- How to determine the required casing diameter for a well

- Types of casing pipes for a well

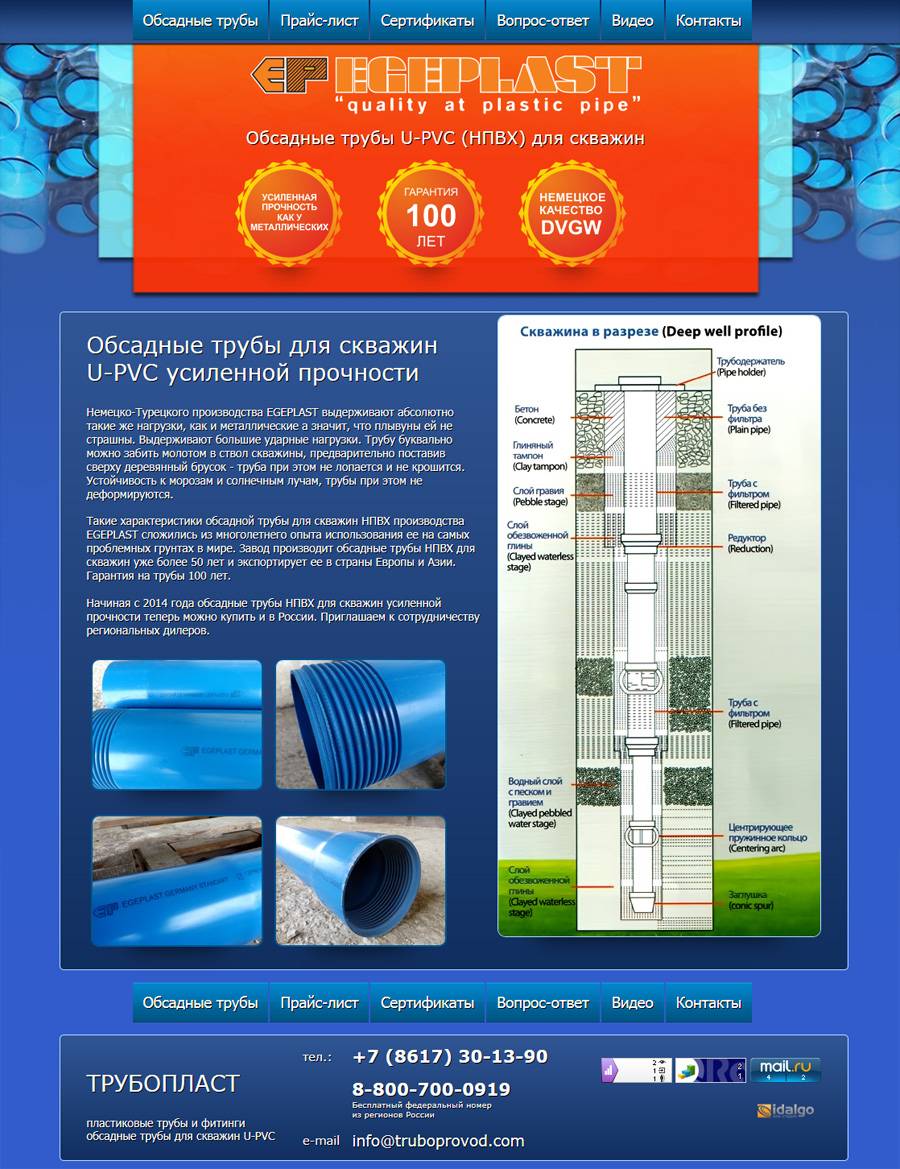

- Plastic casing products

- What type of products to choose

- Asbestos cement pipes

- Steel pipes

- plastic models

- Types of casing pipes for wells

- Metal pipes

- Asbestos cement pipes

- Plastic pipes

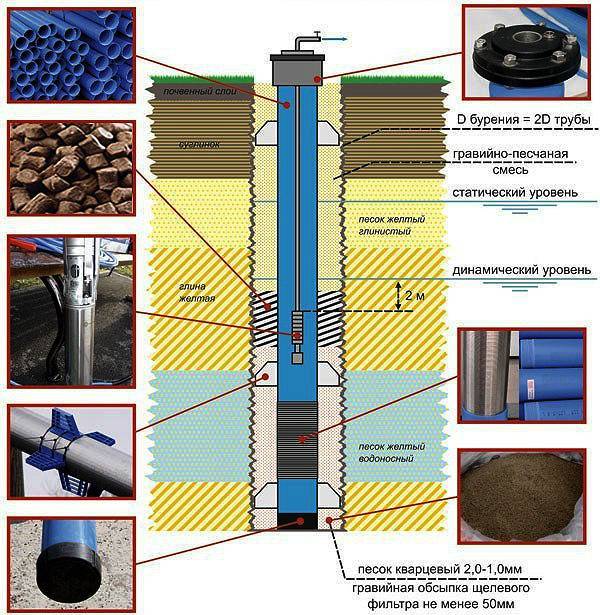

- Calculation of pipe diameter for well casing

- Types of casing pipes

- Well support during drilling

- Dependence of the diameter of the production pipe on the dimensions of the pump ↑

- Types of pipes and selection criteria

- Well casing device

- Definition and purpose of the casing

- Mounting Features

How to determine the required casing diameter for a well

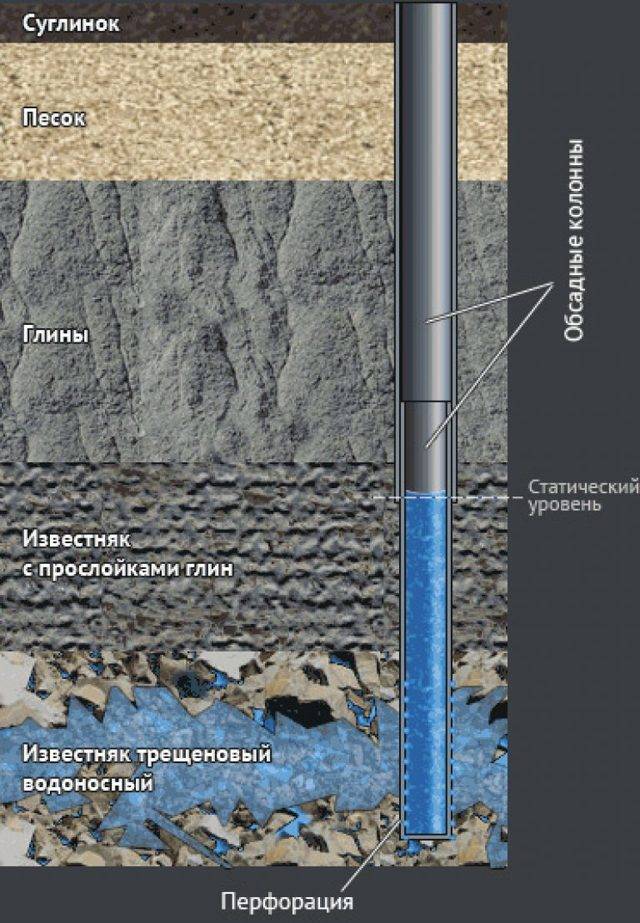

The dimensions of the well, and, accordingly, its casing pipe, depend on a lot of factors. To begin with, it is necessary to analyze the already available data on aquifers underground. For such information, you can contact your neighbor, but it is best to get it from specialized companies.

