- The difference between white brick and red

- Red ceramic

- silicate brick

- Where is it applied?

- The difference between red and white brick

- What to choose?

- Dimensions

- General information about red ceramic bricks

- Advantages and disadvantages

- Comparison of red and white product

- The difference between white brick and red

- Red ceramic

- Where is it applied?

- The difference between red and white brick

- What to choose?

- What is the difference between red brick and white

- Peculiarities

- Classification of bricks depending on the purpose of use

- Construction or ordinary

- Facing brick

- Furnace, fireclay brick

- Clinker brick

- Differences

- Composition and method of production

- Scope of application

- Dimensions

The difference between white brick and red

When building a house or garage, there is a question about the choice of material from which to build. White and red brick is the most popular type of building materials.

Both products have similar qualities, but there are still some differences that affect the choice of the developer. When planning a construction site, the pros and cons of materials are studied and the required number of bricks is calculated.

Much depends on the functional purpose of the building and its location.

Red ceramic

The product has several varieties that differ in appearance and properties, which gives it versatility and popularity.

Brick buildings stand out for their strength and durability.The material is made from clay, sometimes with an admixture of additives, by burning in special furnaces. The production technology takes 7 days. The long period of production gives strength to each brick. In addition, red ceramic brick has the following properties:

- frost resistance;

- moisture resistance;

- heat and noise insulation;

- wear resistance;

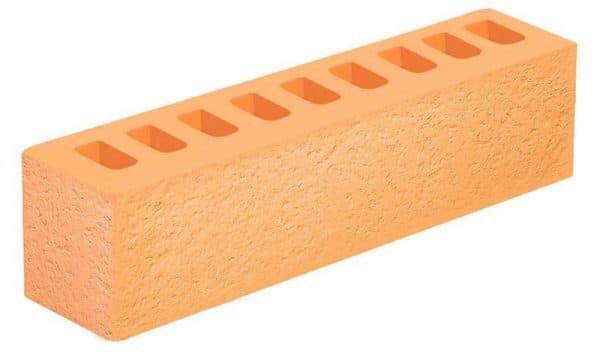

- light weight, depending on the degree of hollowness;

- fire resistance;

- environmental friendliness.

silicate brick

The production of silicate material occurs using an autoclave.

The composition of the product includes sand and lime with the addition of water. The production technology of the material consists in exposure to steam at high pressure. A similar effect is achieved using autoclaves.

The technological process of creating silicate brick takes 1 day. Such products do not differ in high moisture resistance, which reduces frost resistance, but increases heat and sound insulation abilities. Unlike red brick, white is inferior in strength.

The ability to withstand high temperatures in silicate material is 2 times less than that of ceramic. White brick is an environmentally friendly product that stands out for its consistent color and size. It is more convenient to use for reuse.

Where is it applied?

White and red bricks are used to build premises for various purposes. A feature of the silicate product is poor moisture resistance, which makes it impossible to use it in buildings with high humidity.

This specificity of white brick is even indicated in GOST, and does not imply its use in the construction of basements, wells and other structures of this type.For such purposes, ceramic products are used. A white brick house is built on a foundation of red bricks.

Both products are well suited for cladding rooms, erecting fences. In such cases, the red material is purchased from one batch, since the color shade of the products depends on this.

Ceramic bricks are highly fire resistant, so stoves, fireplaces and other structures are built from it, which are susceptible to high temperature conditions.

The difference between red and white brick

Sometimes the purchase of silicate material is more justified and economical.

The properties of red and white bricks are similar, but there are functional differences that affect the choice of material.

When there is no difference in efficiency from both products, then the decisive role in resolving this issue is played by the cost, which is much lower for the silicate product. The durability of the structure depends on the quality of the masonry, regardless of the type of brick block.

When choosing a material, the specifics of each product are taken into account. For clarity, it is better to use a table.

| Low | high |

| high | Slightly taller than white |

| Better than red | high |

| Not recommended | used |

| More susceptible to prolonged exposure to high temperatures | fire resistant |

| White | Red, but depending on the batch, the shade differs |

| Weight more than red | Depends on the degree of hollowness |

| Low | high |

What to choose?

When planning construction, it is better to be guided by the advice of a bricklayer who has come across these building materials and knows from his own experience which brick is better to choose, white or red. After studying the specifics of the materials, a suitable product is selected.

In structures that are susceptible to excessive exposure to moisture and high temperatures, red ceramic bricks are definitely used. If the influence of these factors is minimal, then the choice is made based on the material possibilities and the aesthetic taste of the buyer.

