Pipe specifications

To better understand the issue, you should consider the characteristics of each pipe separately. The main idea in heating is the amount of coolant that we heat and which circulates through the pipes and transfers the accumulated heat to the room, heating it.

Let's take air as a coolant. Air heating is considered the most economical, because the air heats up on its own, without pumps, and begins to circulate through the pipes

If water or another liquid is taken as a coolant, then its quantity is important. The less coolant is heated, the heating system is considered more economical. For an underfloor heating pipe with a diameter of 16 mm, the amount of coolant is 110 ml per 1 linear meter, for a pipe with a diameter of 20 mm - 180 ml per 1 linear meter

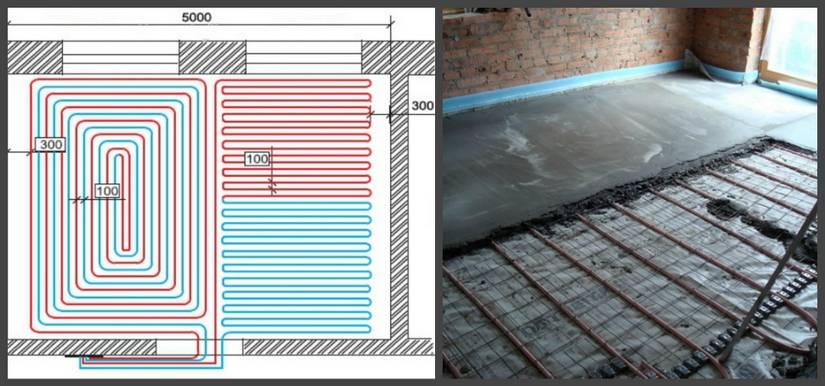

It is not difficult to calculate that the difference will be about 40 percent, a rather large figure. Thus, under the same conditions, a 20mm pipe loses in this characteristic.However, the step with which the pipes are mounted is different. For a diameter of 16mm the standard pitch is 150mm and for a diameter of 20mm it is 250mm. By increasing the pitch, the length of the pipe used decreases, and the amount of coolant becomes approximately the same for a pipe with a diameter of 16 mm, and for a diameter of 20 mm. In addition, due to the larger diameter, the heat transfer area of the pipes is 20 mm larger than that of 16 mm pipes.

For an underfloor heating pipe with a diameter of 16 mm, the amount of coolant is 110 ml per 1 linear meter, for a pipe with a diameter of 20 mm - 180 ml per 1 linear meter. It is not difficult to calculate that the difference will be about 40 percent, a rather large figure. Thus, under the same conditions, a 20mm pipe loses in this characteristic. However, the step with which the pipes are mounted is different. For a diameter of 16mm the standard pitch is 150mm and for a diameter of 20mm it is 250mm. By increasing the pitch, the length of the pipe used decreases, and the amount of coolant becomes approximately the same for a pipe with a diameter of 16 mm, and for a diameter of 20 mm. In addition, due to the larger diameter, the heat transfer area of the pipes is 20 mm larger than that of pipes of 16 mm.

