is somewhat lower than that of boilers that operate only on pellets, and the requirements for installation and piping remain quite high.

During the installation of a pellet boiler, it is necessary to install a bunker, a burner and a screw mechanism for feeding pellets. Often, experts also recommend using a special buffer tank, the volume of which can be 50 liters per kW of pellet boiler power. All this significantly increases the size of the boiler room, in which the installation and piping of the equipment will be carried out.

Single-circuit and double-circuit heating boiler.

A single-circuit boiler has a fairly simple principle of operation. During installation, it is connected to the chimney. For the normal functioning of the system, the presence of ordinary natural draft is sufficient.

Often, single-circuit boilers are installed, which in their design have an open combustion chamber, which requires the creation of certain conditions in the room.

In the process of its operation, the boiler uses the air from the room.That is why it should be installed in a separate room. It should be noted that during the operation of a single-circuit boiler, substances and gases harmful to the human body accumulate, this is the main reason for the need to equip a room with a boiler with a chimney or exhaust hood. If all the above conditions are created, the risk of explosion will be eliminated, and the safe use of the equipment will also be ensured.

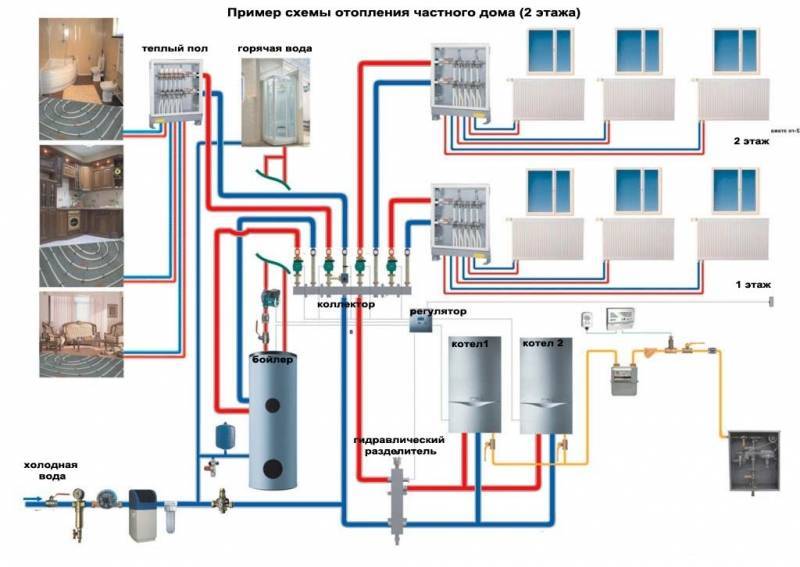

A double-circuit heating boiler differs from a single-circuit analogue in its universal purpose: it maintains the degree mode of the coolant in the heating circuit, and heats water for domestic needs. Single-circuit generators can also indirectly heat water. The process of heat transfer is carried out during the passage of the coolant through the secondary heat exchanger.

The main difference between a double-circuit boiler and a single-circuit boiler is the direct release of thermal energy to water. The main feature is that when hot water is consumed, the coolant is not subject to heating, moreover, the parallel operation of two circuits is excluded. Practice shows that the mode of operation of the boiler is not important for houses with high-quality thermal insulation, it follows that with thermal inertia, the heating scheme will be the same for any type of heating. An impressive volume of hot water can be obtained by combining a single-circuit design and heating columns.

A double-circuit boiler should not be designed in combination with a natural circulation system, since after the heating of the coolant stops, the movement of the liquid quickly stops. The process of secondary heating lasts quite a long time, and the heat in the radiator is distributed unevenly.

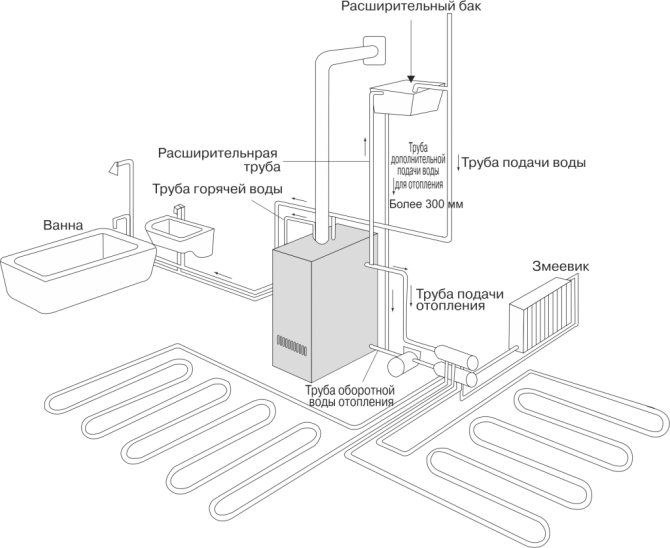

The main advantage of the circuit is the ability to work in natural circulation mode. In this case, the accelerating collector is a pipe through which the coolant moves to the top filling.

