- Pros and cons of hot water systems

- Which electric floor is better - comparison table

- Choosing a warm floor for specific conditions

- What floor can be used if the room is supposed to fill the screed

- What to do if there is already a screed, and there is no way to increase the height of the floor

- What underfloor heating to use under laminate, linoleum and carpet

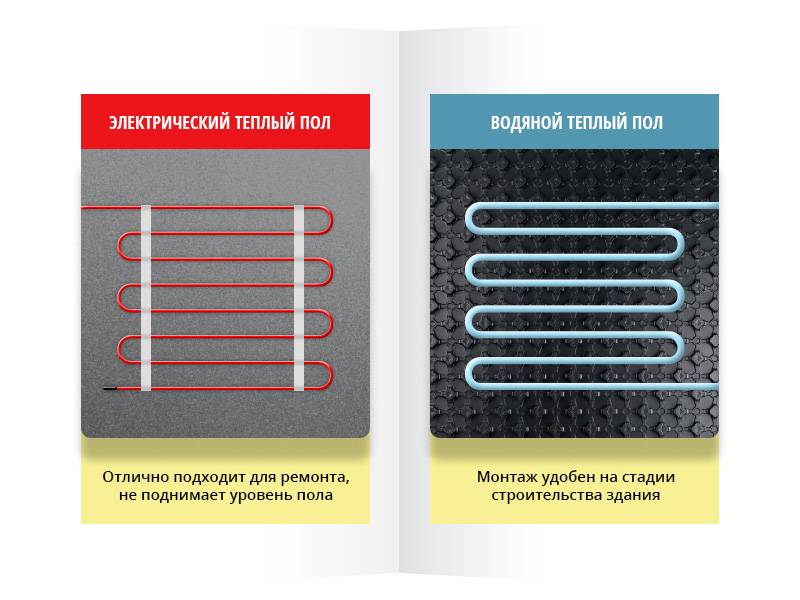

- What is the difference between an electric "warm floor" and a water

- Strengths and weaknesses of the water "warm floor"

- Strengths and weaknesses of the electric "warm floor"

- Options for optimal use of underfloor heating

- Electric floors

- Water floors

- Heating mats

- The principle of operation of electric underfloor heating

- Mistakes and rules when installing a warm floor

Pros and cons of hot water systems

The main advantage is economy. There is no need to spend electricity on heating, as hot water from the heating system enters the pipes on the floor. The disadvantages of water heated floors are much greater:

- reducing the height of the ceilings, since during installation thermal insulation of certain parameters is used to reduce heat loss from the room, as well as a screed;

- the complexity of the repair, due to the need to fill the communication with a solution;

- water heated floors are usually not installed in apartment buildings, as this not only leads to a reduction in ceilings, but is also a violation, because a connection to the heating system is required.

Which electric floor is better - comparison table

| Options | Cable underfloor heating | Heating mats | Infrared warm floor |

|---|---|---|---|

| Mounting method | Mounted under a concrete screed with a thickness of at least 3 cm. | Mounted in a layer of tile adhesive or screed, depending on the type of flooring. | The film is laid directly under the coating. |

| Types of flooring | Since the use of a screed is mandatory, it is suitable for any coating. | Tiles, porcelain stoneware, wooden floor. Installation under a laminate, parquet board, carpet is possible, but a screed layer of at least 20 mm is required. | Any floor covering, but if glue or screed is required to fix the covering, then it is necessary to lay a layer of drywall on the film. |

| Possibility of use as the main source of heating | maybe | Only as an additional source | maybe |

| Maximum possible power | 110 W/m2 | 160W/m2 | 220 W/m2 |

| Possibility of laying on various surfaces | Floor, walls | Floor, walls | Any surface |

| Possibility of shaping | There is | There is | The film can be cut in increments of 25 cm. |

| Energy efficiency compared to convection heaters | Medium | Medium | high |

| Security level | High | High | High |

| Warm-up method | uniform convection | uniform convection | Warms up everything |

| Ability to reuse in another room | Not | Not | There is |

| Electromagnetic field | 0.25 μT | 0.25 μT | Hardly ever |

| Life time | Over 30 years | Over 30 years | Over 30 years |

| Guarantee | 15 years | 20 years | 20 years |

To better understand the features of each type electric floor heatingWe invite you to watch the following video.