To calculate the diameter of the casing pipe, you need to analyze the maximum possible water flow.

This should take into account not only the amount of water required for drinking or cooking, but also for all other household needs, such as keeping animals and watering the garden.

Based on this value and the depth of groundwater, you need to choose a submersible pump model.When choosing a design, it is worth considering that with an increase in the diameter, drilling a well using a casing pipe will become much more expensive, so you should not make the cavity too large.

Having information about the outer diameter of the submersible equipment, taking into account the double thickness of the pipe walls and the technological gap, the size of the casing pipe is selected. Most often, the nearest standard value is chosen in the direction of increase. Before purchasing it, you should find out the capabilities of the drilling equipment used in your area, often its functionality is limited.

Pumps offered by manufacturers can be installed in wells of various diameters. The most economically optimal is the casing for a well with a diameter of 125 millimeters. It is with its choice that you can achieve an excellent ratio of the cost of drilling a well and pumping and submersible equipment. The use of larger diameter pipes is almost never practiced for domestic water sources.

Types of casing pipes for a well

The specific type of casing communications is selected individually, for each specific section, the following is taken into account:

- well depth,

- ground structure,

- cost of consumables.

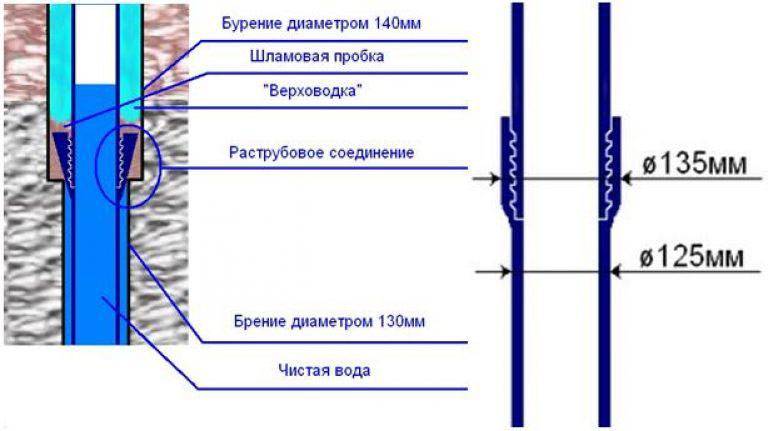

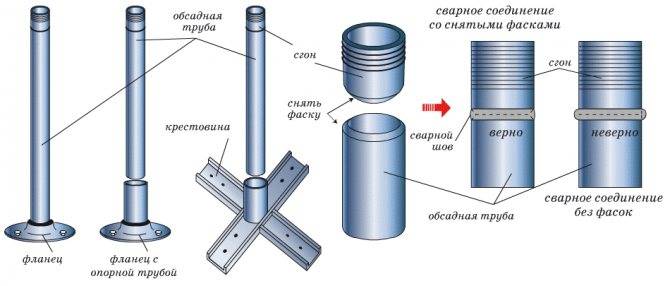

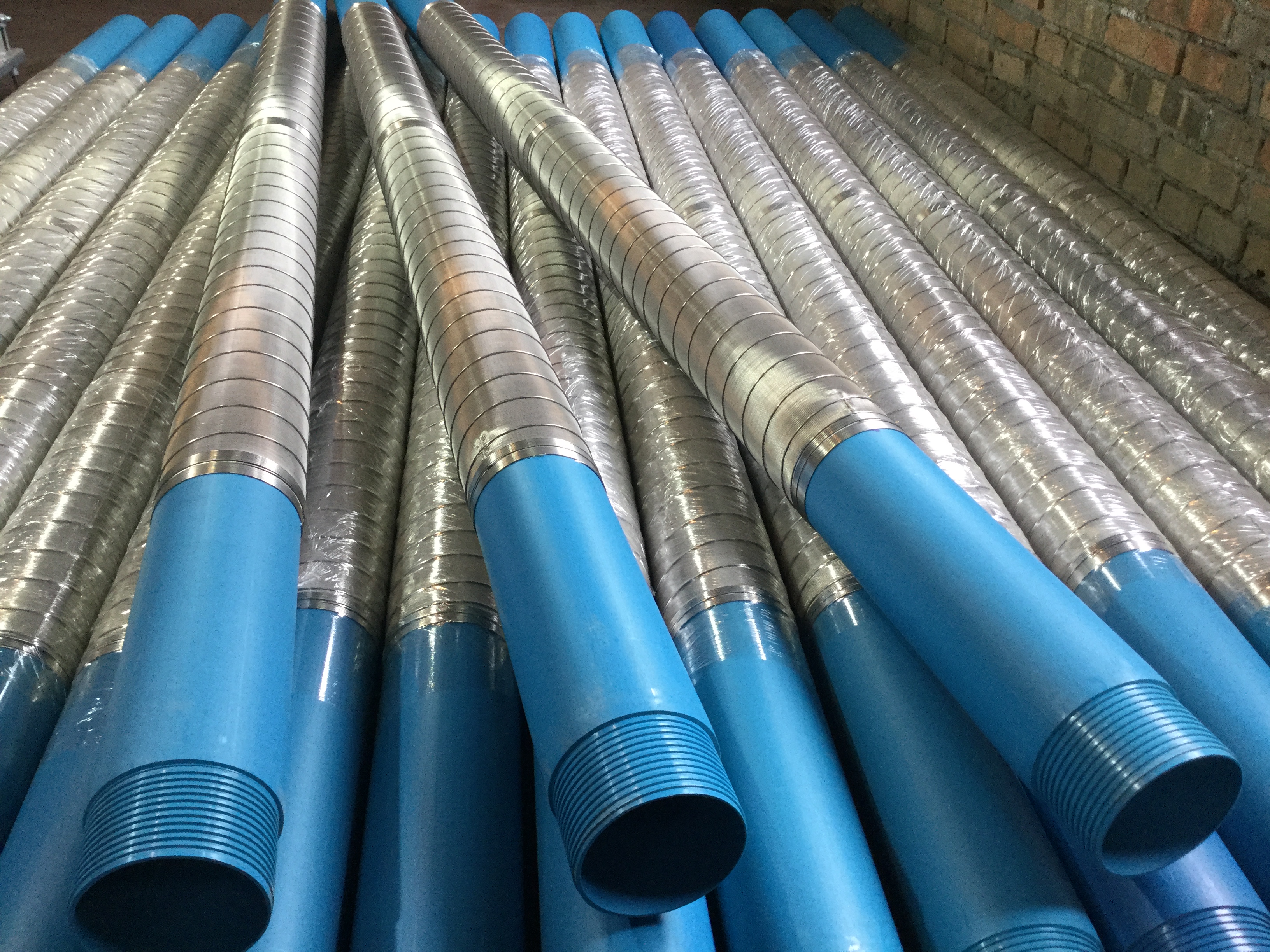

It is not always possible to make the bypass pipe one-piece - very often several sections have to be joined together. Experts recommend using threaded well pipes. Thanks to the threaded connection, the sections are securely fixed to each other. The use of butt or coupling joints is highly undesirable, since soil can penetrate into the pipe through the joints and the submersible pump may fail.

