- How is scale formed and why is it dangerous?

- SAFETY INSTRUCTIONS

- It is forbidden:

- Seasonal Service

- Floating Head Heat Exchanger Repair

- Flushing the shell and tube heat exchanger

- How does a water heater work?

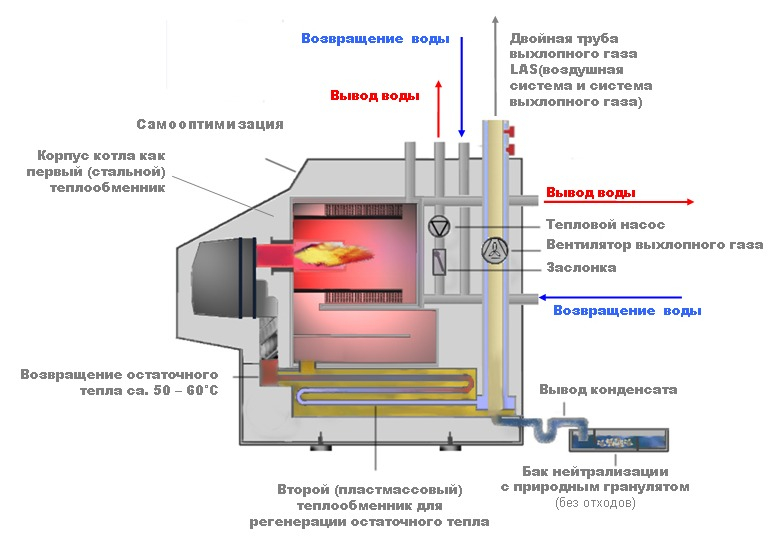

- Classification of heat exchangers for boilers

- Primary

- Secondary

- Bithermic

- Replacing gaskets with glue

- Cold welding as a repair option

- How often should the boiler be cleaned?

- Possible malfunctions and do-it-yourself repair methods

- Smells like gas in the house

- Fan not working

- Boiler chimney clogged

- High temperatures

- Sensor failure

- Self shutdown

- Methods for cleaning a gas boiler

- Mechanical

- Chemical

- Cleaning with drugs

- Booster for cleaning the heat exchanger

- hydrodynamic

- Electrodischarge

- When to clean up

- Why do heat exchangers need periodic cleaning?

How is scale formed and why is it dangerous?

No liquid can compare with ordinary water in terms of specific heat capacity. Depending on temperature and pressure, this indicator varies in the range from 4174 to 4220 Joules / (kg deg). Water is non-toxic, readily available, and cheap, making it an almost ideal heat transfer medium.

And yet, N2O has a significant drawback - in its natural state it contains salts of alkaline earth metals Ca and Mg. When heated, they form on the internal surfaces of the heat exchange equipment insoluble carbonate, or, otherwise, lime deposits - scale.

Hard water is typical for a significant part of Russia, and especially for the middle zone, where the degree of mineralization reaches a maximum.

The negative consequences of scale formation are as follows:

- efficiency decreases;

- the water pressure is reduced;

- boiler wear is accelerated;

- expenses increase.

Domestic heating boilers and water heaters are mainly equipped with surface heat exchangers, in which heat is transferred through the surfaces of metal walls. But the scale has a high thermal resistance, that is, low thermal conductivity.

For this reason, in contaminated heat exchangers, the heat transfer coefficient decreases, which leads to a decrease in the temperature of the heat carrier in the heating circuit and insufficient heating of the water at the outlet of the hot water circuit.

If your boiler does not heat water well, check the condition of the heat exchanger, it may be due to scale, which caused a decrease in efficiency

Hard deposits with a thickness of only 0.2 mm increase fuel consumption by 3%. If the scale thickness is 1 mm, the gas overrun will reach 7%.

When heat transfer decreases, more gas is required to maintain the desired water temperature, which indicates a decrease in efficiency. At the same time, with an increase in fuel consumption, the volume of flue gases increases, the emission of harmful substances increases, polluting the air around the household and the atmosphere as a whole.

Deposits completely or partially block the flow area of the pipe, which leads to an increase in hydraulic resistance in the system, disruption of the circulation of the coolant, and a decrease in the supply of hot water at water intake points.

When using water of normal hardness, a layer of scale 2-3 mm thick is formed per year. With higher salinity, the rate of carbonate sedimentation increases.

Violation of heat transfer leads to overheating of pipes, which causes the formation of microcracks - future centers of corrosion. Due to the work at the limiting modes, the unit fails prematurely.

To prevent damage to equipment, scale must be removed periodically. Scheduled cleaning of heat exchangers of gas wall-mounted boilers and floor-standing units is carried out within the time limits set by the manufacturer. A simple procedure helps to maintain the energy efficiency of the equipment at the initial level, extends the period between repairs, reduces the total cost of operation.