Single-circuit boilers with hot water supply

In order to provide hot water, along with a safety group, a pump and an expansion tank, the piping of a single-circuit gas boiler must include an indirect heating boiler. It is possible to connect an indirect heating boiler with recirculation. Water heating in this case is carried out thanks to the coolant from the heating circuit. This leads to the appearance of two circulation circuits - large (through the heating system) and small (through the boiler). Each of them has shut-off valves, which allows you to turn them on separately. To break the filling of the supply, a piping scheme for a single-circuit boiler with a boiler is used, immediately after which a bypass with a crane is mounted.

What is a heating boiler piping

strapping heating boiler is a gas boiler connection to the heating system, water supply (if provided) and gas as fuel. The boiler piping includes the connection of all necessary devices to ensure reliable operation and control of the boiler.

According to building regulations and manufacturers' instructions, gas supply to the heating boiler must be carried out only through a rigid connection. A rigid connection means a metal pipe, and the connection is made using plumbing technologies for connecting metal pipes, through a metal “squeeze”. Polypropylene pipes with fiberglass for hot water supply are also suitable.If you live in Kazakhstan, you can view and download the pipe catalog at Allpipes.kz.

Important! As a seal of the gas supply pipe connections, EXCLUSIVELY, paronite gaskets are used. Other gaskets such as rubber, as well as sealing the threads of the joints with fum-tape and tow, are PROHIBITED. Paronite is a sealing material based on asbestos, mineral fibers and rubber, produced by vulcanization and is not flammable.

Paronite is a sealing material based on asbestos, mineral fibers and rubber, produced by vulcanization and is not flammable.

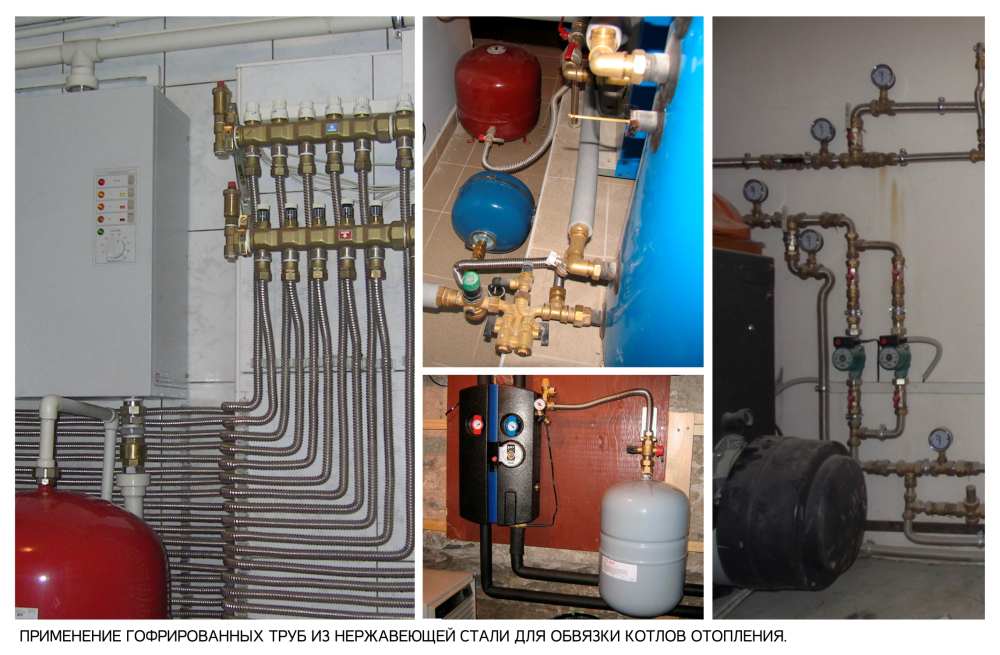

What pipe options can be used

When carrying out work on the installation of a heating boiler, elements made of metals and polymers can be used.