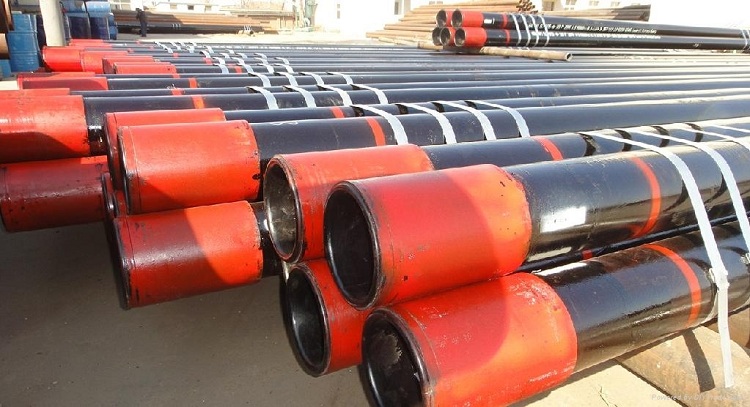

Steel pipe for a well

Steel pipes have been used in well drilling for a long time.They are known for their reliability and durability. A steel pipe with a wall thickness of about 5 mm can last more than 40 years without any complaints. In some cases, well drilling is only possible using steel products.

The disadvantages of steel casing pipes should also be noted. The metal is constantly in contact with water, which leads to its gradual corrosion. As a result of this natural process, the incoming water may contain rust impurities. Although, in principle, this problem is solved by installing a water filter. Another disadvantage is the high cost. This is especially noticeable in recent years, due to the rise in price of metal products.

Asbestos-cement casing pipes

Asbestos cement pipes are also very common for well construction. Their popularity is due to their low cost and availability. The service life of such pipes is more than 60 years.

In fairness, the disadvantages of asbestos-cement pipes should also be listed. First of all, it is a lot of weight and thick walls. For the installation of such pipes, it is necessary to use larger diameter drills and lifting equipment. This leads to an increase in the cost of the well. Also, the installation of such products should be carried out by organizations specializing in this, since the joining of pipe sections to each other has a number of features./p>

During installation, it is necessary to exclude the possibility of gaps in the joints. Not all specialists can perform such work with high quality, because the design has butt joints.Some sources contain information that asbestos fibers contain a dangerous element - chrysotile, which over time can lead to a deterioration in the health of people using water from such a well. However, the effect of asbestos-cement products on humans has not been fully elucidated.

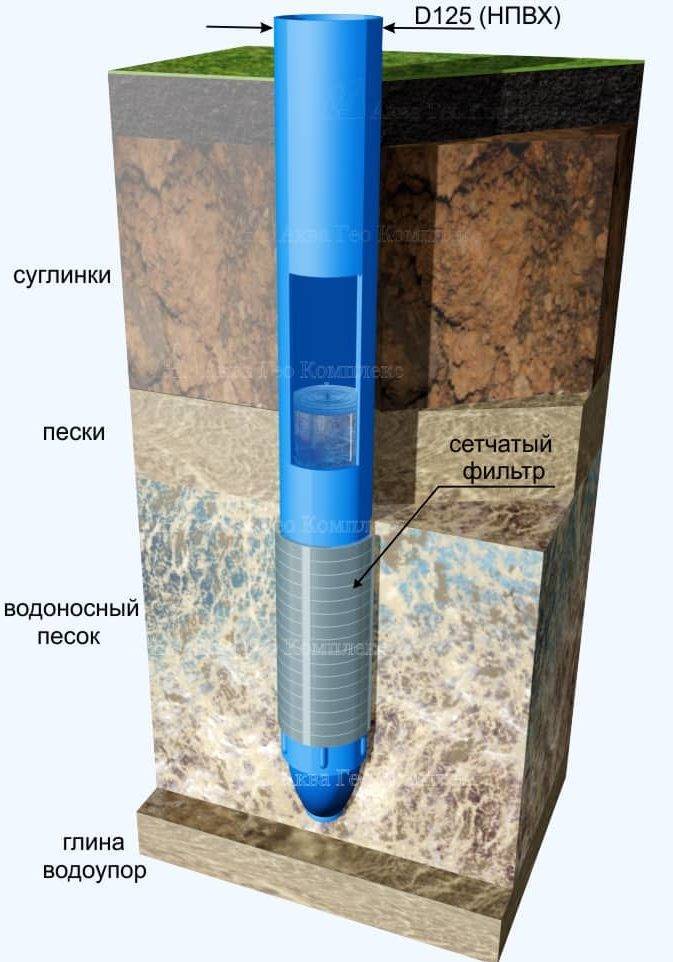

Plastic casing products

The most modern material for wells is plastic. Plastic pipes for a well are lightweight compared to steel or asbestos-cement pipes. In addition, the price for them is not so inaccessible compared to metal. Simple installation and high tightness of connections allow us to conclude that plastic pipes are now the main material used for drilling wells.

A polyethylene pipe for a well can be operated for more than 50 years. Plastic is resistant to corrosion and is neutral when interacting with aggressive chemicals. Deposits do not form on the walls of plastic pipes, and repair of plastic products is an extremely rare need.

PVC pipes for wells can be of two main types:

- uPVC,

- HDPE.

Plastic pipes for HDPE wells are low-pressure polyethylene products. They are easy to install and environmentally friendly. Like all plastic pipes, they are not afraid of internal deposits, they are able to bend if necessary, taking a given shape.

Therefore, builders try not to install HDPE pipes in wells, recommending the installation of PVC-U pipes. Although HDPE products are quite suitable for laying sewers, gas pipelines and water pipes. HDPE pipes do not have a threaded connection, but are joined together by a flange or coupling connection.

Pipes plastic UPVC are made of unplasticized PVC. The material is highly durable. In terms of strength, PVC-U pipes can be compared with their steel counterparts.

UPVC products have a higher allowable stress, yield strength and density compared to HDPE.

For example, a PVC-U pipe with a diameter of 125 mm, being immersed to a depth of 30 meters, is able to withstand a load of more than 5 tons. Such products can be installed in almost any soil. PVC-U pipes differ from HDPE pipes by the presence of a threaded connection.

Only after carefully studying the types of casing pipes, make a decision on the choice of a particular material.

Consider your abilities and needs

What type of products to choose

If you need a well casing, you can make it from pipes of various types:

- asbestos-cement;

- plastic;

- steel, etc.

They are distinguished not only by the price, but also by the performance characteristics. Below is a detailed description of each product type.

Asbestos cement pipes

This type of materials has been successfully used for many years, since they are characterized by the following positive qualities:

- neutrality;

- resistance to corrosion;

- resistance to chemicals.

Pipe in the well

However, in addition to the positive properties, there are also negative ones, which led to a drop in the popularity of this material:

- high requirements for tightness and accuracy of joints;

- impossibility of installation in sandy soil;

- the impossibility of equipping wells whose depth exceeds one hundred meters;

- high price of the material.

Steel pipes

These models have increased resistance to virtually any load.

However, this positive characteristic is offset by negative ones:

- susceptibility to corrosion;

- high iron content in water;

- the need to install a filter to combat iron and rust;

- the probability of failure of the pump as a result of rust getting into it;

- metallic taste of water;

- installation complexity.

steel models

Note that the installation of the casing in the well in this case is carried out only on two types of soils:

- sandy;

- limestone.

plastic models

This type is considered the most optimal today, because:

- reliable;

- easy to install;

- durable;

- inexpensive.

However, if you are interested in how to install the casing in the well, if a plastic product is chosen, then please note that they are only suitable for shallow sources.