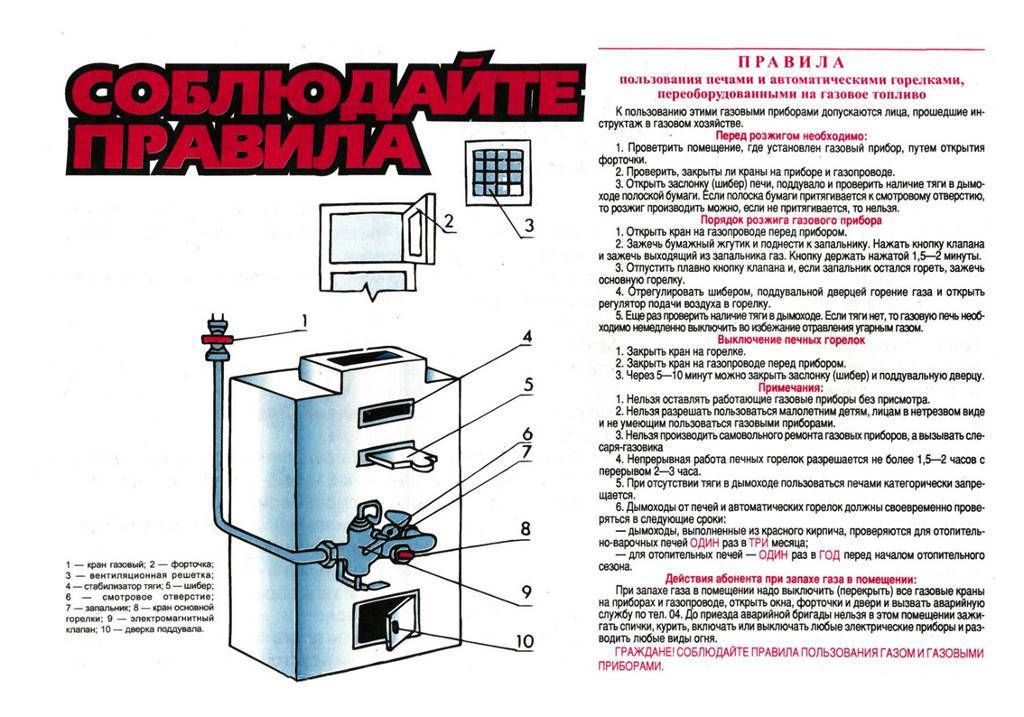

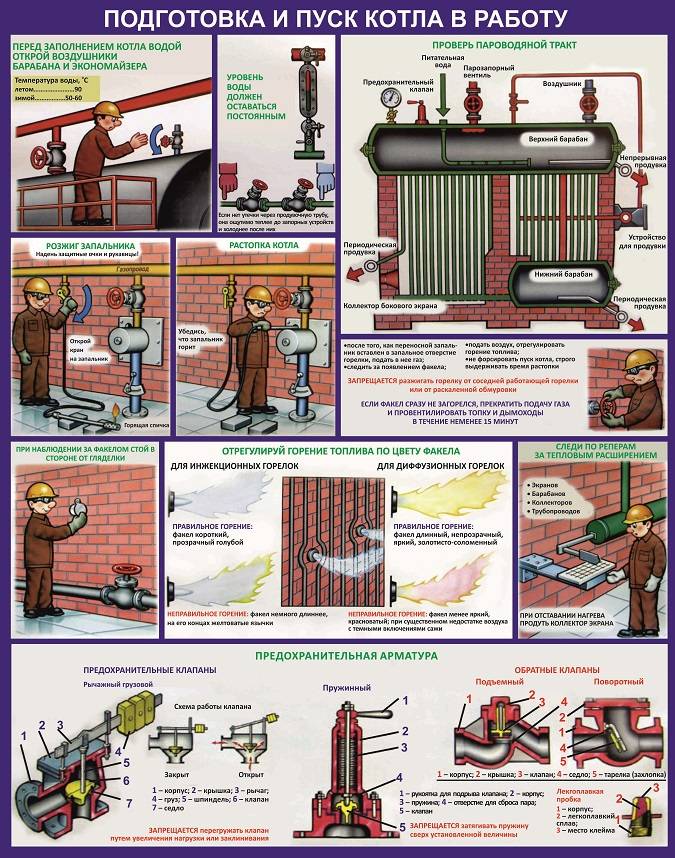

SAFETY INSTRUCTIONS

Persons who have studied this passport are allowed to service the device.

The installation and operation of the apparatus must comply with the requirements of the Rules for the Design and Safety of Operation of Hot Water Boilers, Water Heaters and Steam Boilers with Overpressure, as well as the requirements of the Safety Rules for Gas Distribution and Gas Consumption Systems. PB 12 - 529", approved by the Gosgortekhnadzor of Russia.

The operation of the devices must be carried out in accordance with the "Fire Safety Rules for residential buildings, hotels, hostels, buildings of administrative institutions and individual garages PPB - 01 - 03".

The operation of the device is allowed only with serviceable automatic safety and thermal control.

Gas safety automatics should provide:

- Reducing the gas supply when the water temperature in the heating system reaches the set value.

- Shutdown of gas supply to the main burner when the set heating temperature is exceeded.

- Turn off the gas supply to the device in the following cases:

- when the gas supply to the apparatus is interrupted (for a time not exceeding 60 seconds);

- in the absence of draft depression or in the boiler furnace (for a time not less than 10 seconds and not more than 60 seconds);

- when the torch of the pilot burner goes out (for a time not exceeding 60 seconds).

During operation of the device, the temperature of hot water must not exceed 95 °C.

It is forbidden:

- operate the device with the heating system partially filled with water;

- use other liquids as a heat carrier instead of water**;

- install shut-off and control valves on the supply line and the pipeline connecting the heating system with the expansion tank;

- operate the device in case of gas leakage through the gas pipeline connections;

- use an open flame to detect gas leaks;

- operate the device in case of a malfunction of the gas network, chimney or automation;

- independently troubleshoot the device;

- make any structural changes to the apparatus, gas pipeline and heating system.

When the machine is not in operation, all gas valves: in front of the burner and on the gas pipeline in front of the machine, must be in the closed position (the handle of the valve is perpendicular to the gas pipeline).

Any malfunctions during the operation of the apparatus on gas must be immediately reported to the emergency service of the operating enterprise of the gas economy.

