- Jam Causes and Solutions

- cable slack when lifting

- Silting a well on sand

- Deposits in a limestone well

- Casing wall damage

- Ingress of foreign objects

- Pump skew inside the pipe

- lifting cable break

- Water well drilling process

- How to get the unit if the cable breaks

- What Not to Do

- Problem situations with the pump unit

- Fallen pump

- How to lift an operating pump

- How to remove the device

- Problem situations when lifting

- Expert advice

- How to pull a pipe out of a well - some options for solving the problem

- What is the problem?

- Possible Alternatives

- How to remove a pipe from a well?

- Causes of a stuck pump

- Silting at maximum depth

- Jamming when lifting

- Causes of failure and ways to eliminate it

- Causes of pump jamming in the body of the well

- 1. Sagging electrical cable

- 2. Silting of the well as a result of long downtime

- 3. Solid-state obstacle - a complex barrier

- 4. Reverse silting effect

Jam Causes and Solutions

When lowering, the equipment may become stuck due to foreign objects entering the equipment. Garbage is pushed into the well or pulled out with a hook.

In most cases, jamming occurs during lifting.

The main reasons for this:

- drilling a well by unskilled, inexperienced people;

- poor quality of fasteners;

- non-compliance with technological requirements when lowering pumping equipment;

- unwillingness to follow the instructions for the operation of the facility.

cable slack when lifting

With a strong sag, the cable can form a loop that overlaps around the unit, thickens it, warps and gets stuck between it and the well wall.

Sagging can occur if:

- the cable is not fastened with clamps to the pipe or hose;

- the rope with the pump is fastened to the hose and the electric cable.

If you try to pull the pump out using a jack or winch, this can lead to a break in the cable.

Silting a well on sand

If water is not pumped in a well on loose soil, and the distance from the pump to the bottom is 2-4 m, insoluble particles of silt and sand gradually accumulate inside the casing pipe. They are deposited both under the equipment and above it, forming a layer of 1.5-2 m in 2 years. When dried, the sludge creates a dense plug.

Deposits in a limestone well

Deposits in a limestone well.

Limestone rocks, in interaction with oxygen, cover the metal body of the unit with a coating of a suspension of minerals that have precipitated.

If the pump is located too deep and has not been removed for 5 years, a strong stone layer of salt build-up forms on the device itself and on the walls of the pipe near it. For some wells, deposits of 3-5 cm in size are enough for the pump to get stuck tightly.

Casing wall damage

The following pipe defects do not allow getting a stuck pump:

- ledge - the equipment falls easily, but when raised it rests at the same level;

- dent - gets stuck, after which it falls with difficulty;

- burrs of an inaccurately made seam or displacement of welded parts - lead to the fact that the pump is stopped with a blow, and moves down easily.

Ingress of foreign objects

Stones, branches, cuttings of plastic pipes can get into the poorly protected head of the well, and during work - tools, wire, fittings and other metal products.

The more foreign objects are in the well, the more difficult it is to remove the downhole equipment. When it gets into the gap between its body and the pipe, the debris jams the device, gets entangled in the cable or cable.

Pump skew inside the pipe

When skewed, the pump does not get stuck abruptly, but with a gradual slowdown and without knocking.

This may happen:

- sagging cable:

- with a sharp pull on the cable;

- when lifting with an electric cable;

- if the cable or rope is caught on the bottom of the machine or the side connection.

lifting cable break

The lifting rope has broken.

If hydraulic hoses and cables consist of separate spliced pieces, when pulled out, the joints may disperse, this will cause the pieces to bend and the unit to jam.

The more spliced pieces, the less durable the cable and the higher the likelihood of it breaking.

Water well drilling process

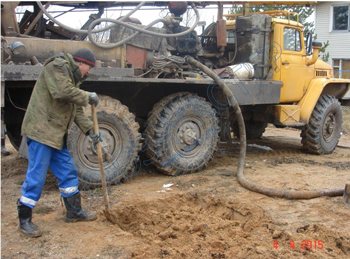

Everyone is interested in how we will drill a well, how we will carry out the work, whether we will spoil the landscape of the site. Especially for this purpose, we have prepared for you a photo report on the well drilling we have carried out.

| To enter the site, a large turning angle is required for drilling equipment; in this case, the gate interferes with free passage. The gate and fence need to be removed. | Removed fence trim. |

|

|

|

| Now you need to cut the supporting structure of the fence.We carry out the dismantling of the supporting structure. | |

|

|

|

| In order not to damage the base of the fence, and, of course, the wheels of the equipment, the protruding parts of the supporting structure are covered with boards and sprinkled with sand. | They come to the site: a drilling rig with a kung (where the drillers live), and a water carrier (visible in the background). It is necessary to place the kung either on the site, which is unrealistic in this case, or to find a place by agreeing with the management of the SNT and place the kung there, supply power (extension cord) 220V for living. |

|

|

|

| After dismantling the fence, the car can freely enter the site. | We drove the equipment to the place where the well is planned to be drilled. |

|

|

|

| A pit is being dug for the technological solution. With the help of which drilling will take place. The pump takes the solution, delivers it through the working tool to the drilling tool. | The boom rises, with the help of substrates it is centered over the drilling site. |

|

|

|

| Technological solution (water + cement) is poured into this pit | The pump is turned on and with the help of it water is taken from the existing source and pumped into the pit. If there is no source, water is taken from the water carrier. |

|

|

|

| A chute is dug from the drilling site to the pit so that when drilling, water flows into the pit. | The process has begun. The pump pumps the solution, delivers it to the drill, under pressure the solution rises to the surface and enters the pit along the chute. (solution cycle). |

|

|

|

| Exhibited working "table" for drilling tools. Rods are folded on it, with the help of which drilling is performed. | The process is going on. |

|

|

|

| Drill rods, with which drilling takes place and by which we measure the depth of the well. | Pipes are brought later. |

|

|

|

| The required number of casing pipes is laid out. | Casing is carried out with steel pipes to limestone. |

|

|

|

| Drilling tool (cone cutter). | Casing extension. |

|

|

|

| Pipe alignment. | Limestone (smaller diameter) is exposed through the casing pipe. |

|

|

|

| Water-bearing limestone. | The drilling master looks at what fraction (stones, sand, clay, etc.) comes out of the well. |

|

|

|

| When drilling is completed, the drilling fluid is removed to fill the pit. | In this case, they dug a channel from the pit towards the road. If it is not possible to dig a channel, then the solution is pumped out by a pump into a storm drain or to another predetermined place. |

|

|

|

| The well is ready. It is brewed to prevent foreign objects from getting inside the well. | Drilling is completed, equipment leaves the site. |

|

|

|

| We restore the supporting structure of the fence (welding works). | Refurbished fence. |

|

|

|

| Site restoration (levelling). | The place where the pit was. |

|

|

|

| The well is ready. We are waiting for the arrangement. | |

|

|

How to get the unit if the cable breaks

This is a disaster in which the owners throw the equipment right in the trunk and lower the new one there. Of course, this can be done if the unit fell to the bottom and drowned. And the depth of the mine allows water intake to be higher than before.

When the break occurred above the water level, the unit will still have to be removed. You need to make a special device yourself. By analogy with a mixer or a kitchen whisk, we twist a spiral with a sharp end slightly larger than the pump itself from the armature. We lower it into the well and weld the rod, immerse it again and attach another rod. So to the very bottom. Armature is needed to twist the spiral and capture the device.If the device could not be hooked, after rotational movements, the remainder of the cable will twist onto the trap and the pump will rise.

What Not to Do

- Pull firmly on the hose or cable. They can come off.

- Continue to operate the pumping equipment. This will aggravate the situation.

- Start actions to lift the pump without finding out the cause of its jamming.

- Work with the included power cable leading to the pump socket.

Problem situations with the pump unit

Before talking about the reasons that complicate the process of extracting the pump to the surface, we want to recall how it is held in the barrel. Pumping equipment is installed in the well as an assembly: a filter (see Filter for a well with your own hands: how to do it right), a supply pipe with a check valve, a power cable and a safety cable.

As the unit sinks, the cable and cable are unwound, and the pipeline is built up.

To avoid tangling and overlapping of the cable, it must be fixed with plastic ties to the supply pipe. But the pump is held only by a cable, which must be fixed on a special bracket located in the pit.

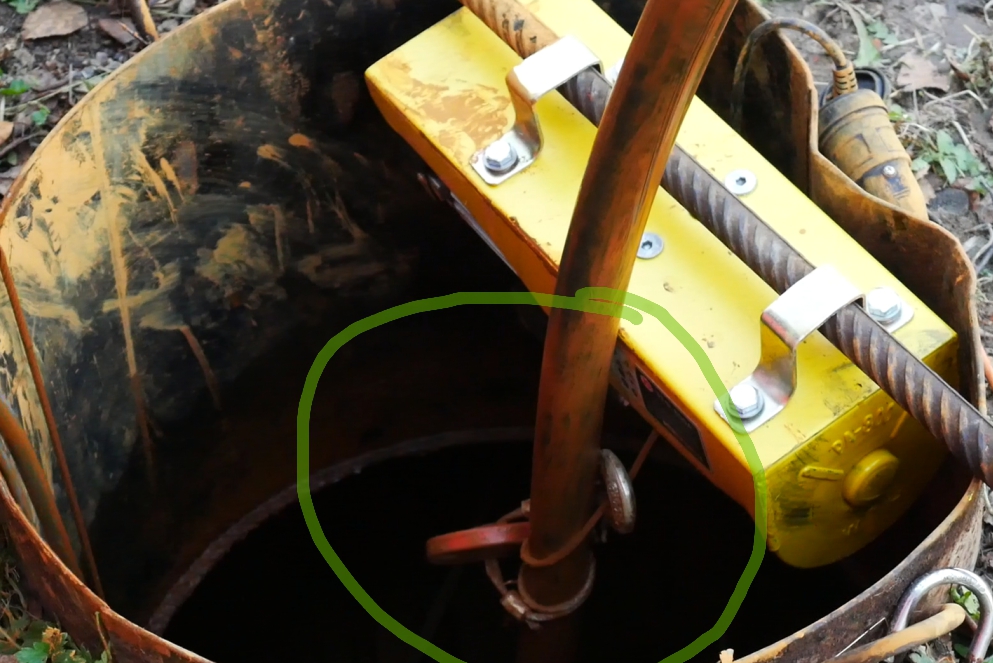

Fallen pump

The first problem may arise already at the installation stage: they did not hold the pump, and it fell to the bottom of the well. Here at least the situation is clear. Organizations engaged in drilling and repair of wells are equipped with a complete set of fishing tools that allow you to get any object out of the well: from a hose to a detached drill.

fishing bell

So:

- With metal objects, which include the pump, it is much easier.There are many fishing tools with which you can get it from the bottom, but it is almost impossible to do it so as not to damage it. Therefore, it is a pity if the new pump was dropped.

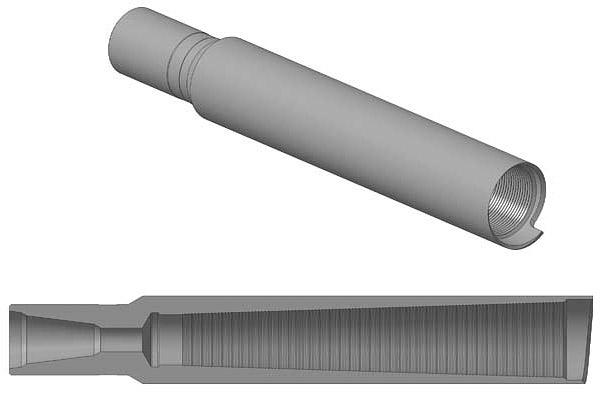

- Take, for example, a fishing bell: it is a steel pipe with a coupling at one end and a fishing thread at the other. In fact, in order to lift a metal object, it is wound onto it with the help of a thread cut along the process.

Other tools: a magnetic cutter-catcher, a bailer, generally destroy the object before pulling it out. By the way, in the process of drilling and performing well piping, tools, nuts, drills, rods quite often get into the trunk - no one is immune from this.

How to lift an operating pump

If the pump is broken, or simply exhausted its resource, it must be raised to the surface. In the normal scenario, this is done in the reverse order of installation: the pump is raised by two meters, one element of the pipeline is dismantled, part of the cable and cable are wound up.

Then another slight rise - and so on, until the pump is on the surface, but the alignment is not always so happy. Sometimes it’s not even possible to move the pump from its place. The reasons may be different:

| Reasons why a submersible production pump can jam | |

| 1 | A foreign object that has fallen into the well. |

| 2 | Incorrect fastening of the power cable, which led to its sagging. In such cases, the wire may become wedged between the pipe wall and the pump housing. |

| 3 | The reason for the impossibility of extracting the pump may be silting of the well. The reason for this is the long-term operation of the water intake without preventive maintenance, or improper installation of the unit. |

| 4 | Damage to the wellbore as a result of reservoir pressure or the impact of pressure groundwater (quicksand). |

- If the problem is a slack cable, it's the easiest to fix. Trying to pull the pump out with a sharp jerk is not worth it, it can come off, and generally end up on the bottom.

It is necessary, smoothly lifting the safety cable, to fasten the cable to the pipeline with clamps. Thus, the slack is eliminated and the jammed pump is released. - This is the only problem that the well owner can solve on his own. In all other cases, the participation of specialists is required. A silted well must be cleaned (see How to clean a well with your own hands), eroding the resulting plug.

The process is quite time-consuming - it is not possible to clean the well manually. What can we say about casing damage, when the removal of sediment to the surface is just the initial stage of large-scale repair work.

How to remove the device

Before starting work on extracting the unit, it is necessary to carry out preparatory work. To do this, you will need the following tools and materials:

- steel bar;

- lifting crane;

- canvas gloves;

- metal wire;

- welding machine.

When carrying out such work, one cannot do without outside help. As for the steel bar, its length should be 1 m, while the diameter should be 5 mm. When preparing metal wire, you must find out how deep the well is. This information is provided in the passport.

It is important to take care of the presence of a piece of wire, the length of which will be equal to the depth of the well. To this value should be added 5 m

The diameter remains the same as that of the steel bar.

Problem situations when lifting

Options for water supply of a private house from a well.

What should I do if, with a slight lifting, there was no sagging of the cable or cable, but the device suddenly bumped into some kind of solid object? For example, it goes down well and rises back, but to a certain level, and then rests again.

In order to lift the pump in such a situation, you need to consider what interference may be. Most likely, a protrusion of the casing was formed. This may be a flattened edge, pipe joint consumption, welding residues, dents. You can try to slowly lift the device yourself, making rotational movements around the axis, holding the hose or pipe. It is possible that the pump will slide off the obstacle, roll around and overshoot the problem area.

Getting into the well of various objects blocks the work. If a screwdriver has fallen and wedged between the walls of the well and the pump, then it will easily move down, and when lifted up, on the contrary, it will stall. The gaps between the walls of the well and the device are very small. Any objects, even small shapes, will jam the pump. In such cases, it is better to use video diagnostics.

Such cases are considered difficult. If you try to remove the object yourself, you can break the cable. Therefore, it is better to abandon self-ascension. Take up the slack in the cable, pull it to its maximum height, fix the pump securely and wait for the specialists with the necessary equipment to arrive.

Expert advice

The internal structure of the vibration pump.

If the pump fell into the well on limestone, experts recommend not to start work without video diagnostics.Thanks to this modern method, it is possible to determine various damages, the condition of pipes that have fallen, the condition of the pump or the presence of objects that have fallen.

This will allow better use of fishing tools, especially since grabbing objects with them that can create obstacles when lifting is considered the most difficult job. If it was found that a ball of cable has formed in the well, then the extraction is carried out with different traps.

"Cats" or a special ruff are used in the formation of dense balls of cable. The cat allows you to grab and wrap up the pieces that were subsequently formed by the cliff. If the pipes are damaged, then they are removed with a pipe finder. After that, lift the pump.

How to pull a pipe out of a well - some options for solving the problem

Drilling a well for water is a rather complicated and time-consuming task in itself. But even bigger problems await the site owners if the device needs to be dismantled. The most difficult of the questions that arise in this regard is how to pull the pipe out of the well?

What is the problem?

A water well is similar to an ordinary well, the diameter of which is small, but the depth can reach several tens of meters. To protect the walls of the well from the quite possible collapse of the soil, a casing pipe is driven into them.

And to keep the water clean and fresh, another one is inserted into the casing pipe - the operational one. Of course, the diameter of the production pipe should be somewhat smaller than that of the casing.

Often, in order to save money, pipes are used that can simultaneously perform both functions: to strengthen the soil and be in contact with drinking water.

Well pipes are made of various materials:

- steel: the most durable, durable and expensive;

- asbestos-cement: rather fragile, but quite high-quality and relatively cheap;

- plastic: a novelty on the market that is stronger than asbestos-cement products, has a low weight and is cheaper than steel.

Please note: To remove fragile asbestos-cement pipes from the well without damaging them, the task is almost impossible. Pulling the pipe is sometimes more difficult than re-drilling the well.

Pulling the pipe is sometimes more difficult than re-drilling the well.

In order to remove a narrow pipe from a well, from a sufficiently large depth, considerable effort and skill will be required. In this case, it is necessary to take into account:

- the material from which the pipe is made;

- immersion depth;

- lifetime;

- Terms of Use;

- reasons for dismantling.

In some cases, it is not possible to successfully solve the problem of dismantling, for example, when the structure breaks at a great depth.

Possible Alternatives

A specialist who is approached with a question about how to get a pipe from a well will definitely ask a counter question: why? Some owners of private houses think that this is the only way to restore the work of an old, abandoned or improperly arranged well. Sometimes the desire to dismantle the pipe is dictated by the need to repair or replace a failed structure.

Since the dismantling process is laborious, troublesome, long and expensive, you should definitely look for alternative solutions. For example, a smaller diameter production structure can be hammered into a damaged casing. The fracture will be securely closed and the well will be restored.

It can be useful to consult with experienced professionals. Sometimes it is enough to properly clean the well and dismantling is simply not needed.

In some cases, it turns out that it is cheaper and easier to drill a new well than to restore an old one.

How to remove a pipe from a well?

If the decision to pull out the pipe is nevertheless made, one of several possible methods can be used to do this.

- Contact professional drillers. They use special equipment (pipe cutters, overshots, taps, etc.), saving the owners of the site a headache and some money.

- Fix the end of the pipe, for example, with a loop or a crimp collar, fasten it to the short arm of the large lever and gradually remove the pipe.

Tip: It may take several people and time to act on the long arm of the lever. There is a known case when a team pulled out a pipe, sitting on the long arm of the lever for half an hour.

Instead of a lever, you can use a suitable jack, for example, from KAMAZ or a railway one.

Alternatively, you can get the pipe out of the well using a large railway jack.

Such a homemade device

Another way to remove the pipe is to make a special tool.

To do this, you need channel No. 10, from which two racks are made in the form of an inverted letter "T". The height of the structure should be one meter, and the width should be 0.6 m. A bearing is welded on top of each rack, the inner diameter is 40 mm.

Now you need to make an axis on which the handles and the drum are fixed. The edges of the axis are inserted into the bearings and the device can be considered ready.

For lifting, the pipe is fixed with a steel cable, which is wound on a drum.To insure long structures, it is recommended to use a special chock to hold the pipe when intercepting the cable.

To pull out the plastic pipe and not damage it, you will need a crimp clamp.

Causes of a stuck pump

In order to figure out how to pull out the pump, it is necessary to consider the reasons leading to this situation. Most often they are explained by the human factor. For example, it was installed incorrectly, the well was not inspected for too long, the requirements for installing pump elements were violated, etc. The main causes of downhole equipment jamming are:

- well silting;

- damage to the walls of the well casing;

- ingress of foreign objects into the pipe;

- sagging power cable.

The main difficulty lies in the fact that sometimes it is impossible to determine exactly what happened to the pump. The gap between the pipe wall and the device itself can be literally 1-2 cm, and it is not possible to see the cause without special equipment. To determine the cause of the jam and decide how to take the pump out wells, you need to analyze all the symptoms.

Silting at maximum depth

The device worked for several years without any problems, but it is not possible to get it. Most likely, the well silted up. This happens quite often, the reason is the downtime of the well for a long time. The water level can be at least a meter and block the device.

Location of the silted area in the well

Location of the silted area in the well

The solution to the problem is to swing the pump with a cable

You need to act carefully so as not to aggravate the situation. You can gently pull up, and then lower

Gradually, the silt deposits will begin to erode the water, and the device can be lifted.

To get rid of such a problem, the well should be cleaned every 1-3 years. Unable to pull pump out of limestone well.

In limestone wells, normal siltation does not occur, perhaps the matter is “reverse siltation”. The reason for its appearance is that the device sank too deep, and water began to stagnate around it. As a result, sediment appears on the end and pipes, which causes blocking of movement. Moreover, the sediment is formed strong, and flushing the well will not give any result.

You can get the pump, as in the case of silting, by swinging. In this case, the device must be turned on, then the water will more successfully wash out the resulting plug. To prevent the problem from occurring in the future, it is worth paying more attention to maintaining the operation of the well, as well as correctly placing the pump in it.

Jamming when lifting

While lifting, the pump is stuck in the well and does not move despite all efforts. This is the most common cause of pumping equipment jamming in a pipe. Most likely, such "symptoms" mean that the cable wrapped around is sagging.

This problem is much easier to deal with than others. The stuck device must be lowered and the cable loosened. After that, pull out the pump again, trying to prevent the cable and cable from sagging again. In no case should you pull with all your might - the cable can break, and then it will be very problematic to get the equipment.

The scheme of fastening the pump to the casing to prevent sagging

To prevent the cable from sagging, it can be attached to a pipe or hose even at the stage of installation of the pumping system. For this, special clamps are used.It is not worth attaching a cable to the cable - when the cable is pulled, the clamps can fly off. Before lifting, they will have to be removed, and then replaced with new ones. But this simple measure will avoid problems with lifting a stuck pump.

The reason is a broken pipe. Perhaps a dent has formed, the edge has flattened, the joint has parted. Burrs formed due to poor-quality welding of the seam can interfere with movement. Before removing the stuck pump from the well, it is given a rotational motion.

In some cases, this can help - the device will pass by the damaged area, although there are no guarantees. Perhaps the result will be one-time, but there is a chance that this will help solve the problem. The pump stuck sharply when lifting approximately in the middle.

The reason may be that a tool or a small object (for example, a small pebble) has entered the well and blocked the movement. Stopping the movement of downhole equipment occurs precisely at the moment when a solid object gets between the wall and the pump.

Jamming intervals may vary - it depends on which cable selection is installed, while the device drops down without interference.

You cannot cope with such a problem on your own; you need to call a team of specialists for help. Using the right equipment, only specialists can pull out the part that causes jamming.

Causes of failure and ways to eliminate it

When lifting the well pump, unfortunately, in some cases it gets stuck, and all attempts to pull it out by force do not lead to anything good.In order to solve the problem effectively, simply and as quickly as possible, you need to have an idea of what caused the device to get stuck. So, let's consider the most likely causes of a pump getting stuck in a well, their "symptoms" and ways to fix the problem:

Sagging electrical cable. One of the most common reasons why a well pump cannot be brought to the surface. Outwardly, this looks like a sudden stuck pump in the process of lifting it and the absence of a positive "reaction" even despite significant efforts. The problem is that the electrical cable sags and a loop is formed that overlaps the pump. As a result, it creates an obstacle between the pump and the walls of the well. The solution to the problem is very simple: you need to slightly push the pump back down and try to raise it again, only first choose the "slack" and lift it very slowly and in small jerks. Despite the fact that the problem is quite simple, it is very common and leads to unnecessary trouble. You can avoid it very simply: before each descent of the pump into the well, fasten the electrical cable to the hose with harnesses. Even if you spend a few extra minutes - by this action you will save yourself from a possible problem.

Often the cause is cable slack.

Often the cause is cable slack.

- Reverse siltation "on limestone". The problem arises in the event of an attempt to get a pump that has not been operated for a long time “on limestone”. Sometimes this problem is also called reverse siltation. Its essence is that calcium salts and iron, which are present in considerable quantities in water in Russia, come into contact with oxygen. As a result, sediment is deposited in the well section.Unfortunately, even a very powerful pump is not able to cope with such a problem on its own. The solution to the problem is similar to the previous case, but the device must be turned on.

- Casing pipe deformation. Outwardly, the problem looks like this: when you try to lift the pump up, this happens quite easily, but at a certain interval of the well, the movement stops abruptly, as if there was some kind of obstacle at the top. The problem is that there was a deformation on the casing. Solving it is quite difficult, but you can try to lift the pipe with rotational movements (while holding the hose): you may be able to gently slip past the “obstacle”.

Casing deformation

Casing deformation

mechanical obstruction. One of the hardest cases. When you try to lift the pump up, the device suddenly jams. The cause of the breakdown is often caused by the illiterate actions of the pump owner. For example, when an anti-vibration ring fails, it is replaced with a part of a plastic bottle. As a result, any foreign object, falling into the well, enters the free gap and “stops” the movement of the pump. Unfortunately, it is unlikely to solve the problem on your own, so it is better to immediately call a team of specialists.

Advice. To protect yourself from a possible stuck pump in the well during its operation, when buying a device, you should give preference to models with the smallest diameter. Although the acquisition will not be very cheap, you will be able to avoid costly repairs of failed equipment with a high degree of probability.

Causes of pump jamming in the body of the well

Basically, all the reasons leading to the occurrence of this unpleasant problem are due to the human factor. When during the installation of the pump the technological requirements for fastening the elements of pumping equipment are violated, and due attention is not paid to their workmanship, it is difficult to expect a favorable outcome during the dismantling of the pump.

1. Sagging electrical cable

For this reason, the largest number of cases of equipment jamming occurs. This happens by biting a sagging electrical cable in a loop that is tightened around the pump housing.

In this situation, you should not pull the device with all your might, as this will not lead to success. But what you pull on can break. Then it will be difficult to do something on your own.

Experts who have repeatedly lifted pumps from wells advise in this case to try to push the device back. Repeating attempts, try to feel the slack and at this moment continue to slowly rise.

In general, “prevention is better than cure”. In order not to encounter sagging of the electric cable in your practice, it is necessary to fasten it with special clamps to the pipe or hose at the stage of system installation. Moreover, it is not recommended to attach an electric cable to the cable, since when it is tensioned, the clamps can fly off.

When lifting the pump, you must also ensure that the cable and hose come out at the same time to the surface.. Weakness must not be allowed either on the cable, or on the cable, or on the hose.

2. Silting of the well as a result of long downtime

There are also often cases in practice when a long downtime of a well leads to its strongest siltation.The resulting layer of silt becomes an insurmountable obstacle in the way of the pump. When the pump is stuck in the well for this reason, experts recommend starting its swing, during which the device is either raised or lowered.

What does this lead to? Water can gradually begin to wash away the silt deposits. In the end, perhaps, the road to the top will be free, which will allow you to remove the pump outside. The main thing is not to rush things and do not be excessively active in order to prevent the pump from deafly jamming.

There is also a non-standard way to deal with a silted well. It is necessary to involve firefighters in solving the problem, who, with the help of a hose lowered into the well, will be able to wash away silt deposits. The released pump will go up smoothly.

To prevent the process of well silting, it is necessary to carry out its preventive cleaning, the frequency of which should be once every three years.

3. Solid-state obstacle - a complex barrier

On the path of the pump, a solid obstacle may be encountered, which will play the role of a wedge. Such a barrier can be:

- a dent in the pipe caused by ground movement;

- flattened edge of the pipe;

- burrs from a sloppy weld;

- defect in the assembly of the sedimentary column, in which instead of threaded connection of pipes, they are welded, allowing axial displacement.

Meeting with such an obstacle is accompanied by a characteristic hard knock, while the downward movement of the pump is free.

Is it possible and how to pull the pump out of the well in this situation? There are cases when the rotation of the pump with the help of a pipe around its axis helps to go around the obstacle that has stood in the way. However, a 100% probability of the release of the movement of the device is not guaranteed.It may be a one-time success. But it's worth a try, suddenly in a particular situation the problem will be solved in this way.

A tool, fastener or other foreign object that accidentally fell into the well can also become a solid obstacle. In this case, the pump stop occurs during the rise abruptly and unexpectedly. This happens when a solid object enters the gap between the well wall and the pump, which leads to jamming. In this case, the downward movement is free, and the jamming intervals upward vary depending on the cable selection. The object will not be able to slip through, the gap is too narrow. Therefore, experts advise to stop, call specialists. The special equipment available to them is able to extract interference from the well.

4. Reverse silting effect

This effect is observed in wells drilled in limestone soils. As a result of long-term operation, a sedimentary layer forms over the location of the pump, turning into a "plug". To stop this process, clean the well every three years.