Choosing a warm floor for specific conditions

To finally decide for yourself which underfloor heating is better to choose, you must first of all carefully examine the base on which these floors will be laid. And then you can choose at random, and then learn with chagrin that this heating system does not fit the existing base or conditions at all. Let's take a look at some of the options ahead of time.

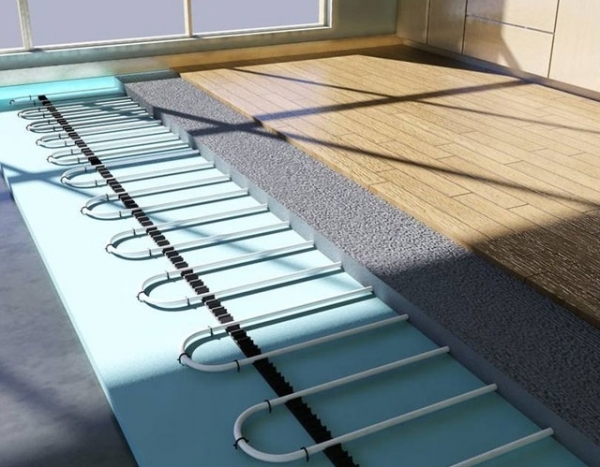

What floor can be used if the room is supposed to fill the screed

If you have a new apartment or house or you are doing a major overhaul, then the floor as such is not there yet. In any case, in most cases this is the case. In a private house with an autonomous heating system, you can arrange a water heated floor. In the apartment, in this case, a heating cable system is installed. After the installation of a particular system, the entire base is poured with a cement-sand screed.

What to do if there is already a screed, and there is no way to increase the height of the floor

Here it is best to use the system of mini-mats. Such a “rug” is rolled out on the old base with heating cables hidden inside. By quickly connecting it, you can start laying decorative tiling. Tiles are laid directly on mini mats.

Applying adhesive to ceramic tile mats.

It is possible in this case to mount and infrared heat-insulated floors. Having laid them on the base, you can immediately start laying the material with which it is supposed to finish the floor.But you should not mount an infrared floor under the tile, as the glue will not stick to it. However, if there is a strong desire to do this, then use only the dry method and put sheets of drywall or glass-magnesium on the carbon film, and then tiles.

What underfloor heating to use under laminate, linoleum and carpet

If you are tormented by the question of which warm floor is better - cable or infrared, intending to lay one of these coatings, but the screed is not supposed to be poured, then give preference to the second. For carpet and laminate with linoleum, a thin carbon film is the best option. Its thickness is only 0.3 millimeters, and only it will perfectly warm up any of these materials.

When underfloor heating is installed, it is usually decided immediately whether the house will have some other source of heating besides these floors. As a rule, the main heating system is already in place (or planned), and underfloor heating is used to create additional comfort. However, more and more often underfloor heating is chosen as the main heating system. Therefore, here you need to figure out which floor heating system to use in a particular case.

#one. If a warm floor is just an addition to the main heating system.

Here you can afford almost any of the systems listed above. Naturally, given the fact that different types of underfloor heating require the presence or absence of a screed, as well as a certain floor covering. Well, let's not forget that the water system is only suitable for underfloor heating in a large private house with an autonomous heating system. Otherwise, the choice is unlimited.

#2.If a warm floor is the only source of heat in a frosty winter.

In this case, you need to remember an important thing: the heated floor surface area should be no less than seven tenths of the total area. Only then will the house be warm. When mounting the heating cable section, it is necessary to lay adjacent turns of the cable as close to each other as possible. So we will increase the specific power (calculated per square meter), respectively, and heat transfer.