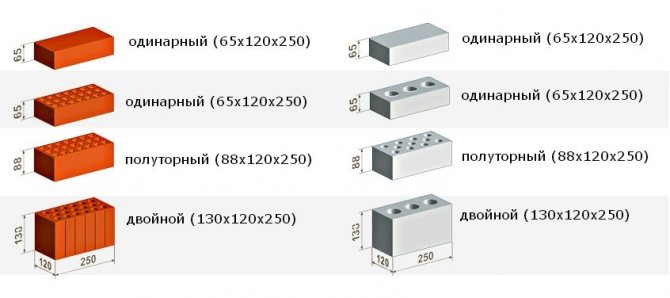

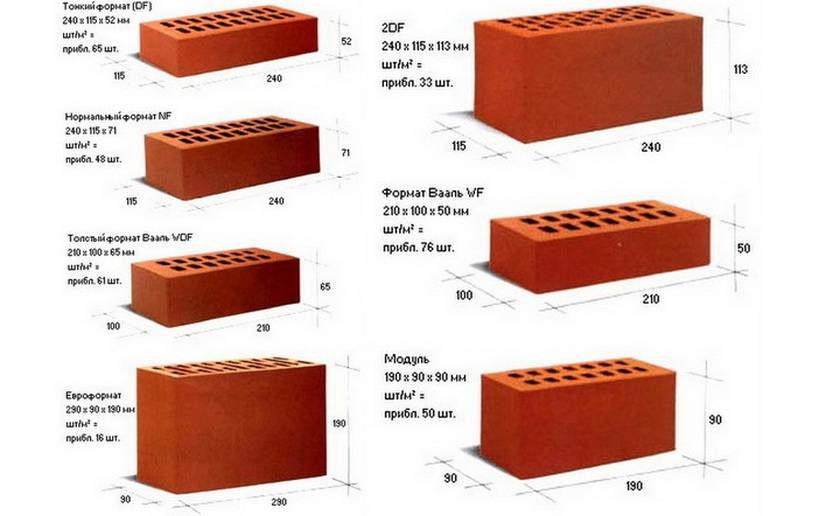

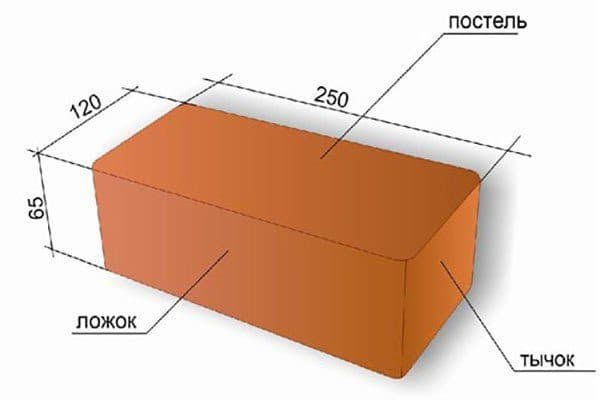

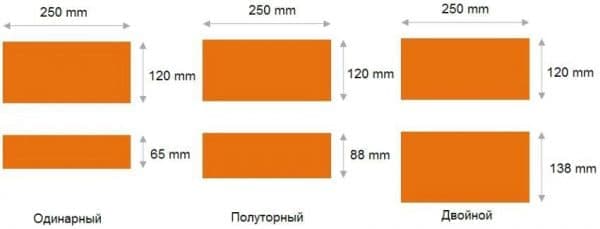

Dimensions

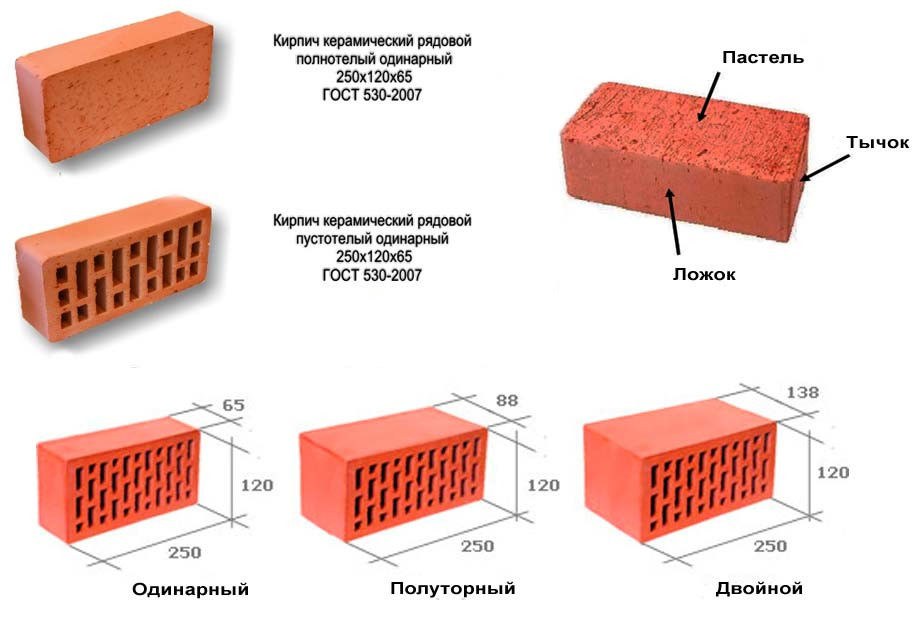

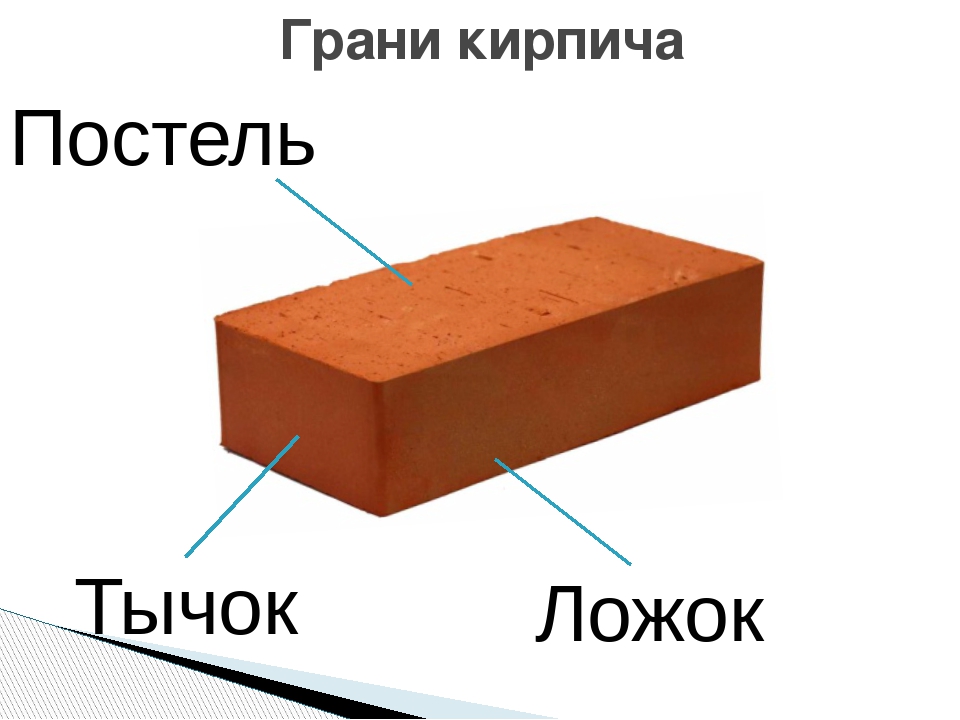

Experienced builders know exactly the dimensions of a solid red brick, this is important when calculating the estimate, as well as determining the joint, planning the foundation, etc., the size can be viewed visually in the photo. Today, the stone is divided into standard and non-standard

Standard refers to the usual single brick, which can be found in most areas of construction

Today, the stone is divided into standard and non-standard. Standard refers to the usual single brick, which can be found in most areas of construction.

The size of an ordinary solid red brick is strictly regulated by GOST, which eliminates significant defects or deviations from various manufacturers.

