- Well casing with plastic pipes

- Types of casing pipes for wells

- Metal pipes

- Asbestos cement pipes

- Plastic pipes

- Calculation of pipe diameter for well casing

- Types of casing pipes for water wells

- Steel

- Plastic

- asbestos cement

- Using a metal pipe for a water well

- Pipe selection based on operating conditions

- Casing Selection Options

- Well features

- Types of casing pipes and rules for their use

- Plastic pipes for wells

- Pipes made of metals and alloys

- Asbestos-cement pipes

- Fixing wells with pipes

- Well before operation. Trial

- How is the installation of water pipes

Well casing with plastic pipes

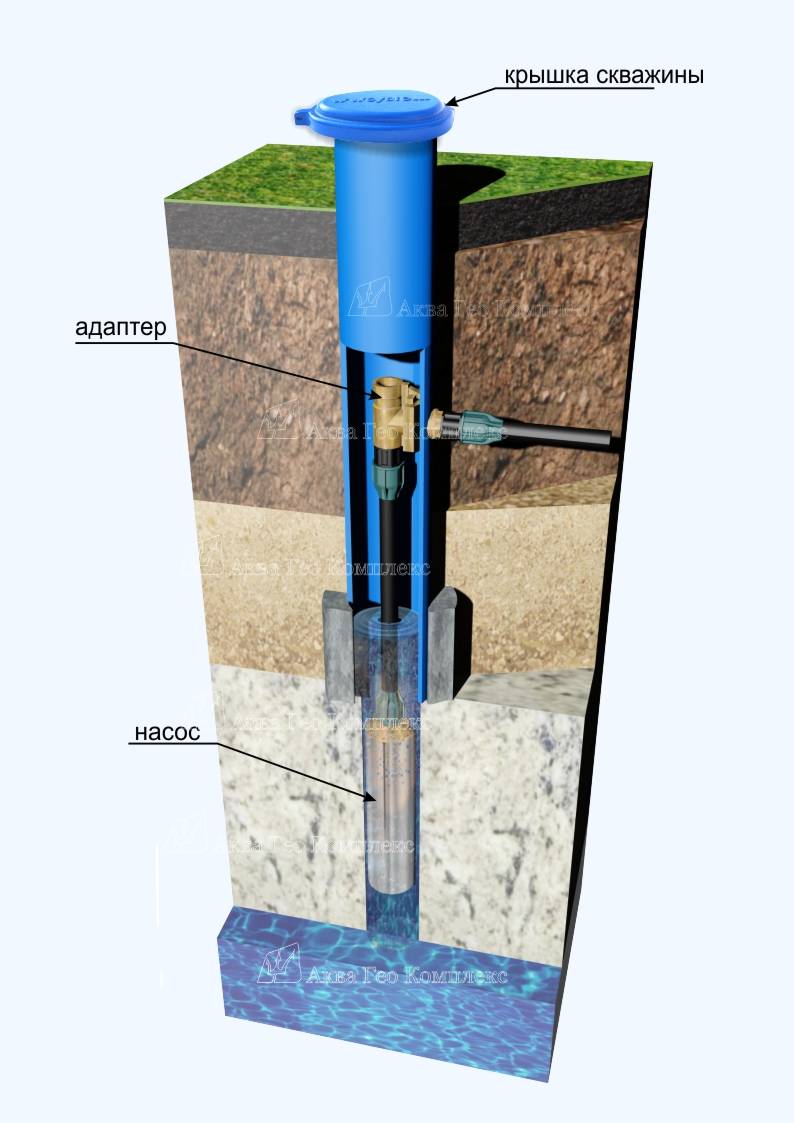

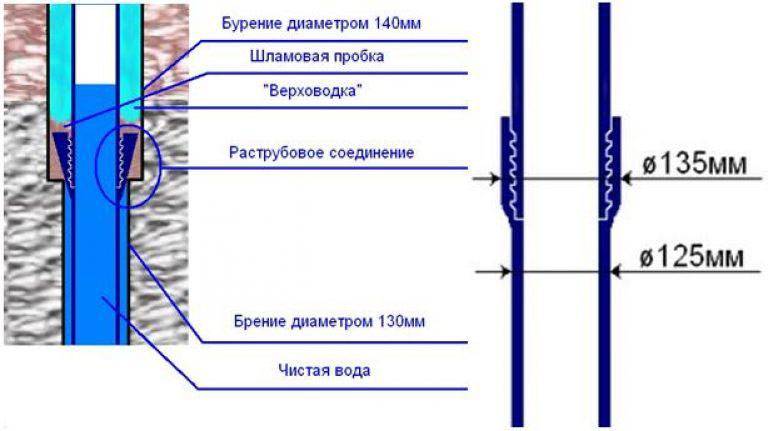

So, the well is drilled and cased with a steel pipe to the limestone, the water is in the limestone and does not rise into the steel pipes. You cannot lower the downhole pump into bare limestone (because it will get stuck), so it is pre-lined with an HDPE pipe and then a pump is placed in this pipe. Previously, metal pipes were used for limestone casing, but they are expensive, today the competition has gained rampant proportions and, in pursuit of the best price, everyone has switched to plastic pipes.

When casing limestone, it is customary to bring a plastic pipe several meters above the water so that it does not surface.

There is a widespread myth that if you bring a plastic pipe under the top, then this provides additional protection from groundwater in the event of through corrosion of a steel pipe. We have to disappoint you: this will not work in most cases. If a steel pipe rusts, then water will get into the annulus, from there into the limestone, and then into your house. If the steel rusts very strongly, then the plastic will squeeze with clays. But sometimes they implement such a well design when a plastic pipe is not lowered to the bottom, but a kind of pocket is made in limestone, where the plastic will be covered with clays. This will protect the well from perched water even in the case of through corrosion of steel.

But sometimes they implement such a well design when a plastic pipe is not lowered to the bottom, but a kind of pocket is made in limestone, where the plastic will be covered with clays. This will protect the well from perched water even in the case of through corrosion of steel.