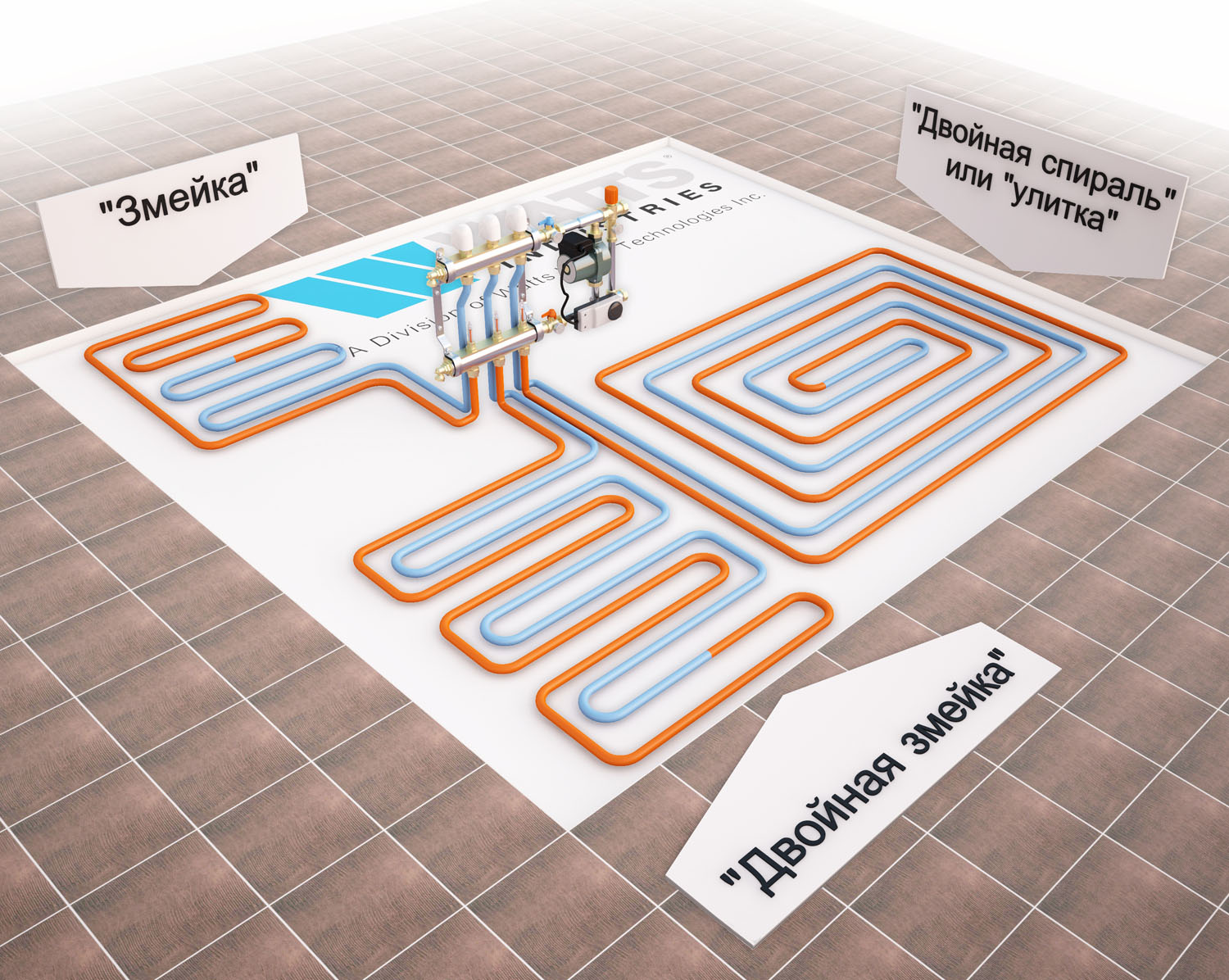

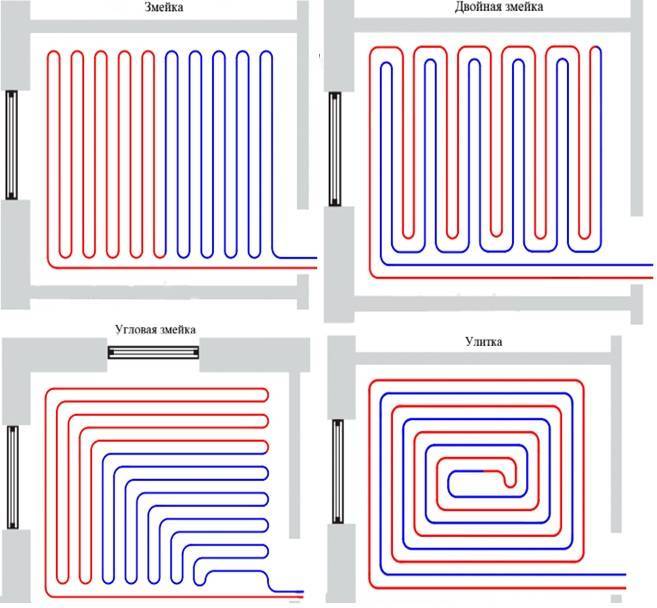

An equally important role is played by the convenience of work when installing pipes. As a rule, pipes begin to be laid on the floor in a spiral, but between adjacent circuits there is a space that is not heated. Accordingly, heat does not spread throughout the floor and unheated areas remain. Pipes are laid in this space in the form of a snake with a minimum step of 100 mm. A 16mm underfloor heating pipe can achieve such a step, but a 20mm pipe does not. In addition, there are many small rooms, such as small corridors, bathrooms, etc., in which it is easier to lay a pipe with a snake.