It should be noted that the heating mats, which are rigidly assembled, initially do not have very high power. Nothing can be done about it, so they are not suitable as the main source of heat. And when deciding which warm floor to choose as the main one, it’s better not to even look in the direction of mini mats. But infrared film, a water floor or cables will do just fine. At the same time, in a private house with an autonomous heating system, it is best to stop on water-heated floors. Their installation is carried out during the installation of the entire heating system of the house, after which the screed is poured and further finishing is carried out.

What is the difference between an electric "warm floor" and a water

A comparative analysis of water and electric floor heating is impossible without taking into account the specific features of each heating system.

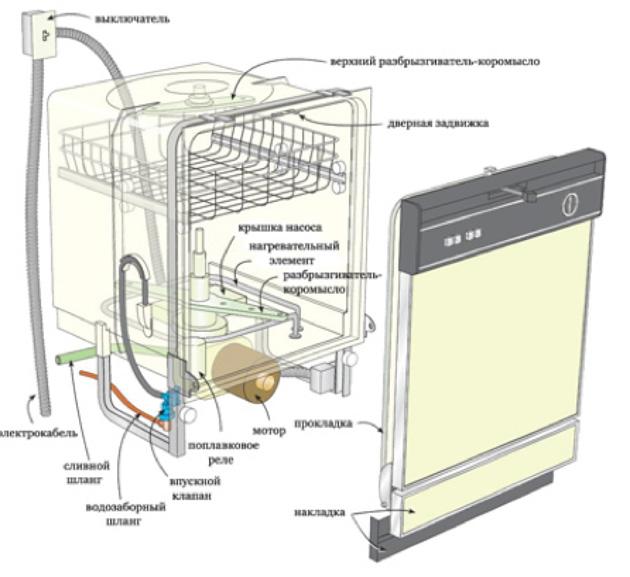

Water "warm floor" uses as a heat source a liquid heat carrier circulating through pipes laid in the floor screed. Water heating is carried out in boilers that can run on gas, liquid and solid fuels.

For electric underfloor heating, the heat source is a special cable that heats up when an electric current passes. It is also mounted inside the screed.

Strengths and weaknesses of the water "warm floor"

- efficiency - according to experts, the water "warm floor" in terms of heating costs is better than central heating by 30%, and in some cases by 60%, electric floor heating - by 4-5 times;

- long, up to 50 years, service life;

- device for all commercially available types of floor (linoleum, laminate, parquet, tile, etc.);

- universality - there are no restrictions on the type and type of premises (there are prohibitions on buildings);

- environmental friendliness - there are no emissions of harmful substances into the air and electromagnetic radiation, the humidity parameters in the room change, but not significantly (radiators dry the air more strongly);

