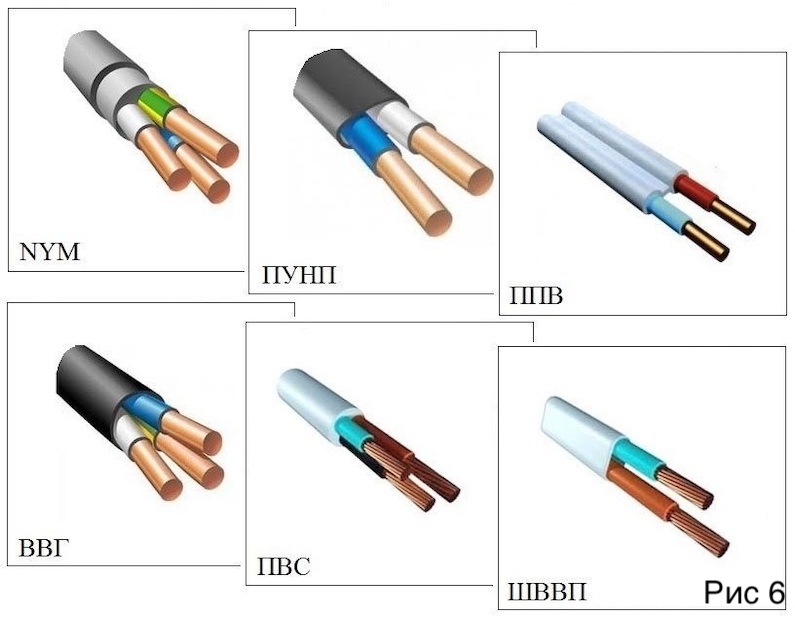

- Types of electrical wiring cables - understand the designations

- GOST and rules for choosing a cable

- Is the VVGng cable on fire

- Important characteristics when choosing a wire

- Device and material

- Cable section

- Insulation and sheath thickness

- Cable marking

- Core colors

- The most famous cable brands

- Internet cable

- computer cable

- TV cable

- golden ratio

- Additional items

- Rules for the installation of electrical installations

- PUNP cable

- Types of containment

- How to independently determine the quality of the cable?

