- Dimensions of sewer cast iron pipes

- Materials for sewer pipes

- Cast iron

- Polyvinyl chloride (PVC)

- Polypropylene (PP)

- Other materials

- Installation of plastic sewer pipes

- Design work and diagramming

- Pipe laying

- Pipe connection

- Performance of treatment facilities

- No. 1 - models for seasonal residences

- No. 2 - septic tanks for year-round houses

- How to avoid mistakes in choosing

- Mistakes that are associated with connecting siphons

- plastic septic tank

- Advantages and disadvantages

- Types of pipes

- Asbestos-cement

- metal

- Cast iron

- Plastic

- metal-plastic

- fiberglass

- PVC

- Corrugated

- Other

- Ceramic and cast iron pipes for sewerage

- Repair of cast iron pipes

- Composition, design features

- Diameter selection according to building codes

Dimensions of sewer cast iron pipes

Cast iron pipes for sewer networks are made of gray cast iron with a length of 750 (mm) to 2200 (mm). The conditional passage is 50 (mm) - 1000 (mm).

Standard dimensions of sewer cast iron pipes:

- Nominal passage: 50 (mm), 100 (mm), 260 (mm), 350 (mm), 600 (mm), 800 (mm), 1000 (mm).

- Outer Diameter: 81(mm), 118(mm), 274(mm), 378(mm), 635(mm), 842(mm), 1048(mm).

- Wall thickness: 7.4 (mm), 8.3 (mm), 11.0 (mm), 12.8 (mm), 17.4 (mm), 21.1 (mm), 24.8 (mm).

- Construction length: 750 (mm), 1000 (mm), 1250 (mm), 2000 (mm), 2100 (mm), 2200 (mm).

Important: if system pressure is low, then when choosing a sewer pipe made of cast iron, it is worth refusing to purchase a material with a thick wall. Marking:

Marking:

The marking of sewer cast iron pipes is carried out according to the nominal section and contains the values:

- Name of the pipe (PTK).

- The size of the conditional passage.

- Construction length.

- Standard designation.

For example: TCHK-100-2000 GOST 6942-98 - a cast-iron pipe, sewer, with a nominal bore size of 100 (mm) and a construction length of 2000 (mm).

The main regulatory document GOST 6942-98.

Materials for sewer pipes

Now that the requirements are presented, it is necessary to consider each of the materials and evaluate how it corresponds to them. And although for sewer pipes use a wide enough a range of products made from different raw materials, the most common are only three options: cast iron, polyvinyl chloride and polypropylene. In addition to them, you can see ceramic, steel, asbestos-cement pipes, but they come across much less frequently.

Ceramic sewer pipes

Cast iron

Without a doubt, if cast iron is not the best sewer pipes, then it is certainly the most durable and durable. Their service life is measured in almost centuries, and this is supported by well-known practice, and not by theoretical calculations. As for the rest of the properties, the resistance to all factors is high, with installation there may be difficulties associated with connections and heavy weight, which is extremely inconvenient during work.The surface has irregularities, sooner or later leading to clogging. Another disadvantage is the high cost.

Cast iron pipes for sewerage

Polyvinyl chloride (PVC)

The strength and durability of these pipes is at the level, at least according to experts, since they have been used relatively recently.

Let's take a look at the rest of the features:

- Resistance to temperature - with an increase above 70 degrees - deformation, at negative temperatures - brittleness.

- Fire resistance is absent, moreover, during combustion, it releases phosgene gas, which is officially classified as a chemical weapon.

- Immune to ultraviolet and aggressive reagents.

- Installation is simple, the inner surface is smooth.

- The cost is affordable.

Summarizing all of the above, we can say that it is better to use PVC for internal sewage, and for the external one, choose another material that is more suitable for this role.