This option is the most convenient and popular today, as it allows you to lay even wide masonry panels and walls without any problems.

Standard

If you delve a little into the dimensions, it becomes obvious that its dimensions are almost 2 times smaller in each of the following parameters.

Due to the fact that the width is almost 2 times less than the length, it is possible to make cross-masonry when the brick is laid perpendicular to the previous layer. This approach is actively used in construction and helps to increase the quality characteristics of the structure.

Alternation occurs at a certain frequency, it can be after 1 row or after 3 rows, this is already determined by the contractor on site.

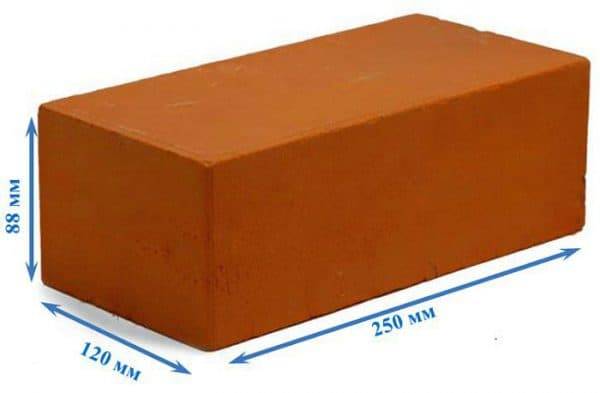

This is done to ensure maximum masonry convenience in specific industries. Such a specific stone is called one and a half. Its basic characteristics, that is, the length and width remain the same, recall 250x120 mm, but the thickness increases slightly.