If gas is found in a room, immediately stop its supply, ventilate all rooms and call an emergency or repair service. Until the malfunction is eliminated, it is forbidden to light matches in the room, smoke, use

** It is allowed to use household coolant "Olga" (manufacturer: CJSC "Plant of Organic Products") according to the instructions for use. After a period of operation, the coolant must be drained and disposed of.

The manufacturer reserves the right to make changes to the design and appearance of the product.

This technical documentation may differ from the description above, see the instruction manual enclosed with each boiler upon purchase.

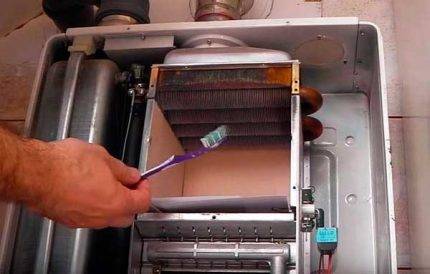

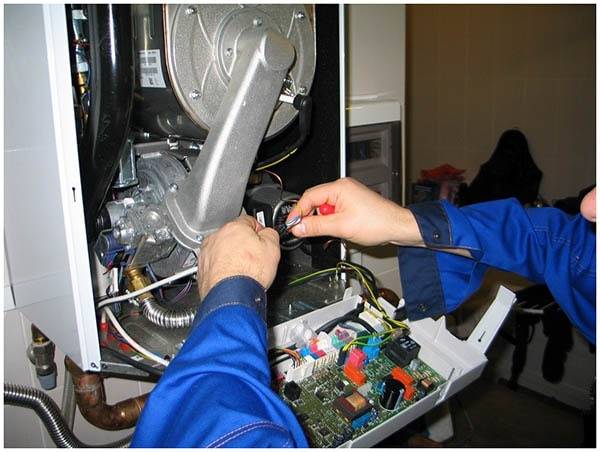

Seasonal Service

Seasonal maintenance of a gas boiler consists in cleaning it from contaminants and checking its performance. To access the elements of the boiler, it is necessary to dismantle the casing or casing. To do this, we determine the method of its fastening, for different models of boilers this can be done in different ways. Most often, these are several self-tapping screws and several latches in the upper part of the casing.

Having gained access to the internal parts of the boiler, when performing seasonal maintenance, we do not remove anything else. Using a soft brush for metal, a toothbrush and fine-grained sandpaper, we proceed to remove carbon deposits from all parts of the boiler:

- heat exchanger;

- burners;

- igniter, if available.

We use the above tool, where it is convenient, without particularly leaning on the metal brush. Then we blow out the collected dust with a compressor. You can use a rubber tube or a tube from a medical dropper by simply blowing into it and directing its other end into the boiler.

Important! Any work on the boiler is carried out with the gas valve closed. Using a thin awl or a strong needle, you need to clean all the holes on the burner and igniter, and then, after cleaning them again, for example, with a toothbrush, blow them out again. If there are overhead sensors, the places of their contact with the parts of the boiler should be lightly cleaned with sandpaper, and then wiped with a soft woolen cloth.

If there are overhead sensors, the places of their contact with the parts of the boiler should be lightly cleaned with sandpaper, and then wiped with a soft woolen cloth.

Using a thin awl or a strong needle, you need to clean all the holes on the burner and igniter, and then, after cleaning them again, for example, with a toothbrush, blow them out again. If there are overhead sensors, the places of their contact with the parts of the boiler should be lightly cleaned with sandpaper, and then wiped with a soft woolen cloth.

The ignition and flame control electrodes are cleaned well only with a woolen cloth, without the use of cleaning agents. If there are submersible temperature sensors, it is necessary to remove them from the sleeves, select the liquid present there from the sleeve, thoroughly clean the sleeve inside using a small metal ruff or a loose piece of steel cable of a suitable size. After rough cleaning, the sleeve is cleaned with a cloth wound around a screwdriver, then two-thirds of the sleeve is filled with machine oil and the sensor is installed.

After completing these works, the boiler is carefully vacuumed. In accessible places, dust and dirt are cleaned with a damp cloth. We put the cover in place.We check the presence of draft in the chimney by attaching a sheet the size of a notebook to the chimney hole, or by letting a trickle of smoke into the ignition hole of the igniter, the gas valve on the descent to the boiler must be closed.

We check the places of seals and possible gas leaks by soaping. In the presence of normal draft, a test run of the boiler is carried out, which must be filled with coolant. In parallel with the cleaning of the boiler, it is visually inspected for mechanical damage and coolant leaks. At this seasonal service can be considered complete.

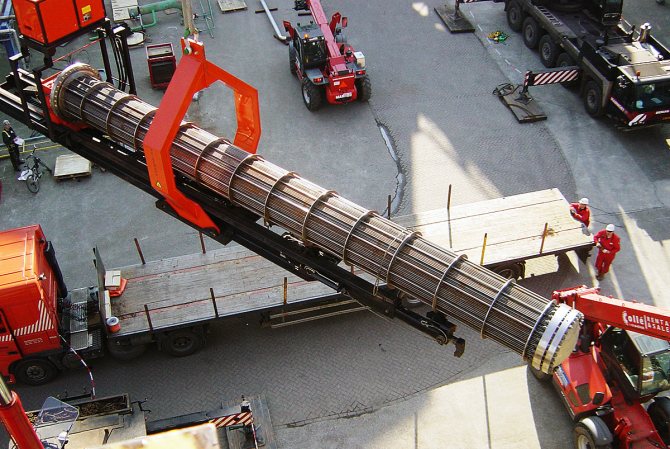

Floating Head Heat Exchanger Repair

The floating head heat exchanger has the ability to extract the tube bundle from the body. To do this, it is necessary to relieve pressure and disconnect the device from the piping by plugging the inlet and outlet pipes for technological media.