The next characteristics are resistance and flow. In order to have optimal resistance for a pipe with a diameter of 16 mm, it is recommended that the length of the circuit be 90 m linear per circuit in increments of 150 mm for an area of 13-15 sq. m. If you take a pipe with a diameter of 20 mm, these characteristics increase: for one circuit, they take a length of 130 linear meters, an area of 20 square meters, a step of 200-250 meters. But, despite this increase, the flow rate is approximately the same, since the characteristics compensate for each other. All this will show you the finished project with calculations. But if there is no project, you can use a pipe with a diameter of 16 mm and take standard data for this pipe for your calculations. This will be the best option.

To summarize: a pipe with a diameter of 16mm is used for residential premises; a pipe with a diameter of 20 mm - for non-residential and in rare cases for residential premises. Before installation underfloor heating it is necessary to make calculations. Decide on the coolant and the method of laying the pipe in accordance with its diameter, and after that do the work.

Read also:

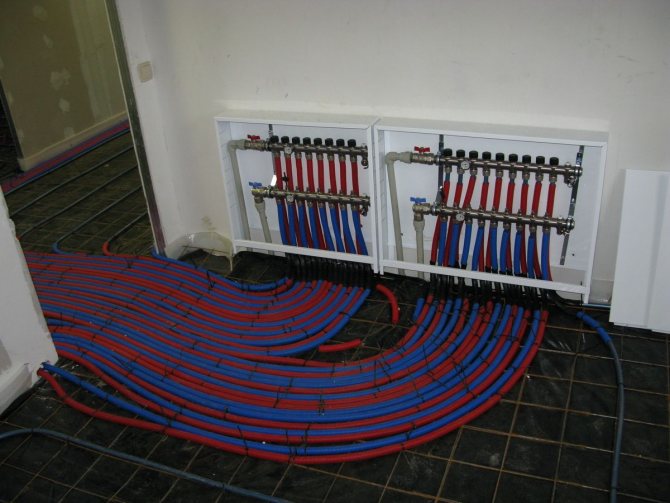

Collector connection diagram

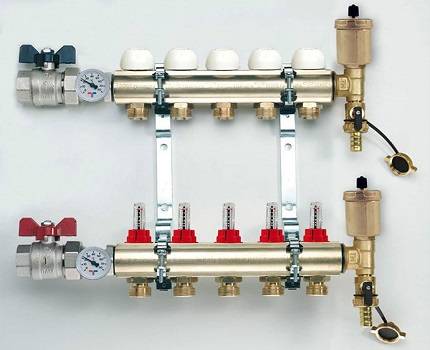

The choice of a ready-made mechanical or automatic collector model depends on the characteristics of the heating system.

The first type of control module is recommended for underfloor heating without a radiator, the second can be used in all other cases.

Valtec manifold groups are the most popular. The manufacturer gives a 7-year warranty for the manufactured products. The installation scheme of the liquid circuit manifold is already included in the package of the finished mixing unit

According to the scheme, the assembly of the distribution comb for underfloor heating is carried out as follows:

- Setting the frame.As an installation area for the collector, you can choose: a prepared niche in the wall or a collector cabinet. It is also possible to mount directly on the wall. However, the location must be strictly horizontal.

- Boiler connection. The supply pipeline is located at the bottom, the return pipeline is at the top. Ball valves must be installed in front of the frame. They will be followed by a pumping group.

- Installation of a bypass valve with a temperature limiter. After it, the collector is installed.

- Hydraulic test of the system. Check by connecting to a pump that contributes to pressurizing the heating system.

In the mixing unit, one of the mandatory elements is a two- or three-way valve. This device mixes water flows of different temperatures and redistributes the trajectory of their movement.