Threaded plastic product

For installation, the following types of products are most often used:

- from unplasticized polyvinyl chloride;

- polypropylene;

- polyethylene.

uPVC casing pipes

Types of casing pipes for wells

Each of them has a number of advantages and disadvantages, which determines the intended purpose. If it is not clear which pipes are best for wells of a particular depth, read on or contact a specialist.

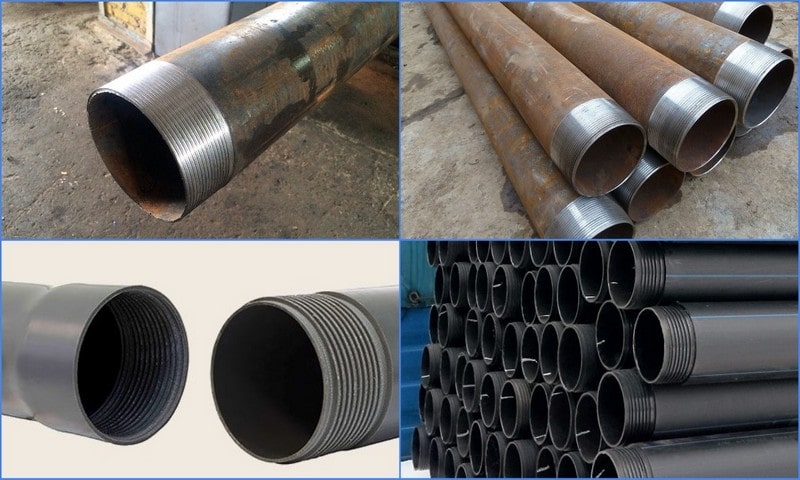

Metal pipes

There is another classification here. Products are divided into types, and there are:

- cast iron or steel;

- enamelled;

- galvanized;

- from stainless steel.

It is impossible to say unequivocally which casing pipe for a well is better, because each type is used depending on the climate, soil characteristics, the depth of the aquifers, and other factors.

The most popular type of metal casing pipes are steel. Steel is applicable for the device of artesian wells when the depth reaches the level of occurrence of limestone aquifers. Not sure which pipe to choose for a well? Steel is a versatile material that is suitable for any type of source and purpose. The advantages are:

- Long period of operation.

- High bearing capacity with small dimensions.

- Immunity to external mechanical influences and deformations.

- Resistance to abrasion, the ability to clean the source from bottom sediments.

You will have to pay for all the listed requirements for casing pipes. High cost and high weight are the minutes of metal casing for wells. During operation, a metallic taste appears in the water. It is difficult to mount the pit on your own due to the large specific gravity.

Asbestos cement pipes

This is a low cost material. It is resistant to salts. Asbestos cement has been used for many years in the construction of hydraulic structures. The list of main benefits is as follows:

- The appearance of foci of corrosion is excluded.

- Permissible operating period - 65 years.

- The cost is affordable, always available.

But there are a number of disadvantages, and the first of them is that such casing pipes are not used for arranging an artesian well. Besides:

- Complicated installation, the need for special equipment.

- The material is fragile, afraid of mechanical shocks, which complicates transportation.

- Flange connection or butt-to-butt joint is provided, which does not guarantee tightness.

- Regular maintenance required.A coating appears on the surface, which will have to be removed.

Well casing diameter and wall thickness varies, but the range presented has a smaller range of applications than metal or plastic.

Plastic pipes

ND polyethylene, PVC and polypropylene continue to squeeze metal and concrete competitors out of the market. Popularity was provided by competitive advantages, of which there are many:

- Extended service life.

- Absolute inertness in relation to salts and other chemical elements.

- The appearance of foci of corrosion, decay is excluded.

- Low specific gravity allows you to perform work without construction equipment.

- A threaded connection is provided to achieve absolute tightness.

- Ease of transportation, storage, use due to low weight.

To understand which pipe is better to use for a well if the budget is limited, add low cost to this list. The disadvantage is the restriction on the depth of the well, which cannot exceed 60 meters. Otherwise, everything depends on the selected wall thickness and section geometry.

Calculation of pipe diameter for well casing

When calculating the planned flow rate, we must not forget that it directly depends on the diameter of the casing pipes. In other words, the supply of water is greater in that source; the project provides for a larger diameter of pipes for a water well for the device.

But this is not the only factor influencing the choice. The parameters of the pumping equipment that is planned to be installed are taken into account. On average, to pump 4 cubic meters of water, you will need a pump with a body diameter of about 8 cm. There must be a margin of 5 mm on each side.

This is the distance from the pump to the inner surface of the casing. Therefore, in this case, 2 times 5 mm must be added to 80 mm. It turns out that for the implementation of the task, a casing pipe with a diameter of 100 mm is required.

Types of casing pipes

Modern industry produces the following types of casing pipes:

metal. It is these products that have found the greatest use as casing pipes. Metal pipes ensure the safety of the water source due to the fact that they easily withstand small ground movements.

But one cannot ignore one significant disadvantage of steel casing - susceptibility to corrosion. As a result, after a short period of time, rust flakes from the inner surface will begin to fall into the water, due to which its quality is significantly reduced. There are two ways to deal with this phenomenon: the initial installation of stainless steel casing and the use of filters

But, since the cost of stainless steel is rather big, this version of execution will cost the customer very much.

asbestos-cement. Pipe products made from this material also have a number of advantages. So, for example, homeowners are attracted by a long service life at a low price of products. But it is possible to use asbestos-cement casing pipes only to a depth of 15 meters, since with a larger value of this parameter, the pressure exerted by the soil can cause the destruction of this fragile material. And the cost of the work increases the need to drill a channel with a large diameter due to the significant wall thickness of this type of tubular product. And you should also remember about the dangers of asbestos for human health.

If we compare plastic pipes with metal and asbestos-cement counterparts, we can distinguish their following advantages:

- not susceptible to corrosion;

- the aging process of the material does not cause hazardous chemical compounds to enter the water;

- limescale does not form on the walls of polymer pipes;

- physical and chemical properties ensure a long service life;

- compared to other materials, the connection of plastic casing elements provides better tightness;

- the cost of polymer pipes is lower than that of existing analogues.

Despite the popularity of polymer pipes, only steel casing strings are used for wells operating in difficult conditions.

Among the shortcomings of such pipe products, one can single out its inability to withstand heavy loads. Therefore, the technology of drilling with a plastic casing is focused on creating a well up to 50 meters deep. Of great importance is the diameter of the tubular product, and it must be chosen as accurately as possible, since the potential water consumption, as well as the possible drilling depth, depend on it.