For one and a half red bricks, the dimensions will be 250x120x88 mm, that is, the thickness of the stone 23 mm morethan the standard single.

One and a half

There is another brick, it is even thicker in cross section in thickness, such a stone is called double.

Double

The size of a brick, in addition to the varieties popular and well-known in our area, may meet other standards. Today, the euro brick is gradually penetrating the market, slowly but surely. Its main difference lies in the small width, namely, 2 times less than the standard one.

Its dimensions are 250x60x65 mm. It is used infrequently for the construction of houses, as it is associated with a high cost of man-hours, but it is often used as a cladding, which makes it possible to facilitate the construction. It is noteworthy that the euro standard is rarely used in Europe itself.

Euro

Infrequently, but some manufacturers can produce other types of bricks, they are mostly made to order. Such uncharacteristic dimensions are rarely used, only for projects that require certain complex types of work.

In most cases, decorative varieties of bricks have distinctive characteristics.

Facade

Until now, there are craftsmen who prepare red bricks by hand, this is mainly done in order to give them a specific aged look. Today, there are very few workshops left; there are none at all in Russia.

Dimensions can vary significantly depending on the type and production process, it is worth specifying individually. Scope of application in most cases is limited to restoration work.

General information about red ceramic bricks

Advantages and disadvantages

In the manufacture of this building material, only natural substances are used - there are no chemical additives here. Due to environmental friendliness combined with strength and reliability, bricks have not lost their leading positions in construction for many hundreds (even thousands) of years. Houses built from them successfully serve many generations without collapsing and without losing their appearance.

If we note the positive aspects of ceramic bricks, then these are:

- High strength, ability to withstand heavy loads.

- Long (hundreds of years) service life.

- Low moisture absorption, resistance to frost and high temperatures.

- Attractive appearance (especially for front products), rich palette and surface design.

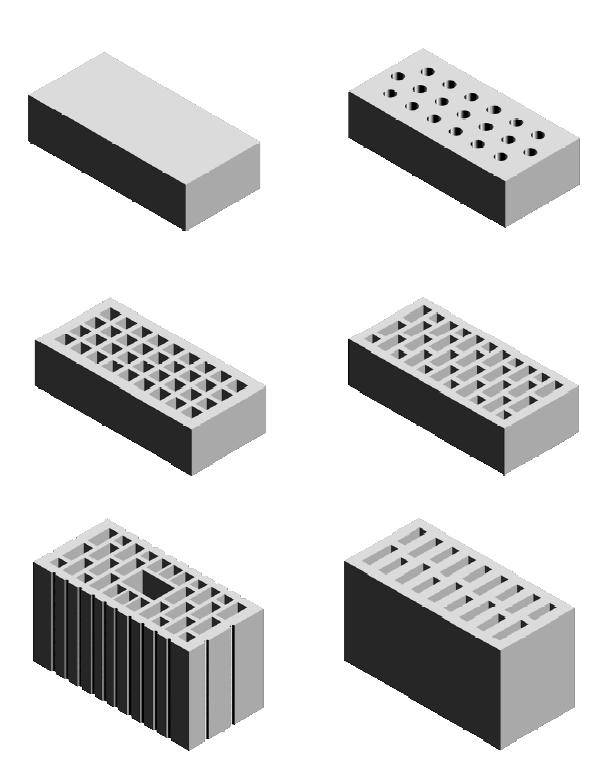

- A variety of sizes and types (ordinary, facial, slotted, solid, curly).

- Not too complicated laying of red ceramic bricks.

- A favorable microclimate is created in a house with brick walls.

There are, of course, this material and disadvantages. It:

- Efflorescence is clearly visible on the red walls, which may appear due to poor quality mortar or due to the quality of the brick itself.

- Different batches of products have different shades - when facing the facade, this can ruin the picture.

- There is a lot of marriage on the market (therefore, it is worth buying bricks only from reliable suppliers, it is better directly from the ceramic brick factory, if possible).

We will talk about which brick is better, red or white, below.