When choosing, you should pay attention to such characteristics as thermal insulation properties, ease of installation and operation, durability, as well as the cost of products.

Based on the sum of these criteria, the following types of pipes are used to perform the strapping.

High-quality, but expensive copper products

Copper piping is relatively rare, since such pipes are quite expensive, and also require special skill when laying. At the same time, structures made of this metal have a number of significant advantages, namely:

- good heat dissipation;

- resistance to corrosion and aggressive substances;

- freezing resistance;

- high heat resistance.

Copper quickly and well warms up with a minimum amount of thermal energy, so parts made of this material will constantly release heat during the transportation of the coolant.

Copper pipes are able to withstand much higher temperatures than plastic pipes (up to +300), while they practically do not change in size. Hot coolant can also circulate in steel structures, but in this case the risk of corrosion increases

Pipes made of this metal can withstand the impact of the environment. Over time, they can only become covered with a thin layer of oxide, which does not affect performance at all. Unlike pipes made of steel or polymers, plastic copper structures do not break when the coolant in them freezes.

The disadvantages of products made of this metal include the impossibility of using pipes to create closed structures in strobes, as well as the already mentioned high cost.

Budget steel products

Another common option is products made of steel. Their benefits include:

- The high durability allowing to transfer easily mechanical loadings.

- Low temperature coefficient of linear expansion, due to which the length of the parts remains unchanged even at high heat.

- High thermal conductivity for efficient heat dissipation.

The disadvantages, first of all, include the tendency to corrosion, which destroys the metal, due to which such elements need to be painted or coated with an anti-corrosion compound.

The disadvantage of steel elements is the complexity of laying, requiring special equipment and professional skills.The manufacture of structures from such elements must be trusted to specialists.

When choosing, it is better to give preference to stainless steel pipes: they are more expensive, but they show greater resistance to environmental influences and better performance.

Durable and lightweight polypropylene piping

Similar products made from modern types of plastics are widely used due to the many positive aspects:

- Affordable cost: the prices for such products are much lower than for metal counterparts.

- Light weight. Such elements weigh very little, so you can save effort and money for their storage, transportation and installation.

- Ease of installation. Plastic pipes are easily assembled into finished structures. With the help of a special soldering iron, even a non-specialist can quickly arrange a strapping.

- Coolant circulation speed. In polypropylene pipes, even if they have a complex shape, there are practically no blockages. This facilitates the flow of water, the speed of which remains unchanged throughout the entire service life (20-50 years).

- Good resistance to high pressure. This allows the use of plastic elements even under difficult operating conditions.

The main disadvantage of PPR pipes is a high coefficient of thermal expansion, due to which these products slightly increase in length when heated. To counteract this phenomenon, it is necessary to take measures by installing compensators.

Polypropylene pipes allow you to create heating circuits of any degree of complexity.However, designs with a large number of elements make installation difficult and adversely affect the efficiency of the heating system.

In addition, there are special pipe options, which include products reinforced with aluminum foil marked PN 25 (they can be used in systems with a pressure of up to 2.5 MPa and a temperature of + 95 °) as well as reinforced PN 20 elements that allow operation in conditions of temperature + 80o C and pressure 2 MPa.

Supply of heating and water pipes

All instructions and standards say that the connection of water pipes and heating pipes with a gas boiler must also be rigid. This means that you can use any pipes for tying a gas boiler, and the very connection of heating and water supply pipes with a gas boiler is carried out through metal drives.

The connection of pipes in the piping is carried out according to the standards of simple plumbing connections, namely:

- Metal threaded connections are made with sealing winding;

- Polypropylene pipes are connected by special welding;

- Polyethylene pipes are connected by compression fittings;

- Metal-plastic pipes are connected by collet joints or compression fittings;

- Connections of copper pipes are soldered or connected with a collet.

How and how to seal pipe joints

Types of seals, sealing methods

To prevent leakage of the working medium of the pipeline, it is necessary to seal the pipe twists with high quality.

When threading steel pipes, the following are used as seals:

- gasket. This method of sealing a threaded joint requires relatively thick pipe end cuts. The presence of even pipe ends can never provide tightness.When using a rubber or plastic gasket, this problem is successfully solved. This option is ideal in the case of articulation with a union nut;

- winding. Linen strands, polymer threads, FUM tapes in combination with hardening sealants, paints, pastes can serve as materials.