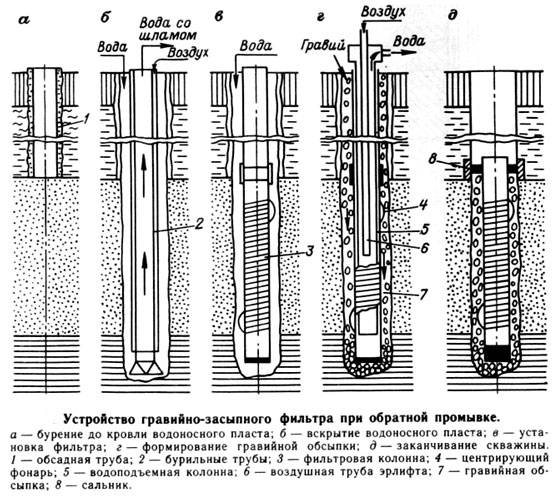

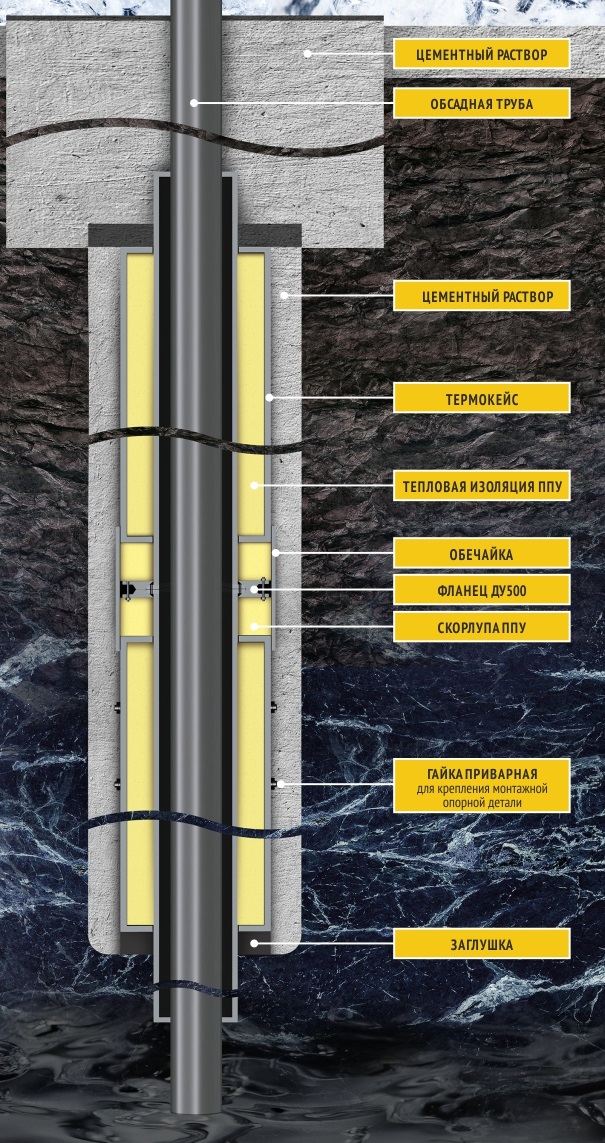

Well support during drilling

- well performance;

- Well operation time;

- The strength and tightness of the channel through which the extracted product will flow from the horizon to the day surface;

- Protection of the production channel from corrosion;

- The strength of the walls of the well in places where the rocks are not sufficiently stable;

- Tightness of separation of all permeable horizons from each other.

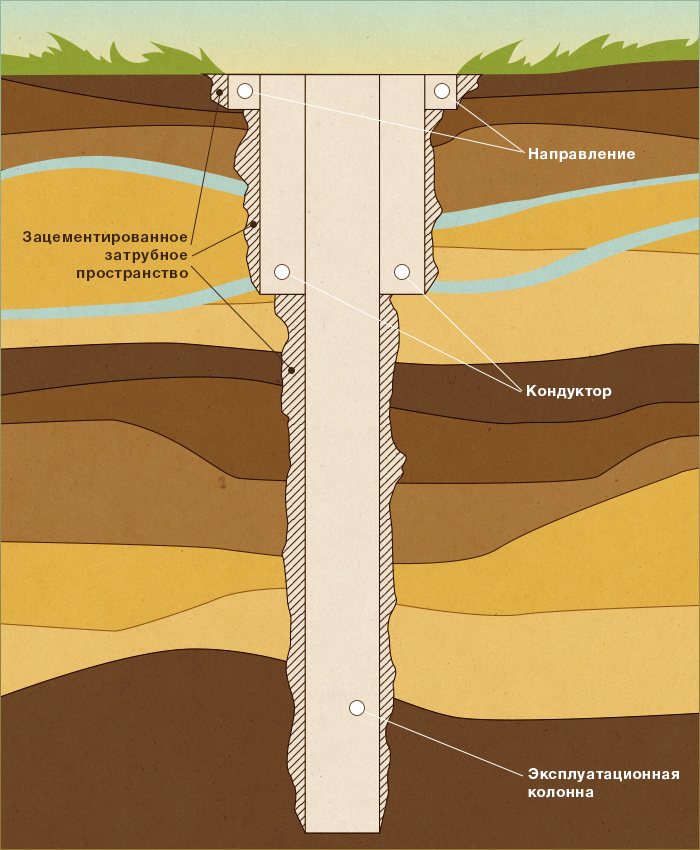

Fixing oil wells involves the use of special columns or packers.The use of columns is the most popular method that allows you to make the well strong, durable, and also separate the permeable horizons. Such columns are made up of special pipes called casing.