Shut-off valves and fittings are mounted on both pipelines, return and supply, connected to the collector unit, designed to balance the volume of the heat carrier, as well as to block any of the circuits

If servo drives are used to control the collector thermostats, then the mixing unit is expanded with a bypass and a bypass valve.

Underfloor heating materials

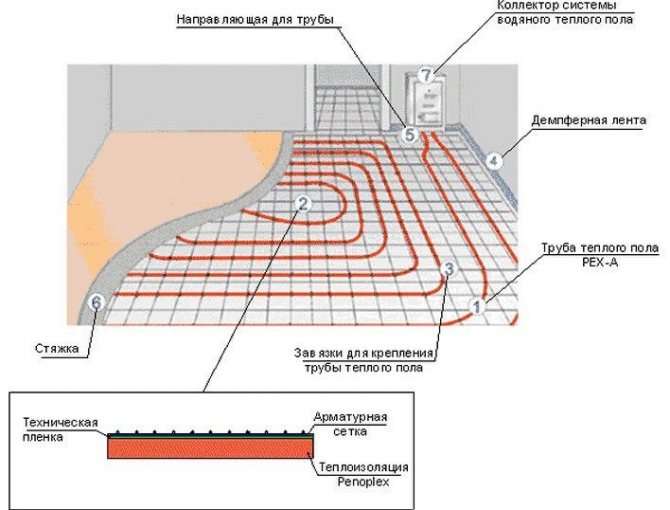

The scheme of such a floor in the picture always looks rather complicated - a mass of interconnected communications, through which water also flows. However, in reality, the system does not include such an extensive list of elements.

Materials for water floor heating

Accessories for water floor heating:

- in the absence of the possibility of connecting to a central heating system - a heating boiler;

- a pump that is either built into the boiler or purchased separately. It will pump water into the system;

- directly the pipes through which the coolant will move;

- a collector that will be responsible for distributing water through pipes (not always necessary);

- for collectors, a special cabinet, splitters distributing cold and hot water, as well as valves, an emergency drain system, devices for venting air from the system will be needed;

- fittings, ball valves, etc.

One of the options for the heating scheme in a private house with underfloor heating on the ground floor

Also, for arranging a warm floor, you will need material for thermal insulation, fasteners, reinforcing mesh, damper tape. If the raw installation method is performed, then also the concrete mixture from which the screed will be made.

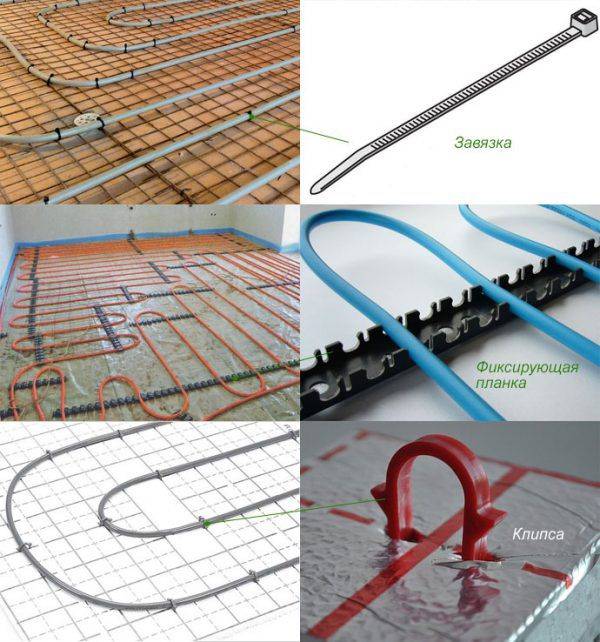

Fastenings for pipes of a water heat-insulated floor

Mounting plate for underfloor heating

The choice of materials and tools for the floor heating system will often depend on the installation technique. There are two types of installation of equipment - it is dry and wet.

-

Wet technology involves the use of insulation, fastening system, pipes, concrete screed. After all the elements are filled with a screed, the floor covering itself is laid on top. A damper tape must be laid around the perimeter of the room. It is desirable to place a waterproofing layer under the insulation in case of water leakage - it will protect neighbors from a possible flood.

