- Operating conditions of non-volatile boilers, features of their installation

- Switching on the gas boiler

- Floor

- Wall

- Features of turning on the old boiler

- Features of switching on boilers of different companies

- If the boiler makes noise or whistles

- Problems of solid fuel boilers

- Features of filling the system with water

- Causes of excess air

- How the boiler works, serving two circuits at once

- Classification

- Table: types of gas boilers

- What to do when a malfunction occurs?

- Abstracts and measurements

- dangerous situations

- Important operating instructions

- The principle of operation of automation on old-style gas boilers

- Electric convector calculation of kW consumption.

- Consumption calculation

- Solution

- EMERGENCY STOP OF THE UNIT

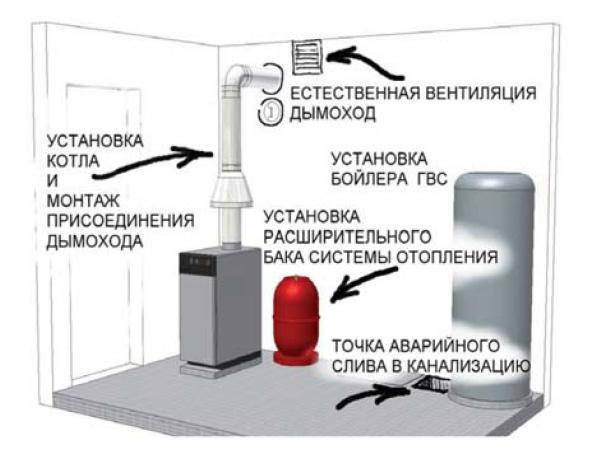

Operating conditions of non-volatile boilers, features of their installation

Gas boiler operation

- Non-volatile boilers do not have a circulation pump. A feature of this equipment is the natural circulation of the coolant. The liquid, heating up, expands, hot water squeezes out cold water, so its movement in a vicious circle occurs. In order for it to be effective, it is necessary, even at the stage of installation of the distribution pipeline, to lay it with a certain slope to enhance the circulation of hot water. This is one of the main conditions for the operation of heating.

- During the combustion of fuel, carbon monoxide gases are released, which are removed using a natural draft chimney. Therefore, almost all single-circuit and double-circuit non-volatile floor-standing boilers have an open combustion chamber. Air enters the furnace from the room, and combustion products are removed outside. For the process to be effective, the described equipment can only be installed in a well-ventilated area. This is the second condition for the use of non-volatile installations. Otherwise, you can easily get poisoned by carbon monoxide.

- But not only these features must be observed when installing a non-volatile gas boiler. When connecting it to the heating system, it is necessary to choose pipes of a larger diameter than usual for transporting the coolant.

- And the last condition that must be observed. An expansion tank must be installed close to the boiler at a certain height. It will allow you to remove excess gas formed in the heating system with a sharp increase in the temperature of the coolant.

Note! Only strict observance of the above rules allows you to organize efficient heating of the house with the help of non-volatile floor boilers. Therefore, for installation it is necessary to invite specialists who are well acquainted with the features of the selection and installation of pipes, as well as with the correct arrangement of chimneys

Switching on the gas boiler

The ignition of the boiler is carried out after checking the draft and supplying gas to the pipe

The ignition of the boiler is carried out after checking the draft and supplying gas to the pipe

It is possible to light a gas boiler after acceptance into operation by a special service. The called worker checks compliance with the installation standards, the efficiency of the hood, and conducts a test run.

The inclusion of semi-automatic boilers is done by turning the regulator to the extreme position and pushing the wheel in to start the gas supply. Piezo ignition is performed by holding in this position for 10 seconds.

Floor

The flow of gas into the system is turned on when the inlet valve is opened. The impeller moves to the ignition position.

Further actions:

- By pressing the handle, forced feeding to the pilot burner is ensured.

- After the appearance of a flame in the hearth, the handle is released.

- The control lever is moved to the number 2 counterclockwise to ignite the main burner.

- The knob is placed in position on the figure that corresponds to the selected temperature.

Near the numbers, the temperature reading is written, which corresponds to the position of the regulator. Actions are repeated when the fire is attenuated.

Wall

The boiler is plugged into the socket, the gas valve opens and ignition is performed

The boiler is plugged into the socket, the gas valve opens and ignition is performed

Before starting the boiler, the device is connected to the outlet and the gas valve on the riser is unscrewed. The start button is pressed and the heating temperature is set using the keys on the control panel. For ease of notation, there are pluses and minuses next to the buttons.

Features of turning on the old boiler

The start of the circulation pump requires attention, in which the blades are slowed down due to an air lock. The corresponding failure is displayed on the panel.

Problem fix:

- the front cover is removed;

- the bolt is unscrewed in the center;

- with a slotted screwdriver, the shaft is rotated in the direction of the arrow;

- the brightly colored air vent cover rises and the air is released.

The gurgling sounds will gradually disappear, as the plugs will leave through the expander valve. The pressure in the manometer is checked regularly.

Features of switching on boilers of different companies

Emergency temperature control device in the Navien boiler

Emergency temperature control device in the Navien boiler

Before turning on the Lemax boiler, you need to make sure that there is a coolant inside the system. The indicator is checked and the optimal operating mode is selected. The number of automatic devices and the power of the unit affect the formation of the regulations. Some models are equipped with traction sensors, which makes it easier to turn on and control work.

Before starting the Navien boiler, an additional emergency temperature control device, a power control device, a fuse and a thermometer are purchased and installed. Some models have these elements, it all depends on the configuration.