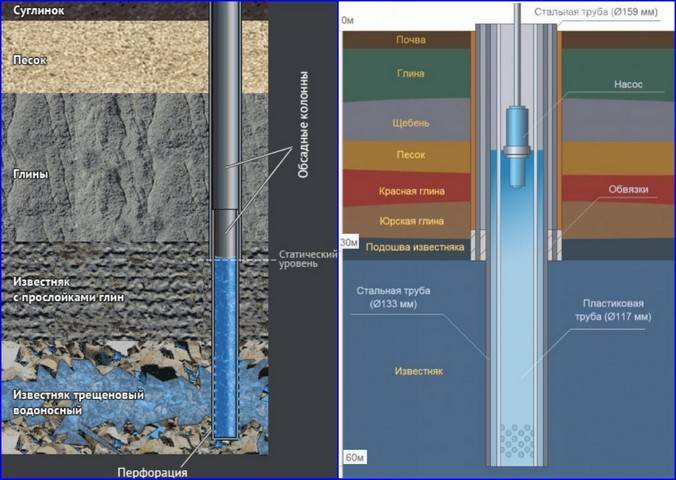

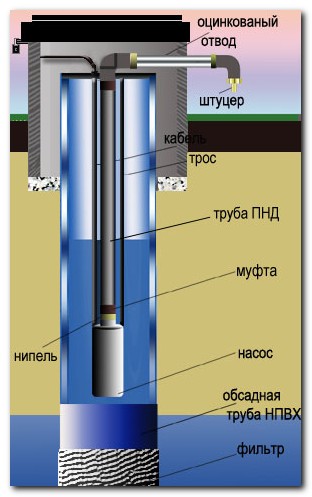

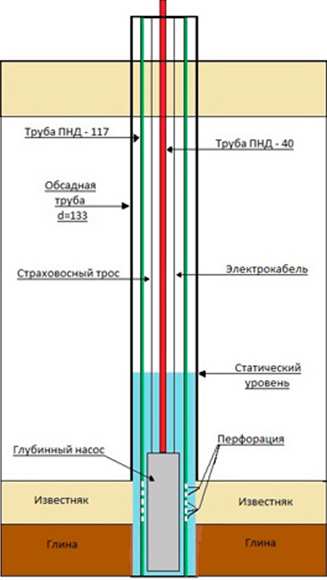

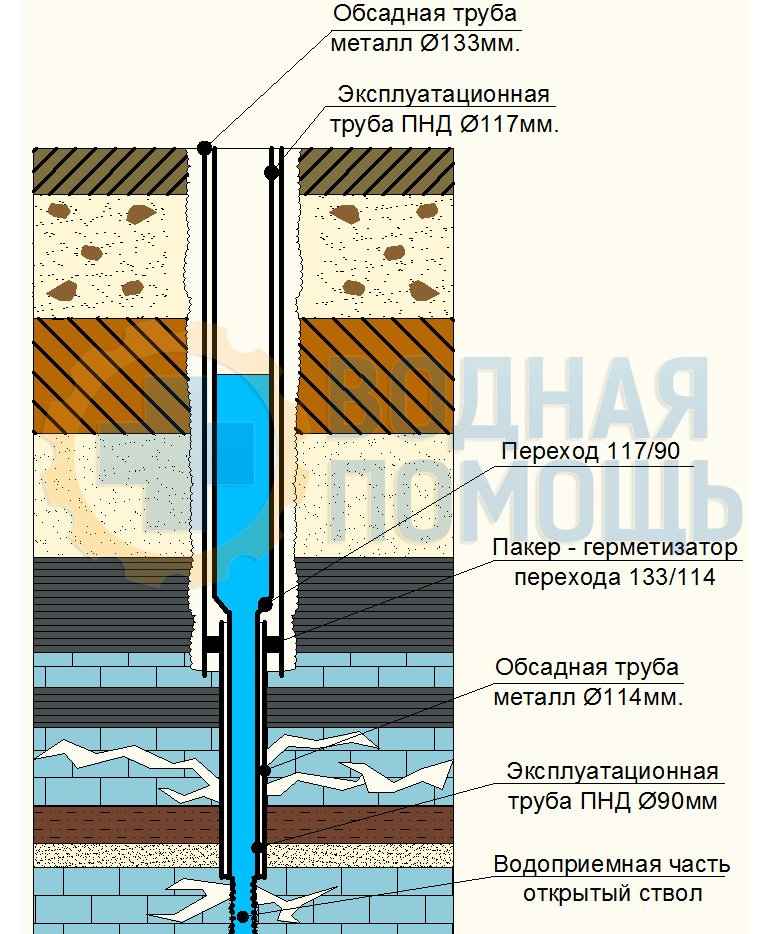

Dependence of the diameter of the production pipe on the dimensions of the pump ↑