-

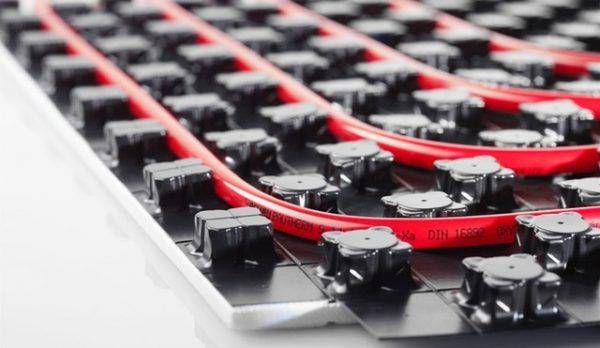

dry technology. In this case, the heating system is laid on wooden plates or polystyrene mats in specially made channels.Sheets of plywood or GVL are laid on top of the system. The floor covering is installed on top. By the way, you should not lay on top of the chipboard or OSB system, since they contain substances that, under the influence of elevated temperatures, begin to evaporate and negatively affect the human body.

Neither the first nor the second methods are ideal - each has its own advantages and disadvantages. However, it is the wet method that is most often used, when the underfloor heating system is laid in a screed. The reason is simple - cheapness, although this type is quite difficult to maintain. For example, it will not be easy to repair pipes in a screed.

Screed for underfloor heating

Laying a warm water floor

One of the key components of the system is pipes and their fixation system. There are two technologies:

-

Dry - polystyrene and wood. Metal strips with formed channels for laying pipes are laid on a system of polystyrene foam mats or wooden plates. They are necessary for a more even distribution of heat. Pipes are inserted into recesses. Rigid material is laid on top - plywood, OSB, GVL, etc. A soft floor covering can be laid on this base. It is possible to lay tiles on tile adhesive, parquet or laminate.

-

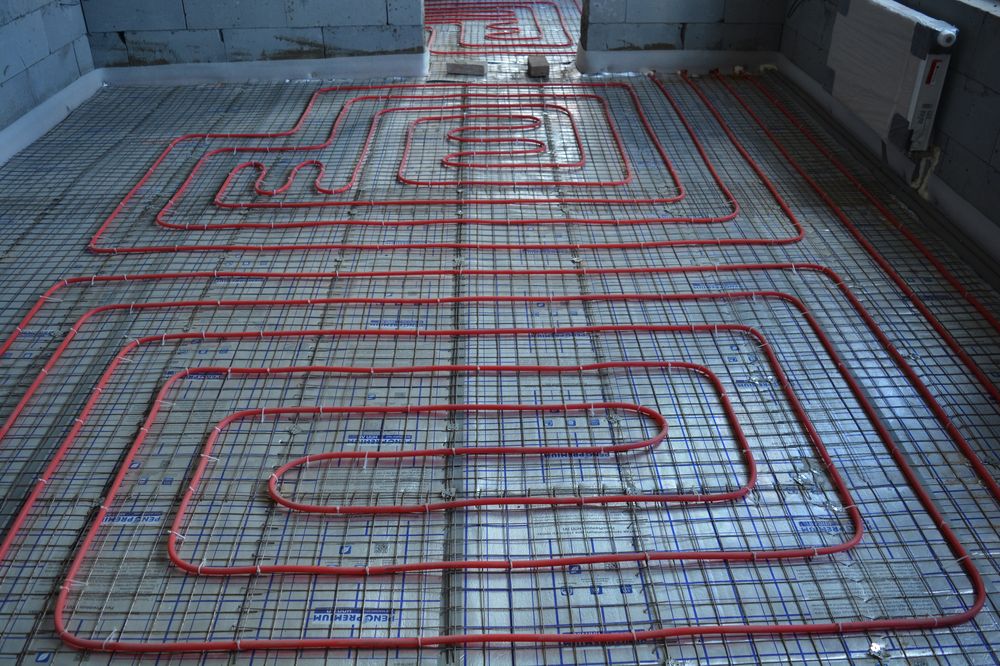

Laying in a coupler or so-called "wet" technology. It consists of several layers: insulation, fixation system (tapes or mesh), pipes, screed. On top of this “pie”, after setting the screed, the floor covering is already laid. If necessary, a layer of waterproofing is laid under the insulation so as not to flood the neighbors. A reinforcing mesh may also be present, which is laid over the floor heating pipes. It redistributes the load, preventing damage to the system.A mandatory element of the system is a damper tape, which is rolled around the perimeter of the room and placed at the junction of two circuits.