PVC sewer pipes

Polypropylene (PP)

Fitting for PP pipes

Looking ahead, we can say that at the moment, the best sewer pipes are still polypropylene. Such a conclusion can be drawn by evaluating them according to all the above parameters, where for each of them they are rated at five. Strength and durability are high, the pipes are resistant to a complex of influences, the only thing is that with constant heating a slight linear expansion is possible. Installation of PP pipes is easy and without the use of any particularly expensive and complex devices, the inner surface is not something that does not retain deposits - it repels them, and after a few years, it will be almost as clean as when installed. The cost is quite acceptable.

Other materials

Going through the rest of the materials, we can say the following:

- Steel. Strong and resistant to most factors, easy to process, but suffers from corrosion and has a large weight that can create serious installation difficulties.

- Ceramics. It is resistant to chemicals, fire, corrosion, strength and durability. Installation is difficult, if the grooves are clogged, it cannot be carried out. Also, ceramics are fragile and cannot withstand mechanical shock loads, and all protective properties depend on the presence of glaze. Today, ceramics can be found, perhaps, in old reclamation structures; it has already been replaced by more modern and practical materials from other areas.

- Asbestos cement. The material has almost disappeared, and has many more minuses than pluses: fragility, fragility, inconvenience during installation, and many others.

Sewerage from PP pipes

When choosing a material for the construction of a sewer, it is necessary to carefully and seriously evaluate and calculate all the minuses and pluses of any option, without bypassing the final cost of the project. At present, the sewerage from plastic pipes, made of polypropylene, is probably the best option, both in terms of practicality and economy.

Installation of plastic sewer pipes

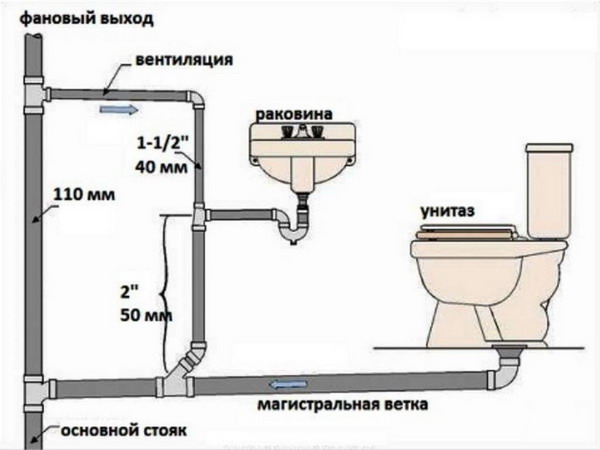

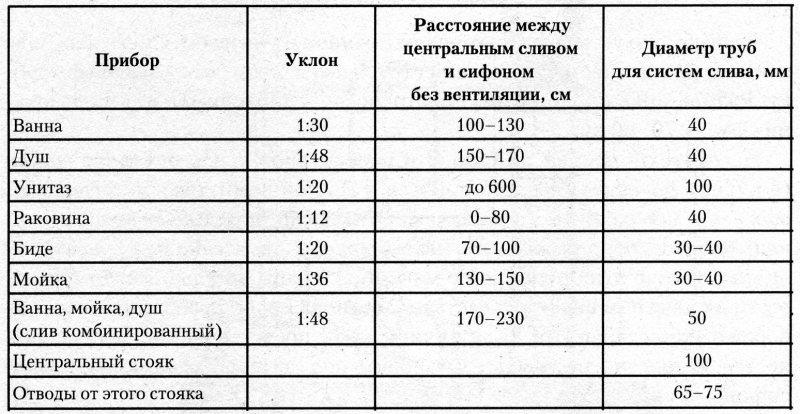

For the device of the system, plastic sewer pipes of different diameters are used, which is selected depending on the load in this area. So, for example, a pipe with a diameter of 50 mm is used inside buildings, as a rule, when distributing wastewater, a diameter of 110 mm is more suitable for transporting waste from toilets, and a pipe with a diameter of 300 mm is used in the construction sewers of apartment buildings or industrial facilities, that is, where it will have a large load.