- For internal wiring

- Brief recommendations on the laying method

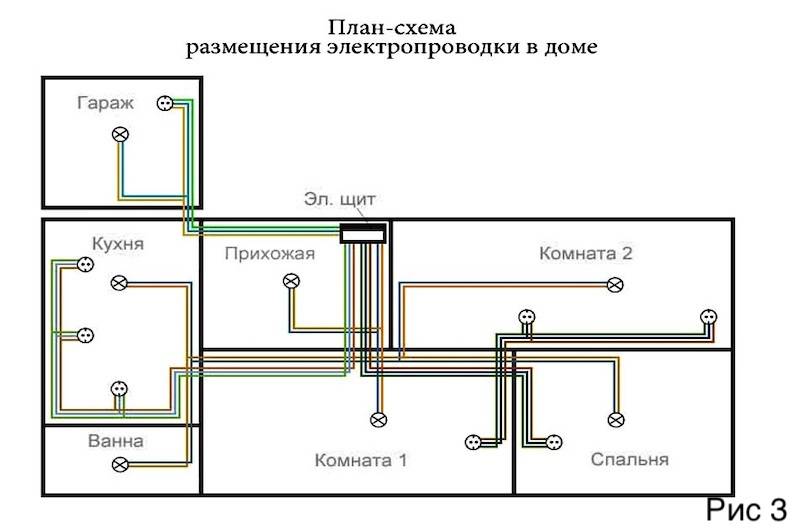

Types of electrical wiring cables - understand the designations

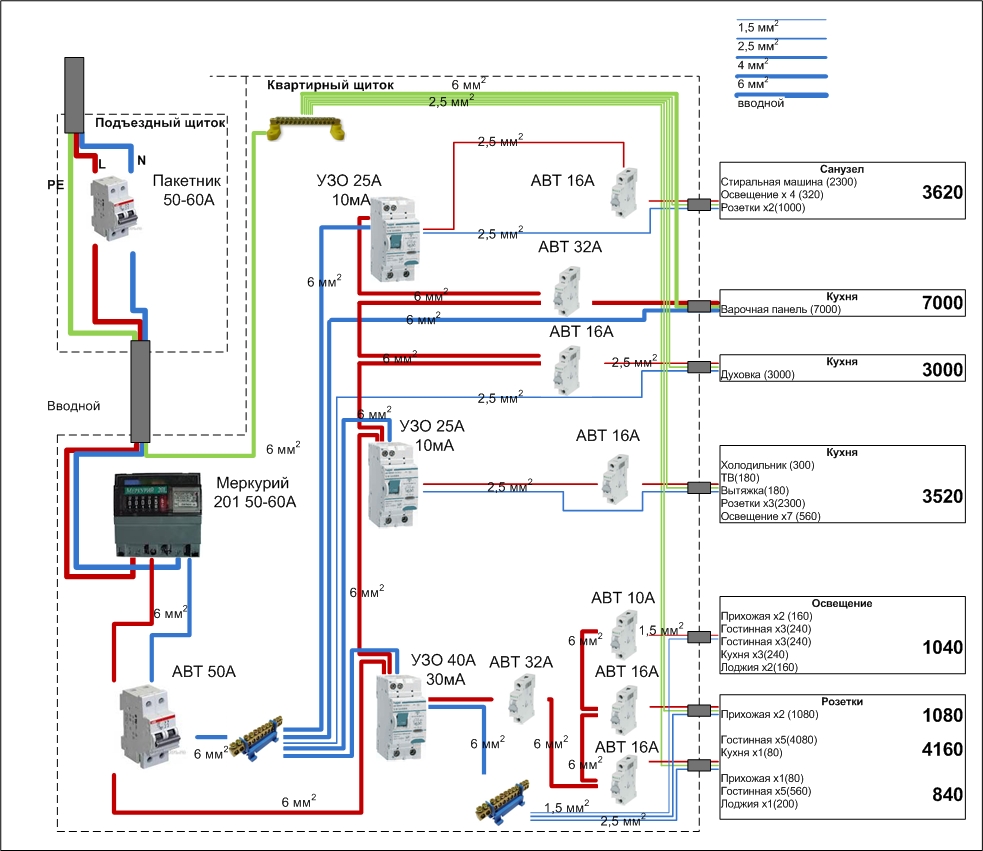

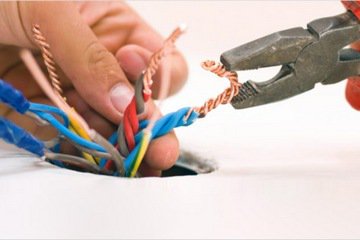

Even with minor repairs, for example, wallpapering, be sure to carry out a slight repair of the electrical wiring - check the quality of the connections, tighten loose sockets. The amount of energy that we consume has increased by 2-3 times over several decades, and in winter, when various types of heaters are also connected, it completely exceeds the permitted norms.

The wire for electrical wiring in the apartment, used during the last repair, may simply not survive for the next one.So if today you choose which wire to use for wiring, then this choice should be with a serious margin! The safety of your family directly depends on this - more than half of the fires occur precisely because of wiring problems.

Of course, it is better not to lay the wire without special skills, but to entrust the work to an electrician. However, in choosing blindly rely on someone else's opinion is not worth it. Let's first understand the notation that you will meet on the wire.

- The first letter in the marking always answers the question of what material the upper insulation is made of. So, “P” is polyethylene, “B” is polyvinyl chloride or just vinyl, “R” is rubber, “K” is a control cable.

- The second letter in the brand reveals the sheath material of the wire itself. "V" - vinyl, "P" - polyethylene, "R" - rubber.

- "SHV" is nothing more than the presence of tight protection, for example, a PVC hose. "E" - this letter indicates the presence of shielding, and "Z" - the presence of a filler between the individual cores. The letter "G" stands for especially flexible wires, "P" logically stands for "flat". "OZH" is found on cables with a single-wire core.