Both systems are not ideal, but laying pipes in a screed is cheaper. Although it has a lot of disadvantages, it is because of its lower cost that it is more popular.

Which system to choose

In terms of cost, dry systems are more expensive: their components (if you take ready-made, factory ones) cost more. But they weigh much less and are put into operation faster. There are several reasons why you should use them.

First: the heavy weight of the screed. Not all foundations and ceilings of houses are able to withstand the load created by a water-heated floor in a concrete screed. Above the surface of the pipes there must be a layer of concrete of at least 3 cm. If we take into account that the outer diameter of the pipe is also about 3 cm, then the total thickness of the screed is 6 cm. The weight is more than significant. And on top there is often a tile on a layer of glue. Well, if the foundation is designed with a margin, it will withstand, and if not, problems will begin. If there is a suspicion that the ceiling or foundation will not withstand the load, it is better to make a wooden or polystyrene system.

Second: low maintainability of the system in the screed. Although it is recommended to lay only solid coils of pipes without joints when laying underfloor heating contours, periodically the pipes are damaged. Either during the repair they hit with a drill, or burst due to marriage. The place of damage can be determined by a wet spot, but it is difficult to repair: you have to break the screed.In this case, adjacent loops can be damaged, due to which the damage zone becomes larger. Even if you managed to do it carefully, you have to make two seams, and they are the potential sites for the next damage.

The process of installing a water heated floor

Third: the commissioning of a heated floor in a screed is possible only after the concrete has gained 100% strength. This takes at least 28 days. Before this period, it is impossible to turn on the warm floor.

Fourth: you have a wooden floor. By itself, a tie on a wooden floor is not the best idea, but also a screed with an elevated temperature. The wood will quickly collapse, the whole system will collapse.

The reasons are serious. Therefore, in some cases, it is more expedient to use dry technologies. Moreover, a do-it-yourself wooden water-heated floor is not so expensive. The most expensive component is metal plates, but they can also be made from thin sheet metal and, better, aluminum.

It is important to be able to bend, forming grooves for pipes

A variant of a polystyrene underfloor heating system without a screed is shown in the video.

Specification overview

Underfloor heating system consists of a circuit and a control unit. The first are located under the floor covering, the second is more often built into niches with open access. This type of heating is used as the main or additional source of heat.

The most effective option is the option of a warm water floor under a tile or laminate. Carpets have low conductivity, so they act as a barrier between the system and the air.

Benefits and Recommendations

Heated floors, unlike heating radiators, warm the air masses over the entire area of the room up to 1.7 m in height.Above indicators will be in the area of \u200b\u200bthe heat source, and not under the ceiling. This indicates a greater productivity of systems built into the ceiling than other heaters.

The efficiency of space heating for different heating systems

If we compare the installation of a warm floor of electric and water, then the second will cost much more. But to obtain the same result, electricity will take more than natural gas or solid fuel. Therefore, the water floor is about 5 times more profitable and is more often used as the main source of heat.

Radiators to maintain the air temperature in the range of 20-25 0С are heated up to at least 60 0С. Water in the underfloor heating system is brought to 35-45 0C. This also suggests that this type of heating system can be considered one of the most cost-effective. Savings will be up to 40%.

In favor of a water heated floor, it is worth noting the fact that the system has a minimal effect on the relative humidity of the air, that is, air drying does not occur. No active circulation of dust. And also there is no electromagnetic field, which affects the well-being of a person in a negative way.

Disadvantages and consequences

Violations during the installation of a water-heated floor lead to leaks and repair work. Therefore, the installation of a water-heated floor takes a lot of time. This fact is often referred to as a minus, but you can’t rush here.

To detect a leak, you have to open the screed

If it is planned to lay a warm floor in a screed, then the floor becomes noticeably heavier (up to 15% of the original mass)

It is important to be careful with your calculations. Not every foundation or load-bearing structures will cope with such a load.