Repair of a floating head heat exchanger consists of the following stages:

- Cleaning the surface of the tubes from external and internal pollution and corrosion;

- Checking the integrity of the tubes, flaring, replacing or plugging the tubes if necessary;

- Checking the tightness of flange connections and replacing gaskets;

- Hydraulic testing of the apparatus;

- Checking threaded connections.

Extraction of a tube bundle is one of the most difficult operations and requires heavy lifting equipment, usually a winch in combination with a crane.

By the way, read this article too: Heat Exchanger Vibration

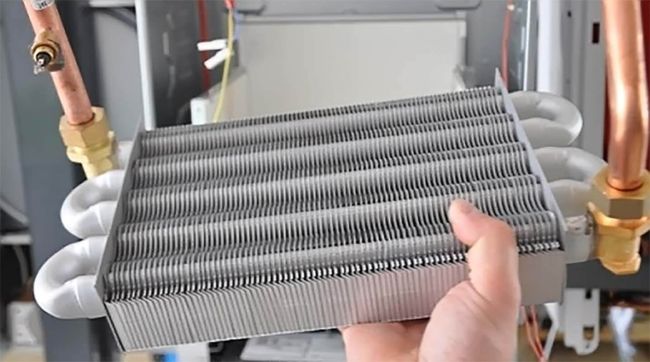

Flushing the shell and tube heat exchanger

Turn off the boiler, turn off the taps on the inlet pipes to keep water in the heating system. Drain the water from the heat exchanger. Disconnect the wires from the thermostat and disconnect the hot water pipes.Unscrew the nuts and self-tapping screws fixing the heat exchanger, remove it.

With regular maintenance of the boiler and its proper operation, soot is formed in moderate quantities and can be removed regular toothbrush

To flush the shell and tube heat exchanger from a thick layer of carbonate deposits, it must be removed from the casing. The dismantling process does not require special skills

Visually inspect surfaces. If there is soot on the fins or other areas, immerse the heat exchanger in a detergent containing alkali. It can also be a solution of ordinary laundry soap.

Unless otherwise stated in the instructions, soaking should last about 15 minutes. Then brush off the soot. Rinse the heat exchanger under running water with good pressure.

Place the heat exchanger in a basin or other container to remove scale. Pour a solution of citric acid (10% concentration) into the pipe. After 12-15 hours, flush the pipes with clean water. Also clean or replace hot water circuit filters.

Reinstall the heat exchanger. After cleaning, it is also advisable to replace all gaskets. If the gaskets are rubber, use silicone to lubricate them.

Next, the heat exchanger must be checked for leaks. A saturated soapy solution is applied to the detachable connections of the gas circuit. If there are leaks, bubbles form in the soapy areas.

Having completed the flushing of the floor boiler, they check its tightness, electrical connections and performance in different modes, restore the settings and put it into operation.

When checking the water circuit in a double-circuit gas boiler, the heating and hot water supply systems are separately turned on and each detachable connection is inspected. If a leak is found, tighten the nut or install a new seal.