This video will tell you about the pros and cons of red ceramic bricks:

Comparison of red and white product

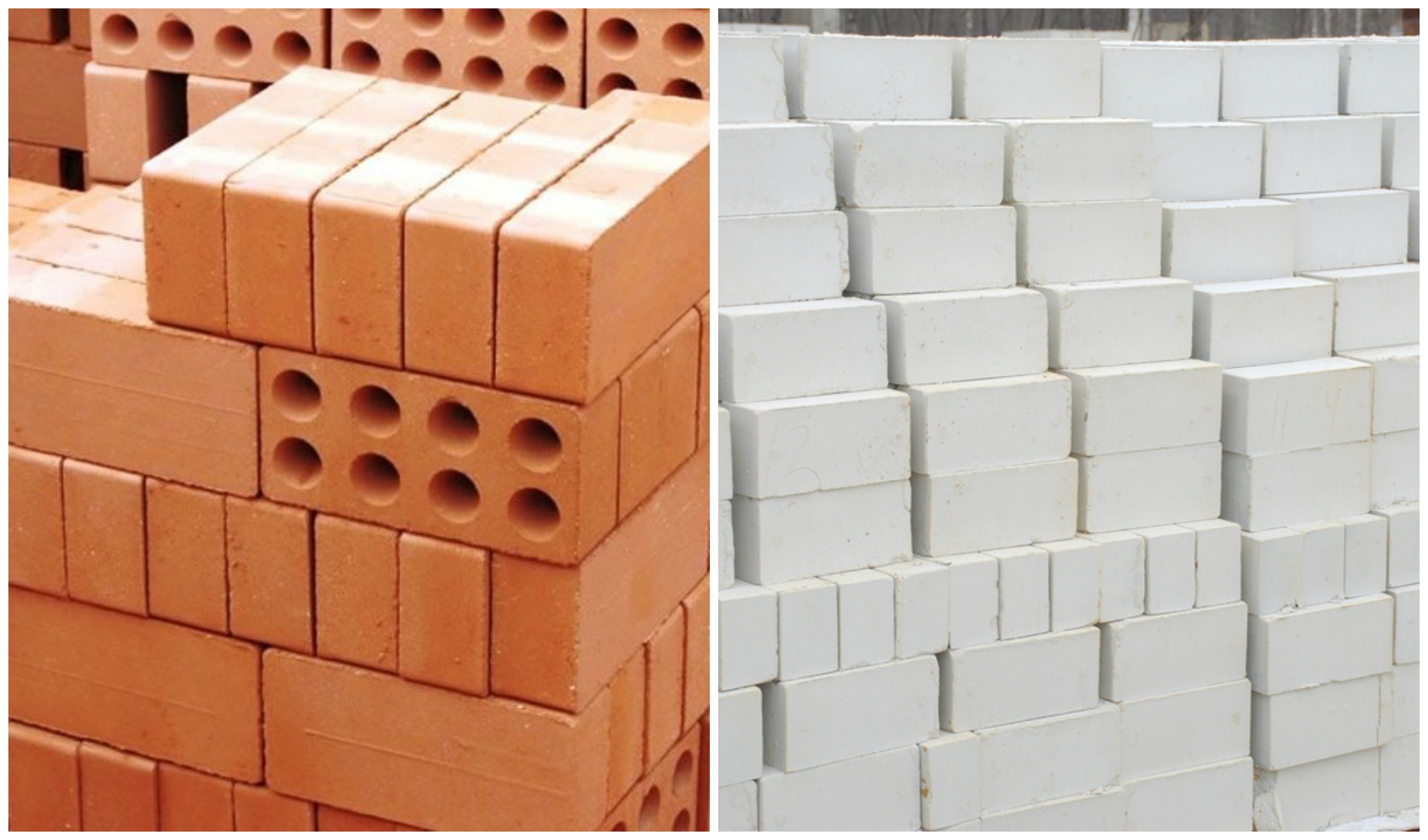

First, let's define what white (silicate) bricks are. Despite the same name as red pottery, they have a completely different composition, including calcareous rocks and quartz sand. In the manufacture of them, they are not fired, but pressed, processed in an autoclave.

silicate bricks:

- Dense, uniform and strong (however, strength depends on the brand). Such a brick is much harder to break than ceramic.

- They hold heat well - also better than ceramics (subject to a hollow structure).

- They have a good soundproofing ability, higher than red bricks.

- They are cheaper than ceramic ones.

But this does not mean at all that white pressed bricks are superior to red ones (made by firing) in all respects. They have two big drawbacks:

- Silicate products are afraid of water (respectively, freezing), soaking and spoiling with prolonged exposure to moisture. Therefore, they are not suitable for foundations and are used more for interior walls and partitions. Red ceramics is devoid of such a disadvantage.

- And the second minus of white brick: the inability to withstand high temperatures. With strong heating, this material is destroyed, in addition, poisoning the air with emitted harmful substances. Therefore, it is absolutely not suitable for stoves and fireplaces, unlike red brick.

Read about the composition of red ceramic bricks below.

Red ceramic solid brick (photo)

The difference between white brick and red

When building a house or garage, there is a question about the choice of material from which to build. White and red brick is the most popular type of building materials.

Both products have similar qualities, but there are still some differences that affect the choice of the developer. When planning a construction site, the pros and cons of materials are studied and the required number of bricks is calculated.

Much depends on the functional purpose of the building and its location.