Required diameters of plastic sewer pipes

Design work and diagramming

The initial stage of the sewerage construction is the drafting of a project, according to which sewer plastic fittings and pipes in the required quantity, observing all the required dimensions

You can draw up a project based on an existing system; before dismantling it, you need to carefully examine it, noting all the features and paying special attention to the shortcomings so as not to repeat them in a new structure

If possible, you should save the entire route of laying pipes, this is done in order to avoid making new holes in walls and ceilings. If the old scheme is preserved, it will also be easier to select the diameter and measure the pipes.

The diagram shows the locations of the riser, sewer units and other key places.

Measuring the length of the pipe on the ground

Pipe laying

The laying of sewerage from plastic pipes begins from its highest point. As you lay, you should not forget about the need for a slope and observe its value.

This is especially important if the sewer is a non-pressure type and the water flows down into the riser by gravity.

It facilitates the task of using the level, with its help it is easiest to control and observe the angle of inclination. It is also necessary to ensure minimum distance between fasteners, since if it is exceeded, the plastic pipe can bend under its own weight.

Proper location of sewer plastic pipes

Pipe connection

Before proceeding with the installation of the system, you should consider how the sewer plastic pipes will be connected. There are two options for docking and sealing: with glue or welding.

- Adhesive connection. Before applying the adhesive, cut the pipes to the desired length, remove burrs with sandpaper and degrease both the surface of the pipe itself and the fittings that will be used for connection. The glue is applied in a thicker layer on the pipe, thin - on the connecting elements. When inserting the pipe into the fitting, it is recommended to turn it slightly to distribute the adhesive more evenly.

- Connection by welding. Before connecting sewer plastic pipes in this way, their surface is thoroughly cleaned of contaminants, the palnik is heated to the required temperature level and the fittings are prepared. Before soldering, both pipes and fittings also need to be degreased; after this procedure, they are put on the nozzles of the soldering iron, where, after heating for the required time, the fitting is inserted into the pipe. The quality of the resulting connection is checked: it should not have burrs and excess plastic.

Pipe welding

Upon completion of the installation of pipes, gaps between pipes and walls or ceilings should be sealed. As a rule, mounting foam is used for this.

Process sewer pipe installations does not require high qualifications, but if there is even the slightest doubt about whether it will be possible to do all the work with high quality, you should turn to professionals.

Plastic pipes are by far the best material for sewerage, their installation and connections are not highly laborious and complex, but certain rules and requirements must be observed.

Performance of treatment facilities

To ensure trouble-free operation of the system and prevent overfilling of the tank, it is necessary to focus on the type of housing and the performance of the model.

No. 1 - models for seasonal residences

If you plan to visit your country house only on weekends or live in it only during the warm season, it is not rational to install a multi-chamber production complex.

zealous hosts cottages for furnishing of their sites, if the average daily volume of effluents does not exceed one cubic meter, they choose mainly single-chamber low-performance drives.

Storage-type structures are ideal for arranging country cottages used for seasonal stays.

Due to their low weight, compact mini-septic tanks are conveniently transported and buried in the pit, managing on their own and without resorting to the services of special equipment.

No. 2 - septic tanks for year-round houses

For areas where year-round use is expected, it is desirable to install a treatment plant that uses all methods of wastewater treatment.

An alternative is the right to serve as septic tanks-settlers with soil treatment systemsif the groundwater horizon lies low in the area of \u200b\u200bthe sewage device.

A septic tank with soil aftertreatment is a two- or three-chamber settling tank operating in tandem with an absorption well, filtration fields or an infiltrator

In order for autonomous sewage to function more efficiently, aerobic and anaerobic bacteria are often used when starting it.

To do this, bacteria are placed inside the tanks, which “eat up” organic matter. Biological decomposition of waste allows you to bring domestic wastewater to the state of process water.

The difference between aerobic microorganisms and anaerobic bacteria is that the former are able to work only when oxygen is available, while the latter do not need it.