Some drilling organizations offer to put a packer in the well, which looks like a winding on a plastic pipe, it is designed to close the space between plastic and steel and ensure tightness. But while the pipe is lowered with winding into the well, this winding will loosen, break and there will be no sense from it. But the main thing is that no one will ever understand whether the packer is out of order or not, because the water will still be clean and transparent.

There are more complex options for packers, but this is additional money, additional time for their installation, and now all companies are on the path of extreme cost reduction and no one will do this for free.

And now the most popular: many drilling organizations say that by installing a plastic pipe, you will only drink water from it. They just throw this pipe down the well and it hangs out there. There is water in it, but there is also water between the plastic and steel pipes. It's not supposed to talk about it, you won't know it anyway. This is how most drillers work without proper experience.

Naturally, if the steel rusts, then the top water will be in your tap.

Types of casing pipes for wells

Each of them has a number of advantages and disadvantages, which determines the intended purpose. If it is not clear which pipes are best for wells of a particular depth, read on or contact a specialist.

Metal pipes

There is another classification here. Products are divided into types, and there are:

- cast iron or steel;

- enamelled;

- galvanized;

- from stainless steel.

It is impossible to say unequivocally which casing pipe for a well is better, because each type is used depending on the climate, soil characteristics, the depth of the aquifers, and other factors.

The most popular type of metal casing pipes are steel. Steel is applicable for the device of artesian wells when the depth reaches the level of occurrence of limestone aquifers. Not sure which pipe to choose for a well? Steel is a versatile material that is suitable for any type of source and purpose. The advantages are:

- Long period of operation.

- High bearing capacity with small dimensions.

- Immunity to external mechanical influences and deformations.

- Resistance to abrasion, the ability to clean the source from bottom sediments.

You will have to pay for all the listed requirements for casing pipes. High cost and high weight are the minutes of metal casing for wells. During operation, a metallic taste appears in the water. It is difficult to mount the pit on your own due to the large specific gravity.