Red ceramic

The product has several varieties that differ in appearance and properties, which gives it versatility and popularity.

Brick buildings stand out for their strength and durability. The material is made from clay, sometimes with an admixture of additives, by burning in special furnaces. The production technology takes 7 days. The long period of production gives strength to each brick. In addition, red ceramic brick has the following properties:

- frost resistance;

- moisture resistance;

- heat and noise insulation;

- wear resistance;

- light weight, depending on the degree of hollowness;

- fire resistance;

- environmental friendliness.

Where is it applied?

White and red bricks are used to build premises for various purposes. A feature of the silicate product is poor moisture resistance, which makes it impossible to use it in buildings with high humidity.

This specificity of white brick is even indicated in GOST, and does not imply its use in the construction of basements, wells and other structures of this type. For such purposes, ceramic products are used. A white brick house is built on a foundation of red bricks.

Ceramic bricks are highly fire resistant, so stoves, fireplaces and other structures are built from it, which are susceptible to high temperature conditions.

The difference between red and white brick

Sometimes the purchase of silicate material is more justified and economical.

The properties of red and white bricks are similar, but there are functional differences that affect the choice of material.

When there is no difference in efficiency from both products, then the decisive role in resolving this issue is played by the cost, which is much lower for the silicate product. The durability of the structure depends on the quality of the masonry, regardless of the type of brick block.

When choosing a material, the specifics of each product are taken into account. For clarity, it is better to use a table.

| Low | high |

| high | Slightly taller than white |

| Better than red | high |

| Not recommended | used |

| More susceptible to prolonged exposure to high temperatures | fire resistant |

| White | Red, but depending on the batch, the shade differs |

| Weight more than red | Depends on the degree of hollowness |

| Low | high |

What to choose?

When planning construction, it is better to be guided by the advice of a bricklayer who has come across these building materials and knows from his own experience which brick is better to choose, white or red. After studying the specifics of the materials, a suitable product is selected.

In structures that are susceptible to excessive exposure to moisture and high temperatures, red ceramic bricks are definitely used. If the influence of these factors is minimal, then the choice is made based on the material possibilities and the aesthetic taste of the buyer.

What is the difference between red brick and white

Red and white bricks are very similar in terms of performance and technical characteristics. However, there are slight differences between them. When choosing a building material, it is necessary to take into account the wear resistance of products.

The red stone has a beautiful noble appearance. It is no less popular than white brick. By its structure, the red stone is strong, durable. May be hollow or solid stone. The material is produced by molding and firing high-fat clay in special kilns. Roasting takes place within 2-3 days. The technology for the production of ceramic products in the general process is 7 days. That is why, ceramics has frost-resistant, heat-insulating, refractory, wear-resistant, noise-insulating properties. It has excellent moisture resistance. The material can be used for arranging a well, a basement, for laying a fireplace or stove. High-rise buildings cannot be built from red ceramic bricks. The optimal construction of facilities should not exceed 3 floors. It also cannot be used in construction in the northern regions and areas with low temperatures.

White silicate bricks are made using quartz sand, lime and water. The ratio of components is made in a ratio equal to 9:1. Stone production takes place at high steam pressure.Production time is only 1 day. For the manufacture of the product you need special equipment. The material is divided into ordering and facing. It can also be full-bodied and hollow. The material is not highly moisture resistant. It is also inferior in strength to red brick. The mass of the product is much higher than ceramic stone. Silicate material is an environmentally friendly stone made from natural natural ingredients. It does not contain harmful hazardous components and compounds that are dangerous to human life and health. It is fire resistant, not subject to rotting, the spread of fungus and various destructions.

Peculiarities

The popularity of red brick is due to its qualitative technical characteristics: the burnt composition is resistant to the negative effects of moisture, is considered a high-strength material, and does not respond to sudden changes in temperature. Additionally, it acts as an effective soundproofing agent.

The stone is based on a fired composition of clay, usually a medium-melting or refractory composition is used. Because of this, the material acquires a characteristic red or orange tint.

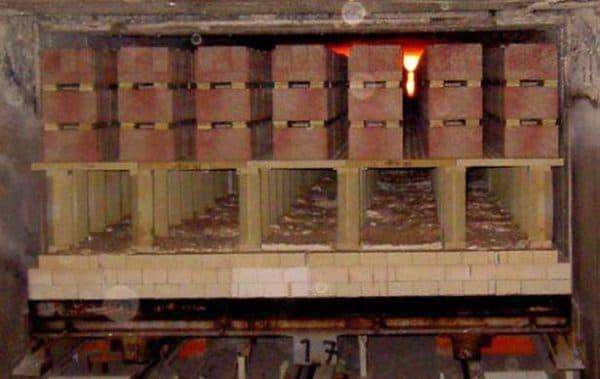

Kiln firing

Thanks to the use of only natural products, it is possible to achieve environmental cleanliness and red brick can be used even in interior decoration without harm to health and the atmosphere.