- In the marking, in addition to this, you will find other designations. "NG" stands for resistance to burning and self-extinguishing. "BB" is a protection in the form of a steel tape sheath, while simply "B" denotes an armored wire that is resistant to mechanical damage. "LS" indicates low smoke emission during heating, burning and melting of the wire.

- The numbers will tell us what class of flexibility the cable has.

- The colors of the wires also say a lot. So, a white, red or brown wire should always be a phase. The blue wire is zero, and the green or green-yellow wire is ground.

It makes no sense to memorize all these designations - make yourself a cheat sheet and feel free to go to the store. For example, the wire is marked as "ShVVP-3". With the help of a cheat sheet, we can find out that we have a vinyl-insulated cord, in a vinyl sheath, and, moreover, it is flat. The three at the end indicates that the wire has a third class of flexibility.

GOST and rules for choosing a cable

These rules are uniform and are currently valid not only for special structures and facilities, but also for offices, apartments and other residential premises. Although, of course, all GOSTs and sets of rules change sooner or later.

For example, few electricians imagined that aluminum wiring would legally return to our homes. But nevertheless, it happened. However, in the matter of choosing a cable for home wiring, we will adhere to the current GOSTs for the time being and see what they are talking about.

At the moment, the main regulatory document regulating the use of certain cable products, taking into account the type of their use, is GOST 31565-2012 “Cable products. Fire safety requirements.”

In this GOST, you can find a transcript of all the letters that are present in the name of the cable and refer specifically to fire safety:

ng

LS

FRLS

LTx etc.

It also describes very clearly which cable version must be used in a particular area. This information is contained in table No. 2.

In the first column, where “Cable without designations” is indicated, we mean the usual VVG. It can only be used in industrial premises and cable structures.

There is no question of residential buildings and apartments here and close.Moreover, if you want to lay it in bunches, then you will have to protect it with pipes and corrugations (passive fire protection).

The second column refers to the cable with the NG index (VVGng). There are additional letters in brackets (A) (B) (C) (D). As a rule, the VVGng (A) cable is used.

The letter in brackets indicates that the cable complies with flame retardant requirements. Simply put, if there is such a letter in the name, then the cable can be used for group laying. But here, too, the scope is cable structures for outdoor installations. As you can see again, no offices, apartments and houses.

The third line is just the VVGng LS cable.

And as you can see from the column opposite, it can already be safely laid in the interior of residential buildings.

Is the VVGng cable on fire

By the way, in practice, the difference between VVGng and VVngLS cables is not so small. As the technologists directly responsible for the production of these products say, when the VVGng cable burns during testing, it is simply impossible to be in the room.

For some reason, many people confuse the abbreviation “ng”, thinking that it guarantees the “non-combustibility” of the cable. In fact, it means that the product does not support and does not spread combustion, after the source of fire is removed from it. But the cable itself, when exposed to flame and other factors (short circuit, overload), even burns and melts.

When the VVGngLS cable is on, everything is much more comfortable and safer. This does not mean some large-scale fire, but some kind of local fire. For example, in the place where the insulation was accidentally damaged during installation.

There are many ways to protect yourself from such fires at the very initial stage. One of the latest, not yet widely introduced into our apartments, is the installation of special spark-proof devices. The fire is localized at the stage of spark formation.

Important characteristics when choosing a wire

It is necessary to take into account the number of lived. In houses where a ground loop is installed, a 3-core one is used, and where not, a 2-core one. Most often, wiring is reconstructed when it is replaced in old houses. It makes no sense to use expensive material there.

Pay attention to the type of cable cores, which can consist of 1 conductor or several twisted wires

A solid core has less resistance than a multi-wire one, but it is difficult to lay wiring for lighting in an apartment with such a cable. Another type is flexible, it is easy to mount it in the voids of concrete floors or other hard-to-reach places.

Having a greater resistance, the wire heats up, and when the load increases, the insulation melts or ignites. Therefore, a flexible cable with a non-combustible coating is used.