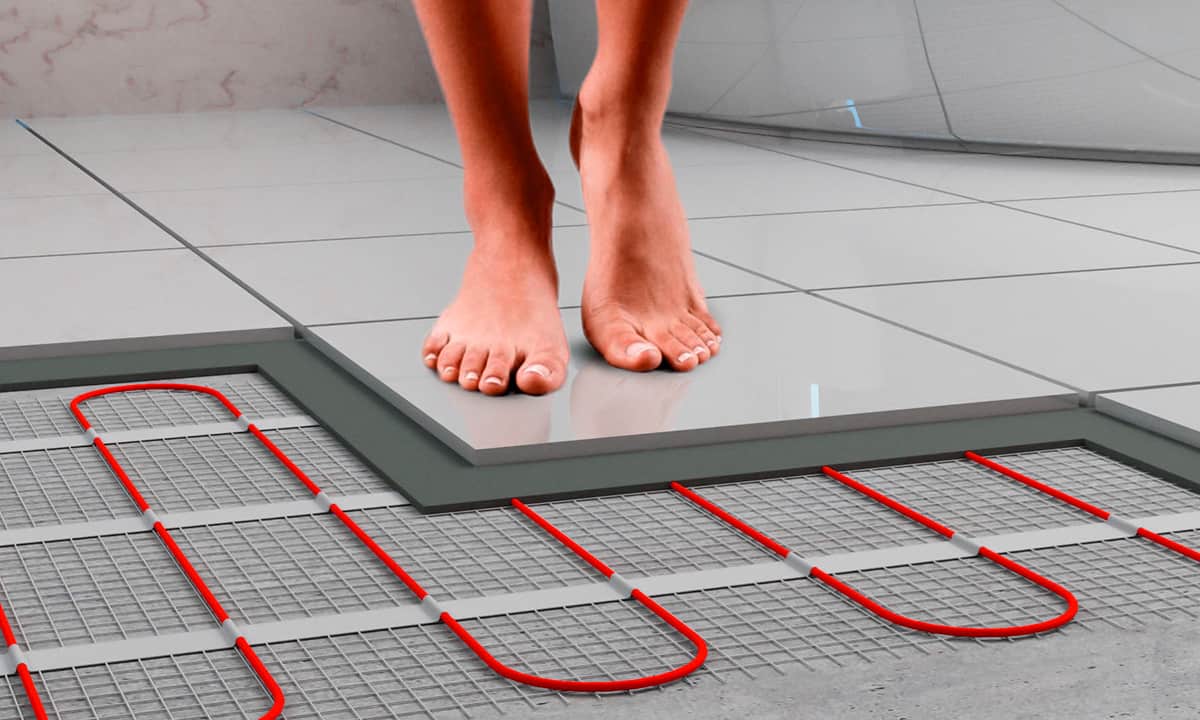

- comfortable walking on the floor barefoot;

- aesthetics - the whole system is hidden, there are no visible pipes and heating radiators. This allows designers to apply the most unexpected solutions when arranging furniture and interior design.

There are also disadvantages:

- it is necessary to have a technical room for heating the coolant;

- the height of the room is significantly reduced, by at least 8 cm, due to the need to lay insulation between the screed and the base of the floor (so as not to heat the basement) and a thicker screed (it is additionally necessary to close the pipes 2-4 cm thick);

- high cost of a set of equipment (heating boiler, centrifugal pumps, mixing units, etc.) - about 5 times higher than the cost of a cable heating system;

- complex and time-consuming installation - you need experience in connecting pipes and pouring a screed (minor errors can open up after a couple of months, as a result, the floor and the system will have to be changed);

- it is forbidden to install in multi-storey buildings;

- there is no possibility of repair - in the event of a leak, both the floor and the screed are dismantled;

- despite the presence of a mixing unit, adjusting the temperature of the coolant is difficult, resulting in constant temperature jumps, which is clearly seen in solid fuel boilers;

- uneven heating of the floor - as it passes through the pipes, the coolant cools down;

- constant maintenance is required when using solid fuel boilers (regularly add fuel);

- the heavy weight of the screed, which requires strengthening the base, if a reinforced concrete floor slab was not laid.

Strengths and weaknesses of the electric "warm floor"

Among the advantages of electric floor heating, experts distinguish:

- the possibility of laying any floor coverings on the electric heating system;

- inclusiveness - can be mounted in one- and multi-storey buildings, apartments and offices, living room, bathroom, kitchen, etc.;

- low price of a set of equipment;

- simple installation - the execution of work is within the power of homeowners;

- very accurate, up to 0.1 degrees Celsius, temperature control of the heat source thanks to temperature sensors and thermostats;

- the system is compact, does not require additional premises and is easily hidden;

- no need for maintenance;

- high level of comfort in the room: pleasant warm floor, adjustable air temperature, no air circulation;

- long service life, subject to elementary operating rules (the most common mistake is a violation of the system on and off mode);

- uniform heating of the floor surface, both in a separate room and in the apartment as a whole.

There are also disadvantages:

- high operating costs (when heating an apartment, electricity consumption reaches 10-15 kW / h);

- it is required to replace the supply wiring with a more powerful one (standard options are not designed for high loads);

- the height of the room is reduced by 7-10 cm;

- a powerful overlap is required due to the heavy screed;

- complex, but not requiring complete dismantling of the screed, repair (unlike the water "warm floor", the place of loss of contact is easily determined by the instruments).

