- Stages of work

- Types of PE pipe connections

- Peculiarities

- We control the quality of the weld

- Welding parameters and sequence of operations

- More on this topic on our website:

- Welding instruction

- Basic Rules

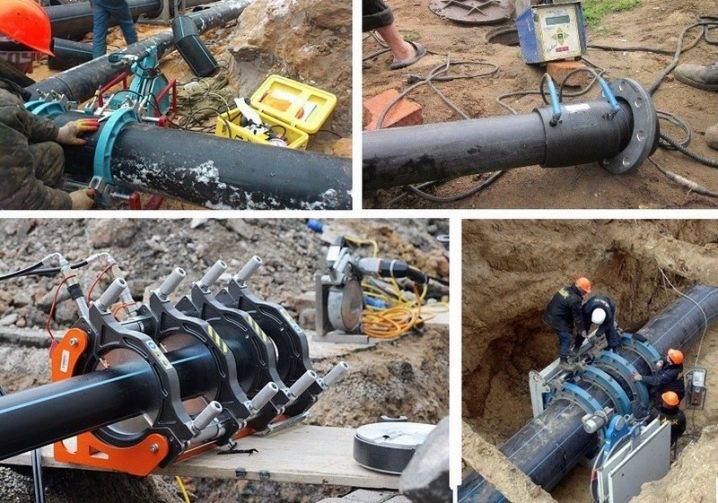

- Electrofusion connection

- Butt welding

- Bell technology

- Diffusion method for soldering PE pipes

- How to bend or straighten a product

- Overview of pipe bending methods

- Effective methods to bend the workpiece

- Butt welding

- Strengths of using electrofusion

Stages of work

Do-it-yourself welding of polyethylene lines is possible using the electrofusion method.

The instruction can be presented as follows:

- preparation;

- fixing with a centralizer and installation of a coupling;

- connection of the welder to the coupling;

- welding;

- removal of the device from under the connection.

Despite the fact that welding is supposed to be done at home, the ends must still be cut with a special tool - a pipe cutter. This will allow you to get better alignment when connecting. It is more convenient to remove oxide deposits from the junction with a hand scraper or using a rod. The layer to be removed should be about 200 mm from the edge of the pipes. The resulting chips must be removed with the same scraper. Jointed parts must be degreased with alcohol. At this stage, you can use special napkins.For the most accurate placement in the centralizer, the line can be marked in accordance with the dimensions of the coupling. According to these values, it will be more convenient to fix the pipes and the coupling.

The assembled structure must be fixed in compliance with safety regulations. The terminals of the welding machine must be connected to the connectors on the coupling. The device turns on and the barcode is recognized, which is on the surface of the coupling. The mode of most welders is automatic. The period of heating and cooling of the coupling is set just at the moment of recognition of the cipher. The welding process will start after the code has been read and end with an audible signal. To cool the pipe, it must be left alone for seven minutes. Only then can the clamps be released from the centralizer, and the equipment can be pulled out from under the soldering point.

Types of PE pipe connections

Polyethylene pipes can be connected into a single line using different methods. Moreover, each of them is suitable for specific conditions.

- So, joining HDPE tubes with fittings and couplings (socket welding) is used mainly for arranging the inside of the plumbing system in the house.

- Do-it-yourself pipeline installation using butt welding. This method is used for the installation of an extended section of communication for outdoor purposes. In this case, pipes can be laid both on the surface of the soil and in a trench, followed by covering them with soil.

- Electrofusion welding. This method of connecting HDPE tubes is produced using special plastic couplings with spiral elements built into them, which heat up as a result of current being applied to it.

Let's take a closer look at each of the methods.

Peculiarities

The main difficulty is that the operational and technological qualities of polyethylene pipes are in many ways similar to the quality characteristics of polypropylene pipes. They are also not subject to corrosion. The inner surface of the pipes is not coated. Pipes have high chemical resistance. The material is environmentally friendly, has a long service life.

Of the differences, professionals note low heat resistance. Therefore, HDPE pipes are used only for cold water supply and ventilation systems. Sometimes they are used for the installation of gas pipelines. The use of polyethylene pipes is possible when transporting in an environment above 40-50 degrees. An exception is cross-linked polyethylene, which is allowed to operate at temperatures up to +95 degrees. Polyethylene pipes have excellent frost resistance, which allows them to be used at temperatures up to -70 degrees.