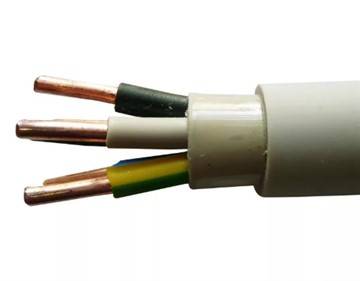

Device and material

According to the requirements of SP 31-110-2003 "Electrical Installations of Residential and Public Buildings", internal electrical wiring must be mounted with wires and cables with copper conductors and should not support combustion. Despite the fact that aluminum is a metal with low resistance, it is a reactive element that quickly oxidizes in air. The resulting film has poor conductivity, and at the point of contact, the wires will heat up as the load increases.

Connecting conductors of different materials (copper and aluminum) leads to a loss of contact and a break in the circuit.During operation, structural changes occur in the metal, as a result of which strength is lost. With aluminum, this happens faster and stronger than with copper.

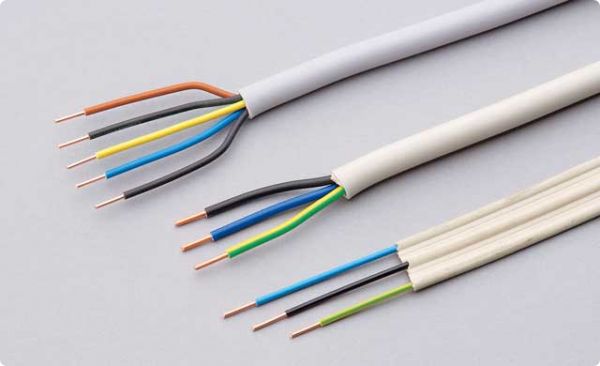

By design, cable products are:

- single-core (single-wire);

- stranded (stranded).

Cable laying for lighting has its own specifics due to increased fire safety requirements.

Single-core wires are more rigid, it is difficult to bend them if they have a large cross section. Multi-wire cables are flexible, they can be used both in outdoor wiring and laid under plaster. But single-core conductors are rarely used for arranging a lighting network in residential premises. For indoor installation in apartment buildings and private houses, 3-core single-wire cables are used. Multi-wire products for these purposes are prohibited due to the high fire hazard.

Cable section

The value is measured in mm² and serves as an indicator of the ability of the conductor to pass electric current. A copper conductor with a cross section of 1 mm² can withstand a load of 10 A without heating above the permissible norm. For wiring, the cable should be selected with a margin for power, because. a layer of plaster reduces heat removal, as a result of which the insulation may be damaged. The cross section of the wire is determined by the formula for calculating the area of a circle. In a stranded conductor, this value must be multiplied by the number of wires.

Insulation and sheath thickness

Each conductor in a multicore wiring cable has an insulating sheath. It is made of PVC-based materials and serves to protect the core from damage. Simultaneously creates a dielectric layer in the bundle of conductors. The coating thickness is standardized and should not be less than 0.44 mm.For cables with a cross section of 1.5-2.5 mm², this value is 0.6 mm.

The choice and installation of the cable must be trusted to professionals.

The sheath serves to accommodate the cores, fix them and protect them from mechanical damage. It is made of the same material as the conductor insulation, but has a greater thickness: for single-core cables - 1.4 mm, and for stranded cables - 1.6 mm. For indoor wiring, the presence of double insulation is a mandatory requirement. This protects the wire from damage and ensures the safety of the occupants.

Cable marking

It is applied to the cable sheath along the entire length at short intervals. It should be legible and contain the following information:

- wire brand;

- name of the manufacturer;

- release date;

- the number of cores and their cross section;

- voltage value.

Knowing the product designation, you can choose the product you need for the job. Knowing the product designation, you can choose the right equipment.

Core colors

The color of the conductor insulation is needed for ease of installation. Wires in the same sheath have a different color, which is the same along the entire length. Depending on the manufacturer, they may vary, but the color of the ground wire does not change. In a 3-core cable, most often the phase wire is red or brown, the neutral wire is blue or black, and the ground wire is yellow-green.

The colors of the wires in the electrician are regulated by regulatory documents.