If the boiler makes noise or whistles

When inside the house you feel how the boiler makes noise, this may mean that the inner walls of the heat exchanger are covered with a thick layer of scale. Under such conditions, antifreeze overheats and boils. Such sounds can be heard when water boils in an electric kettle.

Sometimes some layers of scale are left behind. Therefore, you can hear the device whistle.

To check whether the noise is really caused by scale, the return line is closed to a minimum, and the boiler is set to maximum operation. This will raise the temperature of the coolant to 80 °C. With it, the rumble of the boiler increases greatly. To eliminate excessive noise, you need to fill the heat exchanger with a special solution and rinse.

Scale also leads to overheating of the heat exchanger. At the latter, a fistula appears, through which the coolant begins to flow.

Injectors can also whistle. They do this at the moment when the boiler is lit. Whistling indicates the presence of air in the gas pipeline. An unpleasant sound is eliminated by dropping air.This procedure depends on the characteristics of the device, the diagnosis and maintenance of which can be quite simple.

Problems of solid fuel boilers

Most often, these devices are “pleasant” with the fact that they begin to flow. This difficulty arises when:

- Overheating, due to which the water boils, and a fistula appears on the heat exchanger. Repair of boilers involves the replacement of the heat exchanger.

- Too low water temperature (less than 60 °C) in the return line. This leads to the appearance of condensate, which corrodes the heat exchanger. Because of this, a fistula is formed, and the coolant begins to flow. In this case, the leak occurs due to improper organization of the heating system at home.

In general, most problems, including leaks and fistulas, arise due to improper installation of the unit and errors in the organization of the chimney, into which the wind easily blows. Such errors also cause accelerated circulation of antifreeze (which means that its volume does not correspond to the manufacturer's standard), breakdown of the pump and other piping units, a fall or vice versa, an excessive increase in thrust.

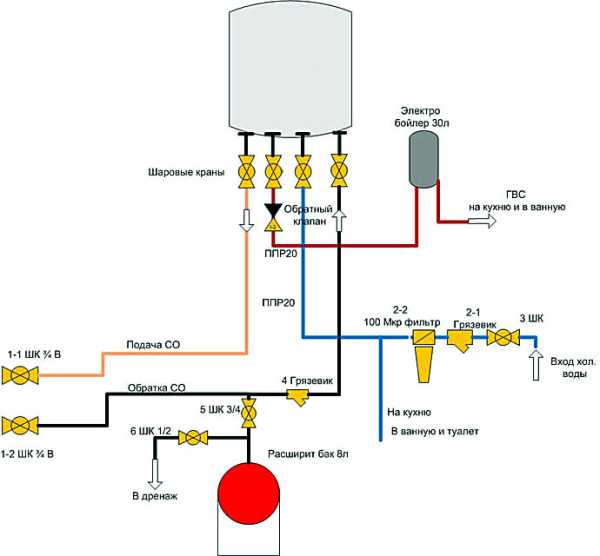

Features of filling the system with water

To turn on the heating system, you must first fill it with a coolant, i.e. water, which, after heating, will begin to circulate. A feature of modern equipment is that special manual make-up is not needed. During the first launch, you need to carefully check everything so that further work goes on smoothly and clearly. Not only a pump is built into the boiler body, but a special tap near the pipe for supplying cold water to the system. During the supply of cold water, noise is heard, this is quite normal, you should not panic here.

During filling, it is necessary to monitor the pressure in the system; for this, special sensors and pressure gauges are provided. Modern equipment necessarily has such additional elements, so you don’t need to buy them separately. As the gas boiler fills up, the mark on the sensor rises. When it reaches 1.5-2 atmospheres, it is necessary to stop the supply of cold water, i.e. filling is completed. The pressure parameter may be different, since it all depends on the equipment manufacturer, its requirements for the operating pressure in the system. But this is not the final filling yet, replenishment is necessary as the heating system is freed from air locks.

Causes of excess air

There are many reasons for the appearance of air, it is quite difficult to completely avoid this phenomenon. Nevertheless, the factors under the influence of which air pockets form in the heating system should be studied in order to minimize their impact on the system.

Most often, air enters the system:

- if the heating was initially installed incorrectly;

- in case of non-compliance with the rules for filling the heating circuit with water;

- if the tightness of the connection of individual elements of the system is broken;

- when there are no or incorrectly used air vent devices in the system;

- after repair work;

- when compensating for the lost volume of coolant with cold water.

Incorrect installation of the heating system leads to its airing in cases where the pipes are laid with the wrong slope, form loops, etc.It is best to track such areas at the design stage of autonomous heating.

The filling of the circuit with water should be carried out according to the principle: the larger the volume of the coolant, the lower the rate of its entry into the system. If water enters too quickly, in certain areas it can become a spontaneous variant of the water seal, preventing the natural process of expelling air from the circuit.

Leaks often occur at the junctions of pipes and radiators. Sometimes the crack is so small that the water flowing out of it evaporates almost immediately. The hole remains unnoticed, and air gradually penetrates through it, which replaces the lost volume of water.

A small gap through which water flows out can cause air to enter the heating circuit and form an airlock

Since in one way or another the circuit can still be air-filled, when designing heating, it is necessary to provide for the installation of special devices designed to bleed air from the heating system. If such air vents already exist, but do not give the desired effect, it is possible that some of them are broken and need to be replaced.

It also happens that air exhaust devices are ineffective due to their incorrect installation or insufficient number. It is inevitable that air will enter the system after it has been repaired. In this case, it is necessary to carry out measures for de-airing.

The air dissolved in water enters the heating system during the filling of the circuit. When heated, it is released in the form of small bubbles, from which an air lock is formed.

If part of the coolant volume is lost, it must be replenished.Fresh water, unlike what is already in the system, contains a certain amount of air dissolved in it. When heated, it is released in the form of small bubbles and accumulates, forming plugs.

If a fresh coolant is added to the system, after a while it does not hurt to make sure that it is not aired anywhere.

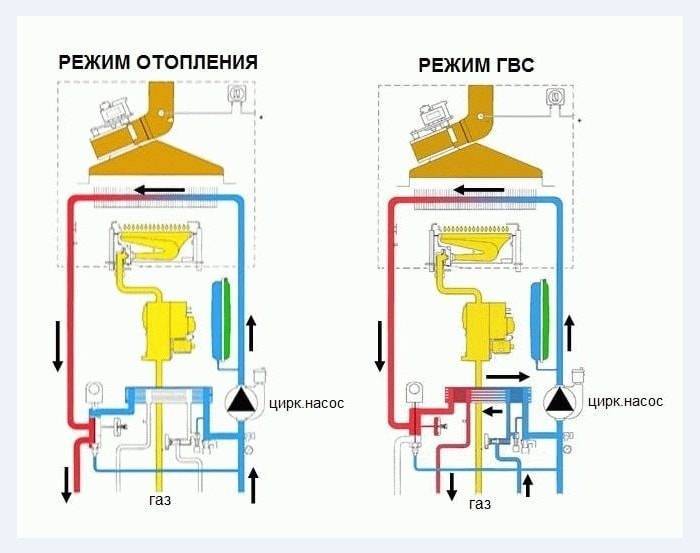

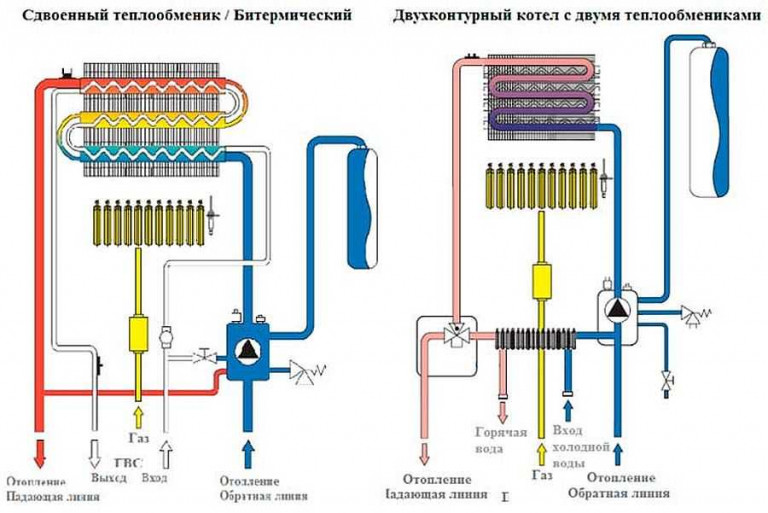

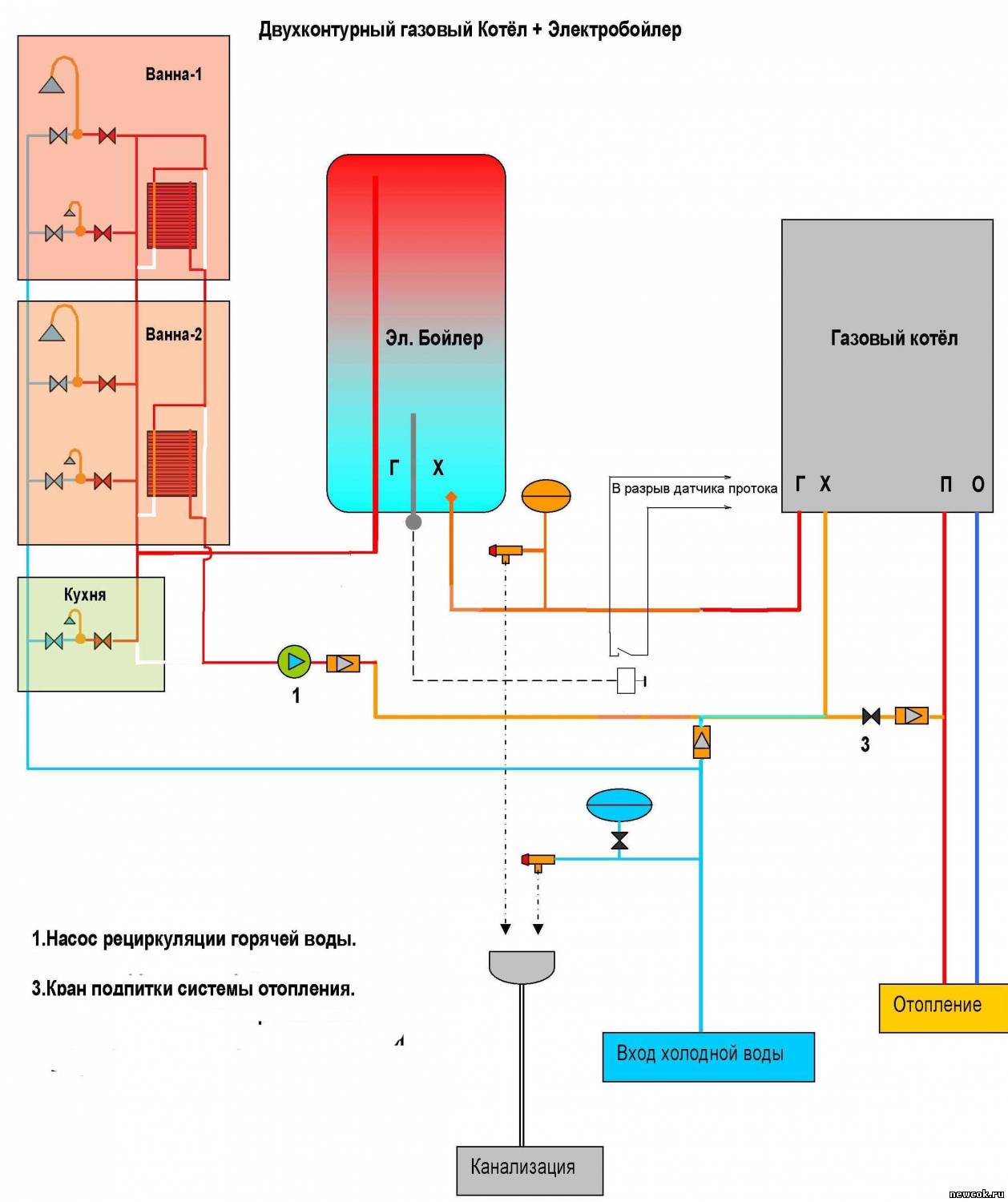

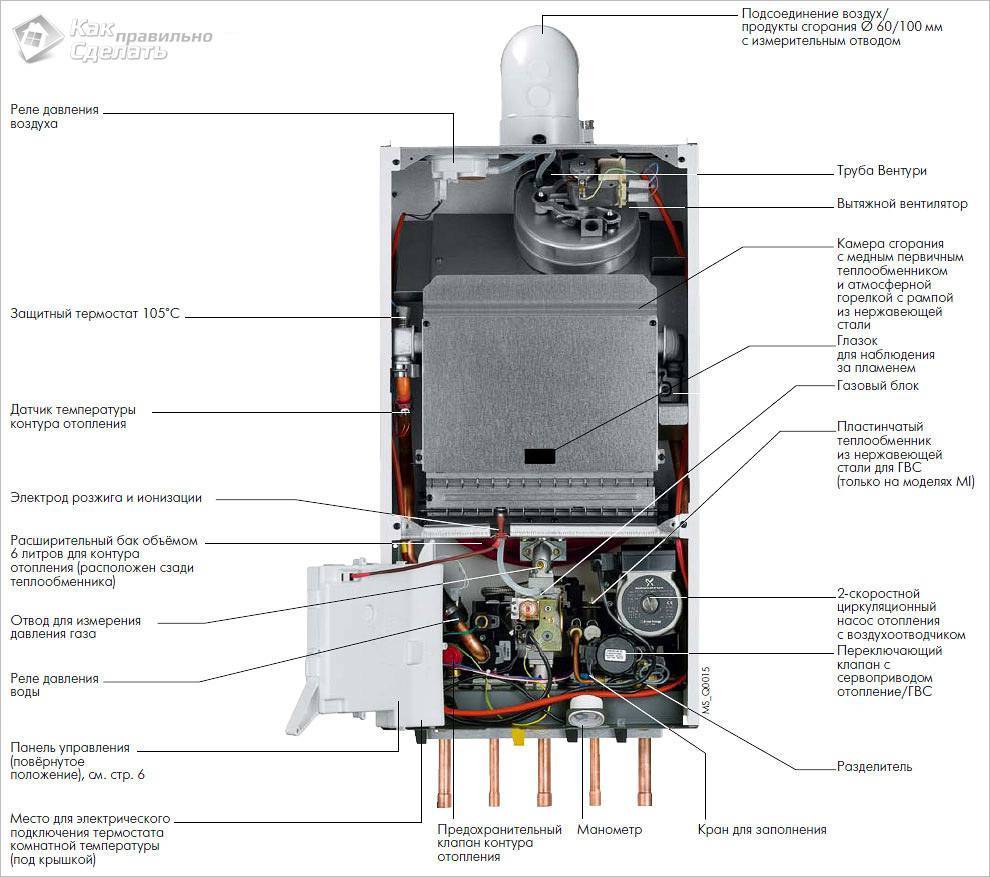

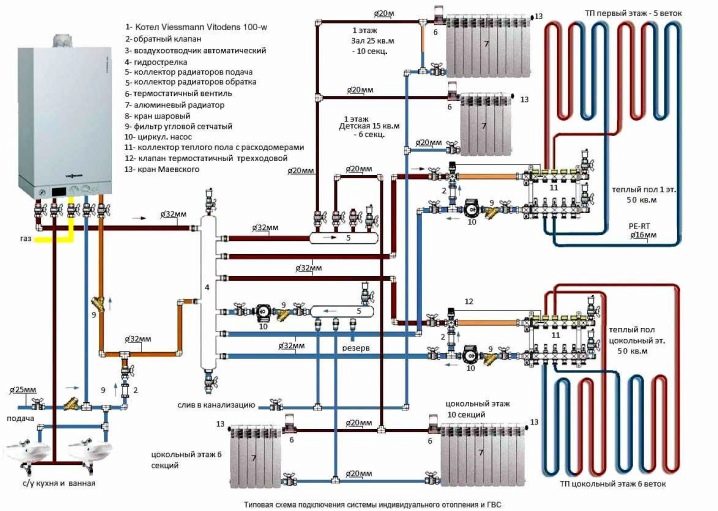

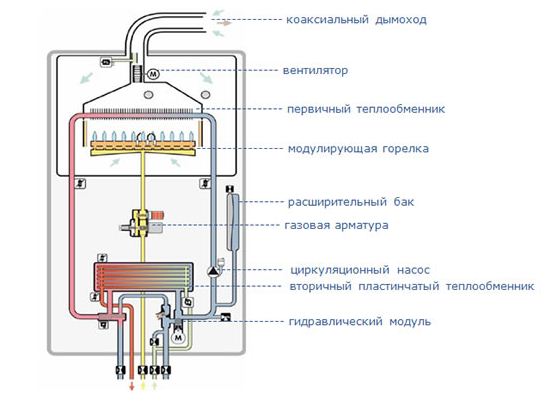

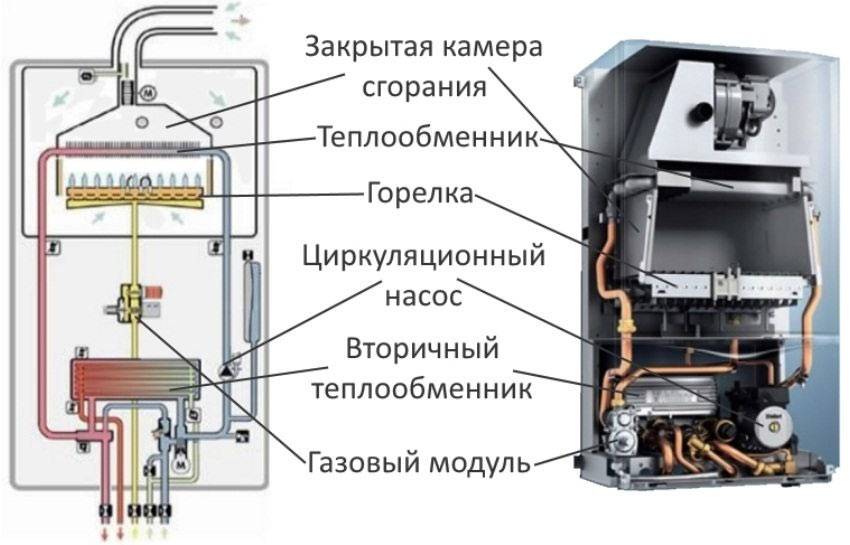

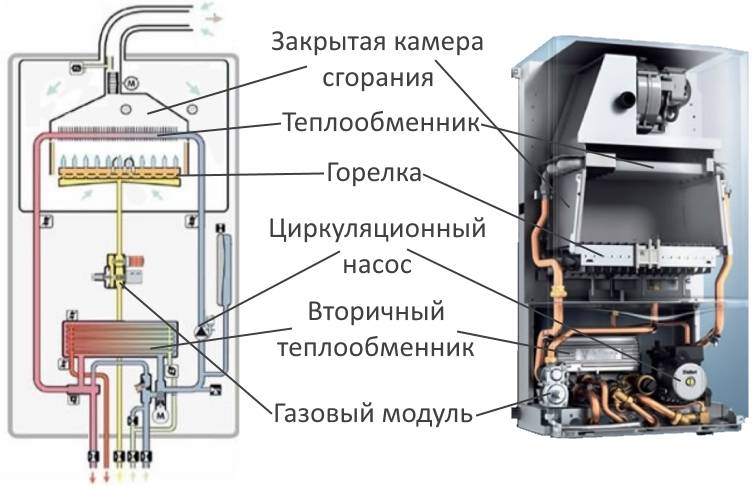

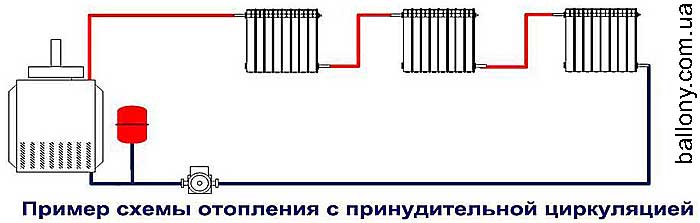

How the boiler works, serving two circuits at once

The main difference between a double-circuit boiler and a similar one with a single circuit is the ability to simultaneously provide the room with heating and hot water. The primary heat exchanger, due to its location, heats the coolant so that the heating system in the entire room can function fully. The secondary is responsible for providing the premises with hot water in the right amount.

The stability of the functioning of the principle of operation of a double-circuit boiler can only be ensured by the complete serviceability and coherence of the operation of each component.

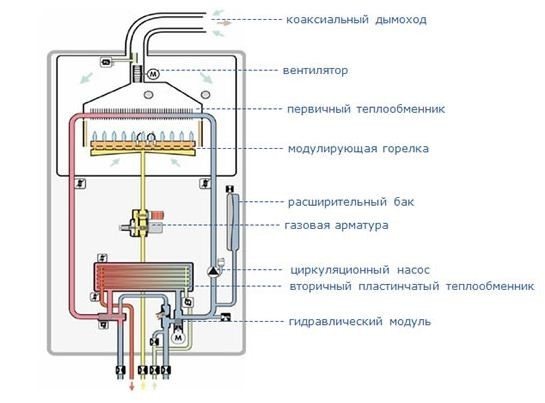

Structurally, any double-circuit boiler includes such elements as:

- heat exchangers in the amount of two pieces;

- a combustion chamber, to which a burner block is necessarily attached;

- protective equipment;

- control system.

To understand exactly how a double-circuit gas boiler is arranged and its principle of operation, each significant component of such a design should be considered in more detail separately.

Classification

There are a huge number of types of this equipment, which allows you to choose the one that suits you in all respects.

Table: types of gas boilers

The gas boiler can be located on the floor and wall

Floor boilers differ from wall-mounted boilers in a wide range of power adjustment.Such equipment can heat a room of 200 m 2. If you connect a boiler to it, then you can also provide yourself with hot water.

Wall-mounted gas boiler will fit perfectly into any interior

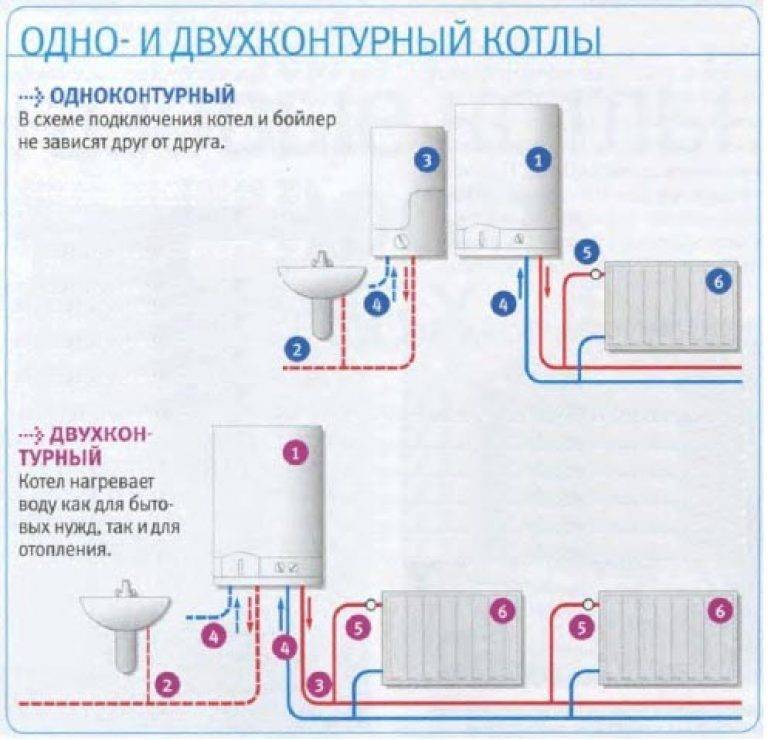

A single-circuit boiler can heat one thing: either a coolant, or a heating system, or hot water supply. When using a double-circuit, it is possible to simultaneously connect space heating and hot water supply.

Boilers with natural draft are distinguished by the fact that the products of combustion are removed using constant influxes of street air. They often heat non-residential premises and small houses. In boilers with ventilation draft, it is forced. In them, combustion takes place in a closed chamber. A special chimney is equipped with external and internal pipes through which air is taken. They do not burn the oxygen of the room, do not need an additional air supply to maintain combustion.

In the room where the gas boiler is located, the ventilation system should be well thought out.

For equipment with an electronic ignition, the activation process is automated. Such models are more economical than piezo ignition boilers, since they do not have a special part with a constantly burning flame. If the power supply is interrupted, the equipment ceases to function, but automatically resumes operation when power returns.

Boilers are also classified according to energy efficiency:

- condensation;

- convection.

The latter do not form condensate, which can dissolve the acids that are on the walls of the device. But the heat transfer in it is lower.

What to do when a malfunction occurs?

Gas consumers should understand that they are not entitled, but obliged, to repair their in-house or in-house equipment. And in a timely manner and with high quality.

And since the frequent shutdown of the boiler is potentially a malfunction, it is impossible to ignore the specified legal requirement. Since for this, according to Art. 9.23 of the Code of Administrative Offenses threatens with a fine.

Repair of any gas equipment the procedure is responsible, as it significantly affects safety. Therefore, you should not overestimate your capabilities or try to save money, risking the lives and health of people nearby, including relatives and friends.

Repair of any gas equipment the procedure is responsible, as it significantly affects safety. Therefore, you should not overestimate your capabilities or try to save money, risking the lives and health of people nearby, including relatives and friends.

The size, which is 1-2 thousand rubles. And, if suddenly the situation, through the fault of the user, becomes dangerous for the life and health of people or an accident occurs, then you will have to part with 10-30 thousand rubles (Article 9.23 of the Code of Administrative Offenses).

It is easier and more reliable to contact the gas company with which the contract has been signed. And all the risks will fall on their shoulders. As well as responsibility for the timeliness and quality of repairs. And for violations, the company will be held liable in accordance with Art. 9.23 of the Code of Administrative Offenses. Where does it say that penalties can reach an impressive 200 thousand rubles

It should also be remembered that one should not take responsibility for trying to eliminate the cause of the on / off on their own. Especially against the background of the fact that problems with equipment inoperability should be solved by specialists of companies with which the gas consumer has signed an agreement. And for ignoring such a rule, additional sanctions in the amount of 1-2 thousand rubles threaten - this is also spelled out in Art.9.23 of the Code of Administrative Offenses.

Any repeated violation of the above norms will be the reason for punishment in the form of a fine, the amount of which will be 2-5 thousand. The basis for this is the corresponding norm in the above article of the Code of Administrative Offenses.

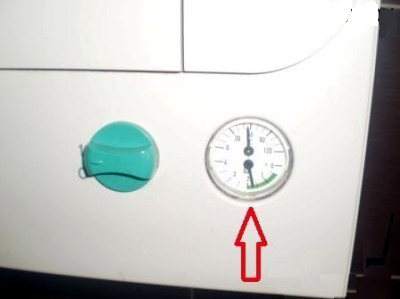

Abstracts and measurements

The normalized functional pressure for an isolated heating system with forced circulation is in the range of 1.5-2 bar.

For models with one or two circuits, the pressure can be:

- Static - natural. It is generated by gravity acting on the coolant. From each meter of the riser, approximately 0.1 bar is obtained.

- Dynamic - artificial. It is created in a closed circuit by a special pump or an expanded heated coolant. This type is determined by the parameters of the pump, the tightness of the system and the temperature indicators of the coolant.

- Functional - real. Items 1 and 2 are combined. To measure it, special devices are used.

- Ultimate. This is the maximum possible pressure for network operation. Any excess of it leads to an accident: pipes, radiators or a boiler heat exchanger are torn.

What pressure should be in a double-circuit boiler? The norm is 1.5 or 2 bar.

A pressure gauge is integrated into many wall and floor models to measure the water pressure in the heating circuit. Even if it is present, it is necessary to mount an additional device. It is introduced into the safety kit, consisting of two valves: safety and bleed air.

The reason lies in the factory dial gauge. Gradually, it fails and displays incorrect indicators. An additional instrument allows you to check and compare values. This eliminates the problem of the pressure gauge, as the cause of the pressure drop.

Other potential reasons for this are:

- The feed valve is broken.

- Heat carrier leakage.

- Air congestion.

- Expansion tank defective.

- Defects in the heat exchanger.

- Relief valve broken.

dangerous situations

The greatest danger is the failure associated with the operation of the burners. If the flame goes out, gas can accumulate in the room, which subsequently causes an explosion. Causes of fire extinguishing:

- the gas pressure has fallen below the permissible norm;

- no draft in the chimney;

- the supply voltage is gone;

- the igniter went out.

In an emergency, it is necessary to immediately shut off the fuel supply to the burners - automatically or manually. Modern versions are equipped with automation devices necessary for the prompt shutdown of equipment. The operation of such devices is not only convenient, but also safe.

How to prevent the accumulation of gas in the room

Modern safety standards provide for the installation of gas analyzers in boiler rooms; they are necessary for signaling when gas appears in the room. A special electronic valve reacts to their signals, which automatically stops the flow of fuel to the burners.

Important operating instructions

In terms of operation, gas boilers with a closed combustion chamber are considered safer. Their firebox does not communicate with the air of the room. However, the power of such boilers is significantly inferior to the power of boilers with an open combustion chamber. Therefore, in private households, the second type of boilers is often installed.

The choice of the future coolant depends on the goals and operating conditions of the system. If frequent shutdown of the boiler is expected, then it makes sense to think about using antifreeze

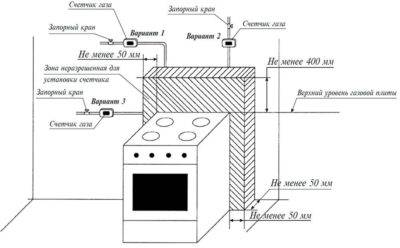

The operation of such boilers requires compliance with safety regulations.So, for arranging a powerful floor boiler, it is customary to use a separate room with certain dimensions. The boiler is mounted at some distance from the walls. Nearby walls must be protected with fireproof material to prevent ignition.

The boiler room needs a ventilation system. Should also be source of natural light. The width of the front door must be at least 80 centimeters. The chimney is laid in accordance with the instructions for the boiler and from heat-resistant material. The chimney must rise above the roof ridge by at least half a meter.

One of the security measures is carbon monoxide sensors. The gas detector will detect the leakage of volatile toxin in a timely manner and warn users about it. It can also be set to automatically turn on the ventilation and turn off the gas supply. Modern automation allows the introduction of a variety of smart systems.

If the temperature, pressure or gas content sensor is out of order, then you must immediately turn off the boiler and call the master from the service department. Using the boiler without these devices is fraught with serious negative consequences.

The requirements of SNiP state that it is necessary to connect a gas boiler to the main line using a copper pipe or a bellows hose. In this case, a crane must be installed

If signs of gas leakage are found, immediately turn off the gas valve and open windows to ventilate the room. Do not turn on the light and try to illuminate the room by lighting matches or a lighter.

The gas boiler must be serviced at the intervals specified by the manufacturer.Data on the necessary procedures are indicated in the instructions for the device. For example, you need to clean the chimney, remove scale from the heat exchanger or clean the cinders from the burner. Then the boiler will last a long time, and the risk of serious malfunctions will be significantly reduced.

When using a gas appliance, do not turn it on at maximum power for a long time. This can lead to the release of steam, which is unacceptable.

Sometimes the boiler starts to make unusual noises and vibrations. This may be due to the operation of the fan. We warn you that all actions for which you have to disassemble the boiler casing automatically deprive the owner of the right to warranty repair or replacement.

However, the owner of the unit needs to control the operation of mechanisms and systems that provide boiler protection against ignition. It is necessary to maintain the temperature in the circuits at around 50 degrees, which significantly reduces the likelihood of mineral deposits on the inner surfaces of pipes and appliances.

The principle of operation of automation on old-style gas boilers

Frequent problems in heating a room with gas boilers are the attenuation of the flame in the burner and the gas content of the room. This happens for several reasons:

- insufficient draft in the chimney;

- too high or too low pressure in the pipeline through which gas is supplied;

- extinction of the flame on the igniter;

- leakage of the impulse system.

In the event of these situations, the automation is triggered to stop the gas supply and does not allow the room to be gassed.Therefore, the installation of high-quality automation on an old gas boiler is the elementary safety rules when using it for space heating and water heating.

All automation of any brand and any manufacturer has one principle of operation and basic elements. Only their designs will differ. The old automatics "Flame", "Arbat", SABK, AGUK and others work according to the following principle. In the event that the coolant cools down below the temperature set by the user, the gas supply sensor is triggered. The burner starts heating water. After the sensor reaches the temperature set by the user, the gas sensor automatically turns off.

On a note!

When using modern automation, it is possible to save heat up to 30%.

Automation of the old model is non-volatile, does not need electricity. Its adjustment, connection and disconnection are made by a person. Commands are transmitted using electromagnetic pulses.

The video tells how the automation of gas boilers AOGV, KSTG works.

…

Electric convector calculation of kW consumption.

Agree, buying an electric convector is one thing, quite another is how much we will have to pay for the heat received, that is the question. We emphasize that our calculation of consumption is based on personal operating experience, and not on manufacturer's formulas. Let's also make it clear that we don't heat the house in a freezing winter, we raise the temperature in the room to a comfortable level. Consider an average room of 18 m2. The technical characteristics of any manufacturer, for heating a room of such an area, regulate the purchase of a 1000 W convector.

Let us clarify that in order to start the central heating, the municipal authorities are guided by the Decree of the Government of the Russian Federation of 05/06/2011 N 354., According to which, the street temperature must drop below +8 ºС and not rise for 5 days. I think many will agree that usually, in the off-season, it may take a month to achieve this goal, and the temperature outside the window is + 12 ° C, already reduces the temperature in city apartments to + 16 - 17 ° C.

Consumption calculation

Upon reaching the set value, the temperature control system will work and the consumption of electrical energy will stop. As it cools, noticeably after 20 minutes, the temperature sensor is triggered and turns on the convector again. Considering that the next switching on does not require heating from 17 °C, but starts from 20 °C, then the time to reach the value of 22 °C. much less, no more than 10 minutes. Then the on/off cycle is repeated and the average operation of the heater does not exceed 20 minutes per hour.

Actually, based on the data obtained empirically, we obtain the consumption of an electric convector. Divide 1000 watts by 60 minutes and get 16 watts - we determined the power consumption of one minute of work. In our experiment, the convector worked for no more than 20 minutes. Now we multiply 16 W by 20 minutes and we get the power that the convector used up per hour of operation - 330 W. Thus, a 1 kW convector “eats” in three hours. The cost of one kilowatt at the beginning of 2018 is 4 rubles.

Gentlemen, for the evening we will need no more than 9 hours operation of the electric convector - 12 rubles. A month off-season will cost about 360 rubles. Let's add another 30% to this amount for reliability (for those who sit up in front of the TV).The total amount of operation of the convector will be 400 - 500 rubles for a normal temperature regime, within a month. Let me ask you a question, is it worth saving this amount, putting your body and your household at risk of cooling? Sick leave and a spoiled mood are much more expensive, drops alone from a cold can offset this kind of savings.

Solution

In order for the boiler to start normally after an emergency stop, it is necessary to fill all the drainage elements with water - pipes and radiators. Just before that, you need to look at the values \u200b\u200bof the working pressures in the system, their minimum and maximum. You can find them in the accompanying documentation for the device.

Pressure and temperature sensor

After that, the gas connection is checked: all hoses are connected, the tap is not closed. And you can start the system with the "network" button.

To unlock, you need to follow six steps:

- Set the heating temperature to the maximum using the regulator knob.

- Turn the thermostat down to zero abruptly.

- Repeat these steps 2-3 times.

- Leave the regulator at maximum temperature and wait until the system automatically unlocks and starts up.

- Wait for the emergency stop lamp to go out.

- Set the required temperature mode.

EMERGENCY STOP OF THE UNIT

- There are the following cases of emergency shutdown of the boiler:

- interruption of the supply of electricity;

- damage to gas fittings or gas pipeline;

- in case of failure or incorrect operation of safety valves;

- if the water flow through the boiler has dropped below the minimum level line;

- in case of defective operation of the steam valve;

- in case of malfunction of automation;

- with an extinguished flame in the furnace during fuel combustion;

- at an elevated water level;

- if the feed pumps are not working;

- when the pressure rises or falls in relation to the norm;

- in case of mechanical damage to the unit, in case of rupture of pipes;

- if cracks or gaps are found in the welds;

- when atypical sound signals appear (crackling, noise, knocking, bumps), etc.

Stopping the heating units involves actions that depend on the type of boiler.

The procedure for emergency shutdown of a gas-fired boiler involves the following manipulations:

- Reduce the gas supply to the burner.

- Reduced air supply (draft limitation).

- Closing the valve (faucet) on the gas pipeline.

- Closing the valve on the air duct.

- Checking the furnace for the absence of combustion.

The instruction manual for the boiler Ariston or another brand contains the information necessary to stop the device in the event of an emergency

It is important to execute it step by step and control the correctness of the actions.