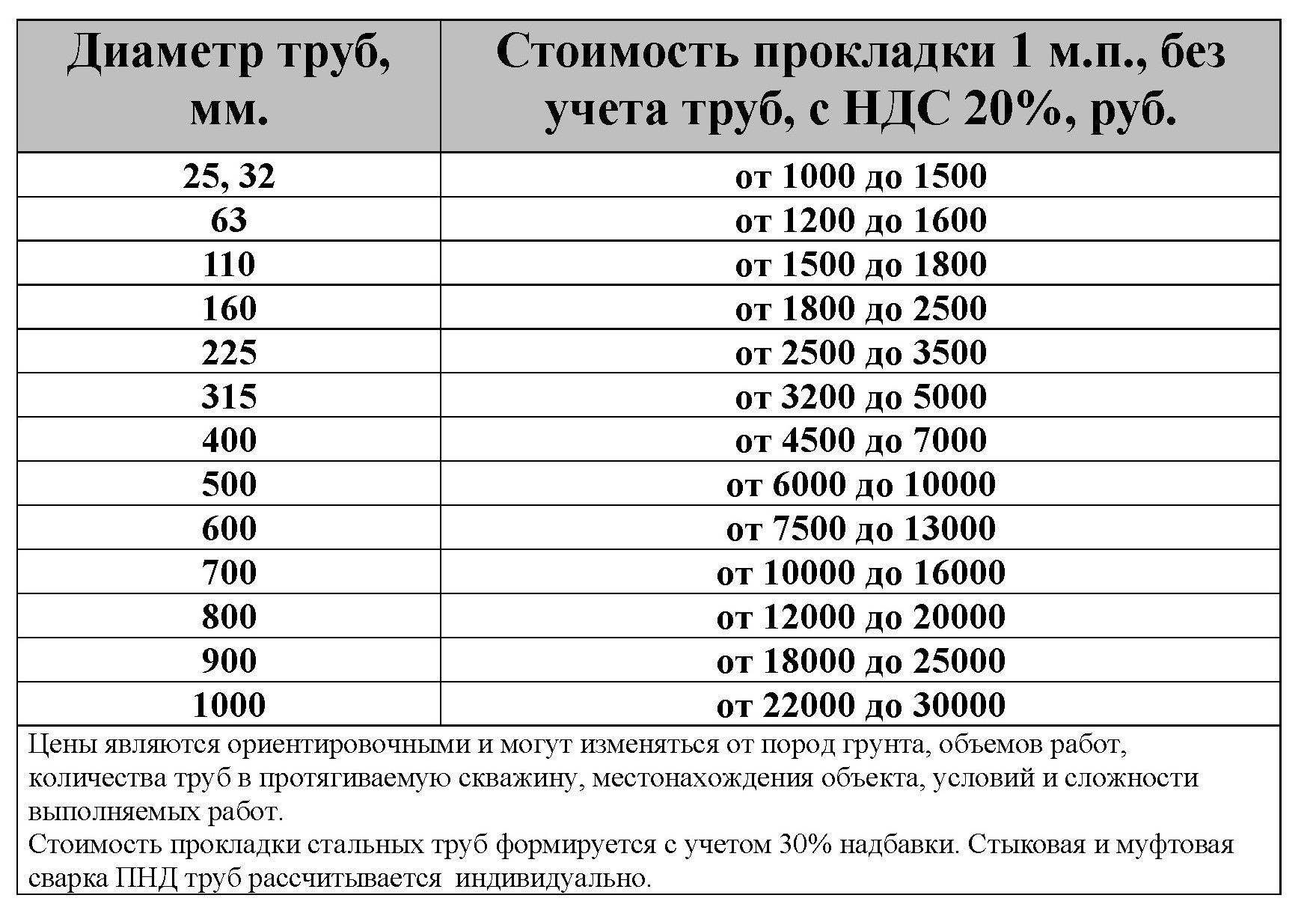

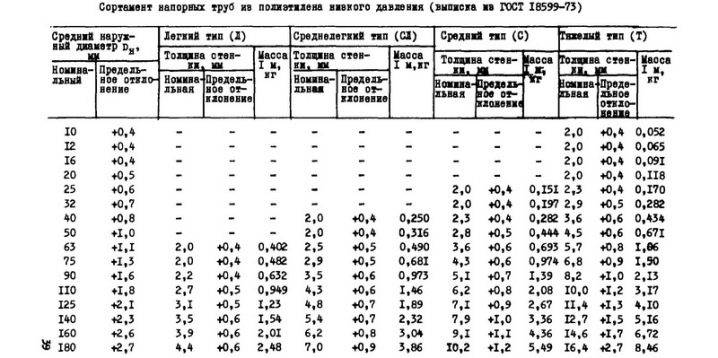

HDPE are commercially available with a diameter of 20 to 1200 mm. Due to the variety of options, they are widely used in various fields. In addition to water pipes, large diameter lines are also bought for sewage, both for internal and external.

The technical characteristics of HDPE pipes are determined by the properties of the base - low-pressure polyethylene. It is lightweight, which makes it easier to install the pipeline, resistant to pressure of tens of atmospheres. Of the negative qualities of the material, it is worth noting the limited possibility of using it at temperatures below zero (HDPE becomes glassy), and at elevated temperatures (more than 40 degrees), HDPE loses its rigidity. When heated to 70 degrees, the polyethylene base increases in size, but not much.