Asbestos cement pipes

This is a low cost material. It is resistant to salts.Asbestos cement has been used for many years in the construction of hydraulic structures. The list of main benefits is as follows:

- The appearance of foci of corrosion is excluded.

- Permissible operating period - 65 years.

- The cost is affordable, always available.

But there are a number of disadvantages, and the first of them is that such casing pipes are not used for arranging an artesian well. Besides:

- Complicated installation, the need for special equipment.

- The material is fragile, afraid of mechanical shocks, which complicates transportation.

- Flange connection or butt-to-butt joint is provided, which does not guarantee tightness.

- Regular maintenance required. A coating appears on the surface, which will have to be removed.

Well casing diameter and wall thickness varies, but the range presented has a smaller range of applications than metal or plastic.

Plastic pipes

ND polyethylene, PVC and polypropylene continue to squeeze metal and concrete competitors out of the market. Popularity was provided by competitive advantages, of which there are many:

- Extended service life.

- Absolute inertness in relation to salts and other chemical elements.

- The appearance of foci of corrosion, decay is excluded.

- Low specific gravity allows you to perform work without construction equipment.

- A threaded connection is provided to achieve absolute tightness.

- Ease of transportation, storage, use due to low weight.

To understand which pipe is better to use for a well if the budget is limited, add low cost to this list. The disadvantage is the restriction on the depth of the well, which cannot exceed 60 meters.Everything else depends from the selected wall thickness and section geometry.

Calculation of pipe diameter for well casing

When calculating the planned flow rate, we must not forget that it directly depends on the diameter of the casing pipes. In other words, the supply of water is greater in that source; the project provides for a larger diameter of pipes for a water well for the device.

But this is not the only factor influencing the choice. The parameters of the pumping equipment that is planned to be installed are taken into account. On average, to pump 4 cubic meters of water, you will need a pump with a body diameter of about 8 cm. There must be a margin of 5 mm on each side.

This is the distance from the pump to the inner surface of the casing. Therefore, in this case, 2 times 5 mm must be added to 80 mm. It turns out that for the implementation of the task, a casing pipe with a diameter of 100 mm is required.

Types of casing pipes for water wells

Today, the following raw materials serve as the material for the production of casing: metal, plastic, asbestos cement. Each has advantages and disadvantages over the others. Detail:

Steel

Metal casing pipes are presented in the following options: enamel, galvanized, stainless steel, traditional steel. The unifying advantage is rigidity. Such pipes are not threatened by movements and soil pressure, vibration, therefore, the well will serve the owners for a long time. Manufacturers give a guarantee of 50 years. In addition, the depth of the well can be any - in length and diameter. But there are nuances of each type:

- Traditional steel is easily corroded.Flaking metal poses a threat to health and pumping equipment that is not protected by multi-stage filters.

- Enamelled well casing must not be subjected to rough cleaning, chips during installation. This will also lead to rust.

- Galvanizing over time is capable of releasing substances harmful to human health into the water. In addition, it is soft and is able to deform from ground movements.

Stainless steel is expensive. Actually, any metal will cost the owners a round sum, so you need to choose the best one in terms of its qualities.

Nevertheless, owners of deep wells should think about installing metal structures. Having paid once and subjecting the autonomous water supply to regular maintenance, you can not worry about anything.

Plastic

All modifications of pipes made of this material - HDPE, PVC, polypropylene - combine several advantages - ease of installation, environmental friendliness, non-corrosion and reasonable price.

However, there are significant disadvantages:

- Plastic casing is powerless against soil movements - it will break. It is also deformed in severe frosts - a heating cable is required.

- Depth for plastic pipes matters - they are usually installed in shallow mines. If, nevertheless, the owners decide to make a casing in a well of considerable depth. That without threaded or coupling connections is indispensable. And they lose their integrity over time. Hence the problems - pollution of drinking water, deformation of the entire casing, destruction of the walls of the mine.