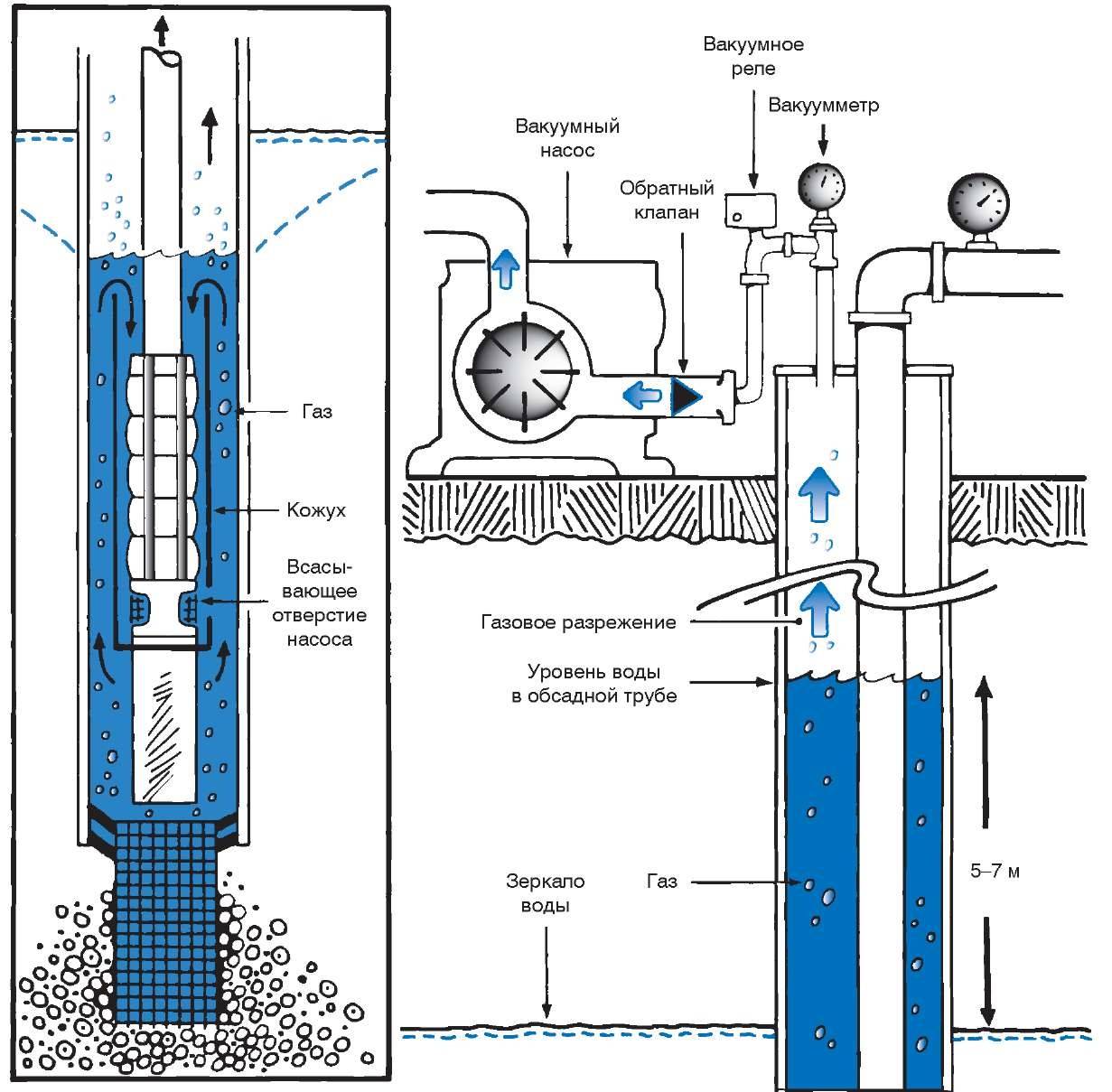

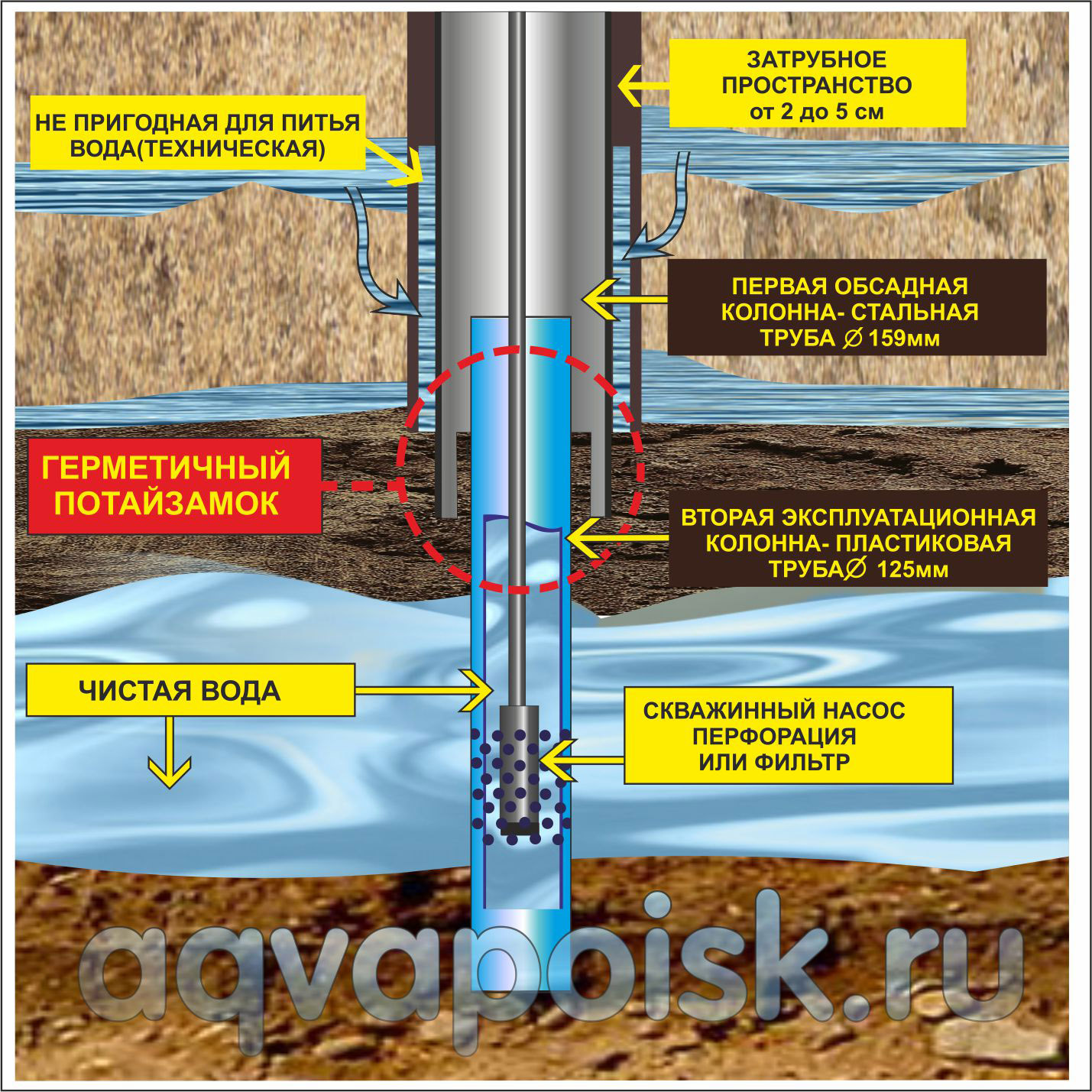

The diameter of the well for water directly depends on the type and size of the pump, and vice versa, the choice of pumping equipment is carried out in accordance with the dimensions of the casing string.

If the water mirror is close to the surface, then self-priming surface pumps can be used for water intake, which are often bundled with hydraulic accumulators and are called pumping stations.

When using a pumping station, the diameter of the water well depends on the diameter of the riser pipe or hose that goes down. As a rule, in this case, a 50 mm casing is sufficient to ensure the normal operation of the water supply system.

The minimum diameter of deep well pumps is 3 inches (76 mm). The installation of such devices can be carried out already in a 90 mm casing pipe. However, for domestic needs, in most cases, 4-inch units are used, which are cheaper and have higher performance. For their normal placement, a production string of at least 110 mm is used.

The distance between the hull and the casing wall should not be less than 2 mm along the entire radius. At the same time, for vibratory submersible pumps, this criterion is more stringent, since direct contact with the production string may result in destruction of the structure.

To accurately determine the diameter of the pipe for a well pump, you can use a simple formula:

D(casing) = D(pump) + clearance + wall thickness

Thus, for a 3-inch unit, the minimum diametral hole size will be:

D=76+4+5=85mm

Based on this, a column of 90, 113 or 125 millimeters (in accordance with the table above) is suitable for such devices.

For 4" (102 mm) submersible pumps, the allowable casing size will be different accordingly:

D = 102 + 4 + 5 = 111 mm

According to the table, we select the required dimensions: 113, 125 or 140 millimeters.

On the one hand, a small-diameter well is difficult to maintain and tends to quickly silt, on the other hand, drilling and arranging too large bore holes is financially unprofitable. Sometimes it is very difficult to find the most rational solution on your own. In this case, it will not be superfluous to take the help of specialists.

Types of pipes and selection criteria

Plastic casing pipes

Plastic casing pipes

Casing pipes are divided into several types in depending on the material manufacture:

- plastic (PVC, UPVC);

- metal;

- asbestos-cement.

Each material has a certain service life, and also affects the quality of well water. To determine the choice of material, you need to study in more detail the features of each.

metal mines

metal mines

Steel for strengthening the casing is used quite often, especially in artesian wells, which are characterized by great depth. Steel products are strong and reliable, with proper installation and maintenance, they can last several decades.Casing for a well from a sewer steel pipe is a common occurrence.

Negatively affect the design of the movement of soil layers. Also, the material is subject to corrosion, due to which the quality of well water is deteriorating. To avoid this problem, stainless steel should be preferred, but the cost of well construction will increase significantly.

Asbestos-cement structures

Asbestos-cement structures

Long service life and excellent characteristic features are characteristic of asbestos-cement products. However, there is a fairly extensive list of disadvantages:

- Insufficient strength at great depths, where the pressure of the soil layers reaches critical levels.

- Asbestos, despite being bound to the cement, over time can begin to decompose into components that have a negative impact on the quality and taste of water.

- Due to the large thickness of the walls of the casing rings, the diameter of the well needs to be drilled larger, which negatively affects the cost of work.

Well casing with plastic pipes is becoming more and more common. This is due to the fact that products made of low-pressure polyethylene or polyvinyl chloride have excellent qualities used in various communications.

- In comparison with previous analogues, the cost of products is much lower.

- The material is not afraid of corrosion, plaque does not form on its surface.

- Products do not decompose, do not adversely affect water quality.

- Due to the high strength and reliability, a long service life is ensured.

- The use of modern methods of connecting parts ensures the tightness of the channel.

- Due to the low weight, the casing is easier to mount.

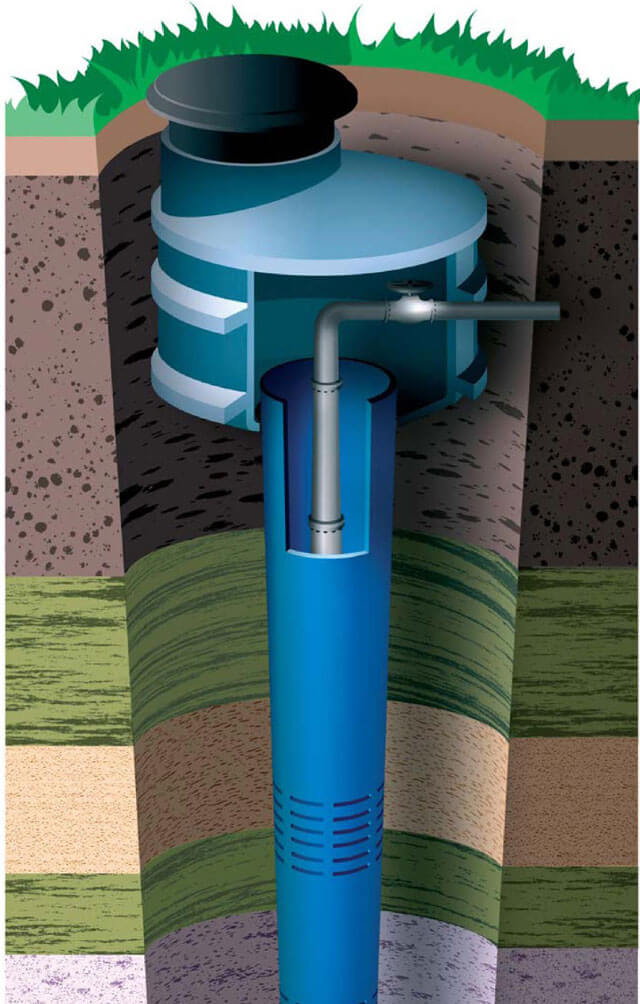

Well casing device

There are only three main nodes that are included in the casing complex:

- Bottom filter. Keeps sand and clay out of the pump, leaving it clean and operable.