The most famous cable brands

- wire PPV (copper), APPV (aluminum) in single insulation - for pulling inside walls;

- cable PVS (copper), GDP (copper) in double insulation - for pulling inside buildings;

- heat-resistant cables RKGM (copper) - up to 180°C, BPVL (tinned copper) - up to 250°C;

- cable VVG (copper), AVVG (aluminum) - for pulling along the walls of houses and in the ground;

- runway cable (copper) submersible - for pulling in water;

- CCI cable (copper) telephone pair - for pulling in the ground;

- TRP wire (copper) telephone distribution wire for subscriber communication (switching on TA)

- cable "twisted pair" UTP, FTP - for the organization of computer networks, the inclusion of intercoms, etc.;

- alarm wire "Alarm" for connecting intercoms, fire alarms, etc.;

- coaxial cable RG-6 for connecting TVs, antennas, surveillance cameras.

Internet cable

The concept of "Internet cable" generalizes many types of cable products. A variety of information cables are used to broadcast information. If you mean connecting to the Internet, then you need to check with the operator - which cable should be pulled along the walls. At the same time, it is necessary to find out both the brand of the cable and the manufacturer in order to accurately determine compatible cable products.

An optical cable can be laid on dedicated Internet lines.

computer cable

The term is also general.

The technology of twisting two strands into a pair has been used in telephony since the last century. Due to the correctly calculated twisting pitch and the quality of the material, the maximum information transfer rate was achieved compared to a standard paired telephone cable. There are quite a few types of twisted-pair cable depending on the number of cores, the diameter of each core, installation locations, etc. Depending on the data transfer rate, the twisted pair cable is divided into groups:

- 3rd category (standard telephone cable),

- 5th category (office networks),

- 6th category (new generation cable for changing the 5th category).

The "twisted pair", which has gained the most popularity in our time, is a category 5 cable of 8 twisted pairs of cores, the core diameter is a minimum of 0.45 mm and a maximum of 0.51 mm.

TV cable

And also "satellite cable" is a coaxial cable. Any 75 ohm coaxial cable can be used to connect satellite and any other antenna, and to connect to cable television. Only one thing matters - whether it is a good cable or not.

All other characteristics of the cable are aimed at improving the data itself 2 indicators and are of secondary importance. In particular, our RK cable is made only from copper wire (sometimes even silver-plated), however, the attenuation of the RK cable will be almost four times worse than that of any current RG brand cable made from inexpensive materials: steel and aluminum. This is achieved through a special cable production technology.

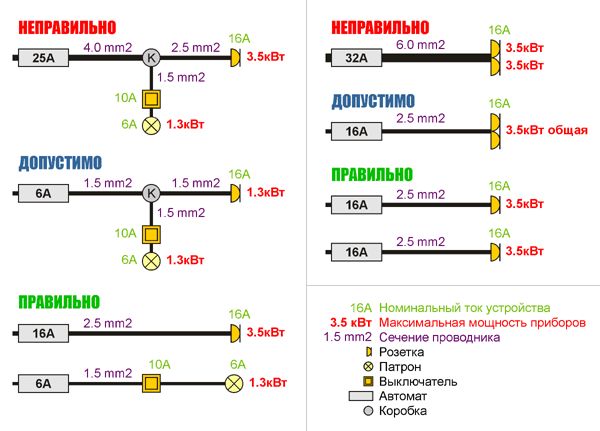

golden ratio

So what kind of wire is needed for wiring in an apartment and what section is suitable for home highways? For the right choice, it is necessary to calculate the current value of all electrical appliances in the apartment. This value will tell you the appropriate cable parameters. It is calculated according to the formula, taking as a basis the power of the device P (the data are indicated in the technical documentation) as a dividend and the voltage in the mains V (usually 220 V) as a divider.

The cross-sectional area is measured in square millimeters. Each such “square” of a copper electrical cable can pass a maximum of ten amperes through itself for a long period when heated to acceptable standards. The aluminum counterpart is inferior: its maximum is four - six amperes.

The cross-sectional area is measured in square millimeters. Each such “square” of a copper electrical cable can pass a maximum of ten amperes through itself for a long period when heated to acceptable standards. The aluminum counterpart is inferior: its maximum is four - six amperes.

Imagine a device that requires a power of four kilowatts. With a standard electrical voltage, the current strength will be equal to 18.18 amperes (4000 watts divided by 220). To power such a device from the mains, you will need copper wiring with a cross section of at least 1.8 square millimeters.