- As a rule, plastic pipe casing is used in tandem with steel pipes. It turns out a double benefit - the strength of the well and the purity of the resource. Naturally, the price goes up.

asbestos cement

Pipes made using concrete pouring technology are classic in their use for wells, septic tanks, wells. They have a large diameter, are resistant to corrosion, and have an unlimited service life. But they lose their popularity due to the fragility of the material. Besides:

- These are rather heavy structures and construction equipment cannot be dispensed with without installing such a casing in a well. Naturally, this will affect the final result of payment.

- Concrete is able to absorb dirt and is not so easy to clean. To do this, you will have to drain the well completely and spend several days on work. All chips and other defects are eliminated immediately.

- Regular preventive maintenance is carried out only by specialists with knowledge of the features of an asbestos-cement pipe. Otherwise, the service life due to inaccurate action is reduced significantly.

- Depending on the wall thickness, asbestos cement pipes can be expensive. Therefore, the price, unlike the cost of the metal, does not always justify the quality of the casing.

Using a metal pipe for a water well

It is extremely prestigious to use copper pipes for an artesian well. Casing the pipe in this way will be very expensive, but it is incredibly good in terms of environmental safety and improving the taste of drinking water.

Among metal products, when equipping a well, as a rule, steel is chosen. Their disadvantages:

- big weight;

- high price;

- susceptibility to corrosion, as a result of which the taste of water is spoiled by rust.

These circumstances have significantly influenced the choice in favor of the use of steel products when it is necessary to build a well.However, steel is still used when other materials cannot be used, such as on moving ground. For artesian wells, it is desirable to use a solid (seamless) pipe. It costs more than welded (seam), but it will last much longer.

Steel pipelines are connected using two types of docking:

1. Threaded. A high-quality conical thread can be applied to a pipe with a wall thickness of at least six millimeters. Reducing the cost of construction by using products with a smaller wall thickness, they provoke damage to the seams in electric welded elements.

Steel casing pipes can be connected using threads on the ends

It is not possible to reuse electrofusion products with a wall thickness of 4.5 mm with a threaded connection. They have to be sent for recutting or replaced, or the defective string continues to be used.

2. Welded. The use of electric welding increases the cost of well construction. Therefore, there is often a desire to use a more economical threaded connection. There is a widespread opinion about the unreliability of welds. However, practice shows that destruction occurs outside the seam zone, since the seam joint is stronger than the rest of the metal surface. Moreover, the use of a special coating for electrodes during welding alloys the seam, increasing its strength and resistance to corrosion.

Drilling specialists suggest using galvanized pipe of conversion origin as casing. Such products were made for field main collapsible pipelines. The nominal diameter of the pipe is 150 mm, the working pressure is 6 MPa.These defense products were not previously used, as they were intended for the state reserve. Although the wall thickness is relatively small (3.2 mm), galvanizing has a positive effect on the duration of operation. It is very convenient to mount six-meter galvanized products, since they are initially equipped with welded sockets 10 mm thick.

The installation of steel products is recommended on limestone and sandy soils. To prevent rust from entering drinking water, it is advisable to install an additional purification filter.

When drilling a well in sandy soils, casing pipes with filters should be used.

Pipe selection based on operating conditions

The internal plumbing includes a piping system (wiring) that transports water to plumbing and equipment. Pipes and connecting elements made of polyethylene, polyvinyl chloride, polypropylene, polybutylene, metal polymers may not be used for all networks. Each of them has its own operating conditions and they can vary greatly.

Without restrictions, pipes made of copper, brass, bronze can be used - for high pressure systems, for transporting drinking and technical, cold and hot water. Steel products with external and internal anti-corrosion coating can also be used for any purpose.

For each type of pipes and their standard size, the value of the maximum pressure in the network that they can withstand is determined. It is better that it be higher than the maximum possible pressure in the water supply network.