The considered strengths and weaknesses of each type of space heating do not allow us to make an unambiguous conclusion: "warm floors" - water or electric, which is better.

Let's continue the analysis. To do this, we will compare the technical and operational characteristics.

Options for optimal use of underfloor heating

Based on the characteristics of underfloor heating systems, it is possible to identify the main situations for the effective use of both types.

Electric floors

Warm electric floors are mounted if:

- need temporary heating of a toilet, bathroom, veranda or balcony;

- an addition to the main heating system is required;

- it is not possible to perform capital work on the floor;

- the apartment is located in a multi-storey building and it is forbidden to install a water system.

Water floors

Installation of water floors is justified in such cases:

- floor heating system is used as the main one;

- additional heating is required for the entire area of \u200b\u200bthe apartment or house.

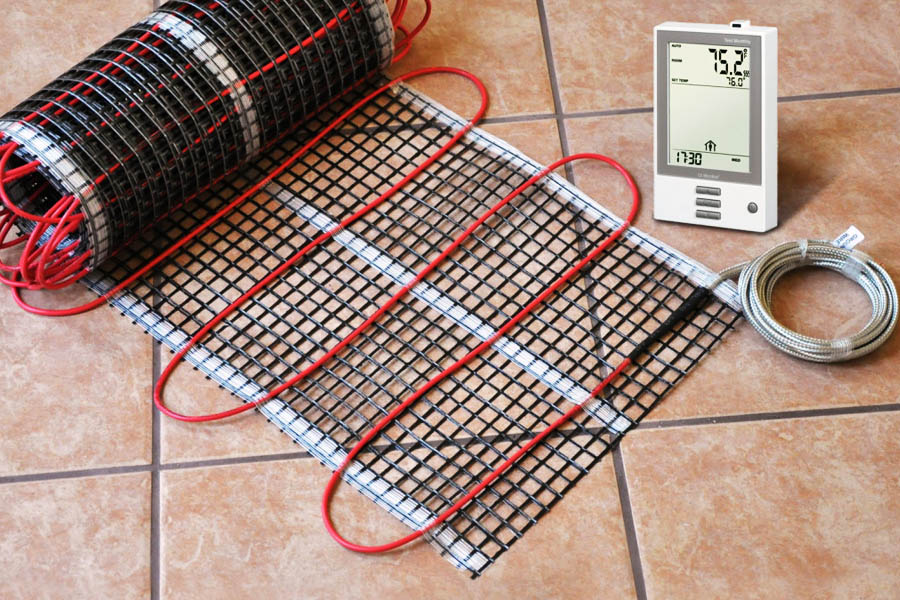

Heating mats

For independent installation, preference should be given to heating mats in which the cable is already laid in accordance with the calculations made by qualified technologists and the rated power is indicated for the consumer.The cable is fixed with the desired pitch on the mounting grid of small thickness.