For safety net, it is better to increase this value one and a half times. The ideal option for this device would be a copper cord with a cross section of two square millimeters. The aluminum-based option should be chosen two and a half times thicker.

If you don’t want to count, you can estimate the parameters according to the table, slightly increasing the indicated powers.

With hidden wiring (in most modern apartments), the data in the table must be multiplied by 0.8. An open option, for example, in a private house involves a wire with a cross section of at least four "squares" with high mechanical strength.

This video will help you decide which wire is better to choose for wiring in an apartment:

Additional items

Of course, these three brands are not the only ones. There is a fairly wide range of models that can be used for electrical wiring at home, both indoors and outdoors. What do manufacturers offer for these purposes?

- PRN, which can be mounted both indoors and outdoors.

- PRI is used in dry and damp rooms.

- PRHE is recommended to be laid only in pipes or ducts.

- PRD is used for laying lighting networks.

- PPV - two-core flat wire.

- PV1 is a single-core wire, very flexible. By the way, in this group of wires there is a huge variety of colors. The color is selected according to the wiring diagram for ease of connection. There is even yellow-green for grounding.

For street lighting, it is recommended to install an armored cable VBBSHV. It perfectly copes with the negative impact of soil and water, therefore it fits into trenches. The number of cores can be different: 4, 5 and 6. But for overhead lines, it is best to use a self-supporting SIP wire. This is, firstly, an aluminum wire, inside of which a steel wire is threaded. Hence, in principle, and greater strength. Secondly, the insulation is a light-stabilized weather-resistant polyethylene, this polymer does not degrade in the open air.

Rules for the installation of electrical installations

Before proceeding to consider which cable to use for wiring lighting in an apartment or private house, you need to familiarize yourself with the rules for operating electrical installations (PEU-7). Clause 7.1.34. document recommends the use of wire and cable with copper conductors in residential buildings.

There is no clear ban on the use of aluminum products, but there are objective reasons why you should stop using this material:

- aluminum, compared to copper, has approximately 1.64 times lower electrical conductivity, which means that, other things being equal, it is necessary to lay a cable for lighting with a large cross-sectional diameter;

- when interacting with oxygen, an oxide film is formed on the surface of the bare aluminum wire, which increases the electrical resistance and leads to overheating at the connection points;

- cable products with aluminum conductors are very sensitive to kinks and mechanical stress due to the brittleness of the material.

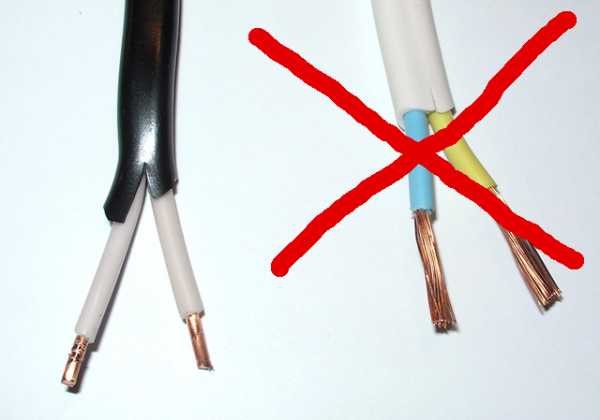

PUNP cable

This is a budget type of cable for electrical wiring.It is a flat two or three-core wire with a core cross section of 0.75 to 6 mm2. PUNP stands for:

- P - wire.

- UN - universal.

- P - flat shape.

Also in the abbreviation, the letter “G” is sometimes found, which means that the wire is flexible. Its main advantage is its low cost compared to VVG and NYM.

There is an opinion among electricians that the PUNP wire is prohibited for manufacture and use. Indeed, on June 1, 2007, a ban was introduced on the use of TU 16.K13-020-93 by members of the Elektrokabel association. However, manufacturing plants continue to manufacture and sell PUNP. In Russia, they can be purchased on a free sale.