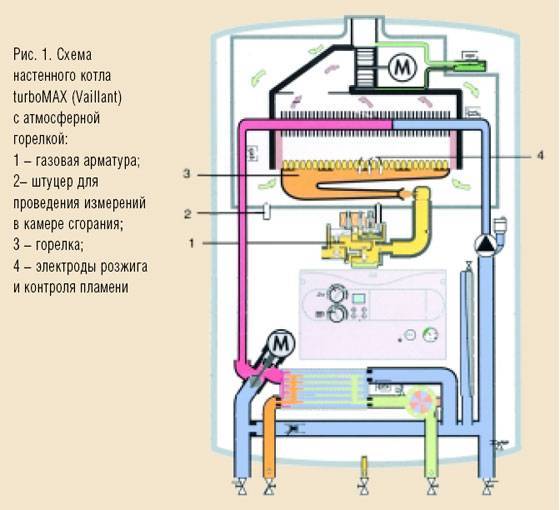

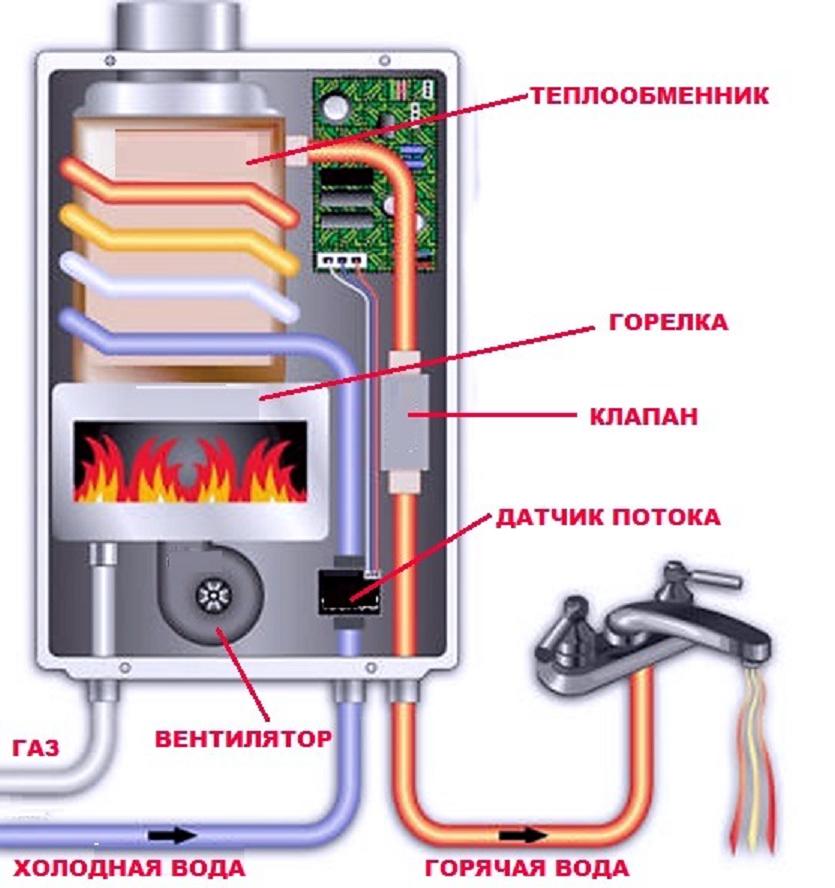

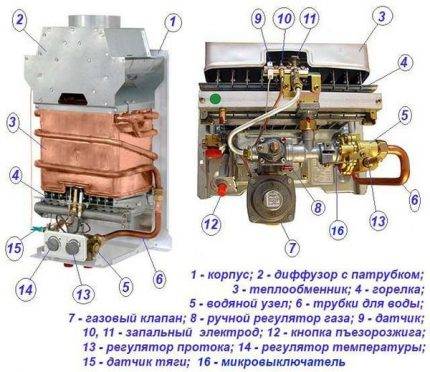

How does a water heater work?

To learn how to repair a geyser, you must first understand how it works and how it works.

Aggregates can be of the following types:

- With an open combustion chamber or atmospheric.

- With a closed combustion chamber or turbocharged. They are also called inflatable.

The air required for combustion of gas enters the atmospheric column from the environment in a natural way. It enters the device through the opening, which is located at the bottom of the column. To remove the products of combustion, a natural draft chimney is installed.

Turbocharged or inflatable columns differ from atmospheric ones in one feature: their combustion chamber is closed, and the built-in fan provides forced draft. The air supply and its removal is carried out forcibly through a coaxial chimney (double-walled).

You can familiarize yourself with the device of a gas water heater in general terms by examining the following illustration.

The photo shows the device of a typical geyser. The design feature of this water heater is the piezo ignition of the burner. Also, batteries (or from a 220 V network), a hydraulic turbine can be used to ignite various models.

The photo shows the device of a typical geyser. The design feature of this water heater is the piezo ignition of the burner. Also, batteries (or from a 220 V network), a hydraulic turbine can be used to ignite various models.

Below is the principle of operation of a modern gas burner with an automatic ignition system:

- The column starts working when the mixer tap is opened. The water flow passes through the water supply unit and the heat exchanger of the gas device.

- Inside the column body is a water regulator membrane that pushes the stem under the pressure from the water. This allows the stem to compress the spring of the mechanical gas valve in the block so that the fuel has a chance to get to the burner itself.

- At this stage, the solenoid valve circuit closes, which occurs when the microswitch button is released by the rod. The valve provokes the launch of gas into a special tube, which is supplied. The gas flows to the already open spring valve.

- The impulse device is activated. It delivers a discharge to the electrodes that are located next to the burner. Sparks are formed, as a result of which ignition begins. This allows you to heat the water passing through the heat exchanger.

The electromagnetic circuit consists of 3 sensors that are connected in series. These include a draft, overheating and flame sensor. When the last element of the chain fixes the fire, at this moment the formation of sparks ends.

We examined the principle of operation of the column in more detail in this material.

Old geysers had one contact and a constantly working igniter. Now they make devices with two electrodes that ignite the burner

Old geysers had one contact and a constantly working igniter. Now they make devices with two electrodes that ignite the burner