Deep cleaning units are ideal for landscaping areas located in close proximity to a natural body of water.

After all, treated wastewater that has passed through stations with a high percentage of filtration can be drained into any body of water.

How to avoid mistakes in choosing

Here are a few criteria that you need to pay attention to first of all:

- Weir diameter. This indicator ranges from 5–15 cm. The diameter should correspond to the angle of inclination of the roof slope, and the larger the slope, the larger the diameter.

- Price. The most affordable option is plastic spillways, as well as galvanized structures. Drains made of copper, zinc and titanium are the most expensive.

- Type of roofing. For bitumen and ceramic - a plastic version is suitable, for metal or corrugated board - only metal products are needed.

- The weight. Before choosing and then installing roof gutters, do not forget that a reliable truss frame is needed to fix metal products;

- Climate. The gutter is selected taking into account the climatic features of the construction region, the temperature regime in the area.

Which drain to choose in the end decides the owner of the house. To buy a reliable product, study the reviews of the products offered on the market, and choose only products from trusted manufacturers.

Mistakes that are associated with connecting siphons

The connection of any plumbing fixture to the sewer is carried out through siphons that look like the letter U. This kind of curved shape allows water to constantly stay in it. It forms a hydraulic barrier and prevents odors from entering the room. But this design stops working when certain oversights are made. The main oversight is the lack of ventilation. In this case, the vacuum simply sucks the water out of the siphon, allowing the aromas to roam freely around the house. The second reason for the formation of an unpleasant odor is the standard evaporation of water from a siphon. This is done with rare use of the device. You just need to plug a rarely used device with a cloth.

The appearance of the waste siphon

This is interesting: How to make manhole for sewerage or drainage - studying the issue

plastic septic tank

Such products, as a rule, are made of high-strength polypropylene. This material is resistant to soil pressure and does not react to the chemical reactions that take place inside it.

In the septic tank there is a chamber in which the drains are first settled. In the process, heavier suspensions sink to the bottom or, on the contrary, float to the top, depending on their type. As a result, purer water is formed in the middle of the so-called liquid column. An overflow device is located at the same level, thanks to which the liquid enters the next cleaning chamber.Thus, the waste undergoes multi-level cleaning offline. There are also models that assume the presence of special anaerobic bacteria. In the course of their life, waste begins to ferment. As a result, organic sediment accumulates at the bottom.

However, neither a plastic septic tank nor concrete rings are able to provide the proper level of water purification so that it can be used, for example, for irrigation. You can't just throw it into the ground. To do this, you will either have to call vacuum trucks (usually cleaning is required no more than 1 time per year), or purchase additional cleaning systems. To do this, it will be necessary to organize another treatment plant equipped with a sand and gravel filter.

But such systems have both pluses and minuses.

Advantages and disadvantages

If we talk about the advantages of such installations, then it is worth highlighting:

- Complete autonomy. The system does not require a power connection.

- Variety of models. You can purchase a ready-made solution for 2-4 cameras or make it yourself.

- The possibility of removing waste not only from the toilet, but also from the shower cabin and sinks located in the house.

- Relative low cost. Of course, a PVC septic tank will cost more than concrete rings, but it will cost less than a biological treatment plant.

- Ease of installation.

Healthy! Easy installation is possible only if the soil normally absorbs water. Otherwise, reinforcement of the structure will be required, which will cost additional money.

Long service life. In plastic septic tanks, there are simply no complex mechanical components, so there is simply nothing to break.

Not without cons:

- Water must not be dumped into the soil.

- Long processing time.It takes time for biologically active bacteria to process wastewater.

- Although rare, you still have to sometimes call the sewers.

If you live outside the city permanently and there is an opportunity to spend more money, then it would be more rational to install a more functional design.

Types of pipes

A variety of types of pipes are used to drain storm water. In recent decades, modern and very diverse plastic ones have been added to traditional cast iron, steel and concrete.