Concerns about the use of PUNP are well founded. The statistics of fires due to the ignition of electrical wiring showed that 60% of the cases, the type of PUNP cable was the source of fire. The reason for this is that TU 16.K13-020-93 states that during the manufacture of the wire, a deviation of 30% from GOST 22483-77 of the cross section of conductive wires is allowed. This means that, for example, a wire with a nominal cross section of 4 mm2 may well be 2.9 mm2 or even less.

In general, it is up to you to decide whether to buy PUNP or not. In any case, if you have the means, it is better to purchase a good quality wire once and do not be afraid of a fire.

Types of containment

For wiring in the apartment, only protected cores are used. The shell for them can be made from:

- rubber;

- Polyethylene;

- Polyvinyl chloride (PVC);

- PVC compound.

The rubber is highly elastic. It can be greatly stretched, and when the force that stretches it disappears, the rubber will return to its previous length.The material does not allow gas and water to pass through, so it is considered an excellent insulator. Both synthetic and natural rubber are used for wiring.

Polyethylene is a white or grayish material with high hardness. Oily insulation has thermal plasticity. The wires enclosed in it can heat up to 100 degrees without consequences.

PVC is a hard material resistant to aggressive environments. He is not afraid of alkalis, acids and mineral oils. Wires with PVC protection are good where the mechanical strength of the sheath is more appreciated.

PVC compound includes oily liquids that give plasticity. The advantage of such insulation is the fact that the burning of the plastic compound stops if it is taken out of the fire. The color of the shell is standard: red, black, white, blue or yellow.

How to independently determine the quality of the cable?

Many manufacturers do not always comply with the standards in the manufacture of cable. Their main "trick" is the underestimation of the cross section of the conductive core. And sometimes significant. Of course, it is difficult to examine the section at the place of purchase. In the store, you can measure any wire with a caliper and a micrometer.

For examination, it is good to have a piece of the “correct” cable with you as a standard. In stores, you can stumble upon a Chinese cable made of aluminum covered with copper (sold as copper with Cyrillic markings).

There are manufacturers who use low-quality copper or aluminum to reduce costs. For such cables, the service life and current conductivity of the core are much lower than for GOST. It is possible to test the quality of the metal of a current-conducting core as follows:

- try bending and straightening the cable a couple of times.In factories, such a test is performed on a special bending mechanism under a certain bending radius. Of course, your number of bends will be less than those provided for in GOST. However, in any case, aluminum should withstand at least 7-8 bends, and copper - 30-40. After that, deformation of the insulation and breakage of the core is possible. It is better to carry out the experiment at the end of the cable, so that later it can simply be cut off.

- high-quality copper/aluminum cable must bend and not spring;

- the copper/aluminum core on the stripped cable should have a bright (glare) color. When the vein is heterogeneous in color and there are hopeless spots, this indicates both large impurities in the metal and its low quality.

And yet, an amateur on his own will not be able to 100% establish the quality of the cable. In this case, there is only one recommendation - to rely on the brand and purchase it in large trusted stores.