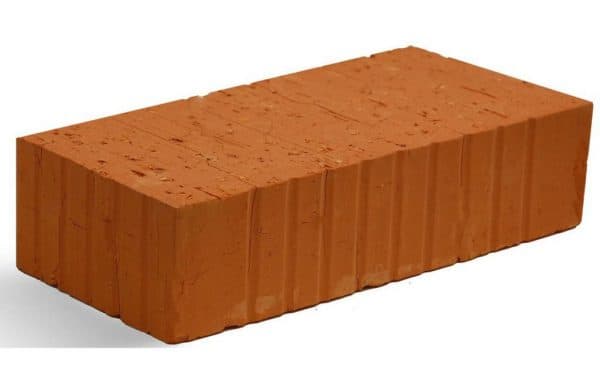

The dimensions of a red solid brick must be known in order to calculate the amount of spent, and, accordingly, the necessary material for construction.

Red full bodied

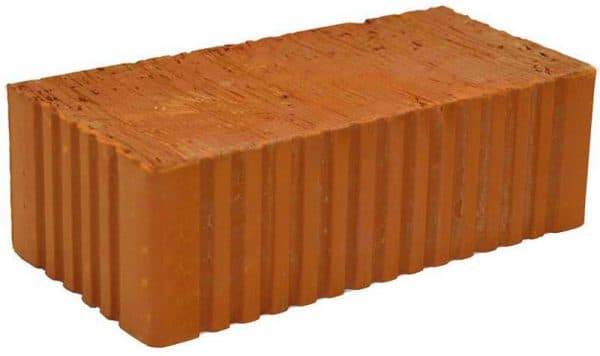

By calculating the amount of stone required, you can reduce the cost of raw materials, and prevent large surpluses or shortages.Red stone is mostly smooth-edged, but distinctive textures can be ordered.

grooved edges

An additional advantage of uneven edges is the greater strength of the structure, the mortar penetrates into the cavities and clings to the edges, the building is more integral and prevents peeling or destruction of the decor.

Classification of bricks depending on the purpose of use

In construction, there are several types of bricks, depending on the application.

Construction or ordinary

Building or ordinary brick (GOST 530-2007 dated 03/01/2008), is used in the arrangement of both the internal walls of buildings and external ones. It is also possible to use such types of bricks for building a house, but only with subsequent insulation or protective finishing of the facade. This type of brick is far from ideal and may contain small chips, which, however, do not affect its strength.