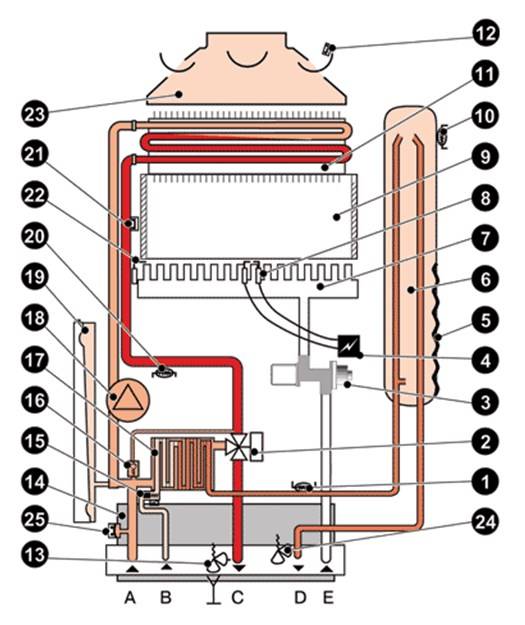

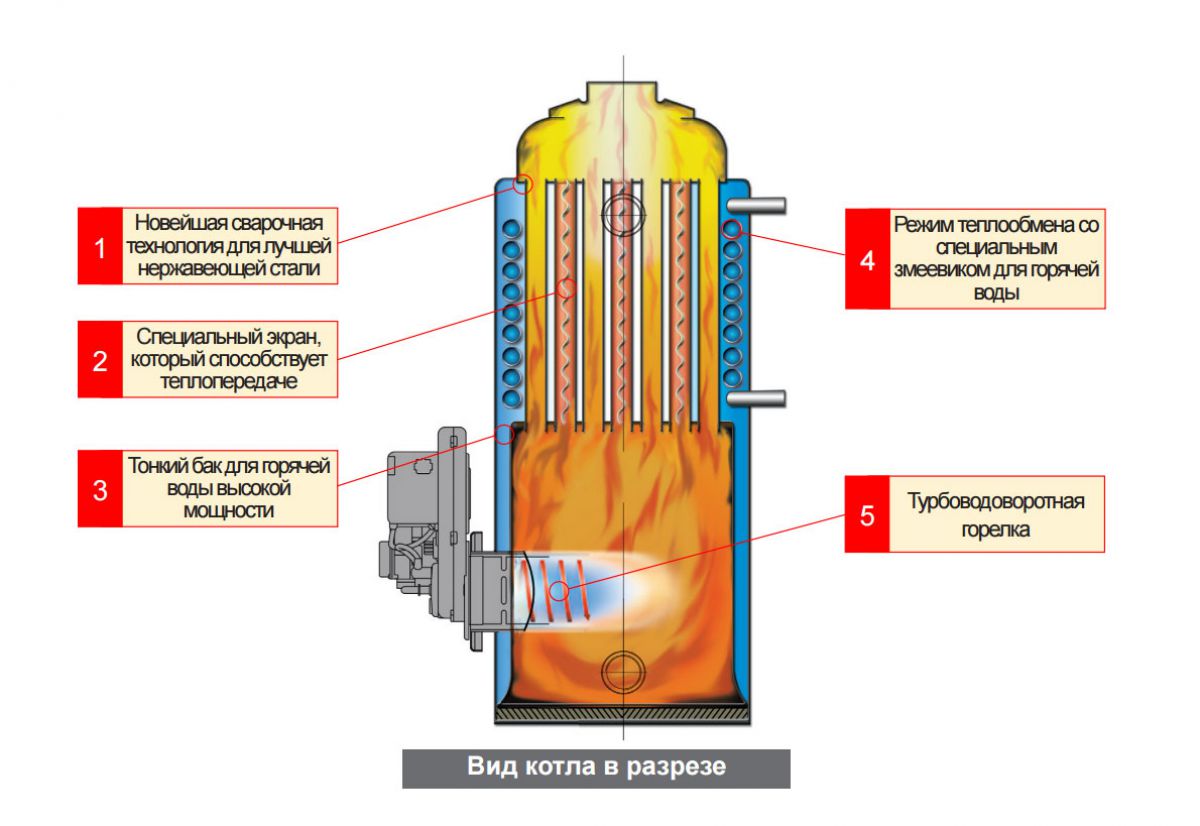

Classification of heat exchangers for boilers

Heat exchange elements for a gas boiler can vary significantly in design and use. The following devices are most often used in thermal equipment:

Primary

This category of devices is used to transfer thermal energy directly to the fuel combustion chamber.

Attention! Primary heat exchangers are operated in very harsh conditions, therefore they must be made of very high quality materials.

Secondary

The secondary heat exchanger heats up due to the transfer of energy from the coolant to another fluid.

Such a device is ideal for meeting the demand for hot water in the presence of a separate heating circuit.

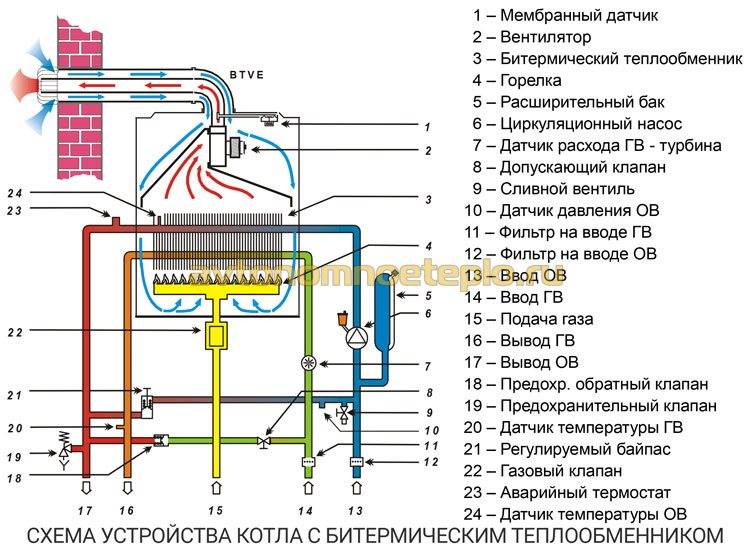

Bithermic

The bithermic heat exchanger is a modern and practical element of a heating boiler.

This design consists of 2 separate tubes installed one inside the other. Products of this type are used mainly for the simultaneous heating of water for heating and for domestic needs.

Replacing gaskets with glue

Adhesive gaskets are removed by heating the reverse side of the groove with a gas burner or hot air gun

Damaged seals must be removed carefully to avoid damaging the plates. Wear a mask to protect yourself from toxic glue fumes

The groove under the seal should be cleaned with a stainless steel brush. Before gluing with a new gasket, clean the entire plate with a mild cleaning solution and water. Use only the correct type of adhesive and original seals. Clean the groove with acid or alcohol. Apply a thin layer of adhesive to the center of the groove. Place the gasket in the groove and secure with tape while it dries. (12 - 24 hours)

Cold welding as a repair option

On the basis of adhesives, the so-called cold welding is made. A popular raw material in this case is epoxy resin. Do not confuse the material and cold welding in understanding the technological process with the plastic deformation of metals without heating.

Choose the most moisture resistant raw material from what the market offers. At the very beginning of work, put on gloves and soften the welding with your fingers. Do this until the mass becomes plastic. Place the material on the fistula and spread over as large an area as possible. Make the layer thick, but not necessarily the thicker the better. Apply with a wooden stick.