For example, in a house with centralized water supply, the pressure can fluctuate between 2.5-7.5 bar at a rate of 4 bar. In this case, peak indicators can sometimes reach 10 bar, and system testing is carried out at values of 12 bar. So that the pipeline does not break through, when choosing pipes, they provide for a “margin of safety” with a focus on maximum performance.

When choosing pipes for the construction of external underground systems, pay attention to the ring stiffness index. When channelless laying a polymer pipeline in the ground, in which it is possible to damage it, products with a protective coating are used. One of the factors determining the choice is the operating conditions:

One of the factors determining the choice is the operating conditions:

Image gallery

Photo from

External branches of water supply systems, regardless of whether they are connected to a central network or to an autonomous source, are laid mainly in the ground. Pipes must withstand ground pressure. When laying above the level of seasonal freezing, external water supply lines must be insulated

Entering the water supply can be confined to the basement or basement of the house. All areas located in rooms with temperatures below +2º C must be insulated or supplied with a heating cable

The pipeline of the water supply system inside the house is assembled from pipes that can work flawlessly at a temperature of +2º C and above

In the case of laying pipes with cold and heated water nearby, they are provided with thermal insulation to prevent condensation on cold pipes.

The choice is influenced by the laying method: open or closed.The contours in wooden houses, as well as metal pipelines in all buildings, without exception, are laid in an open pattern

If a hidden laying is planned in foam concrete or brick walls, only polymer pipes can be used. PP or PVC

Polymer products also predominate in the construction of summer country water supply systems. When laying above the ground, HDPE pipes that do not react to UV are used; when buried in trenches, PVC is used

Control point of the water supply system

Connecting an external branch to the central network

Entering the system into the basement of a private house

The device of the internal part of the water supply

Thermal insulation of pipes with hot and cold water

Open laying of water supply pipes

Hidden location of water pipes

Summer plumbing at their summer cottage

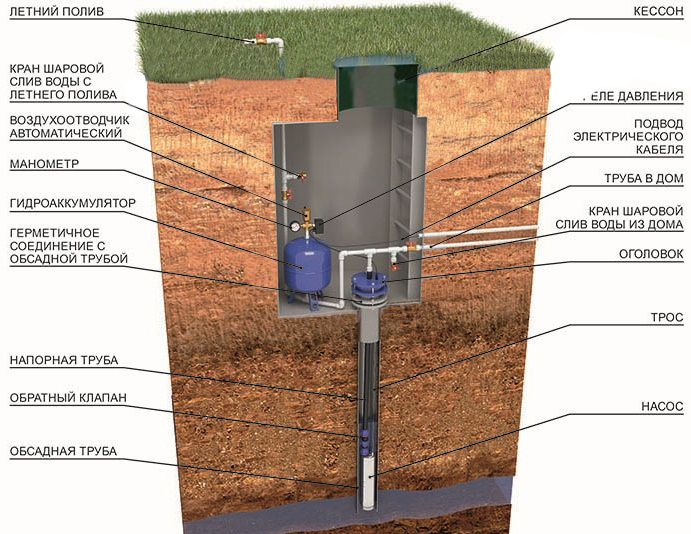

Casing Selection Options

There is no single true standard for drilling. The well organization method is determined on an individual basis.

Many indicators are taken into account: the structure of the soil, the height of groundwater and aquifers, the parameters of pumping equipment, water quality, the diameter and depth of drilling.

Well design is best entrusted to a specialized company. Employees will compare all the parameters, offer the optimal design, calculate the flow rate of the well, taking into account the static and dynamic water levels (+)

Any drilling company will offer its own version of the project and recommend, in their opinion, the best type of pipe. The final decision on the choice of casing string is made by the customer.

The performing organization, first of all, defends its own interests, so their decision is not always objective.Some contractors specialize in any one type of downhole system device and try to "impose" a profitable option for them.

The only right decision is to decide in advance which pipe to choose and use for the well, comparing all the pros and cons, and after that, apply for the development and implementation of the project.