Asbestos-cement

Asbestos-cement pipes for storm drains have been used for a very long time. They do not rust, are relatively durable, strong enough, chemically inert. But recently, due to their shortcomings, they have lost their former popularity. Disadvantages: weight, fragility, cost, lack of ready-made fittings, installation complexity. The service life is 30 years, which is not very long by today's standards.

metal

That is steel pipes. Sturdy, securely welded together. Galvanized ones will last 40 years, but the joints rust, like ordinary "black" pipes. "Black", that is, without coating, pipes will stand for 25 years. Heavy, difficult to assemble, transport. Overgrown with magnesium and calcium salts and rust.

Cast iron

Socket products are quite easy to assemble into the pipeline. Very heavy, durable, reliable, can stand for 50 years. Overgrown with salt and rust, but more slowly than steel.

Plastic

For underground pipelines, PVC and low-pressure polyethylene are practically used. Products made of high-density polyethylene are more expensive and are not produced in large diameters, they have insufficient rigidity for laying in the ground. Polypropylene is too fragile and costs more.These materials are used only for water supply and indoor heating.

Plastic has sufficient strength and some ductility, it is not brittle. Plastic is mounted using special couplings; traditional socket sewer elements can be used. The price of plastic is low. In seismic areas, with the danger of landslides, soil movements, the strength of plastic pipelines may be insufficient.

metal-plastic

The maximum outer diameter of metal-plastic products is 48 mm (inner diameter is 40 mm). The main feature of metal-plastic - the ability to reduce the thermal expansion of the pipe - remains unclaimed for underground laying at a stable cool temperature. Showers are not hot. Therefore, metal-plastic for underground pipelines is not used.

fiberglass

Fiberglass is a composite consisting of polyester or epoxy resins and fibers made of glass, basalt or carbon. Lightweight, durable, chemically inert material, not subject to corrosion.

Comparable to steel in strength. These features make it one of the most promising materials for stormwater. Disadvantage: relatively high price.

Installation: traditional assembly of bell-shaped elements, like in cast iron; assembly of products with flanges; coupling connection; yoke connection (using special fittings and bolts).

PVC

Very strong, light, reliable and inexpensive pipes. Installation is a little difficult - special couplings and glue are required.

Corrugated

The most promising and durable type of plastic pipes.There are single-layer and double-layer, there are many varieties of fittings. In a two-layer corrugation, the outer wall has bends along the length, the inner wall is smooth.

They have all the advantages of single-layer plastic pipes, but are much stronger than them. The price is slightly higher than that of single-layer ones, but it more than pays off with strength and durability. Two-layer corrugation can stand for more than 50 years.

Other

Previously, ceramic pipes of large diameters were used - very durable, but heavy, fragile and difficult to install (besides, there are practically no fittings for them).

Very heavy reinforced concrete (usually called concrete) pipes of large diameters were also used. Now these species are gradually fading into the past. Although for very large headers and where greater strength is required from pipes, reinforced concrete is still used.

Ceramic and cast iron pipes for sewerage

- Ceramic pipes. For the manufacture of such pipes, clay with small impurities of kaolin or fireclay is used. The products themselves are produced by firing, which gives them good mechanical strength. On top of the pipes are covered with a special glaze, which provides resistance to aggressive chemicals, a certain water tightness and creates a smooth surface. Both sides of the pipe are treated with polyester resins, which make it possible to connect parts without using a sealant. The disadvantages of ceramic pipes include a lot of weight and high cost. In addition, transportation and installation of products will be difficult due to their fragility.

- Cast iron pipes. Cast iron pipes are durable, high strength and resistant to temperature extremes.The problem lies in the high weight of the products and their susceptibility to corrosion (for more details: "Pig-iron sewer pipes - types and methods of installation"). Also, one cannot fail to mention the high cost of cast iron pipes. The inner walls are not smooth, so the products will clog rather quickly. Installation is also very problematic due to the weight and complex sealing.