- Fine filter. Purifies water from small inclusions, making it suitable for domestic use.

- head. A kind of hermetic cover of the casing, which has holes for connecting the pipeline and laying the power cable.

The walls of the casing themselves can be metal, plastic or asbestos-cement at the request of the customer. Only the technological features of the site and the qualitative composition of the soil cut can serve as limitations.

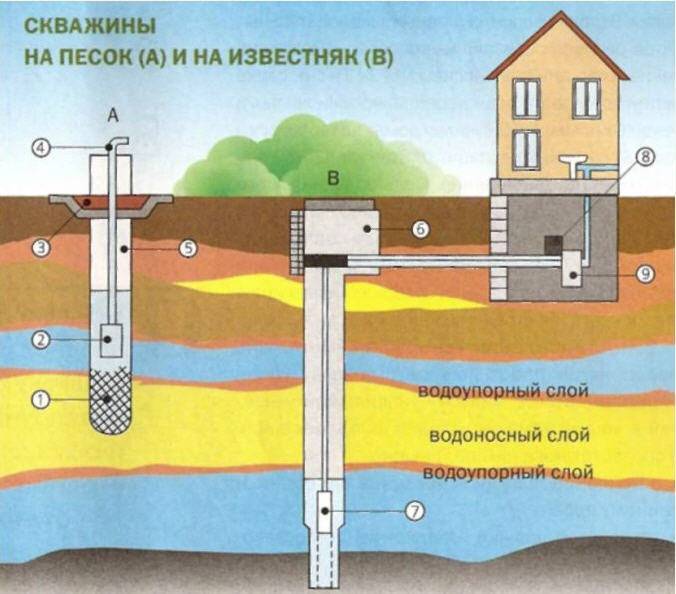

Don't forget about the value of the destination and source type:

- Abyssinian well for irrigation. Concrete pipes are suitable, as their cost is fully justified.

- Well in the sand. Plastic is suitable, since the depth of such a well is not more than 90 meters.

- Artesian source. Metal pipes. Artesian water is at a depth of 100-350 meters.

Definition and purpose of the casing

This is an important element of a hydraulic structure, since it is installed in the very center of the structure. Thanks to the pipe, the probability of soil collapse is excluded, which may be due to its low density, mobility of soil layers. For this reason, only the most durable casing should be selected. The space between this structural element of the hydraulic structure and the soil is filled with concrete.

Another purpose of the casing is to prevent disruption of the pumping equipment that is lowered into the well. At the same time, there is a risk of contamination of its main components when pumping a liquid containing large fractions.

Additionally, it is noted that it is possible to prevent the penetration of groundwater into the well. Thanks to the protective casing, the rate of siltation of the hydraulic structure is significantly reduced. As a result, the life of the well is increased.

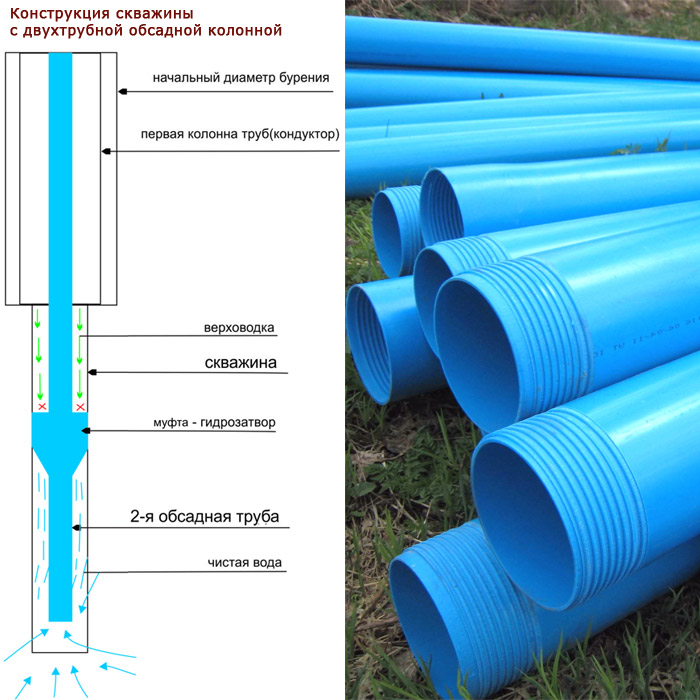

The pipe is a product with a reinforced casing, which is made from durable materials. Depending on the depth of the well, the type of structure is determined: one-piece, assembled from several products.

The first option is more preferable, but it is not always possible to install a pipe of significant length. When the depth of the well is large, it is recommended to consider the option of mounting a prefabricated structure. It must be airtight, which will eliminate the risk of water getting between the concrete layer and the outer wall of the pipe. As a result, the protective layer can be destroyed by water due to leakage under pressure.

If you plan to use water from a well for irrigation, it is enough to install only 1 casing. It will serve as a pipe through which water rises from pumping equipment to the water supply system. If you plan to use water from a well for drinking, then another one is installed inside the reinforced pipe. It should differ in size.

Seating requirements:

tightness of seam joints during the installation of a prefabricated structure, and it is recommended to choose a threaded method of connecting pipes;

long-term operation, helps to increase the service life of the use of products made of durable material (for example, steel);

the column must be located in a vertical plane, it is important to observe the straightness of the structure;

the absence of toxic substances in the composition of the casing material: it must not be allowed to affect the quality of the water raised from the well;

corrosion resistance, because

the column is in constant contact with the liquid.

Mounting Features

Casing is installed simultaneously with drilling

Casing is installed simultaneously with drilling

Installation of casing parts is carried out by drilling the soil with a drill. The diameter of the drill must be less than the diameter of the casing. Then it is taken out of the ground and impurities are removed. The descent of the casing pipe is carried out when the depth of the well reaches 2 meters. Further drilling should be carried out together with the casing until the aquifer is reached.

The classic version of the casing string looks like this:

- The filter for coarse cleaning of well water is a wire or stainless steel mesh.

- Bottom filter, which is made from gravel. Protects water from contaminants that can penetrate the source from a greater depth.

- Sealed head, which prevents the ingress of contaminants into the well shaft from the outside. Its fastening is accompanied by the formation of negative pressure, which leads to an increase in the flow of water. To increase the negative pressure, the head is cemented.

Wells with great depth are recommended to be decorated with metal products equipped with external and internal threads. If the depth of the well shaft is less than 50 meters, they prefer the budget analogue - plastic pipes. Asbestos-cement products are installed at a well depth of not more than 15 meters, otherwise the material may not withstand the pressure exerted by the soil layers.