- In what cases it may be necessary to dismantle

- Pipe removal procedure

- In what case is such work required?

- Extraction equipment

- Methods for extracting casing pipes from wells

- Stretching Method for Column Extraction

- Extraction by washing

- Applying the spin method

- Casing Retrieval Procedure

- How to remove a stuck pump

- interferes with the cable

- Silting

- Deformations or deviations of the casing pipe vertically

- foreign objects

- How to pull a pipe out of the ground: an overview of the process

- Extraction by stretch

- Extraction by pacing

- Dismantling by unscrewing

- In what cases it may be necessary to dismantle

- How to prevent the pump lifting problem?

- Possible reasons

- slack cable

- Well silting

- Reverse siltation

- Pipe wall damage

- How to pull a pipe out of a well - some options for solving the problem

- What is the problem?

- Possible Alternatives

- How to remove a pipe from a well?

In what cases it may be necessary to dismantle

Wells drilled in a suburban area usually serve for a very long time. Even non-galvanized steel casing pipes, despite the tendency to rust, are able to maintain the normal operation of the aquifer for about 40 years.Rotting plastic can even last for decades in water.

Dismantling of casing pipes in suburban areas is carried out, thus, quite rarely. But sometimes the need for this procedure among the owners of private houses, unfortunately, still arises. It is usually necessary to pull out a pipe reinforcing the walls from the well shaft in the following cases:

- rusting of the reinforcing layer and its inability to perform its functions;

- decrease in water quality due to contact with the pipe walls;

- clogging in the body of the pipe.

Sometimes the holes of the filters are clogged in the wells. Correcting the situation in this case is usually also possible only by excavating the pipe.

Pipe removal procedure

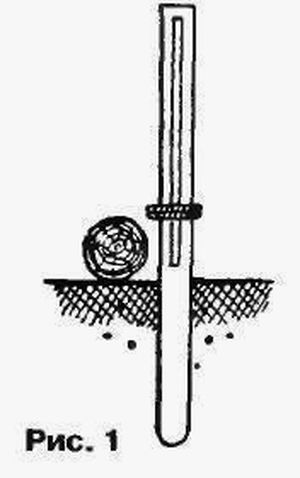

Around the head of the well, you need to dig a trench 1 m deep. Then it is worth pouring water into the trench

If you decide to pull the casing out of the well with your own hands, you should follow the following sequence of actions:

- To begin with, it is worth assessing the severity of the column. To do this, it is necessary to measure the depth of the hydraulic structure, find out the diameter of the casing elements and the thickness of their walls. Further, knowing the material of the pipes, their diameter and wall thickness, in the directory you can find how much one linear meter of such a product weighs. The found value should be multiplied by the length of the pipeline (the depth of the structure). As a result, you will find out the weight of the entire casing string. According to this value, it is worth selecting the traction force of the lifting element (crane or winch). If this number does not exceed several tons, then a conventional winch will be enough for dismantling. And to extract the heavy structure, you need a crane.

- Now you can start earthworks. Around the head of the well, you need to dig a trench 1 m deep.Then it is worth pouring water into the trench. Water is added as it is absorbed. This is continued until no more water is absorbed. This procedure will reduce the coefficient of friction of the casing string against the ground. To speed up the process of saturating the soil with water and prevent the collapse of the rock after the extraction of the column, a vibration generator is installed on the pipe head. Vibrations will loosen the column and make it easier to extract it, since it will move away from the rock itself and will not allow it to collapse into the penetration.

Hydraulic mechanism with gripper for casing retrieval

- Now you can dismantle the pipes. To do this, steel rods 1.5-2 cm thick are welded onto the body of the element to be removed. The winch lines are hooked onto the rod. To lift the element, the cable must be thrown over a block installed at the top mark of the vertical structure. Then the winch is turned on and the rise of the column from the hydraulic structure begins. Instead of a winch and a frame with a block, you can use a crane.

A light narrow string can be removed from the well using a conventional jack. To do this, one end of the lever should be brought under a rod piled on a column. In this case, the rod will perform additional functions of the fuse. With excessive load, the rod will break, this will save the casing from breaking.

In what case is such work required?

Dismantling a pipe is a troublesome and time-consuming task, therefore, before undertaking it, you need to think about whether it is really required? Often, the owners of the house decide to dismantle it only for the reason that it seems to them that this will improve the operation of the well in case of any problems.

The decision to pull the pipe out of the ground may be motivated by system breakdowns, the need for repair work. But not always  dismantling is the best way out. The owner of the well can also use alternative methods to solve the problem.

dismantling is the best way out. The owner of the well can also use alternative methods to solve the problem.

For example, when a pipe is deformed, a smaller structure can be placed in it. So the hole will not be eliminated, but it will not interfere with the normal functioning of the well. Alternatively, you can also simply clean the system.

Most often, the structure can be restored, but it will take so much time and money that it is much more reasonable to drill a new well in the ground.

For all methods that are an alternative to dismantling, it is better to consult with specialists. A person without relevant knowledge will hardly be able to determine in which case one cleaning is enough, and in which it is better to start designing a new system.

Extraction equipment

When extracting the pipe, along with all the main mechanisms, it will be necessary to prepare auxiliary devices. So, in the option of taking out the winch, you should acquire a strong retaining floor. For the construction of the latter you will need:

- timber with a cross section of at least 100 × 100;

- steel bars or beams.

In this version, the extraction is carried out by means of a specially assembled hydraulic mechanism, which includes a winch, special clamps and elevators. The end of the movable winch cable is attached to the auxiliary elements tightly fixed on the pipe and gradual fishing out of the ground is carried out. As the column exits, the coupling devices move as close as possible to the ground surface.

The use of the winch method should be carried out after all the preparatory work has been carried out. Gradually removing the pipe, it should be fixed with a special clamp located on the prepared support, or with a winch locking mechanism.

Along with the winch, the method of extracting the pipe with a jack often finds its application.

Extraction winch

In most cases, this technology includes several simple steps. The first of these is the arrangement of the mouth of the mine. To complete this item you will need:

- lifting mechanism;

- timber or metal beams;

- swivel clamp;

- welding machine.

On the selected site, a solid foundation should be assembled, and then a jack should be installed. Then, its lifting platforms are brought under the elevator mounts with clamps and the column is fished out.

For greater efficiency, several lifting mechanisms should be used, since even pressure on each side will significantly speed up the extraction process, as well as prevent skewing and deformation of the pipe.

To get more benefit from the planned event, it would be useful to try to use additional devices that have become firmly established in the everyday life of the masters of this area. One such device is a safety pad. It consists of two inverted T-shaped supports, which are interconnected by four parallel beams. The bases are installed on the prepared area by slipping through the top of the column. Then a clamp or an elevator is put on the pipe cut, which are located on the welded upper transverse beams of the substrate and tightened. This ensures a secure fixation of the pipe.

This device can be used with both a winch and a jack. Its use will avoid unintentional failures of the pipe back into the mine and will remove a significant load from the main lifting mechanisms.

Methods for extracting casing pipes from wells

If there is a need for a complete dismantling of the well, then it is necessary to proceed with the appropriate work. Let's figure out how to pull the pipe out of the well with your own hands with the least financial loss. To do this, it is necessary to carefully study the situation, clarify what kind of soil we are dealing with and what condition the well is in.

There are several effective methods for extracting casing pipes from the ground:

- by stretching and extracting the entire column;

- soil washing method;

- by unrolling the entire structure.

Let's take a closer look at each of these methods.

Stretching Method for Column Extraction

This is an excellent way to recover large diameter casings. Well applicable when obtaining a bend in the wellbore. To implement the plan, it is necessary:

firmly grab the upper edge of the pipe and gradually pull it up;

all work must be done slowly and carefully, with jerks, the product may break;

the torn piece clings again using a special nozzle, the structure rises further to the next break.

With painstaking repetition of such actions, the entire structure is pulled to the surface. It is necessary to work slowly and systematically, since otherwise it will be more difficult to get the whole pipe out of the well. First you need to take care of the availability of the necessary tools.With frequent breaks, the reuse of such a design will not work.

Extraction by washing

Often, a sand plug forms around the casing pipe, which holds it and does not allow for quick extraction from the ground. How to pull the casing out of the well in this case? An excellent option would be to use water. For this you need:

- prepare the pump and special equipment for flushing;

- connect the pump outlet to the top of the pipe;

- through the pumping device, water is let into the structure, gradually increasing the pressure;

- with the help of special equipment, the wellbore is loosened and scrolled;

- as a result of the simultaneous action of water and a rotating mechanism, the friction force of the restraining structure in the soil decreases.

Thus, the casing pipes are removed. Ideally, use two pumps, namely one at the top of the structure, the second - to immerse in the mine itself to its foundation

It is important to consider that the pulling force must be exactly in the vertical plane. The upper part of the structure must be firmly fixed to the lifting mechanism. It is necessary to avoid sudden movements, which can lead to a rupture of the structure.

It is necessary to avoid sudden movements, which can lead to a rupture of the structure.

Applying the spin method

For this method of extracting the casing, you will need the following tool:

- crown for catching and fixing the upper part of the structure;

- rotary hammer;

- cumulative torpedoes.

Casing Retrieval Procedure

- the above crown and drill pipe are lowered into the mine;

- with the help of the rotor, the pipe is rotated against the rotation of the clock by about 2 tens of revolutions;

- there is a pacing of the structure gradually increasing the effort to the maximum limit;

- after that, a pipe break should occur, if it does not occur, the process is repeated;

- the result of these efforts should be incomplete untwisting of the joints of the casing parts.

If a positive result does not occur, it is necessary to use special equipment that will allow you to transfer the torsional force of the mine structure. After unscrewing a part of the structure, a vertical tension force is applied to it and it is removed to the surface. Such actions continue until the complete analysis of the structure and its extraction to the surface.

If these measures do not lead to the desired result, a cumulative torpedo is lowered to the depth of the proposed separation. As a result of its explosion, the structure breaks and the upper part rises with the help of the vertical force of special mechanisms. On the surface, damaged areas due to the explosion are cut off with a grinder. This method is considered expensive, requires special skills - it is not used in private wells.

How to remove a stuck pump

There are many ways to release pumping equipment from wells. They depend on the degree of pump suction or stuck in the casing, as well as the suspected cause of the problem. Unfortunately, it is not always possible to solve it due to insurmountable difficulties. But trying to remove the equipment is still worth it.

interferes with the cable

The most common cause of device jamming is a sagging electrical wire.It can be quite difficult to get a pump wrapped with a cable out of the well. When lifting the equipment, even with force, only additional sealing of the gap between the casing and the pipe will occur. In this case, do not use jacks or winches, otherwise the cable may break under significant loads.

It is necessary to try to push the pump down with rotational movements either clockwise or counterclockwise. Scrolling is carried out by means of a water intake pipe. The cable sag that has appeared is tightened and the rise begins again. The main thing here is to be patient and not overdo it.

Silting

The pump, overgrown with silt, releases the "swing" by raising and lowering it many times. Start with the smallest step and increase as needed. In this case, only a cable or a cable with a hose should be used. As a result of reciprocating movements, the hardened sludge will gradually begin to liquefy and, in the end, weaken the position of the pump.

No one can predict in advance how long it will take to “build up” the pump. It depends on the duration of the non-production period of the well, the thickness of the silted layer above the pump and the density of the deposits.

Deformations or deviations of the casing pipe vertically

A slight lifting of the pump to a certain point, a knock and a sharp stopper indicate that there are deformations inside the well that make it difficult for the equipment to move up. But there may not be a knock - it all depends on the nature of the defect.

In this situation, you can try to get around the obstacle by simultaneously lifting and rotating the pump by the hose. This should be done smoothly and slowly.With a successful combination of circumstances, the body will eventually “slip”, and with an unsuccessful one, you will have to part with the equipment or the well.

foreign objects

Jamming of the pump can be caused by a small object or a pebble, since the gap between the wall of the casing pipe and the casing of the device is usually minimal. In most cases, independent attempts to extract only lead to a break in the cable. But the situation may be subject to professionals with experience and diagnostic equipment.

In the arsenal of specialists there are underwater cameras, with the help of which the cause of jamming is determined. The masters will analyze the situation and offer an option to save the well. But you should immediately make a reservation - the services of such companies will be expensive. It is recommended to contact them if expensive equipment is located in the well.

How to pull a pipe out of the ground: an overview of the process

So, the decision to dismantle the pipe was made. Now we need to decide how to implement these intentions.

And modern drilling technologies offer us at least three options for the technological process of dismantling casing pipes, namely:

- Extraction by stretch of the body of the pipeline, followed by a break.

- Flushing with reciprocation of the body of the casing.

- Conventional unscrewing system.

In a word, there are three ways to get a pipe from a well. And further in the text we will get acquainted with the nuances of these dismantling technologies.

Extraction by stretch

This technology is practiced on pipes of large diameter and in case of curvature of the well channel.The essence of the process is to capture the upper end of the casing and stretch upwards. And the pipe is pulled in parts. Indeed, in the process of stretching, a force arises that exceeds the plasticity limit of the structural material of the casing. And the pipe simply bursts at a certain depth.

Extraction by stretching the body of the pipeline

In this case, a special nozzle is immersed in the well, which clings to the end, and the whole procedure is repeated, until the next break. Such actions continue until the pipe is completely removed from the well.

In this case, you need to use a tool with a large lifting force. And the pipe itself will be unsuitable for reuse.

Extraction by pacing

Extraction of the pipe by pacing

This technology allows you to remove a narrow casing pipe, but without guaranteeing its integrity. Well, if the diameter of the pipe allows you to immerse the pump of the circulation system into it, then the pipe can be removed safe and sound.

The essence of the process is to saturate the soil surrounding the pipe with moisture. After that, the coefficient of friction decreases, and the pipe is removed by a tensioner. To do this, pumps of the circulation system are attached to the upper part of the pipe or, if the diameter allows, pumps are immersed to the very bottom of the well. Moreover, in the process of circulating flushing, the pipe is paced - twisted and swayed from side to side.

Such manipulations save the pipe body from tight contact with the soil plug, and the process of tension extraction after such manipulations will go “like clockwork”.

Dismantling by unscrewing

To implement this technology, a drilling rig equipped with special devices is used.The essence of the process is a combination of torque load and tensile force, due to which the casing elements are first unscrewed and then removed from the well.

Well, the process itself is implemented as follows: a special fishing bit is introduced into the well, the upper edge of the pipe is fixed and, having made at least 20 turns counterclockwise, the unscrewed section of the casing is removed.

In this case, it is very important to control the magnitude of the torque and the longitudinal tension force. Otherwise, the pipeline will break

In what cases it may be necessary to dismantle

Wells drilled in a suburban area usually serve for a very long time. Even non-galvanized steel casing pipes, despite the tendency to rust, are able to maintain the normal operation of the aquifer for about 40 years. Rotting plastic can even last for decades in water.

Dismantling of casing pipes in suburban areas is carried out, thus, quite rarely. But sometimes the need for this procedure among the owners of private houses, unfortunately, still arises. It is usually necessary to pull out a pipe reinforcing the walls from the well shaft in the following cases:

- rusting of the reinforcing layer and its inability to perform its functions;

- decrease in water quality due to contact with the pipe walls;

- clogging in the body of the pipe.

Sometimes the holes of the filters are clogged in the wells. Correcting the situation in this case is usually also possible only by excavating the pipe.

How to prevent the pump lifting problem?

Pulling a deep well pump out of the well with your own hands, if it has come off, is not difficult at all if you follow all the recommendations of specialists.

The catchphrase says: "Forewarned is forearmed." To prevent the occurrence of unpleasant situations, you need to follow a number of simple rules that can save equipment, time and money.

- Work only with strong cables. You can't skimp on this item. Choose quality products and fasteners.

- The hose must be intact. Get it of sufficient length, even if the one that comes with the kit does not meet the required indicators. So you make the risk of breakage much less.

- Choose the right size. The unit should be one third of the pipe diameter. Otherwise, congestion during lifting cannot be avoided.

- Install headband. This will ensure the “protection” of the well from unwanted “guests”: garbage, bottles, stones, boxes.

There is no doubt that no one is immune from unpleasant situations when working with complex structures and equipment. This activity requires attention to detail at the stage of developing a plan for a future well and installing a pump. If you neglect the generally accepted safety rules, take measurements inattentively, use low-quality equipment, you can encounter a lot of problems. But even in this case, we must remember that any of them is completely solvable. In case you decide to deal with it on your own, you need to remember about accuracy, measured movements, and patience.

If there is a feeling that it will be difficult to cope on your own, you need to contact specialists who will fix it very quickly. But you need to understand that sometimes it can be complicated to such an extent that even professionals with many years of experience cannot cope. Therefore, the most important factor in the smooth functioning of the equipment is prevention.Using high-quality materials and carrying out timely installation of the necessary elements of the mechanism, it is possible to prolong the functioning of the pump for a long time. The initial design is also of great importance. A competent approach to planning the arrangement of a future well and equipment in it is the key to success and smooth operation.

The following video will tell you more about what to do if the pump is stuck in the well.

Possible reasons

The most common cause of equipment getting stuck in the well is human error. This can be both a violation of technological requirements during the installation process, and the quality of installation materials.

It is very important that during the installation process you choose proven equipment, and the installation itself is carried out by qualified specialists.

But improper installation and poor-quality equipment are only a factor influencing the causes themselves. But why the pump can get stuck in the well, let's look below.

slack cable

A slack cable is one of the most common reasons that pumping equipment can get stuck in a well. If the electrical cable is sagging, it can simply be bitten by a cable loop that holds the equipment. When this happens, in no case should you pull the cable with all your might, as you can break it, and it will be much more difficult to get the pump out of the well on your own.

It is worth noting that this is the most common and quickly solved problem. If the pump is stalled and won't go up, try lowering it a bit and choosing the moment when the cable loosens, repeat the lift. In the process, make sure that the cable, cable and hose do not sag.

In order to avoid such troubles in the future, simply connect the cable to the hose with clamps, fixing it. During the lifting process, make sure that the cable and hose come out at the same time, and do not allow any slack, as the situation may repeat itself.

Well silting

Quite often, the reason that it is not possible to pull the pump out of the well is its silting, due to rare use. It is the layer of silt that serves as an anchor that prevents you from pulling out the pumping equipment.

If silting is the cause, you can try to get it by rocking it, slightly raising and lowering the pump down. Under the influence of mechanical up and down movements, the water will erode the space around the pump, thus facilitating its release.

If the pump is stuck, it is important not to rush during the rocking process, and not to pull with all your might, as it may completely jam or completely break the cable. If you can’t get the pump on your own, you can resort to the help of firefighters so that they lower the fire hose and wash away the layer of silt with water pressure

Reverse siltation

One of the reasons for pump jamming in the well can be the effect of reverse siltation. It should be noted right away that it is observed only in wells drilled on limestone soils, therefore, if your well is not on limestone, this option can be excluded.

Jamming of pumping equipment occurs due to the deepening of the pump during operation. Over time, a precipitate forms, which settles on the pipes and pump

It is important to note that you will not get off by flushing the well, as in the previous version, since the sediment can be very dense. In this case, you can pull out the pumping equipment by swinging it up and down, after turning it on

Pipe wall damage

Damage to the walls of the casing is a fairly rare reason that the pump is stuck. But, nevertheless, it should be considered. If, while lifting the pump up, you encountered an obstacle and heard a knock, then most likely the problem is in the casing. This can be either its deformation (plastic), formed in the process of soil displacement, or marriage in welding and pipe connection. In this situation, you can get the pump out of the damaged pipe using rotational movements. By rotating the pump in a circle, you have a chance to go around the obstacle.

Lime deposits on casing pipes

An object that has accidentally fallen into the pipe can also serve as an obstacle to lifting the pump. If it gets into the space between the pump and the well, it can stall the lift. In such a situation, as a rule, the downward stroke is free, but when moving upward, the pump begins to wedge. Try to rotate the pump and lift it up again. If there is no positive trend, it is better to call specialists who have all the necessary equipment to fix the problem and raise the pump.

How to pull a pipe out of a well - some options for solving the problem

Drilling a well for water is a rather complicated and time-consuming task in itself. But even bigger problems await the site owners if the device needs to be dismantled. The most difficult of the questions that arise in this regard is how to pull the pipe out of the well?

What is the problem?

A water well is similar to an ordinary well, the diameter of which is small, but the depth can reach several tens of meters. To protect the walls of the well from the quite possible collapse of the soil, a casing pipe is driven into them.

And to keep the water clean and fresh, another one is inserted into the casing pipe - the operational one. Of course, the diameter of the production pipe should be somewhat smaller than that of the casing.

Often, in order to save money, pipes are used that can simultaneously perform both functions: to strengthen the soil and be in contact with drinking water.

Well pipes are made of various materials:

- steel: the most durable, durable and expensive;

- asbestos-cement: rather fragile, but quite high-quality and relatively cheap;

- plastic: a novelty on the market that is stronger than asbestos-cement products, has a low weight and is cheaper than steel.

Please note: To remove fragile asbestos-cement pipes from the well without damaging them, the task is almost impossible. Pulling the pipe is sometimes more difficult than re-drilling the well.

Pulling the pipe is sometimes more difficult than re-drilling the well.

In order to remove a narrow pipe from a well, from a sufficiently large depth, considerable effort and skill will be required. In this case, it is necessary to take into account:

- the material from which the pipe is made;

- immersion depth;

- lifetime;

- Terms of Use;

- reasons for dismantling.

In some cases, it is not possible to successfully solve the problem of dismantling, for example, when the structure breaks at a great depth.

Possible Alternatives

A specialist who is approached with a question about how to get a pipe from a well will definitely ask a counter question: why? Some owners of private houses think that this is the only way to restore the work of an old, abandoned or improperly arranged well. Sometimes the desire to dismantle the pipe is dictated by the need to repair or replace a failed structure.

Since the dismantling process is laborious, troublesome, long and expensive, you should definitely look for alternative solutions. For example, a smaller diameter production structure can be hammered into a damaged casing. The fracture will be securely closed and the well will be restored.

It can be useful to consult with experienced professionals. Sometimes it is enough to properly clean the well and dismantling is simply not needed.

In some cases, it turns out that it is cheaper and easier to drill a new well than to restore an old one.

How to remove a pipe from a well?

If the decision to pull out the pipe is nevertheless made, one of several possible methods can be used to do this.

- Contact professional drillers. They use special equipment (pipe cutters, overshots, taps, etc.), saving the owners of the site a headache and some money.

- Fix the end of the pipe, for example, with a loop or a crimp collar, fasten it to the short arm of the large lever and gradually remove the pipe.

Tip: It may take several people and time to act on the long arm of the lever. There is a known case when a team pulled out a pipe, sitting on the long arm of the lever for half an hour.

Instead of a lever, you can use a suitable jack, for example, from KAMAZ or a railway one.

Alternatively, you can get the pipe out of the well using a large railway jack.

Such a homemade device

Another way to remove the pipe is to make a special tool.

To do this, you need channel No. 10, from which two racks are made in the form of an inverted letter "T". The height of the structure should be one meter, and the width should be 0.6 m. A bearing is welded on top of each rack, the inner diameter is 40 mm.

Now you need to make an axis on which the handles and the drum are fixed. The edges of the axis are inserted into the bearings and the device can be considered ready.

For lifting, the pipe is fixed with a steel cable, which is wound on a drum. To insure long structures, it is recommended to use a special chock to hold the pipe when intercepting the cable.

To pull out the plastic pipe and not damage it, you will need a crimp clamp.