When making a decision, you should take into account the main parameters for choosing a riser pipe:

- Manufacturing material. This parameter determines the budget for installation work, the bearing capacity for reservoir loads, maintainability and longevity of the well.

- The method of joining the elements of the column. The choice of method depends on the pipeline material, drilling depth and casing diameter. In any case, the connection must be completely sealed, otherwise the water quality will deteriorate over time, and the pump and the well as a whole will fail.

- Pipe diameter. The calculation of the value is made taking into account the maximum possible water consumption per day.

The larger the diameter of the supply pipeline, the higher the productivity of the well.

Experts recommend using pipes with a diameter of 110 mm or more. This size is optimal for a normal flow rate of a deep well and facilitates the selection of a submersible pump

Well features

Well drilling technologies are different. By contacting a specific company providing this kind of service, the owner will receive a preliminary analysis of the soil on his own site. Based on the results, a drilling method will be found. Pipes are selected according to the characteristics of the wells:

Depth. In the case of a low occurrence of the aquifer, it is necessary to think about the reliability of the connection of the pipes through which the flow will go, if the solid structures are small for the parameter.Threaded ones require regular inspection. Welding is the only way out.

Soil structure. Heavy soils, movement - will have a destructive effect on the casing of the well. But do not flatter yourself if the well is equipped on sandstone. Then the level of freezing is taken into account - the climate has a strong effect on the pipe material.

Well diameter

This is important for pumping equipment - the impact of pump vibration on the walls of the well pipe should not be allowed. Or you will have to choose equipment without centrifugal force, which is weaker in performance. Conscientious employees of the company will give practical advice on possible pipe material

If it is decided not to resort to the services of professionals, then the situation should be assessed using the example of neighbors or a nearby well. There is a nuance - in the same area, the existing horizon and soil structure may vary, and the accepted calculations will be inaccurate

Conscientious employees of the company will give practical advice about the possible pipe material. If it is decided not to resort to the services of professionals, then the situation should be assessed using the example of neighbors or a nearby well. There is a nuance - in the same area, the existing horizon and soil structure may vary, and the accepted calculations will be inaccurate.

Types of casing pipes and rules for their use

The determining criteria for choosing casing pipes is the length of the wellbore, the design pressure of the soil. Based on this, you can install plastic, metal or asbestos-cement structures. Each type has its own advantages, disadvantages and requirements for installation and operation.

Plastic pipes for wells

Made from polypropylene, PVC or HDPE. Must comply with GOST 2248-001-84300500-2009.They do not collapse under the influence of moisture, but the plastic case is less resistant to mechanical damage than the metal one. It is possible to form a wellbore entirely from polymeric water pipeline, but only with the right choice of model.

How to choose a good plastic pipe for a well:

- The design pressure in the lower part of the barrel should not exceed 16 atm. An alternative is to install check valves every 10-15 meters of the well to normalize the pressure.

- For HDPE, diameters from 90 cm, wall thickness - from 7 cm.

- Polypropylene is rarely used because of the high cost. For structural rigidity, models PN25 or higher must be used.

- Connection method - threaded coupling (couplingless) or welded. The latter is rarely used for a well.

At low temperatures, the polymer loses its plasticity, which can lead to damage due to external pressure. This also complicates the maintenance of the system at low temperatures. Installation in regions with an average winter temperature of -10°C is not recommended.

Pipes made of metals and alloys

More often, iron (steel) pipes are used for drilling a borehole. The reason is the availability of the material, relatively simple processing, resistance to mechanical stress. Disadvantages - gradual destruction due to corrosion, large mass, which complicates installation. The latter requires a special technique.

How to choose a metal pipe for a water well:

- Steel grade - ST.20 or higher.

- It is recommended to use seamless patterns. Welded ones are more likely to be damaged if the seam is made poorly.

- Wall thickness - from 5 mm.

- Connection - threaded coupling. Welding complicates maintenance (replacement of damaged sections).