How to make a warm floor in an apartment? In a multi-storey building with a central water supply, the installation of the system is necessarily accompanied by coordination with the service authorities. The connection is made to the water supply. There is an increase in hydraulic resistance, which is designed for vertical, and not for horizontal systems. As a result, problems with heating will arise in neighboring apartments from above, and the central system as a whole may fail. Therefore, it is far from always possible to obtain permission to install a warm floor.

The control block includes several elements. Their installation, configuration and maintenance are expensive. But in the general mass, the costs pay off with the result.

Underfloor heating control unit

Materials such as linoleum, carpet, carpet are not recommended as a finishing floor covering. The list also includes laminate. But there are brands that are allowed for styling. The package must have the appropriate sign: water floor heating

It is important not to confuse with electric, because the parameters are slightly different there.

Requirements for the premises

The device of a water-heated floor selects in height from 8 to 20 cm of space. Therefore, doorways must be higher than 2.1 m, and ceilings at least 2.7 m.

It is important that the supporting structures and the foundation cope with the load that is generated from building materials and coolant. Differences on the base are allowed within 5 mm, so that there is no air and an increase in hydraulic pressure. Efficient heating of the premises with a water system is possible only with heat losses up to 100 W / sq.

m.This means that the windows must be inserted, the walls plastered, measures taken to isolate the structures.

Efficient heating of the premises with a water system is possible only with heat losses up to 100 W/sq. m. So, the windows must be inserted, the walls plastered, measures taken to isolate the structures.

Cross-linked polyethylene or metal-plastic for underfloor heating

At the end of the comparison of pipes made of cross-linked polyethylene and metal-plastic pipes, we can draw the following conclusion - these two types have approximately the same characteristics.

The differences are that the metal-plastic pipe has a high thermal conductivity, warms up faster, and reduces installation time, however, such pipes have a slightly higher cost than those made of cross-linked polyethylene.

Cross-linked polyethylene is increasingly being used for arranging underfloor heating. The material itself is, of course, quite expensive. However, cross-linked polyethylene is very easy to use and meets all the above requirements, including durability and high thermal conductivity.

- The characteristics and properties of these two types are very similar:

- connection of elements does not require special tools and special qualifications of the performer;

- the mounting process does not take long;

- both types of products are bendable. By the way, it is this feature that distinguishes them from another type of pipe - polypropylene, which requires various tees and corners.

If we analyze the degree of reliability, then, of course, cross-linked polyethylene is in the first place, because systems with its use use special fixing sleeves, the role of which is to seal the junction of the segments.

Metal-plastic does not have such an element and there the connection of the pipe and fitting is open, which over time can cause a leak.

Both types have different temperature regimes: if cross-linked polyethylene is operated at +95°С, and in isolated cases even at +110°С, then metal-plastic is not recommended to be operated at temperatures above +75°С.

With regard to oxygen impermeability, both types have a fairly high level of this factor, but if we take into account the issue of strength, then, of course, cross-linked polyethylene has the advantage. For example, cyclic freezing and thawing does not affect PEX in any way, but if water freezes in metal-plastic, then such a product will most likely simply tear. For example, cyclic freezing and thawing does not affect PEX in any way, but if water freezes in metal-plastic, then such a product will most likely simply tear

For example, cyclic freezing and thawing does not affect PEX in any way, but if water freezes in metal-plastic, then such a product will most likely simply tear.

More recently, domestic construction markets were overflowing with metal-plastic pipes, as this material was very popular. At the present time, it has long been no longer a sales leader.

- This was preceded by two problems:

- the appearance of low-quality fake material;

- leaks at the junction.

In conclusion, I would like to point out that it is best to use a pipe for underfloor heating from well-known official manufacturers, in which careful quality control of pipe production guarantees uninterrupted operation throughout the entire declared service life, and an important factor is the availability of quality certificates and the provision of a guarantee.

These are such brands as Rehau, Valtec, Tece, Uponor, Ekoplastik, Aquapex, Kan, Fado, Icma. All of them provide a guarantee, have European certification, and most importantly, they have long established themselves in the market.

In the presence of gas, the most economical way to heat a private house is a double-circuit gas boiler.

Or alternatively an electric boiler.