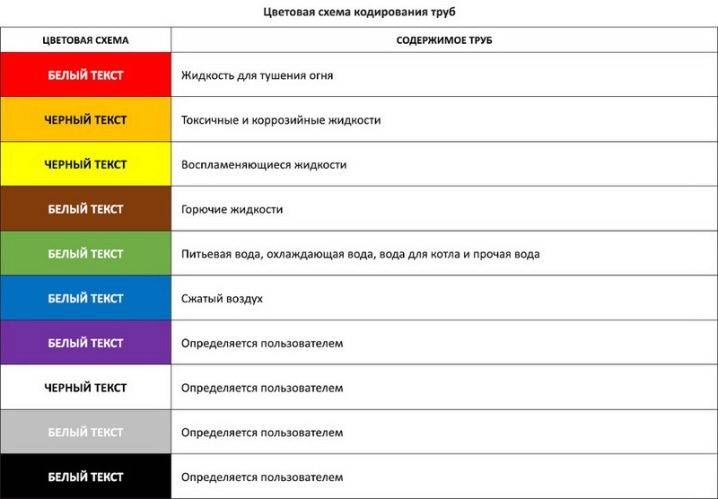

The range of HDPE is regulated by GOST, which was published back in 2001.All markings applied to one of the surfaces of the highways comply with the standards. Marking makes it very easy to choose the right options. The first letters include the name of the supplier, then the PE assortment, for example, 1000 mm. The table also contains the designation of the thickness of the lines, the possible working and maximum pressure, the date of manufacture and the batch number.

The technological map of markings also contains color designations in the form of stripes. If the socket is painted yellow, the pipes can be used for gas pipelines, if the stripe is blue, then only water supply can be laid from the pipes. The pipe connection scheme is drawn up taking into account standard commercially available segments - from 5 to 25 meters. Main water pipes are usually made to order, have a length of up to 0.5 kilometers, and therefore contain a minimum number of connections.

We control the quality of the weld

When installing welded joints by any of the methods described above, it is very important to correctly assess how high-quality the weld is. It depends on whether this section of the pipeline can be used, or whether everything will have to be redone.

Part with two regular welds

There are actually not so many evaluation criteria, and remembering them is quite simple:

- The most important sign of quality is the presence of a uniform polyethylene roller around the entire circumference of the pipe. If the roller is curved, or if there is a depression instead of a roller, the connection cannot be used;

- The next important factor is alignment. A slight displacement of the joined parts is allowed, but it should not exceed 10% of the thickness of the pipe wall;

Photo of the defective area in case of misalignment

- The height of the molten polyethylene roll is also limited. For pipes with walls of 5 - 10 mm, this value is 2.5 - 3 mm, for pipes with walls up to 20 mm - 5 mm or less.

Of course, if you are installing a low-pressure pipeline or non-pressure communications, then a small deviation can be neglected, but you still should not do this. It is much easier to make a new welded joint than to subsequently repair an existing pipe.

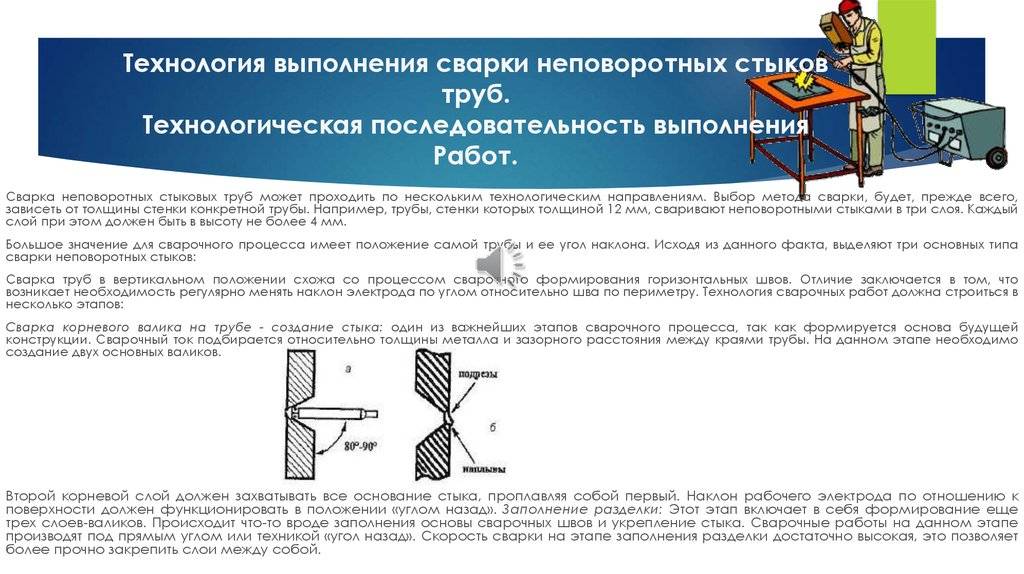

Welding parameters and sequence of operations

Butt welding options include:

- The degree of pressure on the ends.

- The temperature at which the material melts. Depends on the brand.

- The force with which the ends are pressed against the heating element.

- Process duration.