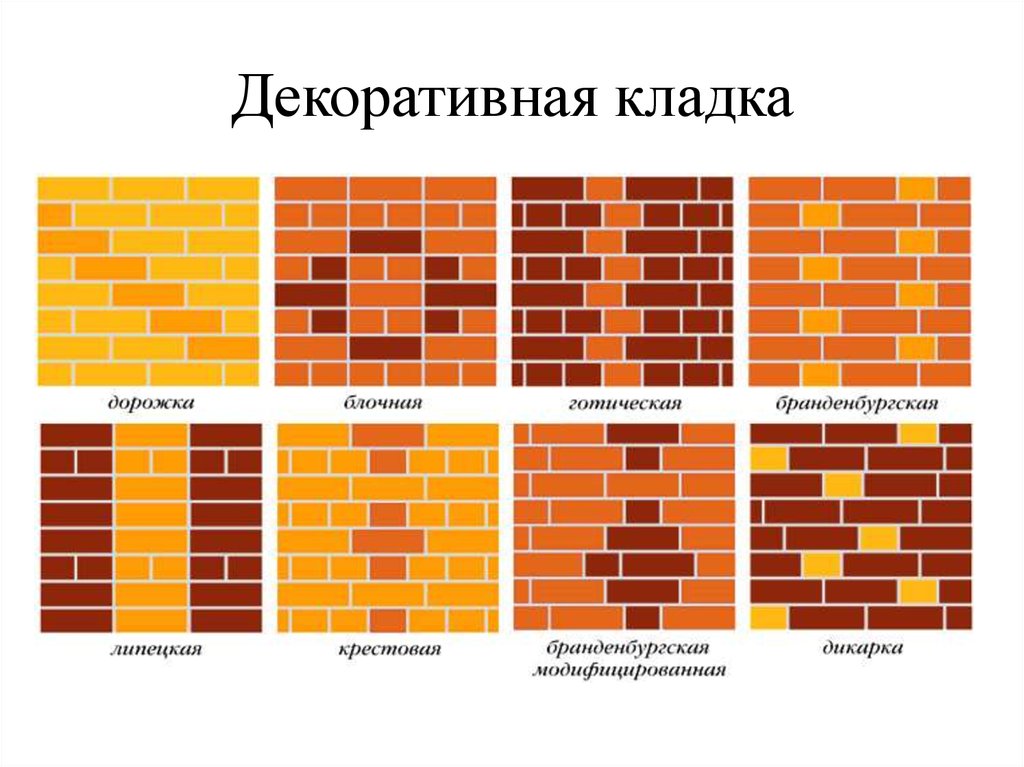

Facing brick

Facing brick, (other names: front, facade) is the most even and ideal material without defects. The maximum permissible deviations according to GOST are no more than 4 mm. in length, 3 mm. in width and 2 mm. in height. Ceramic, silicate or hyper-pressed brick can be used as facing.

There are two types of facing bricks - textured and shaped bricks.

1. Textured brick, with smooth or uneven edges (Ragged stone) is produced for cladding building facades and arranging fences. The edges of such a product can be either rolled, smooth or without processing.

2.A shaped version with different profile configurations, designed for laying complex shapes around windows, window sills, arches, pillars, fences, arbors. For example, shaped types of building bricks with round edges for corners are perfect for arranging complex facades of buildings, namely corners.

The gamut of colors of facing types of bricks is large and ranges from light yellow to almost black.

Furnace, fireclay brick

Furnace, fireclay brick, this refractory product according to GOST 390-96, has a regular geometric shape, a granular base and can be straw-colored, with reddish or brown patches. They serve for isolation and construction of objects exposed to constant high temperatures (stoves, fireplaces). Forming a heat-resistant shell, with the function of protecting the furnace from direct fire or hot coal.

The main qualities that such products should possess are: heat resistance, high cyclicity, low thermal conductivity. Fireclay must withstand quite a long heating and many cycles up to a temperature of 1000 ° C without loss of quality and strength. The refractory version is not necessarily made in the correct shape, there are other formats of such products (ShA-25 and SHA-47) - wedge-shaped.

Clinker brick

Ceramic clinker bricks are made from refractory layers of clay, which are sintered until a homogeneous mass is formed. In the choice of clay mass as a raw material for production, they are treated carefully. The composition of the clay should be clean and plastic, it should not contain chalk and alkali metal salts, unnecessary minerals. In the process of heat treatment, the clinker acquires the highest strength and good density.Low hygroscopicity and unpretentiousness to negative temperatures. Shale clay has a suitable composition for this, it is elastic and refractory.

This brick has many colors and textures. Therefore, clinker bricks are used for cladding walls, plinths, paving garden paths.

Differences

If each of us can easily answer the question of how stone differs from brick, then not everyone knows how one brick differs from another. Both of them are of artificial origin and the correct form. What are the differences?

Composition and method of production

Differences begin already at the stage of extraction of raw materials:

- Clay is needed to make red brick;

- For white - quartz sand and rocks, the firing of which produces airy lime.

Move on.

The next difference between silicate brick and ceramic brick is the method of its production.

Molded blanks of silicate products are processed in autoclaves, where they are exposed to hot water vapor under high pressure;

Sand-lime brick production equipment

Sand-lime brick production equipment

The clay mixture after molding goes through the stage of drying and firing.

The history of clay bricks is very old - they learned how to make it several millennia ago, and until recently it was produced in an artisanal way, with their own hands, since the technology is quite simple.

Its silicate counterpart is a little over a hundred years old, and its production requires special equipment that cannot be assembled at home from improvised materials.

And, nevertheless, the price of the latter is much lower, which explains its high demand, which is not inferior to the popularity of ceramics.

Scope of application

Differences in composition inevitably entail different properties of materials. Let's return to the question of why white brick cannot be used to build the foundations of houses, basements and other structures that are in direct contact with a humid environment. And also for the construction of structures exposed to high temperatures.

This is prevented by the following properties:

High hygroscopicity. In other words, this material has excessive moisture absorption, and the presence of water in its composition negatively affects the strength and heat-saving functions. While ceramics with its low moisture absorption resists such influences better.

The basement and foundation are built only from red brick

The basement and foundation are built only from red brick

But this material has high soundproofing properties, which makes it more preferable for the construction of internal brick partitions.

With the same thickness, such partitions have better sound absorption

Dimensions

It has already been mentioned that the linear parameters of both materials are the same, but only if we are talking about products of a standard format. However, in recent years, large-format ceramic stones have become widespread.

How is stone different from brick? Basically, the size. It is a block, which is equal in volume to several standard bricks laid in mortar.

Photo of ceramic stone masonry

Photo of ceramic stone masonry

And we are talking only about ceramic products. The maximum size of silicate is double. That is, the difference lies also in different ranges of effective sizes.