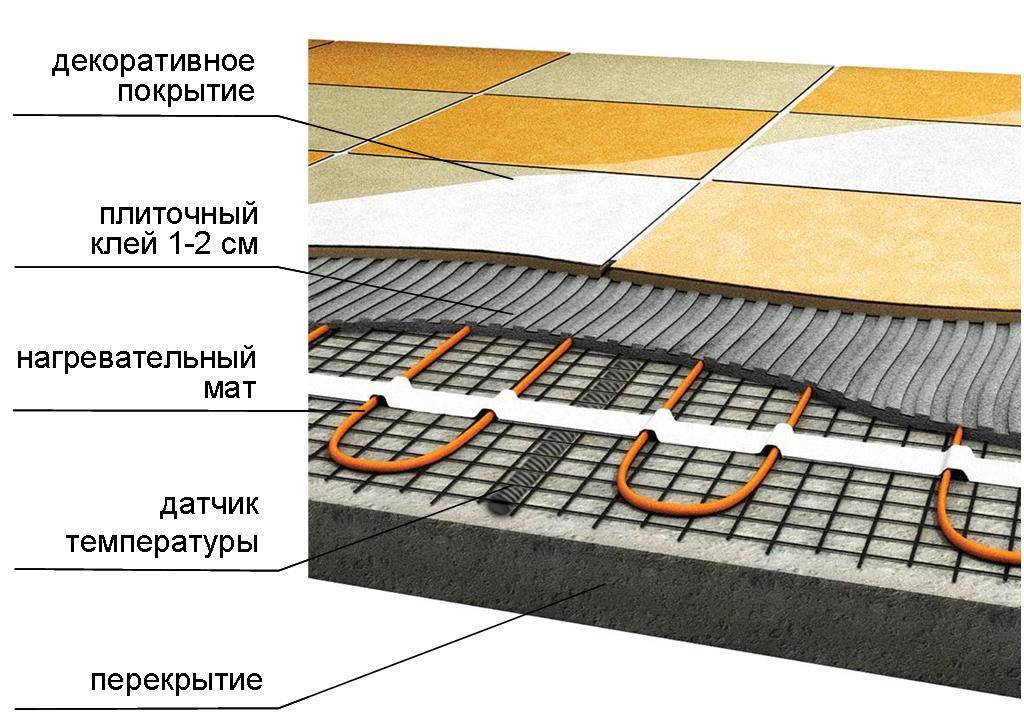

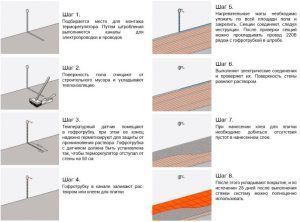

Installation of heating mats

Scheme of installation of electric universal heating mats for underfloor heating

In accordance with a pre-drawn scheme, the mats are laid out and after checking their flawless functioning, the screed is poured, which should close the surface, rising above it by at least 30 mm.

After about a month, you can install the finish coating and connect the structure to the mains.

Heating mats are convenient because they can be mounted under the tile and without a screed. To do this, a layer of special glue is applied to a flat draft floor, mats are spread according to the scheme, orienting them with the side with the cable down.

Having laid out all the elements with a slight push, it remains to distribute another layer of glue on the upper plane of the mats, on which the tile is fixed.

Floor heating mechanism with heating mat

When choosing a similar option for underfloor heating, it must be borne in mind that mats cannot be placed in areas where it is planned to install large-sized furniture.

The principle of operation of electric underfloor heating

The main working element is the heating cable. Unlike conventional wiring, its resistance is greater. An electric current is passed through it, which leads to heating of the cable. In this case, heat is transferred to the concrete screed. For comfortable heating, the cable is equipped with a thermostat that maintains the set temperature by turning off the electricity after it is heated to the set temperature and turning it back on when it drops.

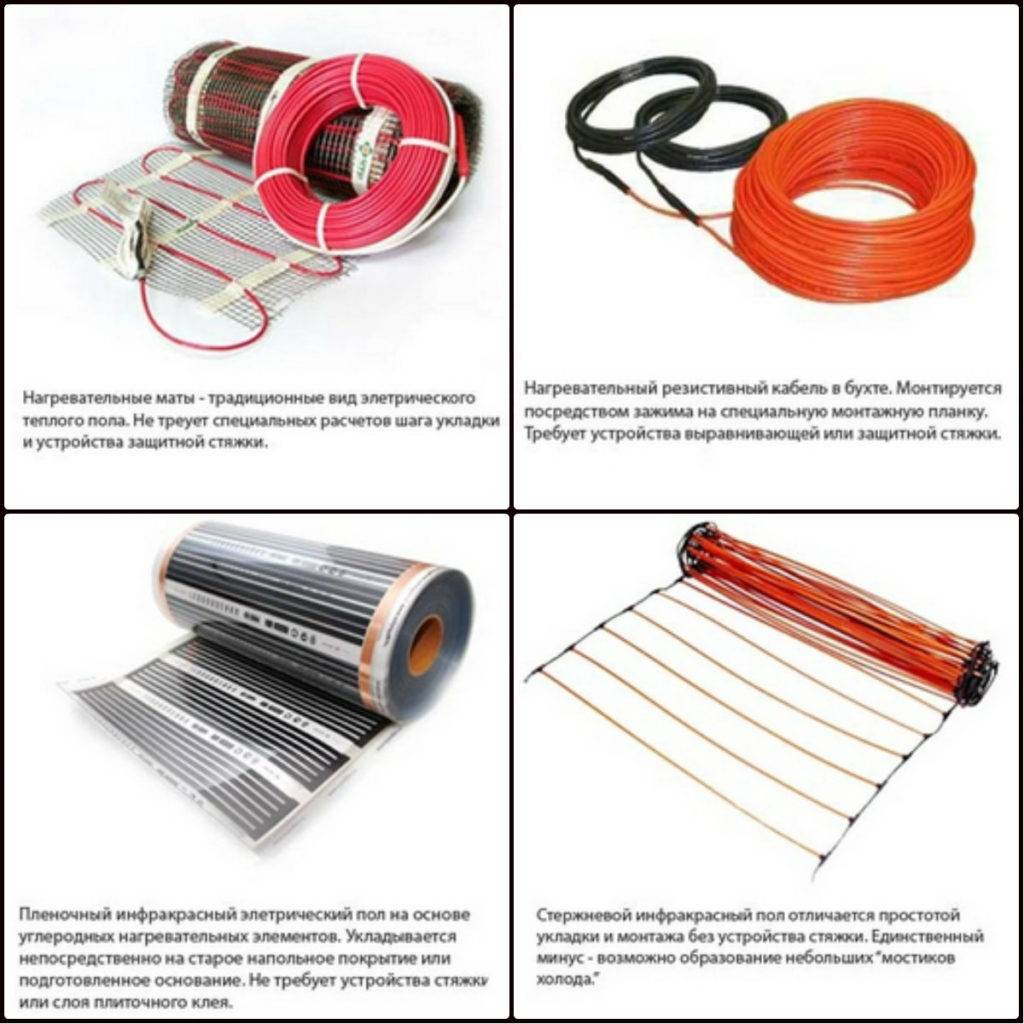

Heating elements for underfloor heating are very diverse:

- Single core resistive cable.The heating core with a shielded sheath is made of nichrome, copper or brass. Heat is released evenly along the entire length when an electric current is passed. If the heat sink deteriorates in a local area of the floor surface, the cable may fail due to overheating. Another disadvantage is the need to return the free end of the cable to the connection point. At the same time, you have to do the entire installation of the warm floor with your own hands, which is a laborious operation. Under the warm floor, the best styling is a “snail” or “snake”. Combinations of them may be used. A single-core cable is chosen because of its low cost. After laying the warm floor, it is connected to a heat regulator and poured into a concrete screed.

- Two-core resistive cable. One sheath contains two cores. Laying a warm floor is easier here, since the return of the cable for connection is not required. It is enough just to close both cores at the end and protect the connection with insulation. Both of them can be heating, or one of them serves only as a current conductor. Local overheating in such a cable can also occur.

- Self-regulating cable. It contains two conductive parallel wires with a semiconductor matrix placed between them, which is a heating element. When connected to voltage conductors, current flows through the matrix from one strand to the other in a transverse direction. The system is closed with an insulating sheath and a shielding steel braid. As the room temperature rises, the resistance of the matrix increases, and the amount of heat generated decreases. In a self-regulating cable, there are no local overheatings, since the magnitude of the current in any section depends only on its temperature.The price for such a cable is higher than for resistive ones, but the service life is longer.

- Heating cable mat. According to the device, the electric cable mat is the same single-core resistive heater attached to the reinforcing mesh sheet. Installation consists in the fact that the rolled warm floor is rolled out on a flat basis. Modern materials have an adhesive layer with which they are attached to the base surface. To rotate the mesh is cut. After the laid warm floor is connected to a power cable and connected to a thermostat, and then laid in a screed or in an adhesive layer under ceramic tiles.

- Carbon mat. The design consists of carbon heating rods connected in parallel to each other using two longitudinal insulated conductors. Thermal energy is released due to infrared radiation from the rods, transmitted to surrounding objects. The rods have the property of self-regulation of heating. If one of them fails, the others continue to function normally. Infrared mats are laid under ceramic tiles.

- The principle of heating is the same as that of infrared rods, but the warm floor is mounted directly under the floor covering: laminate, carpet, parquet board, etc. Carbon heaters are sealed in a film and connected to film conductive tires. Underfloor heating is sold in rolls and serves mainly to create additional heat.

Mistakes and rules when installing a warm floor

1

They are enough for a maximum of 1 season, or even less. Here is a visual video experiment of what happens with similar foil isols.

Don't waste your money. In addition, without reinforcement of a thin screed, as a result of the destruction of the foil insulation, subsidence and cracking of the floor covering may occur.

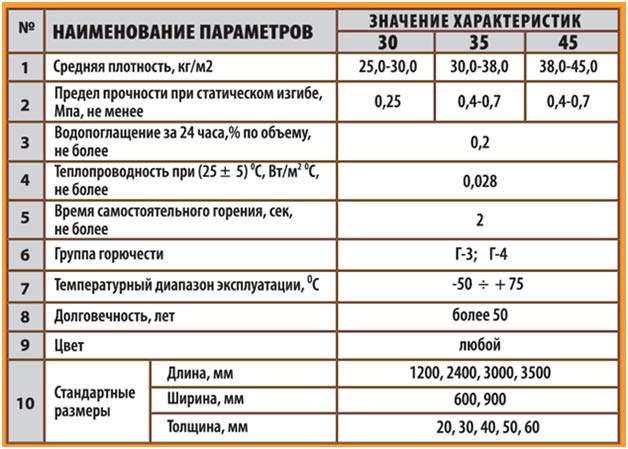

The best solution is to use extruded polystyrene foam with a density of 35 kg / m3 or multifoil as insulation.

The basis of the multifoil is air pockets in the form of tablets or pimples. They are very strong and you won't be able to crush them just like that.

You can easily walk on them for as long as you like. Moreover, the aluminum coating is applied on the reverse side, i. it is not possible to damage and corrode it with a screed.

2

This is a kind of damper, which is laid along the perimeter of the slab with a warm floor. It is necessary to compensate for the expansion of the screed, which inevitably occurs when it is heated.

This is a kind of damper, which is laid along the perimeter of the slab with a warm floor. It is necessary to compensate for the expansion of the screed, which inevitably occurs when it is heated.

If this is not done, the concrete screed will rest against the walls and it will have two options, either to break these walls themselves, or to break itself. When pouring, the edge of the damper film should be above the screed, then the excess is cut off.

3

Since all expansions during heating of such a concrete layer, only flanging cannot compensate.

Since all expansions during heating of such a concrete layer, only flanging cannot compensate.

4 5

5

None of this should get into your screed.

6

This thickness of concrete will help save you from cracking, even with not very high-quality cement.

In addition, 85mm helps with striping (thermal zebra). And finally, this is the inertia of such a screed.

If you have electricity as an energy source, at night at a cheaper rate you can “disperse” the warm floor and not turn on the boiler all day. The stored heat should be enough until the evening.

This mode of heating is approximately 3 times cheaper than usual.

7

Ultimately, you need to get concrete that will easily withstand temperature deformation.

8

First of all, when you are forced to pour only 50-60mm of screed instead of 85mm. But if possible this should be avoided.

9

Even if this coupling occurs, everything will come off when the plate is first heated. The underfloor heating slab, figuratively speaking, should "float" without connection with the base and with the walls.

10

The system must be filled and the pressure must be 3 bar. This is primarily due to the need to preserve the geometry and shape of the pipe. Without pressure inside, it is easy to crush.