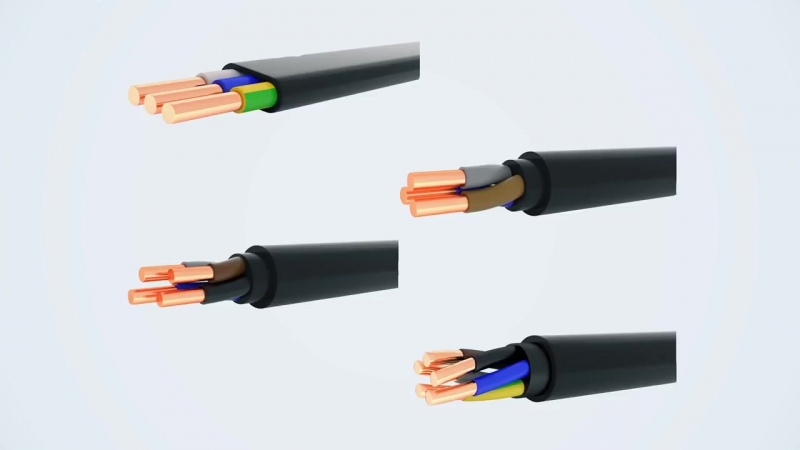

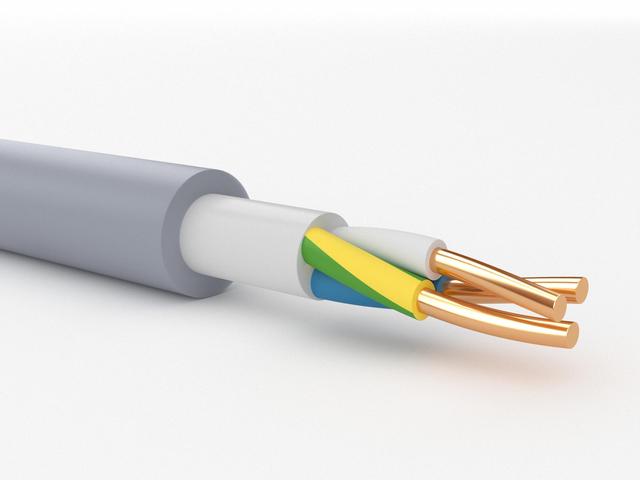

For internal wiring

For the device of the internal electrical network, they mainly use the domestic copper cable VVGng-ls or its imported analogue NYM (DIN 57250 standard). The core insulation and sheath of the VVGng cable are made of PVC.

NYM cable has the following advantages:

- better protected: there is an additional intermediate shell made of chalk-filled rubber;

- can be laid outdoors in a place protected from direct sunlight;

- external PVC insulation not only does not support combustion, but also has a reduced gas and smoke emission.

But the NYM cable is more expensive than VVGng-ls, because it is mainly used to connect junction boxes to the floor shield, powerful electrical appliances (a separate line is laid to those from the shield) and indoor shields, if any.

The wiring is usually performed with a VVGng-ls cable or at least VVGng. They mainly use a flat version as it is more convenient for installation, but this cable is also available with a different cross-sectional shape - round, square, triangular and sector.

In rooms with high humidity, laying the VVG cable is also allowed. The cheapest cable for internal wiring is PUNP cable with PVC insulation and sheath. The cross-sectional shape is flat, the cores are single-wire. The disadvantage of the PUNP cable is the poor quality of the insulation: when heated, it loses its working properties.

The following cables are also used:

The following cables are also used:

- with rubber insulation: PRI (indoors without restrictions (open laying is allowed at any humidity), PRH (both indoors and outdoors), PRTO (exclusively in a fireproof pipe), PRH and PVH only for lighting and in a dry room) ;

- flat cables PPV and PPP. The first is with PVC insulation, the second is with polyethylene. Due to the flat shape, the wires are suitable for open laying. The cores of the PPV cable are separated from each other by a curved metal tape (ribbon dividing base), which gives it strength and reliability;

- flat cable PPVS. It is deprived of a dividing base, therefore it is not so convenient in work;

- PV wire. Here, unlike the cable, there is only one core, which can be either single-wire or multi-wire. Versions with different color of insulation are produced. In hard-to-reach places, the most expensive types are used - PV3 or PV4, which are characterized by increased shell flexibility.

Single-wire cables are intended for the wiring device. Stranded, as more flexible - for the manufacture of power cords for electrical appliances, extension cords, etc.

Electricians recommend wiring with multi-wire cables. They withstand higher overloads (by 5-10%). They are difficult to fake, while scammers (most often Chinese) make single-wire cables from aluminum with subsequent copper plating.

Brief recommendations on the laying method

Another factor to be considered is the installation method. Most popular options:

- Air. This option is suitable for cases where the cable has a length of 3 meters. The advantages of the method are high installation speed and ease of maintenance. On the other hand, aesthetics suffer and the resource of the product is reduced. In the process of such laying, a steel cable is used, to which the cable itself is attached with the help of ties.

- Underground. This method is used in most cases when it is required to lay a long cable. Installation is carried out in several stages - choosing the type of cable, marking the place and laying. The depth of the trench is about 70 cm. From the bottom there should be a “cushion” of sand about 8-10 centimeters thick. The cable must be laid without tension, after which it is covered with sand, soil and finally rammed.

An example of laying a cable in a trench is shown in this video: