- Making a filling with your own hands

- #1: Homemade non-pressure seal

- #2: Seal for seams and small cracks

- Weaknesses of a well made of concrete rings

- Popular materials used to seal wells

- Hydroseal - modern technology for sealing holes

- Features of sealing wooden wells

- Operation Precautions

- How to prevent displacement of well rings in the future

- Violation of the integrity of the plastic well

- Under what circumstances does the seam leak?

- Safe waterproofing materials

- We eliminate the leak in the upper seams from rainwater

- Using compressed air plaster

- How to close the seams in the well: types of hydraulic seals

- Plastic and reinforced concrete wells: which cause more problems and why?

- What is a hydro seal

- We prepare a solution to eliminate a pressure leak

- We prepare the solution ourselves

- Leak sealing technology

- Other applications for hydraulic seals

- Safety

Making a filling with your own hands

Self-made hydraulic seals have some features. In quality, they are somewhat inferior to ready-made fillings produced by an industrial method.

These disadvantages include:

- there is no guarantee of inertia, i.e. “Homemade” can come into contact with the environment, while changing its properties;

- a homemade seal hardens much more slowly than a sample of industrial production;

- there is a possibility of the seal breaking up and getting its components into the water.

Based on the last point, we do not recommend using toxic compounds to create "home" hydraulic seals!

The advantages of homemade seals include low cost and availability, which is especially important in emergency cases when there is no industrial seal at hand.

#1: Homemade non-pressure seal

For the preparation of a waterproofing seal, materials are needed: fine-grained, preferably sifted sand, cement grade not lower than M300. The proportions are 2 parts sand + 1 part cement. Water is added to the composition immediately before use.

Water must be added gradually, stirring constantly. The consistency should be thick so that the mixture can be easily formed into a ball that does not spread.

A filling is inserted into a large crack by hand, into a small one it is rubbed with a spatula. After the repair is completed, the section of the well must be closed with an iron plate. After 2-3 days, the iron is removed, and the filling is treated with cement mortar and covered with waterproofing.

This method can only be used to eliminate non-pressure and low-pressure leaks. Under high pressure (over 3 atmospheres), such a home-made composition is quickly washed out.

To seal a deep crack, it is recommended to make a filling in two layers, while the first filling (bottom layer) should be thicker, almost dry, than the second

#2: Seal for seams and small cracks

For all their shortcomings, homemade hydraulic seals are great for sealing joints in concrete wells.They cope with this task “excellently”, while allowing you to save a significant amount on industrial products.

Being environmentally friendly and safe, self-made hydraulic seals made of sand and high-quality cement reliably protect well water from groundwater, impurities, and soil.

To increase the effectiveness of waterproofing the seams of the well, the composition "liquid glass" can be added to the solution of sand and cement. Such a mixture will make sealing better and more durable. Proportions 1:1:1 (sand:cement:liquid glass). It is necessary to add "liquid glass" 1 minute before sealing, because. hardening of the composition occurs very quickly!

Work production technology for sealing the seams of a concrete well is as follows:

- Surface preparation, which consists in removing exfoliated concrete, remnants of old sealing.

- If necessary, treatment of the walls of the well with an antibacterial composition to remove / prevent mold.

- Cleaning the seams from dust, dirt, old waterproofing. Expansion of the seam by 5-10 mm by strobing. Tools used - perforator, hammer, wall chaser.

- Preparation of waterproofing mixture.

- Seam pre-wetting. The seam should not be wet, namely moistened. It is optimal to use a fabric that absorbs water for this procedure.

- Applying the waterproofing mixture with a spatula. Filling cracks and sealing joints.

- Applying a penetrating waterproofing solution.

How often are waterproofing seams carried out? Waterproofing the seams of a concrete well is carried out on average 1 time in 5 years, provided that the well is operated correctly.Emergency waterproofing is carried out in the event of a leak, deterioration in the quality of well water, after a sharp drainage.

It is best to carry out waterproofing work in the spring, after the final melting of the snow, when the average daily temperature is not lower than +5 degrees.

It is necessary to carry out sealing, moving from the bottom up, simultaneously inspecting the walls of the well, eliminating chips and sealing existing cracks and crevices

Weaknesses of a well made of concrete rings

If the waterproofing of the well rings is not carried out in time, then the greatest load goes to the butt joints

That is why they should also be given special attention. When improper processing of the joints is performed, they gradually collapse, this also happens due to some processes: - Increased humidity, both outside and inside, affects the ends of the concrete rings, gradually destroying them. - If the concrete collapses and cracks appear, moisture gradually seeps inside and negatively affects the steel reinforcement in reinforced concrete. - If the reinforcement itself collapses and the corrosion process begins, the rings may begin to move under the pressure of the soil, thereby violating the integrity of the well shaft. Thus, connections that have defects can pass inside the well water with sand and clay

In this case, the process of flowing clay and sand will go on constantly, gradually increasing the speed. Under the action of such an abrasive solution, over time, the connecting seams expand and become large holes. The water becomes polluted, and its quality decreases accordingly.Before consumption, such water has to be additionally filtered. After cracks form in the seams, the reinforcement is exposed and begins to rust and gradually collapse. In such a situation, the well, as a source of drinking water, must be urgently saved. Therefore, you need to know how and with what to seal the seams between the rings in the well, so that such negative phenomena do not occur, and the structure retains its integrity for a long time, despite the changing climate and the impact of various external factors.

Popular materials used to seal wells

Photo of the finished mixture for waterproofing well seams.

Now there are many materials for sealing seams in the well. Each of them has a different degree of effectiveness and features, so let's look at the most popular options in more detail.

So, the sealing of the seams in the well is carried out mainly using the following list of materials:

- Ready dry mixes. These new generation materials are based on cement with the addition of chemically active additives, due to which they acquire improved waterproof properties. Also, their advantage is that such mixtures are able to adhere well to concrete surfaces, therefore, for sealing wells made of this material, this option is preferable.

For example, high-tech mixtures "Penetron" or "Waterplug", which have proven themselves in waterproofing work, allow you to create an almost monolithic surface that cannot be destroyed for many years. Ready-made dry mixes are sold in specialized stores.

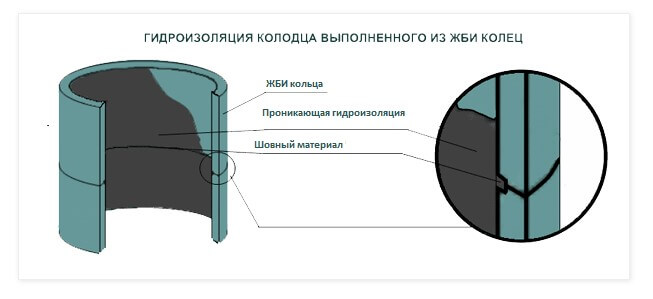

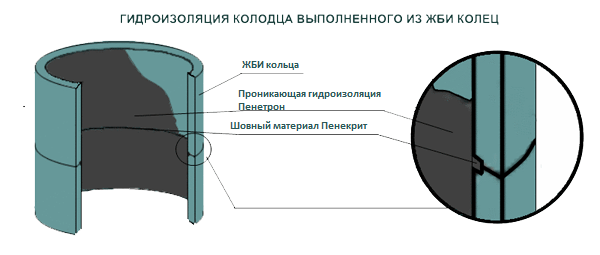

Schematic representation of the waterproofing of a concrete structure using Penetron and Penekrit.

- Bituminous-gasoline solution. Such a mixture can be prepared with your own hands from gasoline and bitumen, the brand of which should be chosen not lower than indicator 3. Sealing well seams with this material should be carried out in 3 layers, the first of which will be a primer.

For the first application of a primer, the solution is prepared in a ratio of 1 to 3, and for subsequent layers - 1 to 1. This mixture is applied using special equipment that supplies liquid building material under high pressure, such as a cement gun.

This solution is flammable, so sealing the seams in the well with it must be carried out with careful observance of fire safety standards.

The process of sealing seams with a bituminous mixture.

A mixture of cement (not lower than grade 400) and PVA. The sealing of well seams with the help of this thick solution occurs by plastering with a conventional spatula. Often, to enhance the sealing effect, liquid glass is applied over the cement and PVA mixture.

Warming tapes (rubber, jute or linen, impregnated with fibro-rubber). These building materials are used in cases where there are no other means at hand to eliminate the leak of the well. There is such a process by the method of caulking.

Caulking with such tapes allows you to seal the seams of the well if they do not exceed 7 mm. However, it should be noted that this is not the most reliable way with which you can achieve excellent results for a long time.

Therefore, when the question arises, what is the best way to seal the seams in the well, it is first advisable to turn your attention to other materials.

Hydroseal - modern technology for sealing holes

Hydroseal is called a quickly hardening substance. Applies hydraulic seal for wells mainly in emergency cases when urgent and effective intervention is required. Where can I get a hydroseal and how to prepare it? For covering concrete joints, it is recommended to use "Waterplug" and "Peneplug" together with "Penecrete" and "Penetron", respectively. The mixture allows you to cover up holes of sufficiently large sizes, up to a hole with a diameter of 10–13 cm.

Hydraulic seal for well treatment

Hydraulic seal for well treatment

How to prepare a hydraulic seal for use (on the example of "Waterplug" and "Peneplag")? Take 1 kg of hydroseal and mix it with 150 grams of water. If it is not possible to measure grams, then you can follow the proportions: 1 part of water to 5 parts of the mixture. Kneading is done quickly and only in warm water (17–23 degrees).

Tip: do not try to close all the holes at once by kneading a large amount of the mixture. The seal sets so quickly that when you return to the container with the mixture, you will find one frozen lump.

Sealing the seams between the rings - detailed instructions:

Well treated with Hydroseal

Well treated with Hydroseal

- Work surface preparation. We knock down the exfoliated concrete with a perforator or jackhammer, slightly expanding the damaged area;

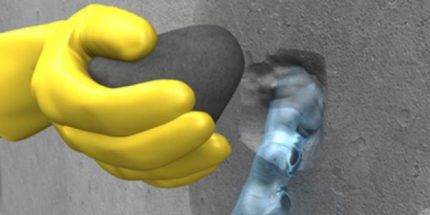

- Mix the hydroseal in a metal or plastic container in a small amount. Form a ball with your hands and press with a sharp movement into the seam between the rings. Hold the filling for 2-3 minutes.

Sealing concrete joints with a hydraulic seal allows you to instantly get rid of leakage. The only drawback of this mixture is its cost - 3 kg will cost 800-1000 rubles.

Features of sealing wooden wells

The photo shows what water should be in a working wooden well.

How and with what to coat the seams in the well, if it is made of wood? As mentioned above, the wooden structures of the wells can rot in some places, so first of all you will need to determine exactly which area this happened, and then restore the tightness by replacing the damaged material with a new one.

To do this, you need to build a working platform using thick boards. Its size should be such that one person who will carry out repair work can freely accommodate on it.

In order for the platform to be able to move freely up and down inside the well, it should be fixed with cables to a beam, which is laid on the head so that it can be conveniently lifted with one's own hands or with the help of a gate.

In this case, the waterproofing of the seams in the well should occur in the following sequence:

- First you need to hang the part of the log house located above the damaged area. To do this, "goats" are installed on both sides of the tank head. After that, 4 logs should be placed on them from all sides of the structure, to which, in turn, 2 strong boards will need to be nailed. Then the crowns of the log house are fixed on them with the help of long nails. This will prevent the collapse of the structure during the excavation of rotten boards.

- Next, the directly damaged areas on the log house are removed.

- After that, you can already begin to install new logs. At the same time, you do not need to immediately throw out the old material, since it is convenient to use it as a template for making blanks. New boards are installed by wedging with a wooden hammer.

Operation Precautions

The technology of using a hydraulic seal for a well is not particularly difficult, and therefore can be done by a beginner without the involvement of experts. When working with the solution, protect your hands with gloves. After use, the tool is immediately washed from the remnants of the mixture, otherwise, after the final hardening, it will be difficult to clean it only mechanically.

Well waterproofing has always been a tricky business. Many, trying to carry out the necessary work, faced serious problems. For clarity, we will give a few examples - problems that arise in cases where the waterproofing in the well is done with violations or even worse, it is completely absent. This is a flow into the well, during the appearance of melt water, this is a violation of the filtration in those places where the seams of the well are located, and much more.

To avoid such troubles, the seams between the rings of the well must be sealed with a mixture of PVA glue and cement. Mix PVA glue and cement, thus obtaining a thick mixture. Next, gently coat the seams with a spatula (you can several times to align the seam). All! Water and dirt will never enter the well again.

Note

: according to a similar scheme, you can first make a liquid primer from PVA and cement and smear the first layer with it to increase the impregnation of concrete in reinforced concrete rings. And after drying, coat with a mixture of PVA and cement.

After hardening and complete drying, you can still smear these places with liquid glass. Only it is impossible to mix liquid glass with cement. There will be instant freezing.

The second way to solve the problem is a clay castle or simply "waterproofing" around the well. To do this, the well is dug outside (the first 3 rings are enough, i.e. 3-4m) and sealed either with clay, but always without sand and earth, or with a cement solution.

And finally, the third option is special solutions for sealing wells, which today are presented in a large assortment on the building products market. They are a thin-layer (1.5-2 mm) waterproofing coating based on cement and special polymers of the latest generation. Possess vapor permeability (breathe) and elasticity, sufficient for application on the low-deformable bases. Coatings have a high degree of adhesion to any surface, weather resistance, environmentally friendly, prevent the penetration of water through the body of concrete even in the presence of high hydrostatic pressure.

It is quite easy to work with materials. Hydrolast is easily applied to a pre-moistened surface and forms a common crystal lattice with mineral bases, which eliminates the possibility of its delamination. Moreover, the coating allows you to carry out any finishing work in the future: applying plaster, painting, laying ceramic tiles, etc.

The process of applying Penetron resembles "staining": the prepared solution is applied to the surface of the concrete with a conventional synthetic bristle brush. More detailed information about each of them can be found on the company's websites ...

How to prevent displacement of well rings in the future

You will have to put up with the displacement of the lower rings - digging the trunk to such a depth is an extremely time-consuming and expensive task. Since most often the shift occurs due to weak soil or quicksand, there is no guarantee that the trouble will not recur after the repair. As for the upper 2-3 rings, they should just be returned to their place without fail - this will make it possible to make high-quality waterproofing and thereby avoid flooding the mine with top water.

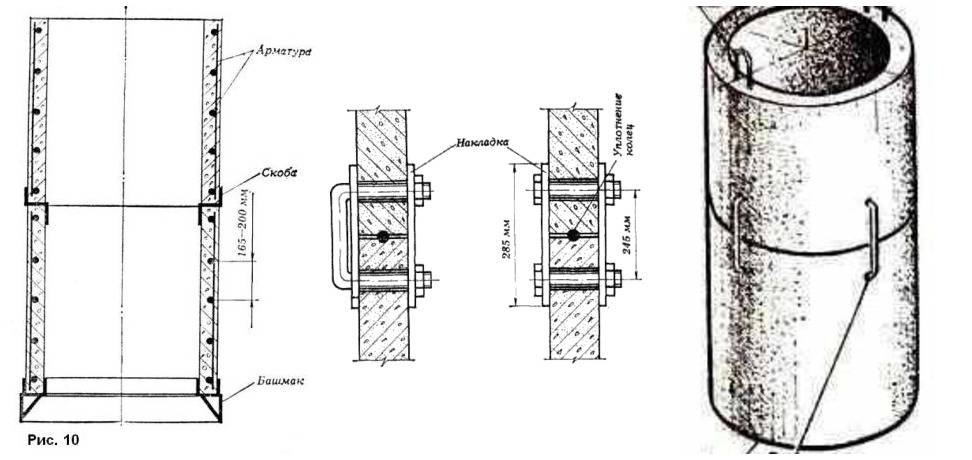

The use of well rings with seam locks prevents them from moving horizontally

The simplest thing that can be done to prevent horizontal movement of well rings is to replace them with hollow reinforced concrete modules with interlocks. For those who are embarrassed by additional costs, it is recommended to connect adjacent rings with strong metal brackets or thick steel plates. To do this, at a distance of at least 25 cm from the joint, holes are drilled into which a bracket is driven in from the outside. The edges sticking inward are bent and carefully sealed. If plates are used, then they are installed on both sides and fixed with bolts with a diameter of at least 12-14 mm.

Concrete rings can be connected to each other with metal brackets and straight or curved thick steel strip plates.

On heaving soils, cracks in the joints appear due to the fact that the soil tries to push the upper rings up, lifting them above the other links of the well shaft.In this case, the trunk is dismantled to a depth below the calculated freezing point and the cylindrical modules are changed to conical ones.

Factory-made or hand-cast cone rings will remain in place even on the most heaving soil

Prefabricated cone rings are almost impossible to find, so you have to cast them yourself. The slope of the latter should be directed inside the structure and be from 10 to 15 degrees. Due to this, the pushing forces reverse their direction, pressing the upper concrete module against the well shaft.

Violation of the integrity of the plastic well

With plastic wells, there are much fewer problems due to the fact that the design has no seams. However, violation of the recommendations for operation or installation work become the reason why cracks and other problems may appear. In this case, it is possible to solve the problem with the degree of waterproofing by using a special sealant.

On sale you can find versions of the sealant on a variety of bases, it is important to choose the most suitable version

Each sealant has its own instructions for use, which should be read before surface isolation. As practice shows, with the correct use of the sealant, the structure will have the necessary insulating qualities.

Improper installation and violation of operating conditions can lead to thinning of the walls of the plastic well, the appearance of cracks that cause leakage into the external environment.

Under what circumstances does the seam leak?

At the time of the repair work, the well is already a finished structure, which has some of its own structural features.

Based on these circumstances, which could cause a leak in the cracks, there are many:

- Rings, which are made by various manufacturers, can be with or without locks. Accordingly, the seams of the latter are less airtight.

- During the execution of the well, the builders did not seal the seams with a tarred rope. This process must be followed by the client in the course of work, otherwise troubles associated with depressurization of the joints will invariably appear in the well.

- Not quite a suitable place for the well was chosen. When planning, it is necessary to take into account the peculiarities of the hydrological and geological conditions of the area. In unstable soils, soil movements are likely, based on this, the seams can diverge, especially if the well was built incorrectly.

- If the upper seams are above the freezing level of the soil, then the cracks can diverge due to demi-season freezing and freezing of the soil.

In any case, the problem can and must be solved by the method of repair work, the quality of which will also determine the level of water quality in the well.

Safe waterproofing materials

Now let's talk about how you can seal the seams in the well, depending on one or another method of sealing. The construction market offers many waterproofing materials for waterproofing large containers.

In works on sealing with the help of safe materials, the following types are used:

- Dry composition, which is prepared at the factory. They are created from very effective new substances, based on cement, to which moisture-proof additives are mixed.Thanks to them, the finished mixture has the best ability to perfectly adhere to the surface of the rings. The use of ready-made mixtures will be the most effective and preferred option for work. On sale, such options for dry mixes for joining joints are often offered: "Penetron", "Waterplug". Proven in use many times, they have proven to be excellent in creating a moisture-tight connection in the space between the concrete rings of the wells. It has been established that as a result of their application to the gaps, a solid, monolithic well structure is created. Moreover, it does not lend itself to the destructive effects of temperature and moisture for many years. You can buy ready-made dry moisture-proof formulations in specialized stores.

- Bituminous-gasoline mastic. This version of a moisture-resistant solution is suitable for those who want to mix all the components with their own hands. When choosing bitumen, the brand must be used with a parameter of at least 3. Sealing of joint gaps from this composition should be carried out in at least 3 layers. The first layer is a primer. For him, mastic is bred in the proportion of 1 part of gasoline to 3 parts of bitumen, and further coatings are 1 to 1. A special device that sprays a rare composition under high pressure, for example, a cement gun, will help to facilitate and make work more efficient. You should not forget about safety in the process of sealing the seams, because the solution is flammable.

- Plaster mixture of cement (highest grades from 400) and PVA glue. Clogging the gaps between concrete rings with such a thick solution is carried out by plastering using a conventional spatula.To improve the efficiency and water resistance of the layer, liquid glass is additionally applied over the cement joint.

- Sealing strips, which come in different structures: rubber, linen, jute or impregnated with a special fiber-rubber coating. This type of building material is used in cases where there are no other suitable means that could become protection against the penetration of external liquids into the well. Clog the gaps using the caulking method. Sealing joints with water-repellent tapes allows you to seal the space between the rings, not exceeding a distance of 7 mm. This method is the least reliable compared to the previous methods. It will not work for a long time to solve the problem of sealing with the help of caulking. This method is best used in the most extreme cases, but then it is better to seal the joints of concrete rings with stronger and more effective materials.

Not knowing about its harm, some owners of wells quite often include it in the composition of the solution to create sealed seams due to its excellent water-repellent properties.

We eliminate the leak in the upper seams from rainwater

If the source is contaminating the top water, there will be little help in filling the gaps with the use of cement mortar. The seam will quickly be washed away by rain streams and it will not even have time to grab properly. What can help in such a situation?

These are special building mixtures: HydroStop, Waterplug, Peneplag and others. The main properties of these compounds are rapid hardening and penetration into all small cracks, which makes it possible to reliably eliminate the leak.

Their advantages over other solutions:

- resistant to temperature changes

- absolutely waterproof

- do not react with salts and other aggressive substances

But the mixtures are not very affordable, because they have a high price.

Dry powder is diluted with warm water at the rate of 5:1. This ratio may vary depending on the size of the gap. The mixture is prepared in small portions, because it quickly hardens.

At the same time, the ingredients are quickly mixed and applied to a pre-prepared place with your hands. You need to manually press firmly on the composition and then hold in this position for 2-3 minutes.

In this case, the flows in the gap between the parts should weaken or disappear, which will facilitate the work of applying a layer of waterproofing composition. When it hardens, pegs are hammered into the holes and also coated.

Using compressed air plaster

Materials for work:

A cement gun is needed to seal the well.

- cement gun;

- high-quality pozzolanic (not lower than 400);

- waterproof expansion cements;

- waterproof non-shrink cements.

The whole process is carried out using a cement gun. The cement is laid in 2 layers with a thickness of 5-7 cm. Each subsequent layer is applied only after the previous one has set. This may take 10 days or more. The solution can only be applied at an ambient temperature of at least +5 °C. If sealing occurs in the summer, then the coating must be watered with cold water every 2-4 hours. In the cool season - every 12 hours.

How to close the seams in the well: types of hydraulic seals

Hydroseal - a special composition that is used to eliminate leaks in wells. It is prone to rapid hardening and is not washed out by the pressure of water.If the crevice in the well is not repaired in a timely manner, groundwater can enter the well water and change its taste and quality.

An ordinary solution of cement and sand was washed out with water, so over time a hydraulic seal developed specifically for such purposes appeared.

Types of hydraulic seals:

- Pressure - harden within a couple of tens of seconds, a special layer of waterproofing is applied over the seal.

- Non-pressure - it takes 5-8 minutes to completely solidify. It is used during scheduled preventive maintenance.

Hydrocement is also used to repair pipelines and small gusts in basements.

Requirements for waterproofing seals:

- Fast freezing;

- Reliability;

- Ease of use;

It is also important that the seal does not corrode and is not deformed by temperature changes. Hydroseal should not change the taste of water and should not affect its composition

Plastic and reinforced concrete wells: which cause more problems and why?

The most common types of wells can be called plastic and reinforced concrete. The modern version of the design are plastic, which have recently been installed everywhere. Their high popularity is primarily due to the fact that the structure has been serving for several decades and there is no need to carry out repairs. With reinforced concrete structures, there are much more problems, which is associated with the prefabrication of the structure, the presence of seams and individual structural elements.

Plastic and reinforced concrete wells are part of the sewerage system that allows you to revise, control and operate the sewer system.

Over time, the quality of concrete can change significantly, cracks and various other defects appear on the surface. Waterproofing is also affected.

What is a hydro seal

Hydraulic seal is a special composition of slurries that are capable of very fast hardening, making it possible to eliminate pressure leaks. It is usually impractical to use hydraulic solutions in such situations, they are simply washed out with water, without even having time to harden.

Until the hydraulic seal was invented, most well craftsmen used wooden plugs or tow, which, when swollen, prevented water from seeping into the structure. But these materials had one serious drawback - they began to rot very quickly, emitting unpleasant odors, which caused changes in the taste and quality of water.

The appearance of a hydraulic seal made it possible to significantly improve the quality of work and increased the service life of the repair site, which became important. However, even in our time, there are companies that instead use the old-fashioned method of fixing leaks to reduce costs, without even thinking about the consequences.

In the photo - a damaged section of the seam between the reinforced concrete rings

In addition, keep a close eye on what the wells are trying to stop live leaks. Remember that a mixture of sand, cement and liquid glass, which is used by about 80% of the craftsmen, cannot stop them efficiently and reliably.

When working with a hydraulic seal, all recommendations related to surface preparation must be taken into account, and when cracks and seams are small, they should be enlarged with a perforator to the required size. If the instructions are followed, it is able to withstand even a very serious pressure of water.

We prepare a solution to eliminate a pressure leak

From the previous paragraph, we learned what a hydraulic seal is for. This fast-hardening material is able to return solidity to structures in a matter of minutes.

When purchasing material, pay attention to the presence of a certificate from the seller, which confirms the safety of the components used in the hydroseal for drinking water

We can recommend such materials as "Waterplug" and "Peneplug", which are used in conjunction only with "Pinecrit" and "Pinetron". Mixtures instantly seize when interacting with strong water pressure, with simultaneous expansion and the formation of a waterproof layer.

Materials from other manufacturing companies that also specialize in the production of instant mixtures for blocking pressure leaks are used in the same way.

Particular attention should be paid to the correct use with the attached instruction

We prepare the solution ourselves

When you decide to make the mixture yourself, be sure to follow the recommendations of the manufacturer. The volume of the dry mixture depends on the activity of the leak.

Most often, the proportion is 1 kg of well seals per 150 g of water. In another way, you can calculate as follows - five parts of the mixture are taken for one part of water.

The mortar should be mixed at a water temperature close to 20°C. The kneading is done as quickly as possible - no more than 30 seconds, which should resemble dry earth.

Do not knead a large volume at once, consider its instant setting. In this regard, it is more reasonable to prepare the mixture in parts, and after applying one pressure leak to the place, immediately begin to prepare the next one.

Leak sealing technology

- The first step is to prepare the surface for work. To do this, using a perforator or a jackhammer, the internal cavity of the leak should be freed from exfoliated loose concrete.

- This area to be repaired must be widened to a width of 25 mm and deepened to 50 mm or more. In this case, the shape of the hole should be similar to a funnel.

- Stir in a clean container a certain amount of the mixture, the volume of which is necessary to seal the leak. Form a lump of mortar with your hands and press it with a sharp movement into the embroidered hole. Hold the seal in place for 2-3 minutes.

Other applications for hydraulic seals

Using fast-hardening solutions, you can effectively resist:

- leaks of liquids from reinforced concrete tanks;

- water breakthroughs in tunnels, basements, galleries, shafts, galleries;

- defects that may appear in the bowl of pools and other artificial reservoirs;

- capillary leaks, which often appear at the junction of walls and floors, as well as between foundation blocks.

Safety

After use, the tool must be immediately washed from the remnants of the mixture, otherwise, when they finally harden, it can only be cleaned mechanically and with great difficulty.