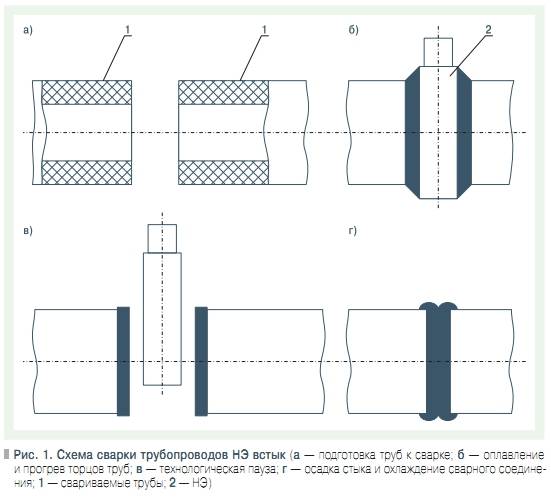

Sequence of operations:

- The first step in welding polyethylene pipes is to clean the ends of the pipes to be joined.

- Fixing pipes in the centralizer of the device where polyethylene will be welded. Processing the ends of the pipes with a cutter to ensure the perpendicularity of the axis. At the same time, finished workpieces are checked so that there are no gaps.

- Heating the ends of the pipes with a welding mirror to the melting point, which is about 220 °C.

- Pressing the ends of the pipes with the necessary force.

- Removing the finished pipe from the device.

In order to understand how plastic pipes are welded, the video on our website will give more detailed information. Thus, you will be able to do the work yourself if you have the necessary equipment.

More on this topic on our website:

- Welding of polypropylene pipes - process video Due to their low cost and ease of connection, plastic pipes occupy a leading position in the installation of thermal and plumbing systems. Compared to metal structures, polypropylene pipes ...

- Types of electrodes for welding - welding with electrodes on video The welding electrode is a metal rod of different lengths used in the process of welding parts from a wide variety of materials. Their main purpose is to supply electric current to ...

- Welding for beginners - video lessons Under the word welding, it is generally accepted to understand a technological process where, as a result of heating, intermolecular and interatomic bonds are established between parts. Thus, direct materials are connected. Mostly…

- Welding video tutorials - watch welding lessons with an inverter for beginner welders Beginners should watch welding video tutorials in order to avoid common mistakes and make their work quality and safe. You must always remember that…

Share with your friends on social networks a link to this material (click on the icons):

Welding instruction

If you chose polyethylene pipes, you acted wisely, but now they still need to be installed correctly. Let's learn

Basic Rules

Regardless of which technology you choose - electrofusion or butt welding of polyethylene pipes, you must adhere to such important principles:

- The elements to be joined must be compatible (both in composition and in physical parameters).

- Butt welding of polyethylene pipes can only be carried out if the parts have the same diameter and equal wall thickness.

- Edges should be thoroughly cleaned and degreased.

- The ends of the structures that are not involved in the connection process must be closed with plugs in order to avoid exposure to cold air, which adversely affects the process.

- During work, it is necessary to minimize the impact of the external environment, namely:

- in the heat, do not allow sunlight to reach the connection area;

- in windy weather, create a barrier to gusts of air;

- in cold weather, it is recommended to heat the room for work.

- During welding and cooling of the structure, exclude mechanical impact on the system.

And now let's consider in detail what the technology of welding polyethylene pipes is butt-welding and using the electrofusion method.

Photofragment of the electrofusion technique: attached heaters

Photofragment of the electrofusion technique: attached heaters

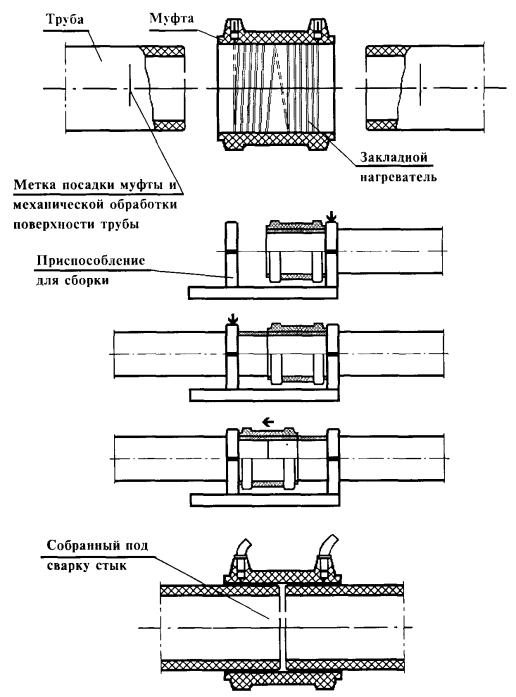

Electrofusion connection

This type of welding, also called thermistor welding, is used to fasten elements of different wall thicknesses and diameters, as well as to install non-pressure pipelines - drainage installations, gravity sewers, etc.

To connect using this technology, you will need special - electrofusion fittings. Now remember the order of work.

- Design the system.

- Calculate the required number of pipes and other parts.

- Make a purchase.

- Cut the structure into pieces of the length suggested by the plan. Make sure that the cut is straight, avoid the flow of molten material into the system.

- Prepare and clean parts, including couplings. It will not be superfluous to degrease the surface of the elements with alcohol, applying it to a piece of rag.

- If the surface of the elements is oxidized, remove the excess with a special scraper.

- Fasten the elements in the positioner, mindful of alignment.

- Wrap the joint with adhesive tape to prevent dust from entering.

- Close the open ends of the structures with plugs.

- Apply voltage to the clutch terminals.

- Wait until the elements, having warmed up, are held together.

Thermistor welding of polyethylene pipes should be carried out only if the connected elements are immovable. In the same position, the structure must remain until the seam has completely cooled.

This is what a splice setup looks like

This is what a splice setup looks like

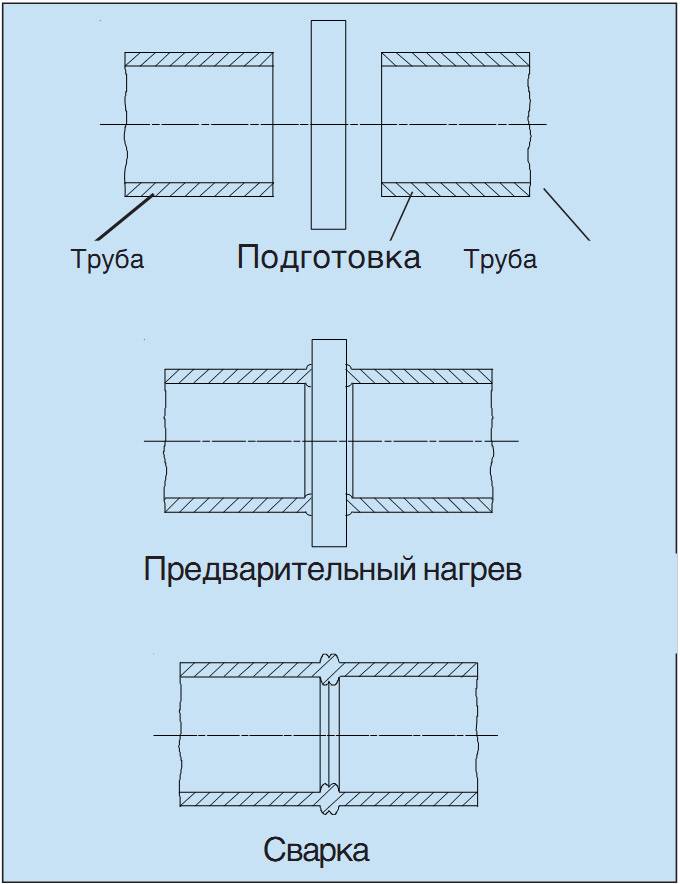

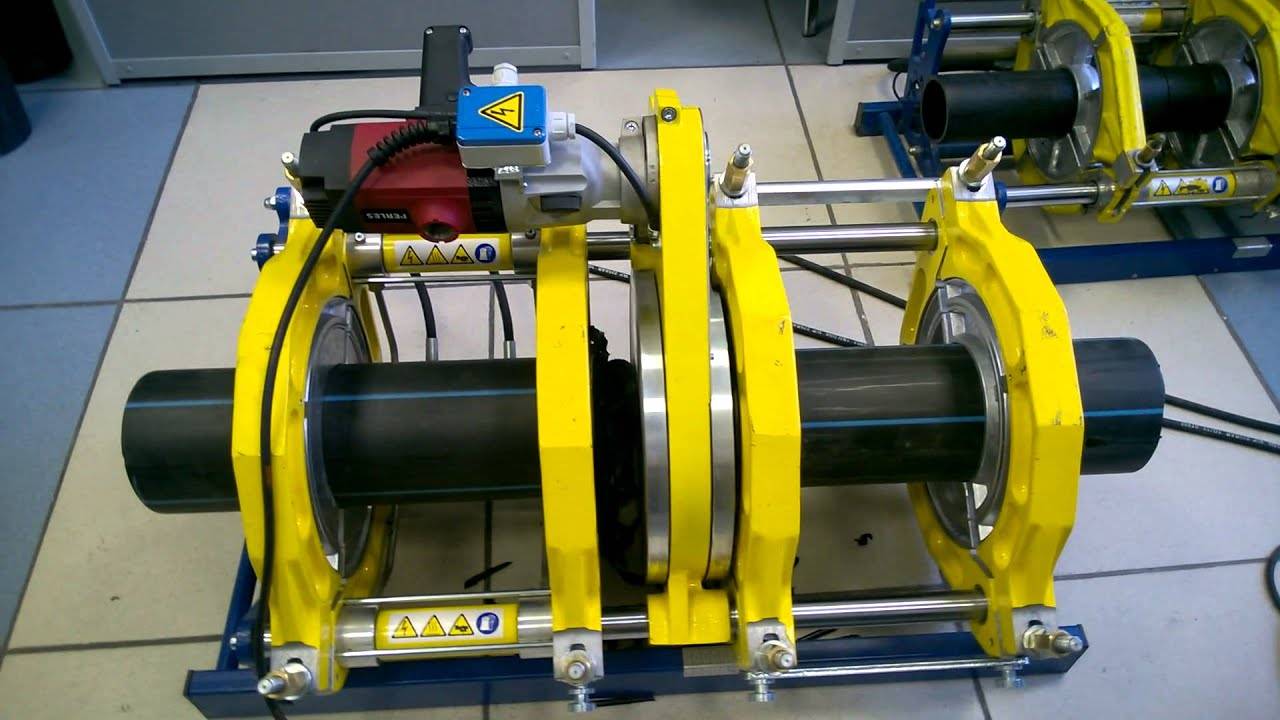

Butt welding

The technology and parameters of butt welding of polyethylene pipes are more interesting, since the elements are connected at the molecular level, forming a stronger seam. This method is used for mounting elements having a diameter of 50 mm and a wall thickness of 5 mm.

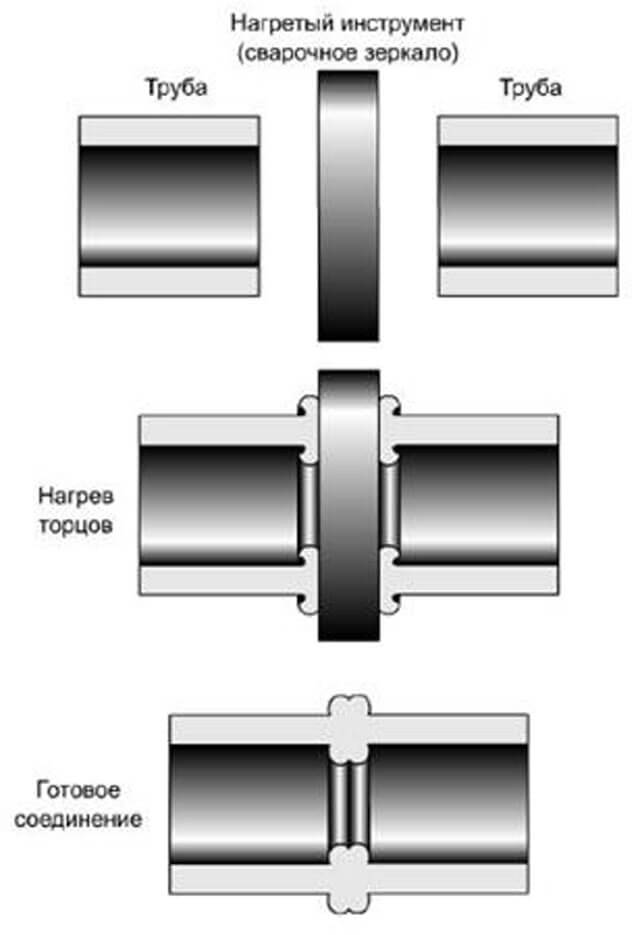

With this method, the edges of the products are heated with a special heating device, and then melted and in this state are joined, forming a single whole and a perfect seam.

The procedure for this type of welding up to point No. 7 is identical to the previous connection option (except that couplings are not required for work).

Table for determining the heating and cooling time of the elements to be welded

And then it differs and goes according to this “scenario”:

- insert the ends of the elements into the apparatus so that the heating plate is between them;

- press the edges against the plate and do not change the pressing pressure until the melting process;

- heat the elements, adhering to the norms (the table below for welding polyethylene pipes will help you with this);

- remove the plate and dock the ends, exerting uniform pressure on them;