Steel casing pipes should be recommended according to GOST-8732-78 (solid-drawn) or GOST-10705-80 (electrowelded seam). For the manufacture of carbon low-alloy steel is used. The use of galvanized steel products is not recommended. The reason - when in contact with the soil, the effect of "stray currents" appears - electrochemical corrosion. The use of additional protective equipment will increase the budget.

Asbestos-cement pipes

The rare use of asbestos-cement pipelines is due to their relative fragility and insufficiently reliable socket connection. Installation is also difficult due to the large mass of asbestos cement. To increase strength, thick walls are made, which leads to an increase in weight. Installation is possible only with the use of special equipment.

However, they do not corrode, and with prolonged temperature exposure, they retain their shape and integrity. The neutral composition does not enter into chemical reactions with the environment, does not affect the water in the well. The service life of asbestos-cement pipes is up to 70 years.

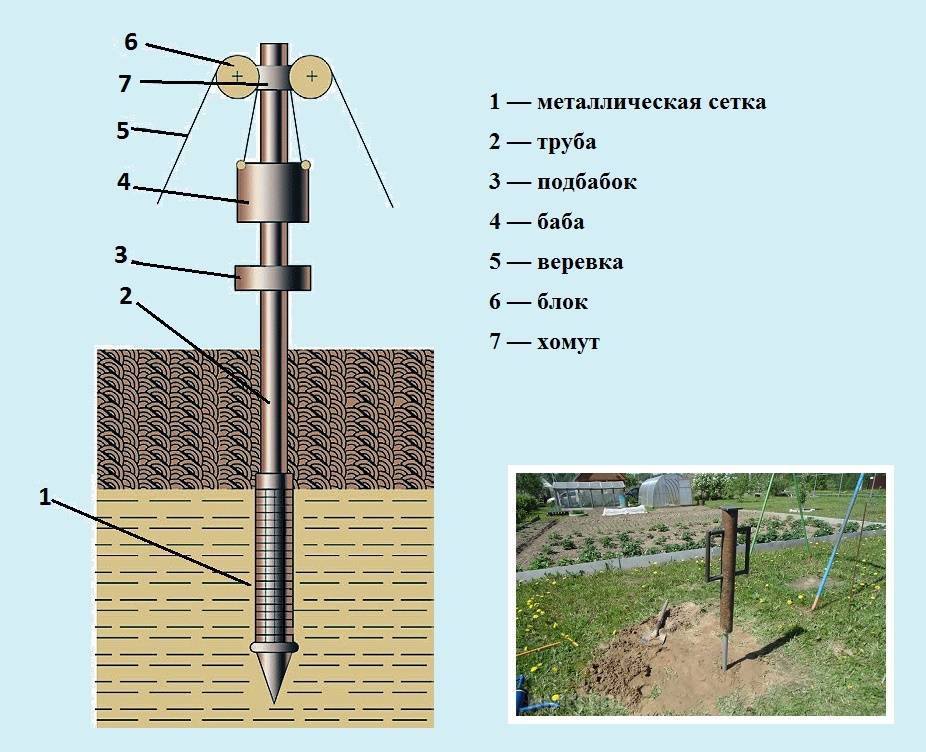

Fixing wells with pipes

Casing pipes are special pipes manufactured in industry with a clear purpose of its use, which is to prevent collapse of insufficiently stable rocks in the walls of various wells.

So, in order to fix the well with the help of columns, casing pipes are immersed in the well, after which the annulus is cemented.

Due to the presence of casing pipes in the well, the well is completely protected from complex stresses, namely:

- External pressure, which is formed by rocks;

- Internal pressure resulting from the flow of working agents through the pipes;

- Longitudinal stretching;

- Bending that may occur under its own weight;

- Thermal elongation, the probability of which in some cases is very high.

All this is tested by pipes, thereby protecting the well and ensuring its integrity.

Before the casing pipes are driven inside the well, the internal diameter of the well is determined using a caliper, and the volume of cement slurry required for cementing the annulus is calculated.