Cold welding is used on copper, brass, bronze, cast iron, iron, alloys, and also on ceramics, wood, stone, but the final quality of the joint largely depends on the work itself.

Wait for the finished layer to harden, and carry out a superficial cleaning of the place with fine-grained sandpaper and a damp cloth.

First, wait half an hour for better hardening. The recommended 3-5 minutes is sometimes not enough. Check the quality of the joint by temperature contrast and water pressure.

How often should the boiler be cleaned?

The technical documentation for the boiler indicates how often it needs to be serviced. For closed circuits with the addition of reagents (single-circuit heating boilers), cleaning is required less frequently. It can be performed 1 time in 2-3 years. The bithermic and secondary heat exchangers must be flushed every year, and under difficult operating conditions (“bad” water composition) - twice a year.

Signs that the boiler urgently needs cleaning:

- the boiler is slowly gaining temperature;

- insufficient traction;

- the burner does not ignite or does not burn well;

- with the same gas consumption, the heat output is less;

- traces of soot or partially burnt paint in the area of \u200b\u200bthe viewing window.

Do not neglect preventive measures, because the result of this can be not only broken equipment, but also a threat to the safety of all residents of the house.Clogged chimneys and pipes with growths inside can cause serious accidents.

Periodic flushing of the gas boiler heat exchanger is a basic requirement for the maintenance of heating equipment. Cleaning significantly affects the smooth operation of the entire system and greatly extends the life of the home heating device. When should I flush and can I do it myself?

During operation of the gas boiler, a layer of scale forms, which prevents the necessary cooling of the heat exchanger. In this case, the circulation pump takes on a large load. Therefore, without flushing the heat exchanger, the heating unit may fail.

At home, cleaning should be done every two years. If the water in the house is hard enough, it is recommended to reduce the interval between flushing.

The first signs for the user that the heat exchanger needs to be flushed are:

- prolonged heating of the gas boiler;

- decrease in heat output;

- partial heating of the system;

- the presence of extraneous sounds during the operation of the heater;

- significant increase in gas consumption.

When scale appears in double-circuit boilers, the water may not completely warm up or the pressure level may decrease.

It is advisable to avoid the combination of such symptoms. But if there are warning signs, flushing should be done immediately.

In addition to the internal cleaning of the heat exchanger, external cleaning of its body from soot is used. Socialized services are engaged in the elimination of scale and pollution in the gas boiler system. Their services are not cheap. Therefore, sometimes you can flush the heat exchanger yourself.

Possible malfunctions and do-it-yourself repair methods

Any malfunction of the gas boiler must be dealt with by a specialist. However, the opportunity to use the services of a master is not always available, and breakdowns are trifling. Consider problems that are solved independently.

Smells like gas in the house

Usually the smell of gas appears when it leaks from the threaded connection of the supply hose. If there is a smell in the room where the boiler is installed, you need to open the window and turn off the boiler. Then proceed according to the instructions:

- Prepare the necessary things: soap solution, FUM tape, open-end or adjustable wrench.

- Apply mortar to all threaded connections. If bubbles begin to inflate, a leak has been found.

- Close the gas valve.

- Expand the connection with the key. Wrap the FUM tape on the external thread and assemble everything back.

- Reapply the solution and restart the gas supply.

- If the leak is fixed and the smell of gas is gone, remove the remaining solution.

Attention! When the leak could not be found, turn off the gas, call a specialist

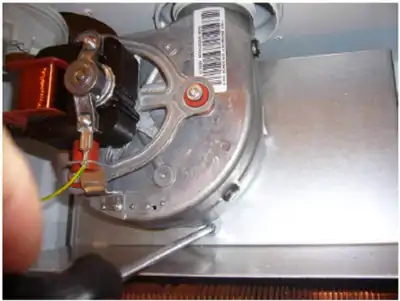

Fan not working

If during the operation of the boiler the sound emitted by the turbine disappears or decreases, this indicates a malfunction of the blowing fan. For repair you will need: a screwdriver, a new bearing, a rag, grease.

- It is necessary to turn off the boiler and turn off the gas.

- Remove turbine.

- Use a cloth to clean dust and soot from the turbine blades.

- Inspect the electric fan coil for blackening. If everything is in order, move on or replace the fan.

- Disassemble the fan housing. A bearing is installed on the turbine shaft inside, it must be replaced. Some fans have a sleeve instead of a bearing.In this case, it must be lubricated.

The turbine may also not work due to low mains voltage or a malfunction of the control board. The first is eliminated with the help of a stabilizer, but the second is only by calling a specialist.

Boiler chimney clogged

Problems with the chimney occur only in floor-standing boilers. This is due to its size and vertical position. Mounted devices do not need to clean the chimney.

The chimney, consisting of metal parts, is cleaned with a metal brush. It must be disassembled and the accumulated soot removed mechanically. The whole chimney is cleaned with special vacuum cleaners or chemicals. But for this you need to call a professional.

Photo 2. Three ways to arrange a chimney for a floor-standing gas boiler. The first option is the hardest to clean.

High temperatures

Overheating of the boiler is associated with contamination of the heat exchanger. To clean the device, you will need: a special solution of hydrochloric acid, an adjustable wrench, an FUM tape, a metal brush. Then proceed according to the instructions:

- Turn off the boiler, turn off the gas and water.

- Remove the heat exchanger using an adjustable wrench.

- Clean it with a brush.

- Pour the acid solution into the heat exchanger through the pipe. If foam appears, then there is a lot of scale inside.

- Pour out the solution and repeat the procedure.

- Rinse.