When installing plastic risers, a sealing method is used based on the deformation properties of the material. The essence of this method is that a plastic pipe with an external thread is screwed into a riser with an internal thread. Plastic during deformation contributes to the excellent filling of the intermediate space, eliminating the appearance of gaps.

When it comes to pipeline structures with high pressure, cylindrical threaded pipe connections are not entirely appropriate here. In such cases, a conical type connection is used. The principle of connection is that when screwing in, a tight pressing of the pipes is observed until such a measure until the gap completely disappears.

Sealing materials

To make the joint impermeable, the following are used as sealants:

- flax (tow);

- asbestos;

- FUM tape;

- natural drying oil;

- white;

- minium;

- graphite lubricant, etc.

A reliable seal when twisting steel pipes on a thread is a linen strand impregnated with red lead or whitewash. This connection is easy to install, reliable in terms of sealing. The sealant has been used for a very long time, does not lose its popularity even today, despite the appearance of artificial analogues.

For those who have little experience in the installation of fittings and pipes, we suggest that in no case use flax without paint. At first, the joint will not let moisture through.But a few months will pass, the flax fibers will get wet and begin to decompose. Therefore, the quality of all connections will deteriorate, and after another month or two, water will seep at the junction.

Many people use FUM tape, which is in no way inferior to the old traditional materials - tow with paint.

Sometimes there is no tightness at the junction of the risers. To eliminate this defect, it is necessary to replace the sealing material, and clean the threaded section from dirt and sealant residues. After that, wind the linen thread, FUM tape or other sealant again, assemble the structure.

Pastes, sealants of chemical origin are used as additional sealants, which will help strengthen this section of the pipeline.

Do-it-yourself battery installation recommendations

- Before starting work, it is necessary to block the flow of coolant in the heating system at the inlet and outlet, or make sure that there is no liquid in the pipeline.

- Even before starting the installation, you need to check the completeness of the radiator. It must be in the assembled state. If this is not the case, we take a radiator key and assemble the battery according to the manufacturer's instructions.

The design must be absolutely hermetic, therefore, abrasive materials cannot be used during assembly, as they destroy the material of the device.

When tightening fasteners, one should not forget that both left-handed and right-handed threads are used in bimetallic devices.

When connecting sanitary fittings, it is extremely important to choose the right material.Flax is usually used along with a heat-resistant sealant, FUM tape (fluoroplastic sealing material) or Tangit threads.

Before starting installation work, you need to carefully plan the connection scheme. Batteries can be connected in a diagonal, side or bottom pattern

It is rational to install a bypass in a single-pipe system, that is, a pipe that will allow the system to function normally when the batteries are connected in series.

After the installation is completed, the system is turned on. This should be done by smoothly opening all the valves that previously blocked the path of the coolant. Too abrupt opening of the taps leads to clogging of the internal pipe section or hydrodynamic shocks.

Following the opening of the valves, it is necessary to release excess air through an air vent (for example, a Mayevsky tap).

Batteries can be connected diagonally, sideways or at the bottom. It is rational to install a bypass in a single-pipe system, that is, a pipe that will allow the system to function normally when the batteries are connected in series.

After the installation is completed, the system is turned on. This should be done by smoothly opening all the valves that previously blocked the path of the coolant. Too abrupt opening of the taps leads to clogging of the internal pipe section or hydrodynamic shocks.

Following the opening of the valves, it is necessary to release excess air through an air vent (for example, a Mayevsky tap).

Note! Batteries must not be covered with screens or placed in wall niches. This will drastically reduce the heat transfer of the equipment. Properly installed bimetallic heating radiators are the key to their long and trouble-free operation.

If you have any doubts about the ability to install them yourself, it is better to contact specialists.

Properly installed bimetallic heating radiators are the key to their long and trouble-free operation. If you have any doubts about the ability to install them yourself, it is better to contact specialists.

Selection of heating pipes

Having orientated which heating boiler will heat the water in your house, you can choose pipes for heating radiators and the system as a whole. Traditional materials for heating pipes:

- steel;

- copper;

- plastic.

Quite expensive and requiring the invitation of professionals for welding, steel or copper pipes are increasingly being replaced in practice with metal-plastic or polypropylene pipes.

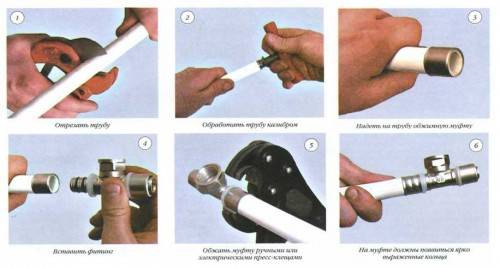

Metal-plastic pipes

The connection and installation of metal-plastic pipes can be performed using compression and press fittings.

To make a connection using compression fittings and the subsequent connection of heating pipes, you will need:

- spanners;

- expander;

- springs for bending pipes.

The main disadvantages of connections on compression fittings are:

- their relatively high cost;

- fragility of rubber gaskets under the influence of high temperatures;

- periodic "simple" heating pipes in the summer, which also does not have a very favorable effect on the durability of rubber parts.

As a result, the need for preventive work to tighten the connections may occur every five years or more often.

Rules for connecting metal-plastic pipes using a press fitting

Reliable non-separable connection on press fittings allows installation of heating with plastic pipes, hiding them directly in the walls.These pipes will last without replacement for many years if the temperature of the heating water flowing through them does not exceed 80°C.

The disadvantage of using this type of connection can only be called the need to purchase special equipment for installation

Polypropylene pipes

Recently, a leading place among suitable water and heat supply equipment has been occupied by a pipe for a heating boiler made of polypropylene. The use of polypropylene is due to the fact that it is very durable, is not afraid of defrosting the system, and has a very affordable price.

Polypropylene pipes can be bent quite evenly (unlike metal-plastic). They will last a long time if all the rules of operation are observed.

Their only drawback is the need to use a special tool for welding.

There are the following features of the connection of pipes made of polypropylene by welding:

- It is more convenient to weld polypropylene pipes together with a partner. The main condition for the high-quality connection of plastic pipes is the choice of the correct heating time so as not to overheat them, and precise fixation, which does not allow shifts and displacements along the axis for the first few seconds after connecting the heated parts.

- Welding and installation of heating pipes is carried out at positive ambient temperatures - above +5 °C. When working in winter, it is necessary to create a "heat zone" where polypropylene pipes are welded.

For high-quality work on soldering polypropylene pipes, it is necessary to comply with all the requirements of the instructions attached to the device.

It would be a good idea to do a few trial welds on individual short lengths of pipe using inexpensive couplings to get at least some initial skill in handling the welding set.

Nuances and strapping options for different types of boilers

General recommendations of experienced craftsmen:

The installation scheme is selected individually.

The boiler is installed in accordance with the rules of SNiP below the level of heating appliances.

The floor boiler is installed on a metal or concrete base before piping with polypropylene.

Forced ventilation and emergency lighting systems are recommended for all unit variants.

A coaxial chimney is included in the piping of a gas-fuelled device, which is sealed at all joints during installation.

After completing the piping of the boiler unit and the chimney, proceed to the device of the security system in the following order: pressure devices (pressure gauges), protective devices and then an automatic air vent.

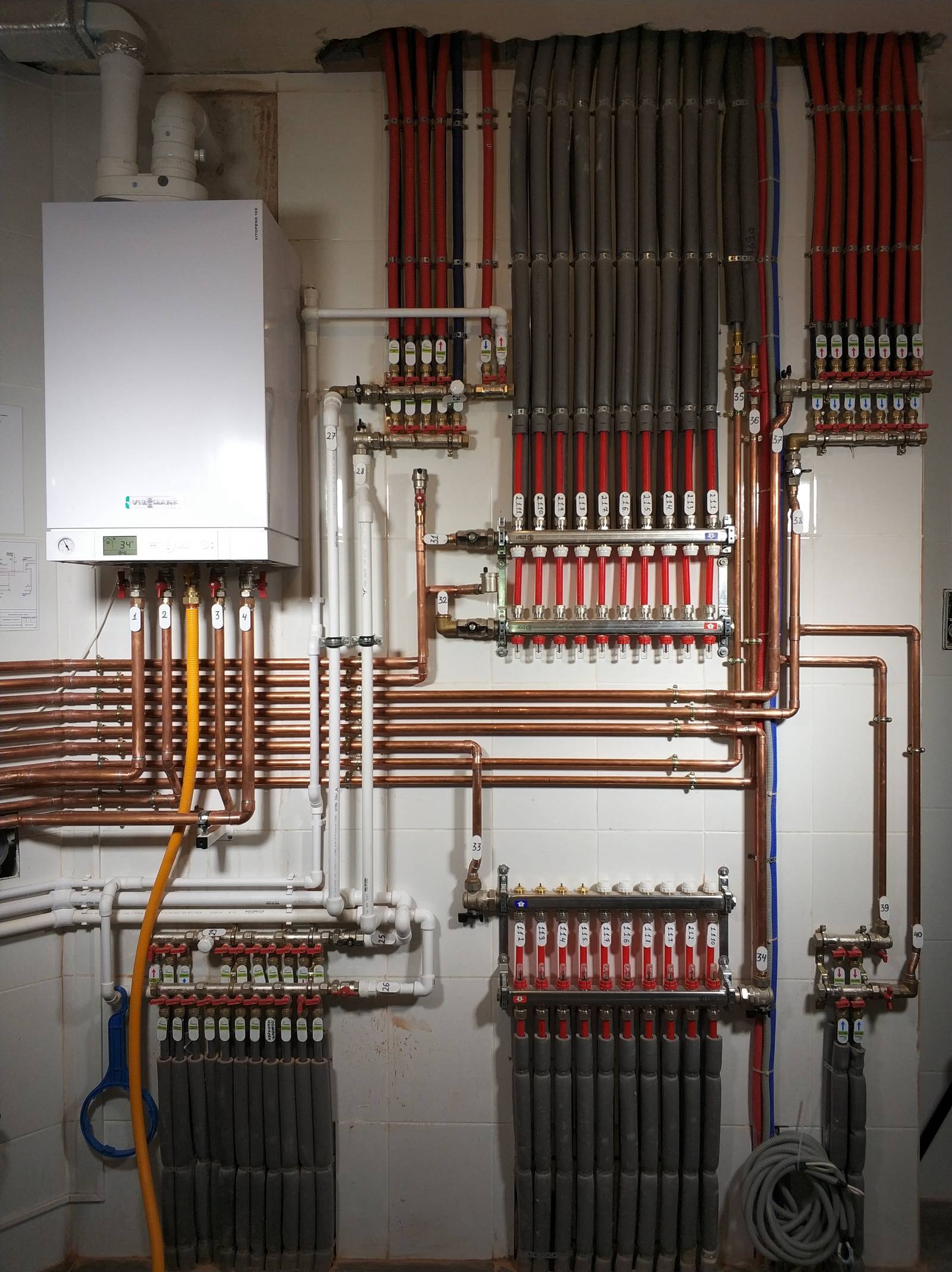

The collector circuit is carried out by a 1.25-inch PPR pipeline, protective devices, a circulation pump, a hydraulic arrow and an air vent are installed according to the movement of the medium.

To supply the heating coolant to the heating devices, 3 branches of the PPR 1.0 inch pipe are removed from the comb, and the rest are closed with plugs.

Connect heating and return devices.

In a combined heating system, the underfloor heating circuit is equipped with an independent pump, while the expansion tank is installed between the hydraulic arrow and the boiler unit.

The piping of the boiler unit is completed by installing a drain valve, it is also used to fill the circuit, but it is better if these are two independent valves

The installation point depends on the chosen system, but there are general conditions - the drain valve is installed at the lowest point, which is especially important if you plan to mothball the system in winter so that there is no water left in it.

Gas equipment

Tying such equipment with polypropylene pipes is carried out with an independent circuit and a loop pump that creates working pressure in a small section of the network from the source to the distributor.

It is allowed to tie a gas unit with such pipes without steel pipes, since the heating temperature at the supply does not exceed 80 C.

In a gas-fired unit with a cast-iron boiler, a heat accumulator is mounted, which helps to balance the hydraulic regime and prevents sudden temperature fluctuations that affect the fragile cast-iron heating surfaces. When piping 2-circuit boilers, it is additionally necessary to place filters for fine and coarse water purification.

Electric heater

Tying an electric boiler with polypropylene is quite acceptable. The boiler has the highest rating of the protective system, which does not allow water to boil in the unit, with the subsequent formation of steam and rupture of the pipe. The heating process stops when the power supply to the electric heating elements is turned off.

In addition, the system has built-in hydraulic accumulators and devices to relieve excessive pressure of the medium, which can form during a sudden power outage and stop the pump for pumping hot water to heating devices and water points.

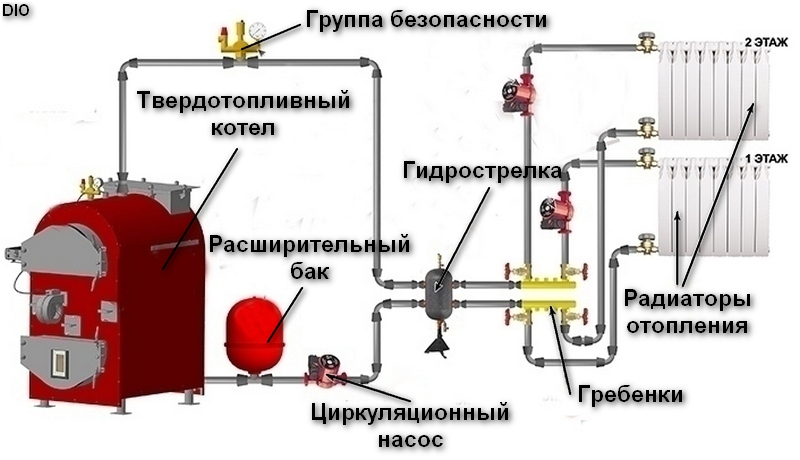

Solid fuel boiler piping

Solid fuel boiler piping

Solid fuel models

This is the most problematic unit for tying plastic pipes.For him, the installation of a protective meter pipe at the inlet / outlet of the medium is mandatory in order to protect them from overheating. For systems with pump circulation, an additional backup power supply device will be required to continue cooling the boiler during an emergency shutdown of the main source of electricity. In addition, a small gravity circuit is performed with a small number of batteries connected to cool the boiler heating surfaces until all the fuel has burned out.

The solid fuel boiler, according to the requirements of fire safety rules, is covered with a protective casing, which significantly reduces heat loss from the walls of the combustion chamber to the boiler room and, consequently, the negative impact on PPR pipes

A small reminder for the installation of plastic pipes - the quality will be determined not only by the installation work, but also by the selected range of pipes. You should purchase all the main and auxiliary equipment of the boiler room, only certified from reputable suppliers. Polymer pipes do not require insulation work and painting, scale and corrosion do not form on them, they are distinguished by high sound insulation. The cost of the material is lower, and the pipes are lighter than those made of metal, so you can do the installation yourself.

Heating system from polypropylene pipes

The technical characteristics of the object and the amount of allocated funds affect the heating installation scheme. In apartments of multi-storey buildings, it is connected to the central heating system, and in private houses - to an individual boiler. Regardless of the type of object, the system can have one of three versions.

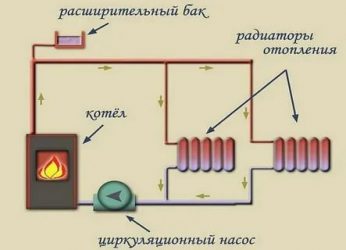

Single pipe

The system is characterized by simple installation and quantity of materials.It mounts one pipe for supply and return, which reduces the number of fittings and fasteners.

It is one closed circuit with alternate vertical or horizontal placement of radiators. The second type is used specifically in private homes.

When passing through each radiator, the temperature of the coolant decreases. Therefore, a single-pipe circuit is not able to evenly heat the entire object. There is also the difficulty of temperature control, since the heat loss factor is not taken into account.

If the radiators are not connected through valves, then when one battery is repaired, the heat supply is stopped throughout the facility. When arranging such a network in a private house, an expansion tank is connected. It allows you to compensate for changes in pressure in the system.

The single-pipe circuit allows the installation of radiators with temperature controllers and thermostatic valves to correct heat loss. Ball valves, valves and bypasses are also installed for the repair of individual sections of the thermal circuit.

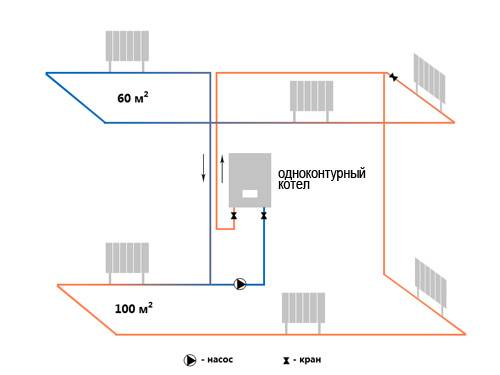

Two-pipe

The system consists of two circuits. One is for submission and the other is for return. Therefore, more pipes, valves, fittings, consumables are installed. This increases installation time and budget.

The advantages of a 2-pipe network include:

- Uniform distribution of heat throughout the facility.

- Minimum pressure loss.

- Possibility of installing a low power pump. Therefore, the circulation of the coolant can occur by gravity.

- Repair of a single radiator is possible without shutting down the entire system.

The 2-pipe system uses a passing or dead-end scheme for the movement of the coolant.In the first case, it is allowed to install batteries with the same heat output or radiators with different capacities, but with thermostatic valves.

A passing scheme is used if the thermal circuit is long. The dead-end option is used for short highways. When installing a 2-pipe network, it is necessary to install radiators with Mayevsky taps. The elements allow air to be expelled.

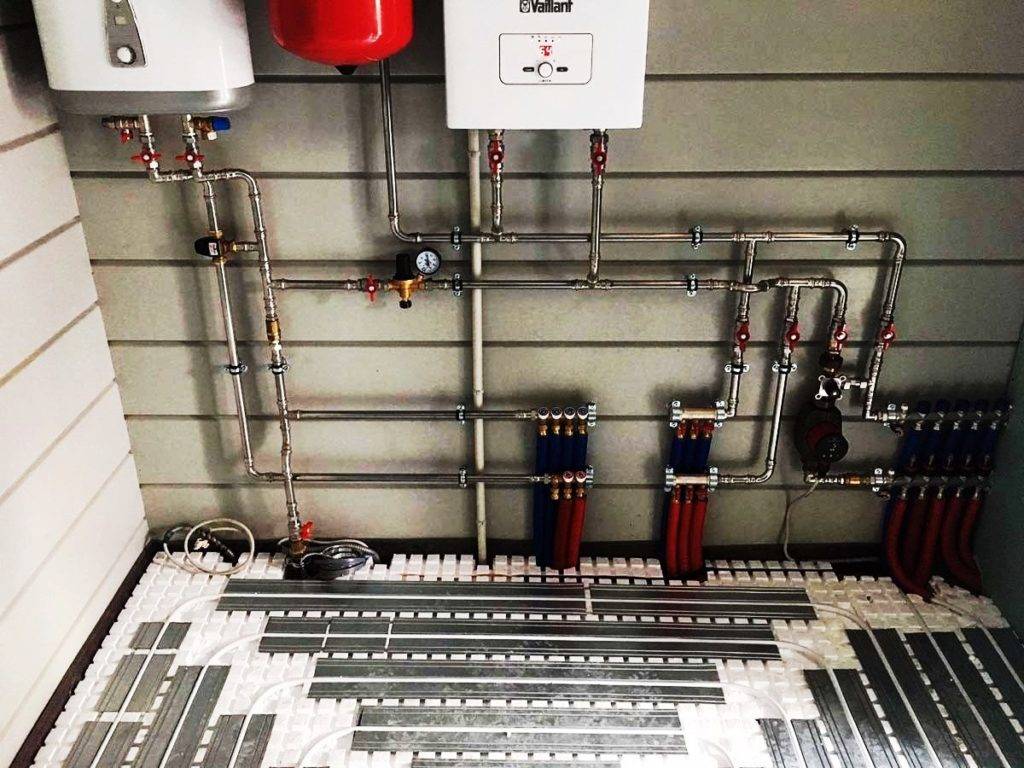

Collector

This system uses a comb. It is a collector and is installed on the supply and return. This is a two-pipe heating circuit. A separate pipe is mounted, both for supplying coolant to each radiator, and for returning cooled water.

The system may consist of many circuits, the number of which depends on the number of batteries.

When installing a collector thermal circuit, an expansion tank is installed. It contains at least 10% of the total volume of coolant used.

During installation, a manifold cabinet is also used. They try to place it at an equal distance from all batteries.

Each circuit in the manifold system is a separate hydraulic system. It has its own shut-off valve. This allows you to turn off any of the circuits without stopping the operation of the entire system.

Collector

Advantages of the collector network:

- It is possible to regulate the heating temperature of any of the heaters without prejudice to the rest of the batteries.

- High efficiency of the system due to the direct supply of coolant to each radiator.

- It is possible to use pipes with a smaller cross section and a less powerful boiler due to the high efficiency of the system. Therefore, the costs for the purchase of equipment, materials and network operation are reduced.

- Simple design process, no complicated calculations.

- Possibility of underfloor heating. This allows you to create a more aesthetic interior, as there is no need to install traditional batteries.

For the device of the collector system, a large number of pipes, fittings and valves will be required. You will also need to purchase combs, a circulation pump, an expansion tank and a cabinet for collectors.

A large number of elements increases the complexity of the installation process. Installation of batteries is carried out together with Mayevsky cranes to prevent airing of each of the circuits.