- holding the knot, wait for the polyethylene to cool.

Bell technology

Soldering HDPE pipes can be done in several ways. There is nothing particularly complicated in these processes, but the welder must decide which method suits him best.

There is a socket connection technology. It is also sometimes called "coupling". Its essence lies in the connection of elements with the help of special devices - fittings. In addition to them, you will need equipment for work, namely a welding machine. You can choose a manual model for small products (up to 50 mm) or a mechanical one for large diameter polyethylene pipes (from 40 mm and more).

You also need to remember to prepare adapters or welding nozzles for work and various tools for cutting products.

When performing such welding, it is necessary to connect the outer part of the pipe to the inside of the fitting. Both of these surfaces are heated by a welding nozzle: a pipe is heated by a sleeve, and a fitting is heated by a mandrel.

The device for welding polyethylene pipes is quite expensive

The actual process of socket welding looks like this:

- The welding machine is heated to the required temperature;

- The fitting is stretched as much as possible on the mandrel, and at the same time, the end of the pipe is put on the sleeve until it stops (all this must be done very quickly);

- Due to the difference in the size of the parts, an extra layer appears, which, when heated, melts and crawls out in the form of a small roller, called a burr;

- The bead reduces the diameter of the pipes and thereby allows them to enter the welding nozzle and be aligned with the mandrel with the fitting;

- All parts must move into the heating nozzle until they stop, and upon reaching this moment, any pressure on them should be stopped;

- Further, all fragments are held in this position for the required time;

- After the end of the time, the fitting is removed, the pipe is removed from the nozzle and these parts are combined as much as possible;

- After the soldered fragment has cooled down, a second product must be welded into the other end of the fitting.

Diffusion method for soldering PE pipes

To date, polyethylene still does not have such authority as metal or metal-plastic, but in fact its strength and performance characteristics are no worse. Modern technologies at the production stage make it possible to make PE pipes of high quality and reliability. The most interesting way to weld them is diffusion, which does not require the use of special equipment. Even a beginner will be able to perform welding work in this way.

High and low pressure polyethylene (LDPE and HDPE) are one of the most popular polymeric thermoplastics, which are in the highest demand in organizing a wide variety of water supply, sanitation systems, etc. A distinctive feature of the polymer material is that when heated, it softens, since the interconnection of the chain of molecules with each other is lost. As it freezes, it regains its former strength, as if the transformation never happened at all. It is this feature that makes polyethylene an ideal material for welding on it. During the softening of the two products, they can be connected, which, after solidification, will lead to the most durable bond. A strong weld will be created between the two pieces.

PE pipes are welded at a relatively low temperature of 270 degrees Celsius, which greatly simplifies the task by choice of equipment and subsequent use.The operating time is extremely short (a few seconds for each stage) and can only be adjusted by changing the thickness of the pipelines.

How to bend or straighten a product

Polyethylene pipes are available for sale in straight 12-meter lengths or in the form of solid products wound on large coils. Being in a twisted state, the products take the form of rings and are deformed. Before straightening or bending a deformed HDPE pipe, it must be heated.

When assembling a pipeline, it often becomes necessary to straighten a twisted or, conversely, bend a deformed polyethylene pipe

Low density polyethylene is famous for its good elasticity. But it loses this property at a heating temperature above + 80 ° C. This moment is used if necessary to change the configuration of the product.

But it is worth remembering that for straightening or bending the temperature can only be increased for a short time period. After all, a polyethylene pipe belongs to the category of building materials that can be damaged if the temperature regime is violated.

Overview of pipe bending methods

It is easiest to straighten the pipe, eliminating the creases that arose during its storage and transportation, after the product is slightly heated. If the replacement or repair of the pipeline is carried out in the summer, when the sun's rays are as hot as possible, you can use them to achieve the task.

To straighten the HDPE pipe, you just need to leave it in direct sunlight for a couple of hours, firmly fixing the ends of the segment

UV rays will not worsen the operational parameters of polyethylene, but at the same time they will be able to soften the walls of the product for a while. You just have to fix the softened pipe along a rigid support or wall, or lay it in a pre-dug trench. Before you straighten the bent HDPE pipe on the ground, you need to clear the area.

If the work has to be done in winter, use hot water to heat the product. But this method is effective for pipes whose size does not exceed 50 mm. As aids for straightening, you can use metal railings and brickwork. In any case: the shorter the length of the product, the easier it will be to work with.

Effective methods to bend the workpiece

If the opposite situation arises when it is necessary to bend the HDPE pipe, all the same heat treatment is used. For warming up, the following methods are used:

- blown with hot directional air of a building hair dryer;

- warm the walls of the product with a gas burner;

- douse the surface with boiling water.

To simplify the bending procedure, it is better to build a molding frame. The frame, the size of which corresponds to the diameter of the bent pipe, can be made from ordinary fiberboard sheets. To make the surface of the frame smooth, sand it with a piece of sandpaper.

To bend the HDPE pipe with a hair dryer, the work is performed in the following sequence:

- The area to be treated is heated with a building hair dryer.

- The softened workpiece is deepened into the molding frame.

- Carefully bend the pipe, without applying excessive force so as not to break the product at the bend.

Having created the required bending angle, you need to leave the product until completely cooled and only then remove it from the frame.

To ensure uniform heating of the surface of a polyethylene product, the pipe must be constantly rotated around its axis, substituting various sections under the rays.

An important point: when heating the pipe, it is necessary to adhere to the "golden mean". If the surface is not heated enough at the time of bending, the pipe may break. If, at the time of heating, the heating element is brought too close to the product, the polymer may ignite.

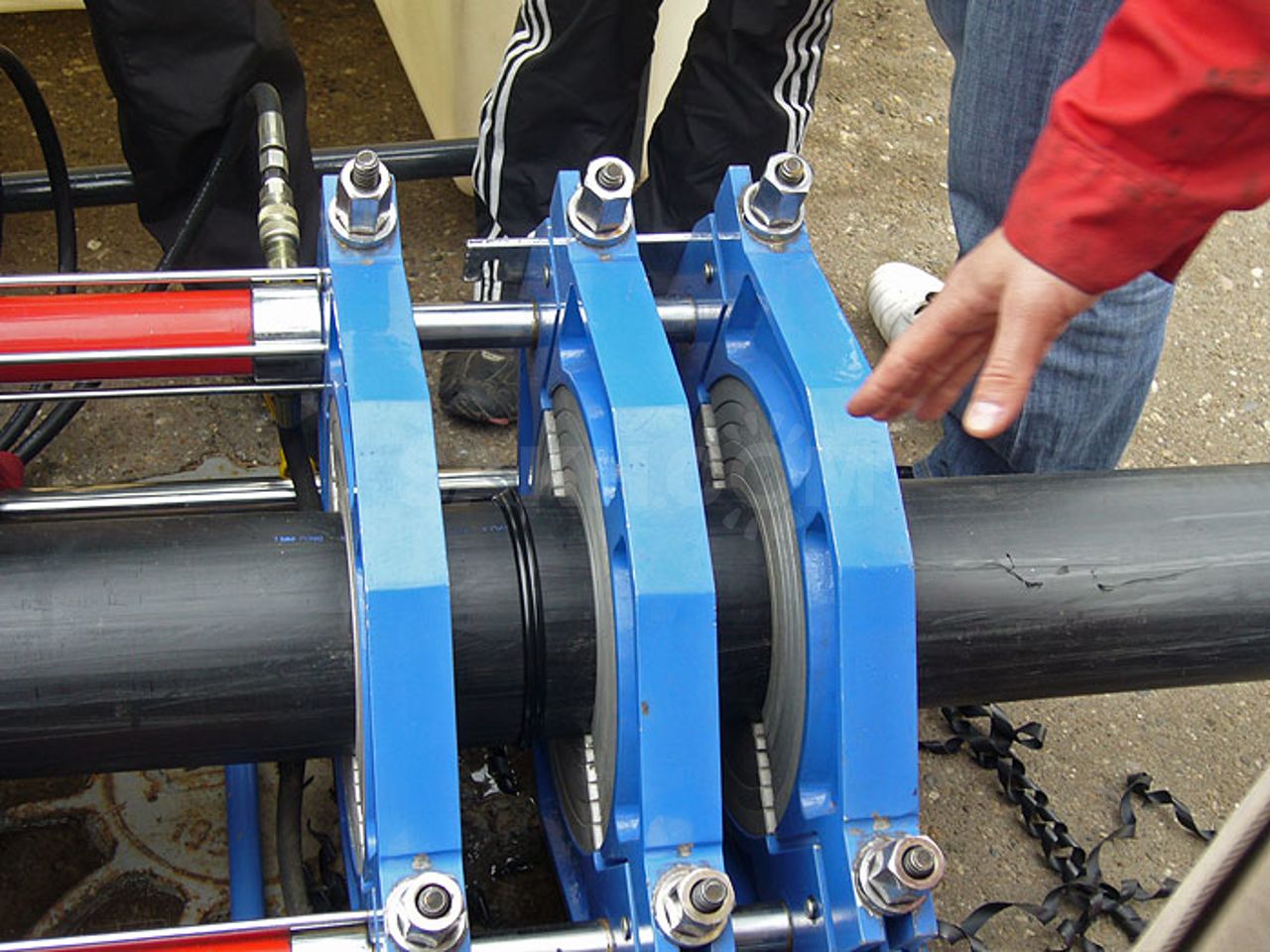

Butt welding

You can butt-weld HDPE pipes with your own hands. Butt welding is performed using special equipment with a mechanical or hydraulic drive. Such a welding machine will allow joining two elements of tubes until a complete and tight connection. The most popular devices are those that have software control. Such equipment is characterized by full automation and the ability to control the welding process without operator intervention in terms of physical effort.

Before doing work with your own hands, HDPE pipes with uniform technical characteristics should be selected. It is advisable to weld tubes even from the same batch. Since here the polymer is joined at the molecular level, this approach will make the welding seam more airtight and reliable.

The principle of butt welding is to heat the ends of the pipe on a special plate. After melting, the PE plate between the ends of the two pipes to be welded is removed and the elements are mechanically compressed until the polymer is completely mixed and soldered. After that, the pipes must be allowed to cool completely.

Description of PVC pipe welding methods

- So, for pipes with a cross section of 20 mm, the melting length (welding depth) will be 14.5 mm;

- Elements 25 mm - 16 mm;

- For tubes with a diameter of 32 mm - 18 mm;

- For tubes with a section of 40 mm - 20 mm;

- Pipes with a diameter of 50 mm - 23 mm.

Strengths of using electrofusion

Typically, electric couplings are used in cases where it is not convenient or practical to weld polyethylene pipes end-to-end. Most often this happens in sewer wells, narrow and inconvenient channels, installation pits in the base and walls of houses. Strictly speaking, electric couplings come to the rescue in cases where butt welding cannot be used.

Another advantage of this method of joining polyethylene pipes is its convenience in case of an accident or damage to the pipeline. As a rule, such situations require very quick troubleshooting. Welding HDPE pipes with electric couplings is characterized by considerable ease of implementation - in this case, no special knowledge is needed.

The ease of installation of the device is ensured by the presence of special holes on it. To determine the optimal temperature regime for docking on modern welding machines, the function of reading the required information directly from the barcode, which is equipped with electric couplings, is provided. The connection procedure is implemented with the simplest tools - a device for stripping the ends of the pipe, an electric coupling and a welding machine.