Repair of cast iron pipes

In case of damage to the pipe material (chips, cracks), it becomes necessary to repair.

To repair a crack, it is necessary to cut the edges, deepen with a scraper and degrease. Then the recess is sealed with a mixture.

1 mix option:

- copper oxide (powder) - 1.5 parts;

- phosphoric acid - 1 part.

Mix 2:

- iron filings - 2.5 kg;

- ammonia (powder) - 60 g;

- sulfur - 30g;

- water (to the consistency of a thick dough).

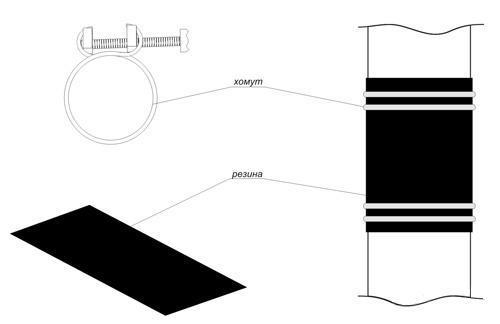

To repair damage with a violation of tightness, apply rubber gaskets (2 - 3 pcs.). They are pressed against a pipe made of cast iron with metal plates. Rubber gaskets with plates are pressed with hoops using bolts or twisted with wire and tightened with pliers.

Cast iron pipe bandage

Composition, design features

The external sewerage of a structure, residential or public building starts from the walls and continues to the tie-in point in the public line or to the filtration plant. It consists of:

- pipelines;

- receiving wells;

- connecting manifolds;

- revision wells;

- tanks, septic tanks (if the system is autonomous);

- installations for forced supply of wastewater (for pressure systems).

In addition, storm water drainage systems are included in the external sewage system. They differ in the seasonal nature of the work, have their own specifics of assembly and operation.All external sewerage systems are created in accordance with applicable norms and rules. The main document regulating the design and construction process is SNiP 2.04.03-85 or its modern version SP 32.13330.2012. You can’t try to get by with your own considerations, since there are clearly defined requirements. They cover all aspects of system development, from choice of materials to laying rules pipes.

The external sewerage device is represented by a system of pipelines laid under a slope. Drains move through them on their own. For clearing blockages or cleaning pipes along the entire length of the underground part, manholes are installed.

Pipelines are laid at a depth exceeding the level of soil freezing. This is not always possible, so there are systems with shallow pipe placement. They need high-quality insulation, otherwise the drains will freeze and stop the sewerage.

Diameter selection according to building codes

Unlike cast iron products, a number of plastic shaped modifications are much richer. Manufacturers of polymer pipes produce products diameter from 16 mm up to 6000 mm.

The need for a diverse assortment makes sense:

- the possibilities of pipeline engineering systems are expanding;

- the pipe size is selected taking into account certain tasks;

- it is possible to replace a section of the main line with a pipe with the smallest possible diameter - when laying the sewage system of a private house, this will reduce the repair budget.

The most common sizes for the internal sewerage network: 50/100/150 mm.

The pipe diameter is selected in accordance with the service area.For example, under a vertical riser and a toilet, a pipeline of 100, 110 or 150 mm is equipped

Scope of pipes based on the flow area:

- 16-25 mm - removal of uncontaminated liquid from ventilation units, air conditioners and dehumidifiers;

- from 32 mm - connection of a washbasin or sink used for washing conditionally clean dishes (glasses, wine glasses, etc.);

- from 40 mm - drain for a bath, shower, kitchen sink, dishwasher or washing machine;

- 50 mm or more - simultaneous connection of a shower and bath, laundry;

- 60-75 mm - combined connection of three and five devices, respectively, with the exception of the toilet.

Dimensions are measured from the inside and display the conditional passage of the line. Considering the wall thickness, the outer dimension exceeds the inner dimension.

In addition to the diameter when choosing polymer pipes should pay attention for the following points: