- Determining the location of damage

- Pros and cons of aluminum batteries

- How to solder a copper radiator

- Repair and soldering of an aluminum radiator of complex configuration

- Tips for Repairing a Plastic Car Radiator

- Radiator selection

- How to solder an aluminum radiator at home?

- Restoring duralumin damage

- Aluminum battery device

- Technical characteristics of aluminum heating radiators

- Advantages and disadvantages of aluminum radiators

- Causes of a Radiator Leak

- How to solder an aluminum heatsink

- The main reasons for the loss of tightness of the radiator, signs, features of repair

- Materials for soldering aluminum

- Features of aluminum radiators

- How to find a leak in the cooling system

- How to seal the plastic parts of a car radiator

- Instructions - how to solder the plastic parts of a car cooling radiator

- Use of cold welding

Determining the location of damage

Automotive radiators are at the greatest risk of damage, as they operate in conditions of temperature with different signs, under the influence of strong vibrations. Cases of mechanical damage to such devices are not excluded.

Automotive radiators are at the greatest risk of damage, as they operate in conditions of temperature with different signs, under the influence of strong vibrations. Cases of mechanical damage to such devices are not excluded.

Less commonly, air conditioner radiators are repaired, which are used as condensers and evaporators. But such cases also happen.It is very unpleasant when the climate control suddenly stops working in a luxury car during the hot season.

One of the most effective and affordable repair methods is soldering radiators.

If a car radiator is damaged, it is very important to identify the malfunction in a timely manner and try to fix it.

The autoradiator, which is part of the engine cooling system, is a very important component of it. Structurally, this device consists of two vertical tanks connected by a large number of thin horizontal tubes. The coolant circulating in them, by means of natural heat exchange, releases heat into the air and cools down. To improve heat transfer, the surfaces of the tubes in contact with the surrounding air are increased. To do this, thin metal plates are soldered to them - fins.

Signs of radiator damage are an increase in engine temperature during operation, as well as a decrease in coolant level. Of course, fluid loss may or may not occur. through the radiator, but most often this node is the cause. Visually, major damage can be determined by observing a coolant leak. But on a hot engine, this will be quite difficult to do, since the antifreeze will immediately evaporate. Some compounds are painted with special pigments that remain on the surface of the part after drying, which helps to identify the damage site.

If it is established that the leak occurred in the radiator, and no damage is visible, it is necessary to remove the device from the car, after draining the coolant.After that, it is necessary to close all the holes, leaving one, and supply air into it under slight pressure, lowering the radiator into a container of water. From the emerging air bubbles, it will be possible to determine the location of the hole.

Pros and cons of aluminum batteries

For proper assembly, disassembly of the aluminum system, you need to familiarize yourself with the advantages and disadvantages of the equipment.

The advantages of bimetallic radiators include:

- Good thermal conductivity of aluminum - helps to compensate for the instability of the coolant pressure.

- The light weight of the material - facilitates the process of installation, delivery to the destination. Repair work related to heating, you can do it yourself.

- The price is more affordable compared to copper, cast iron counterparts.

- Sufficient hole diameter.

- Fast heating, fast cooling - allows you to set the optimum temperature in a short time, in accordance with the weather outside.

- It is not universal, it does not fit with all systems, adapters are needed for installation.

- High risks of air stagnation, leaks, aluminum radiators do not respond well to pressure surges.

How to solder a copper radiator

To carry out the work, you will need the following tools and materials:

- Soldering tool.

- Alloy for soldering (solder).

- Solvent (acetone).

- Flux or rosin.

- Pliers.

- Tassel.

- Metal brush.

- Fine-grained sandpaper.

As a soldering tool, an electric soldering iron with a power of at least 100 W or a gas burner is used.

For copper heatsink soldering two types of soldering irons are used with their own hands. To repair large areas of damage, soldering irons with a wide tip are used.For sealing small defects - with a narrow tip.

Pliers are designed to remove the destroyed elements of the lattice.

The solvent is necessary for degreasing the surface.

A metal brush is needed for rough cleaning of the grate from dirt and rust.

Sandpaper is required to clean the damage site from metal dust and melting products.

The brush is designed for applying rosin or flux. These materials are used for better adhesion of the solder to the metal surface.

For soldering copper radiators, tin-lead solders of the POS-60 and POS-61 brands are used.

Repair and soldering of an aluminum radiator of complex configuration

When it comes to deciding how to weld an aluminum car radiator, methods using iron rosin flux and homemade flux are not effective. Thin-walled tubes of an automobile radiator are difficult to solder due to the design features of the product.

In such a situation, you can resort to an alternative method using solder with a low melting point and a special sizing.

Preparatory steps before soldering:

- remove the oxide film with emery or a special nozzle on a drill or screwdriver;

- degrease the defect site with a solvent;

- crimp the damaged section of the radiator tube with pliers to reduce the hole.

Then proceed to the soldering process. First, the desired area is heated by the fire of a gas burner. Then a rod of solder with a low melting point is introduced into the flame and passed through it several times over the damaged area. Each time, solder particles will cling to the edges of the hole, getting inside the hole. The defect on the tube will gradually "tighten".

The last thing to do with this method is to additionally seal the defect with a high-temperature adhesive for aluminum. It will close the smallest micropores, and the repair will be of better quality.

Tips for Repairing a Plastic Car Radiator

Vehicle cooling systems are extremely important components that ensure the regular functioning of the most loaded components and parts of the vehicle.

If in the early periods they were completely made of metal of various types, then today it is increasingly necessary to deal with plastic samples.

Although they are somewhat more dynamically stable than some metal radiators, significant problems can arise when repairing them.

A fluid circulates inside the radiator, which removes heat from the car engine through it.

As a result, if this component malfunctions, the engine simply overheats above the specified rate and may even jam.

In this case, the radiator is a rather vulnerable element. Even a minimal impact can lead to significant mechanical damage.

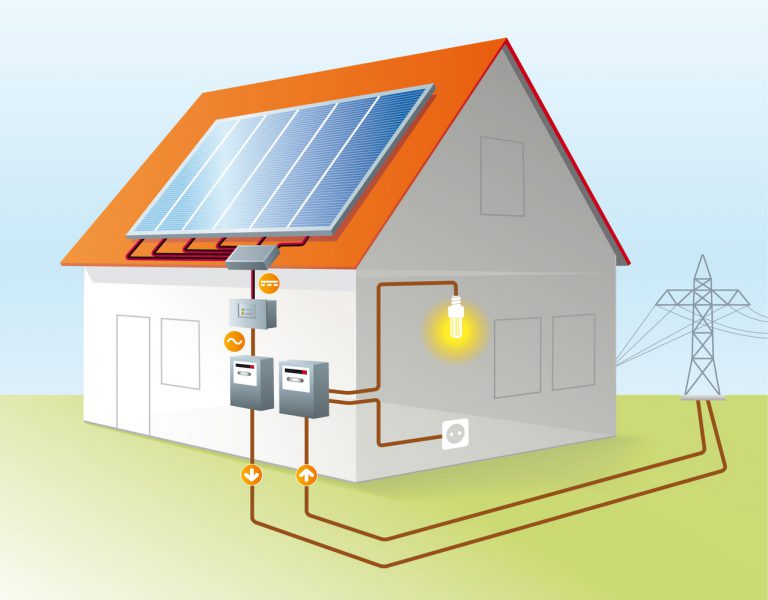

Radiator selection

You should start by choosing a radiator, and the main criterion for choosing will be the operating pressure for which the radiator is designed. For a private house with its own heating system, a radiator with a working pressure of 6-7 atmospheres will be enough, but if you need to connect a radiator to the central heating system of an apartment building, it must withstand a pressure of at least 10 atmospheres.

Currently, the consumer is offered two options for aluminum radiators - standard or European and reinforced.The latter can operate under pressure up to 12 atmospheres. When connecting to a central heating system, it is necessary to choose among reinforced radiators.

The number of sections plays a big role

Next, you need to decide on the required number of sections. To do this, we determine the amount of heat. Necessary for heating the room and divide by the heat transfer of one section of the selected radiator.

The amount of heat required for a standard room can be taken equal to 1 kW per 10 m 2 of the room area. For non-standard premises and more accurate calculations, we will use the finished table:

Radiator power table

It should be remembered that a battery connection diagram of more than 12 sections must be double-sided, diagonal or saddle. With a one-sided battery connection scheme from a large number of sections, a "pocket" of cold water will form on the side of the radiator opposite to the pipes. "Extra" sections simply will not work, we get harmful ballast.

Using forced injection, the battery can be extended up to 24 sections even with one-sided supply, but in this case the radiator must be reinforced.

It should be remembered that it is necessary to supply the coolant to reinforced radiators under high pressure only through metal pipes. Metal-plastic can not withstand such pressure, and the consequences will be the saddest.

It should also be taken into account that the heat transfer of the radiator indicated in the documentation is relevant only for one-sided or diagonal supply of coolant to the radiator. When using the bottom feed, feel free to subtract 10-15 percent.

If the heating system is installed in a private house, then it is possible to choose the general scheme for organizing heating - one- or two-pipe.

How to solder an aluminum radiator at home?

Decided to self-recovery - carefully read all the subtleties and features of the process

It is very important to properly prepare the work surface by cleaning it of all existing contaminants and removing the remnants of the paint layer with sandpaper or a special solvent.

Immediately before soldering, the base is treated with alcohol-based degreasers and wiped thoroughly. Remember that even a small amount of moisture or grease on the surface will significantly degrade the quality of the result. The success of the entire repair operation depends on the literacy of the preparatory process by 90%. The further sequence of actions will be as follows:

- when using an iron-rosin mixture, the molten flux is applied to the damaged area, completely covering the soldering surface, thereby blocking the access of air. Then a little solder is collected on the soldering iron and “rubbed” under the flux layer in a circular motion. The role of the abrasive in this process is played by sawdust that damages the oxide film;

- when working with a flux, the resulting mixture is preliminarily melted in a crucible and applied to a heated base. For soldering, you will need tin-lead-bismuth solder.

The first option is applicable in the presence of minor defects on the heating radiator, the second will help to cope with more serious damage. After completion of the repair work, it is necessary to check the quality of the resulting seam, and for this the heater is filled with water.Preliminary dilution of potassium permanganate in a liquid will help to get the best visual effect. If within 2-3 hours no leaks were found at the seam, then the process can be called successful.

Knowing how to solder an aluminum heating radiator, and having at least minimal soldering skills, you can easily repair minor damage to the heater. The main thing is not to forget about security measures. You should work with gloves, because many of the substances used are quite toxic, and no one is safe from burns. Restoration must be carried out in a well-ventilated room, otherwise poisonous fumes will cause serious harm to health!

Restoring duralumin damage

Any welding of aluminum, as well as its soldering, is impossible without cutting off from the air, otherwise instant oxidation cannot be avoided. Since it is impossible to solder an aluminum radiator, like copper, it is possible to take solder from bismuth with indexes 33 or 50.

But for him, you first need to prepare a powder of four chemical elements that are difficult to find. They are used only at car service stations.

You can apply another method. To do this, have a cylinder of carbon dioxide. Direct its jet to the place where the solder is applied. Apply solder and place it evenly over the area with a soldering iron.

Remember that self-repair is not always the best solution. The problem can be fixed temporarily. Therefore, do not delay and, as soon as possible, seek advice and diagnostics from the specialists of the service center. Repairing a radiator is a task, the solution of which should still be trusted by experienced craftsmen.

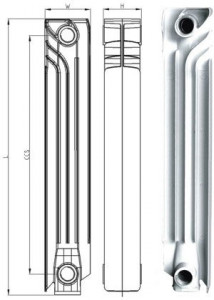

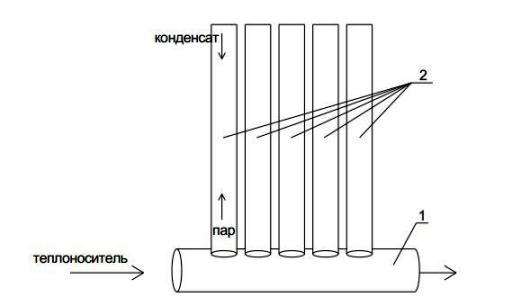

Aluminum battery device

Considering the device aluminum heating radiator It should be noted that the design of the battery can be solid or sectional.

Sectional aluminum heater consists of 3-4 separate sections. As a rule, titanium, silicon, zinc are added to aluminum. These metals make the product more durable and resistant to tearing and corrosion. All sections are connected to each other with a threaded connector. Silicone gaskets are used to seal the connection. Inside, the radiators are polymer-coated to prevent the possibility of battery rupture.

Whole aluminum radiators consist of profiles. Profiles are produced by extrusion.

No additional metals are added to aluminum radiators.

What gives plasticity to the material. The profiles are connected to each other by welding. Such a connection is characterized by high strength and reliability. Like sectional, solid models of radiators are covered with a polymer layer inside.

Depending on the production method, radiators are made by casting, extrusion and anodized products (made from aluminum of a higher degree of purification).

Technical characteristics of aluminum heating radiators

In view of the high technical characteristics, many decide to buy an aluminum radiator for heating an apartment. The main technical parameters include:

- operating pressure. It is in the range from 10 to 15 atmospheres. In residential apartments, the working pressure can exceed the norm by 3-4 times. In this regard, such radiators are rarely installed in city houses. But for private houses - such a heater would be an ideal solution;

- pressing pressure. It is in the range from 20 to 50 atmospheres;

- heat transfer coefficient. For a standard section, it is 82-212 W;

- the maximum temperature of the coolant can reach +120 degrees;

- one section can weigh from 1 to 1.5 kg;

- the capacity of each section is from 0.25 to 0.46 l;

- the distance between the axles can be 20, 35, 50 cm. There are models in which this parameter can reach 80 cm.

The manufacturer indicates the parameters for each radiator model in the device passport. Given the technical characteristics of aluminum heating radiators, their price is quite justified and depends on the type of battery, the number of sections and the manufacturer.

Advantages and disadvantages of aluminum radiators

Before you buy aluminum heating radiators, you need to consider what advantages and disadvantages this device has.

The main advantage of aluminum batteries can be called compactness and much less weight than cast iron systems. You can read more about cast iron radiators here. The equipment warms up very quickly and perfectly transfers heat to the room. The service life is long enough. Another advantage is the division into sections - it is possible to choose the desired length of the battery. It should be noted that the price for aluminum radiators is indicated per section. This makes it easy to calculate the approximate cost of a sectional device.

Because the equipment is small and light, it is easy to install. Installation can be carried out even on a plasterboard wall. Modern models look aesthetically pleasing and stylish. Aluminum is easy to work with.This allows manufacturers to experiment with battery design. You can choose an option for any interior. Most of all, aluminum radiators are suitable for autonomous heating systems. Despite the high technical characteristics and a lot of advantages, the price of aluminum heating batteries is quite affordable.

The disadvantages of aluminum radiators include low resistance to corrosion. And this can greatly affect the overall condition of the battery. Aluminum is naturally a fairly active metal. If the oxide film covering the surface is damaged, the protective layer will collapse due to hydrogen evolution. To improve the anti-corrosion properties, a polymer coating is used. If the battery does not have a polymer coating, then the taps on the supply pipes must not be closed. Otherwise, under pressure, the battery may burst.

Today, aluminum batteries occupy a leading position in sales of heating equipment.

Many people prefer to buy this type of heater and because of the relatively low cost. For aluminum heating radiators, the average price per section is about 230-300 rubles.

Causes of a Radiator Leak

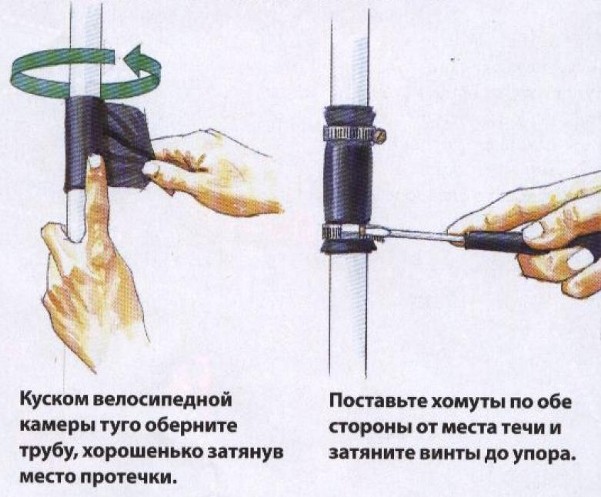

Scheme for sealing a leaky radiator.

Very often, the cause of leaks in the heating system is corrosion processes affecting the metal (of course, if the radiator is not plastic). So, metal pipes from the inside are affected by a liquid that constantly circulates in the system. It is difficult to call it water, since very often various chemical compounds of unknown origin are added to it to improve the properties of the coolant.From the outside, the material is susceptible to moisture and temperature fluctuations. These factors together lead to corrosion and, consequently, leakage.

Plastic pipes are not subject to corrosion processes, but they have their drawbacks. So, pipes made of polypropylene or polyethylene can leak if the installation was incorrectly performed or consumables were incorrectly selected. A common mistake is an acute desire to save on materials. Cold water pipes are much cheaper, and many mistakenly use them for heating systems. Hot water has a destructive effect on them: under its influence, they can burst, swell or deform.

Metal-plastic radiators are also susceptible to leakage: this may be the result of non-observance of the bending radius or poor-quality installation work. When installing a heating system, you should be guided in how to seal the radiator, depending on the material from which it is made and on the place of leakage.

A leak can occur at the most unexpected moment in any place - on a flat section of the radiator, in the places of a threaded connection or fastening of fittings, in the place where radiator sections are joined.

How to solder an aluminum heatsink

When asked by motorists whether it is possible to solder an aluminum cooling radiator with their own hands, experts answer with a positive answer.

For soldering aluminum you will need:

- Soldering tool.

- Alloy for soldering (solder).

- Solvent (acetone).

- Flux or rosin.

- Iron filings.

- Refractory container (crucible).

- Pliers.

- Tassel.

- Metal brush.

- Fine-grained sandpaper.

For soldering aluminum products, the following types of solder are used:

- for the repair of small cracks - tin plus lead (grade POS-40);

- for the repair of large cracks - tin plus bismuth (grades POSV-33 and POSV-50).

To prepare the flux you will need:

- Rosin - 2 parts.

- Iron shavings - 1 part.

Rosin and sawdust are thoroughly mixed. The resulting composition is placed in a crucible. A container with flux is heated over an open fire. After cooling, the flux is ready for use.

For the preparation of iron filings, a hacksaw with a fine tooth is used. Iron filings are designed to destroy the aluminum oxide film when applying solder to the metal.

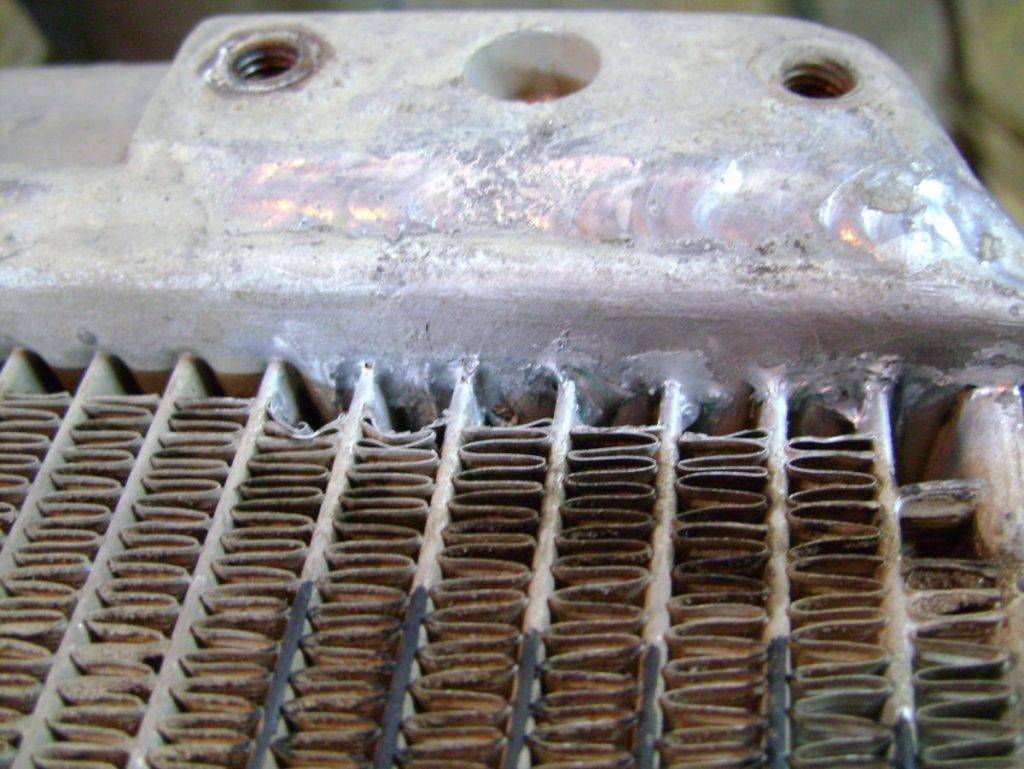

The main reasons for the loss of tightness of the radiator, signs, features of repair

The loss of tightness of the radiator of the cooling system may be due to the following reasons:

- Natural wear. The approximate life of the radiator is about 10-12 years. In the process of wear of the device, its inner working surface is covered with a layer of scale, deposits, formed as a result of chemical and thermodynamic processes. The walls of the plates and tubes of the radiator become thinner. Since the liquid is under pressure in the device, microcracks are possible, as a result of which the liquid begins to leave the system.

Given that the size of microcracks is small, a strong leak in this case is not observed. Wet leak marks may disappear after the engine and antifreeze have cooled down. It is advisable to immediately detect the consequences and the place where the liquid leaves. The sooner this situation is repaired, the less damage will have to be repaired. Can be successfully repaired by cold welding.

- Filling the cooling system with water.Freezing in the cold season. With a slight leak of antifreeze, many drivers add water to the system in a limited amount. During the warm season of car operation, the number of such top-ups can be large. As a result of this, the concentration and characteristics of antifreeze change. In winter, even at slight negative temperatures, it can freeze. In this case, the volume expands. The radiator can "break".

The resulting crack is usually large. It can occur at the junction of plastic and metal elements of the radiator. In most cases, such damage is difficult to repair.

- Refueling the cooling system with low-quality antifreeze. Overpressure. In most modern engines, the coolant is under pressure. In this case, the boiling point of antifreeze increases by more than 100 degrees Celsius. This allows you to increase the efficiency of the engine. If low-quality antifreeze is poured into the system, it may boil at a lower temperature. Doing so may damage the radiator. It may be small. In such cases, it is better to use soldering repair, as it provides better performance in terms of resistance to increased pressure. Soldering is easy to do at home.

- Mechanical damage. Such a malfunction may be due to:

- ingress of foreign objects into the radiator area;

- accident;

- destruction of fan blades;

- poor quality repair.

Read more: The ratio of gasoline and gas consumption

Depending on the location and size of the damage, cold welding and soldering methods can be used for repair.

Materials for soldering aluminum

Scheme of cold welding.

Soldering aluminum is a tricky business. Usually this procedure is performed in workshops. If you try, you can do this work at home. To repair an aluminum radiator, you need to prepare:

- cracked radiator;

- a soldering iron with a power of 100 W, and preferably from 250 W;

- rosin;

- ordinary solder;

- refractory crucible or muffle furnace;

- iron filings;

- bismuth;

- potassium chloride;

- cryolite;

- lithium chloride;

- sodium sulfate;

- table salt;

- emery skin;

- gas burner for heating large surfaces;

- potassium permanganate (potassium permanganate).

Components that are not in the arsenal of a home master can be found and bought in chemical stores.

Features of aluminum radiators

Aluminum ranks third in the world in terms of abundance in the earth's crust. Among other industrial metals, it stands out for its strength, low weight and high thermal conductivity. High resistance to corrosion in contact with the environment provides an oxide film.

These qualities have made aluminum indispensable in the manufacture of products with a large area and increased heat transfer. Good plasticity of the material expands the design and technological boundaries in the manufacture of heating radiators. Considering that sections of aluminum batteries are easy to remove or build up, they can be placed in any niche and harmoniously fit into a sophisticated interior.

Aluminum heating batteries will perfectly fit into the interior of any apartment or private house.

Aluminum heating batteries will perfectly fit into the interior of any apartment or private house.

Having such positive qualities as fast heat dissipation and attractive design, aluminum radiators still have a significant drawback - sensitivity to water quality and pressure drops. Because of this, microcracks and fistulas often form on the batteries, provoking the flow of liquid into the room.

When a leak occurs in the battery, it becomes necessary to seal the hole formed. You can fix the problem by soldering or gluing the damaged area. Conventional soldering is not suitable, since the protective film is formed immediately after cleaning the treated area and prevents reliable connection of the solder to the surface of the radiator.

In order to bypass the aluminum oxide film, even when repairing such a hole, fluxes are used.

In order to bypass the aluminum oxide film, even when repairing such a hole, fluxes are used.

For efficient soldering of aluminum products, fluxes are used that have the following qualities:

- The components that make up the product dissolve the oxide film and prevent its further formation;

- Protect the place of soldering from environmental influences;

- Do not allow the solder to spread over the surface, holding it only on the treated area;

- Reduce the tension of the soldered surface;

- Contribute to the uniform distribution of solder over the treated surface.

Fluxes are made on the basis of:

- cadmium;

- zinc;

- Bismuth;

- Combined substances;

- Smooth (made at home).

Industrial fluxes are expensive, so they are often made at home.

Fluxes for aluminum contain organic and inorganic components that allow destroying the protective film on the metal

Fluxes for aluminum contain organic and inorganic components that allow destroying the protective film on the metal

How to find a leak in the cooling system

Malfunctions of the cooling system are detected during the maintenance and repair of the car.

To identify damage, the radiator is removed from the installation site. Through a special hole, the coolant is poured into a pre-prepared container. To drain the coolant, the device is turned over and shaken several times.

There are two main methods for detecting leaks:

- visual;

- instrumental.

The instrumental method is carried out using various diagnostic equipment. When a leak is detected, the equipment emits a light and sound signal.

How to seal the plastic parts of a car radiator

Let us consider in more detail the adhesive method of repairing a damaged radiator using the example of the use of Hosch two-component industrial adhesive.

To seal the radiator tank, you should prepare the following materials and tools:

- powder welding granulate and liquid component of glue-welding;

- sandpaper;

- acetone for degreasing surfaces;

- gloves;

- cotton buds.

Stages of work:

- Training . Both surfaces to be bonded must be free of grease and other contaminants. If traces of other glue remain on the parts, they must be completely removed. In most cases, ordinary acetone is suitable for cleaning;

- Applying glue. The minimum amount of adhesive welding is applied directly to the crack. To fill the void or in the absence of body fragments, a powdered adhesive component is sprinkled onto the liquid base. If it is necessary to restore a large depression, gluing is recommended to be carried out in several stages (several layers are applied sequentially with an interval of 10 minutes).After the gap is filled with dry granulate, it must be evenly impregnated with the liquid component.

- Seam processing. After 10-15 minutes after completion of the work, you can start machining the seam with a grinder or fine-grained sandpaper to give the seam an aesthetic appearance.

VIDEO INSTRUCTION

Instructions - how to solder the plastic parts of a car cooling radiator

For soldering (welding) a plastic radiator, the following materials and tools should be prepared:

- Special building hair dryer for heating the place of soldering;

- Soldering iron with a sharp tip and precise temperature control;

- Solder for plastic - special welding rods. The marking on them must match the marking on the radiator housing. As a rule, it is "PA" - polyamide (nylon) or "PP" - polypropylene. Instead of purchased welding rods, you can use pre-prepared strips cut from a similar plastic tank;

- Acetone.

Work order:

- Degrease the repair site with acetone;

- While the soldering iron is heating up, we heat the junction with a building hair dryer;

- We connect the seam and gradually draw along it with a heated soldering iron, forming a groove equal in width to the thickness of the welding rod;

- We apply a welding rod and, heating it with a soldering iron, put it in the groove of the seam;

- We check the radiator for leaks, and then install it on the car.

The welding temperature (heating of the soldering iron) is selected in accordance with the brand of plastic. For PP, this is about 250 degrees.

An article on how to repair a car cooling radiator - causes of malfunctions, troubleshooting methods. At the end of the article - a video about professional radiator repair.

- Causes of malfunctions of the cooling radiator

- Typical malfunctions

- How to accurately determine the location of a radiator leak

- Repair methods

- Video about professional radiator repair

After the combustion of fuel in the engine, about 70% of the generated energy is converted into heat. Some of the heat escapes through the exhaust pipe, but most of it stays inside the engine, heating it to a high temperature.

To prevent the engine from overheating and dissipate heat into the environment, a cooling radiator (heat exchanger) is used, which is the main component of the vehicle's cooling system. A healthy and well-maintained (clean) radiator keeps the engine at optimum operating temperature, allowing it to run at full power.

However, the radiator, like all other elements of the car, can fail and stop performing its function. But at the same time, it is not at all necessary to immediately contact a car service for repairs. As practice shows, in most cases, the malfunction of the heat exchanger can be eliminated independently. To do this, you just need to identify the cause of the breakdown and know how to eliminate it.

Use of cold welding

This method of soldering the engine cooling radiator does not involve heating. The hole is sealed with a special substance that covers the damage. Repair is done like this:

- Prepare the detail. To do this, the surface is cleaned of dust, degreased. Moisten a rag with alcohol, gently wipe the radiator with it. You can’t make an effort, the metal will be damaged even more.

- Prepare the adhesive composition. It is chosen according to the type of metal. Cold welding is a thick mixture that must be evenly distributed over the defect.Accurate application improves the quality of the seam. They wait for the composition to dry, inspect the brazed radiator.