This process is mandatory, since it is thanks to the quality of the cement slurry and its pouring that success in mining will be determined. After all, cement mortar not only provides complete tightness of the well, but also is an excellent protection for pipes from exposure to aggressive environments, such as salt solutions and groundwater. When the process of casing the well with pipes is completely completed, the well is left to "rest" for a period of 16 to 24 hours. This is done so that the cement is completely frozen. However, the rate of setting of the solution can be controlled by applying various chemicals. So, the hardening time can either be increased or decreased.

Also, a very important point is the fact that during the preparation of cement mortar for fixing wells, pipes do not use fresh water. This is because the cement on fresh water does not provide proper sealing of the well due to the formation of a loose boundary layer. The reason for the formation of such a layer is the interaction of excess fresh water in solution with rocks.A much higher quality of the interaction of cement with clay, for example, is provided by a saturated aqueous salt solution.

During the casing of the wellbore with pipes, a sufficiently concentrated solution of sodium chloride is used to flush the wells before cementing, as well as during the displacement of cement. In the latter case, for the correct distribution of cement in the annulus, the velocity of the supplied saturated salt solution must be at least 1.2 m/s.

Well before operation. Trial

The casing of the wellbore is considered completed only after the well test, which involves two stages.

The casing of the wellbore is considered completed only after the well test, which involves two stages.

The first stage is carried out immediately after the cement mortar has hardened. If the well is not deep, then the string is tested at a pressure 2-3 times greater than the pressure that the working agent has directly during development. The strength test of deep wells is carried out at a pressure of 600-1000 MPa.

The second stage of testing oil wells in the pipe and under the casing string after the cement shoe is drilled out. In this case, the optimal pressure for testing is one that is equal to twice the pressure of the working agent.

Carrying out all the necessary tests allows you to determine in time the presence or absence of damage and all sorts of malfunctions that could harm the well, and eliminate them in time.

Thus, a well, formed with all the subtleties, is a durable and strong tool for oil production.

How is the installation of water pipes

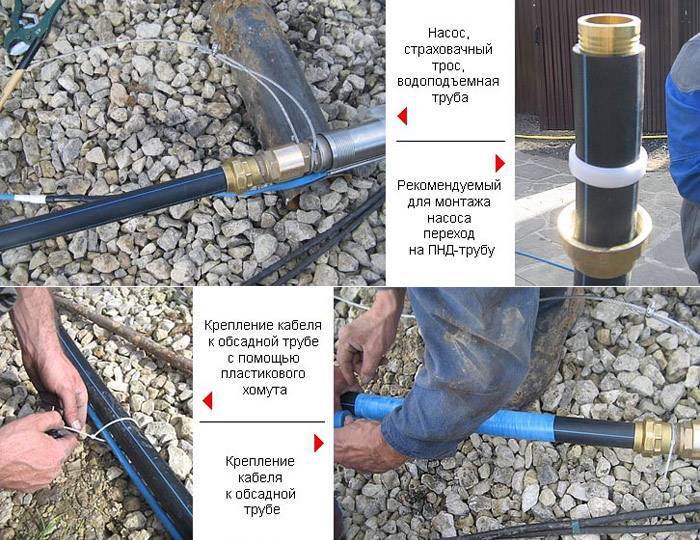

It is immediately worth noting that it is most convenient to immediately install both the pump and the pipes.In this case, all the necessary calculations should be done in advance, otherwise you may encounter a lot of difficulties. The descent of the pump into the well should be smooth. Moreover, if the preliminary preparation is not carried out correctly, then you can not receive enough water, which is required to provide the house. The lack of pressure will affect the comfort of residents. As a result, they will have to choose between doing laundry, using the shower, or watering the garden. Simultaneous side procedures will become impossible.

Modern pumps are most often equipped with a flanged or threaded version for connecting a pipe. Although sometimes a coupling type of connection is also used. Experts recommend first attaching the water-lifting element on one side, and only after that proceed with the installation of the second part of the pipe. Lowering the structure to the ground is strongly discouraged. This can cause damage to important components or displacement of certain parts.