- Install back, after wrapping all threaded connections with FUM tape.

Sensor failure

Problems usually arise with the combustion electrode. If the burner flame goes out after a few seconds, and the boiler gives an error, then the problem is in the combustion sensor. Turn off the boiler, turn off the gas.

To repair the electrode, you will need sandpaper, with which the sensor probes are cleaned without removing it. If the failure remains, the sensor is replaced.

Self shutdown

There are two problems that lead to spontaneous shutdown of the boiler. The combustion sensor is broken or the chimney is clogged. Repair of both faults is described above in the article.

Methods for cleaning a gas boiler

There are several options. These include traditional methods: mechanical and chemical method. In not the most difficult cases, hydrodynamic cleaning is chosen. Sometimes serious help is needed.

Mechanical

This method involves the use of the simplest tools. Manual cleaning avoids wasting money and time, but its effectiveness is low. The mechanical method does not guarantee an excellent result at all, so using it can be called a half measure. Actions with "crazy" hands will help only if cleaning is carried out regularly.

The usual tools act as tools - brushes, brushes, toothbrushes, and a vacuum cleaner is also used in the struggle for cleanliness. All mechanical devices should not have sharp edges, since it is very easy to damage the parts of the unit with them. The necessary element is disconnected from the system, carefully treated with brushes, trying not to damage the surface. To clean the inside, use a brush, or blow the parts with a vacuum cleaner.

Sometimes the mechanical method is combined with the chemical one. In this case, before “manual work”, small knots are soaked in a container where a weak acid solution is located. Use citric or hydrochloric acid: 100-200 g is enough for a bucket of water.After such a preliminary half-hour preparation, the scale is easier to remove, as it softens.

Chemical

This method is more efficient than manual work. Chemicals allow you to remove blockages in those places where tools simply cannot be reached. This option is not only more efficient, it saves a lot of time. However, there were some downsides here. You have to pay for reagents, and for high-quality work you will need special equipment. It will either have to be bought or rented from familiar craftsmen.

Cleaning with drugs

This option is suitable for small local pollution, but in this case, you need to proceed with extreme caution. Mandatory personal protective equipment

Too long contact of elements with chemicals can lead not only to the elimination of soot, but also to the destruction of the metal. Therefore, it is better to carry out the processing very carefully.

Booster for cleaning the heat exchanger

Booster - a water pump with a tank for the reagent. For maximum efficiency, the units are supplemented with heating elements. Instead of ordinary water, aggressive substances are used for cleaning. For example, solvents, phosphoric or hydrochloric acid. Their heating increases the efficiency of cleaning the gas boiler.

The booster is connected to a heat exchanger. When the device is started, the liquid begins to circulate continuously inside it, gradually corroding all deposits. The reagent is recommended to be changed, as it loses its properties, and all deposits enter the tank and accumulate there. To neutralize the remnants of the caustic liquid, after cleaning, a special (alkaline?) solution is run through the pump. Or clean water.

hydrodynamic

Such flushing does not require disassembly of the gas boiler, but a booster is also needed for the procedure. This operation is the pumping of water (in exceptional, severe cases - with an abrasive filler) with a subsequent increase in pressure in the system. The accelerated movement of the liquid provokes the destruction of deposits, and then their safe removal from the equipment. However, this option is fraught with serious consequences.

If a critical increase in pressure indicators occurs, then it can provoke a pipe rupture. Due to the potential danger of independent work, such “water procedures” are best left to professionals working with gas equipment. In this case, the owners of the gas boiler will be able to avoid all problems.

Electrodischarge

This is another way to clean a gas boiler, but it requires serious equipment - a whole complex. In this case, the scale is exposed to a liquid through which an electric discharge is passed. Such a formidable treatment causes the deposits to crack and subsequently be washed away.

The advantages of the method are a high degree of purification, the absence of a negative impact on the metal parts of the equipment. Disadvantages - more processing time, procedure noise, expensive and bulky equipment (Streamer complex). Such flushing of boilers is usually done only in service centers.

When to clean up

There are 3 options for the development of events:

- Preventive cleaning of the gas boiler is done by the homeowner himself once every 2 years at the lowest cost.

- The procedure is performed as the heat exchangers are contaminated with soot and scale, which reduces the efficiency of heating and heating water for the needs of hot water supply.In this situation, you can still clean the boiler yourself, although the call of the master is also not excluded.

- The heat generator has stopped due to a breakdown, which often happens during the heating season. The malfunction is eliminated by the called specialist, who also cleans the heat exchanger from soot.

In the photo, the master maintains a condensing boiler with a closed cylindrical combustion chamber. Inside there is a heat exchange coil, which is better not to touch it yourself

The last 2 scenarios are clearly unattractive for the owners of the house, since they are associated with inconvenience and financial costs. You can not do without a master even if a condensing boiler with a burner and a specially designed heat exchanger is used for heating. Climbing there on your own is not recommended, unless you are well versed in heating equipment of this kind.

Why do heat exchangers need periodic cleaning?

During operation, soot settles on this element. Sometimes the soot layer is so thick that the efficiency of the boiler drops by almost half. As a result, the unit does not heat up and the owner has to bring the device to full power. Preventive measures can remove this soot. But also scale forms inside the gas heat exchanger. Due to this scale, the passage channel is significantly narrowed, the coolant warms up much more slowly. This negatively affects the efficiency of the heating system and increases the load. In addition, energy costs are rising.

To avoid problems with the equipment, it is recommended to clean the heat exchangers of gas boilers every three years. This process is a set of works that you can do yourself without special skills.The whole complex of events will take from one and a half to four hours of time.