- METHODS FOR PRESERVATION OF BOILERS

- 4.3. WATER BOILERS

- 4.3.1. Preparation for conservation

- 4.3.2. List of monitored and recorded parameters

- 4.3.3. Instructions for carrying out work during conservation

- Tips and advice for care

- Installation in the heating system of the safety group

- Rules for the use of hot water boilers in a water heating system

- Recommendations for owners of solid fuel boilers

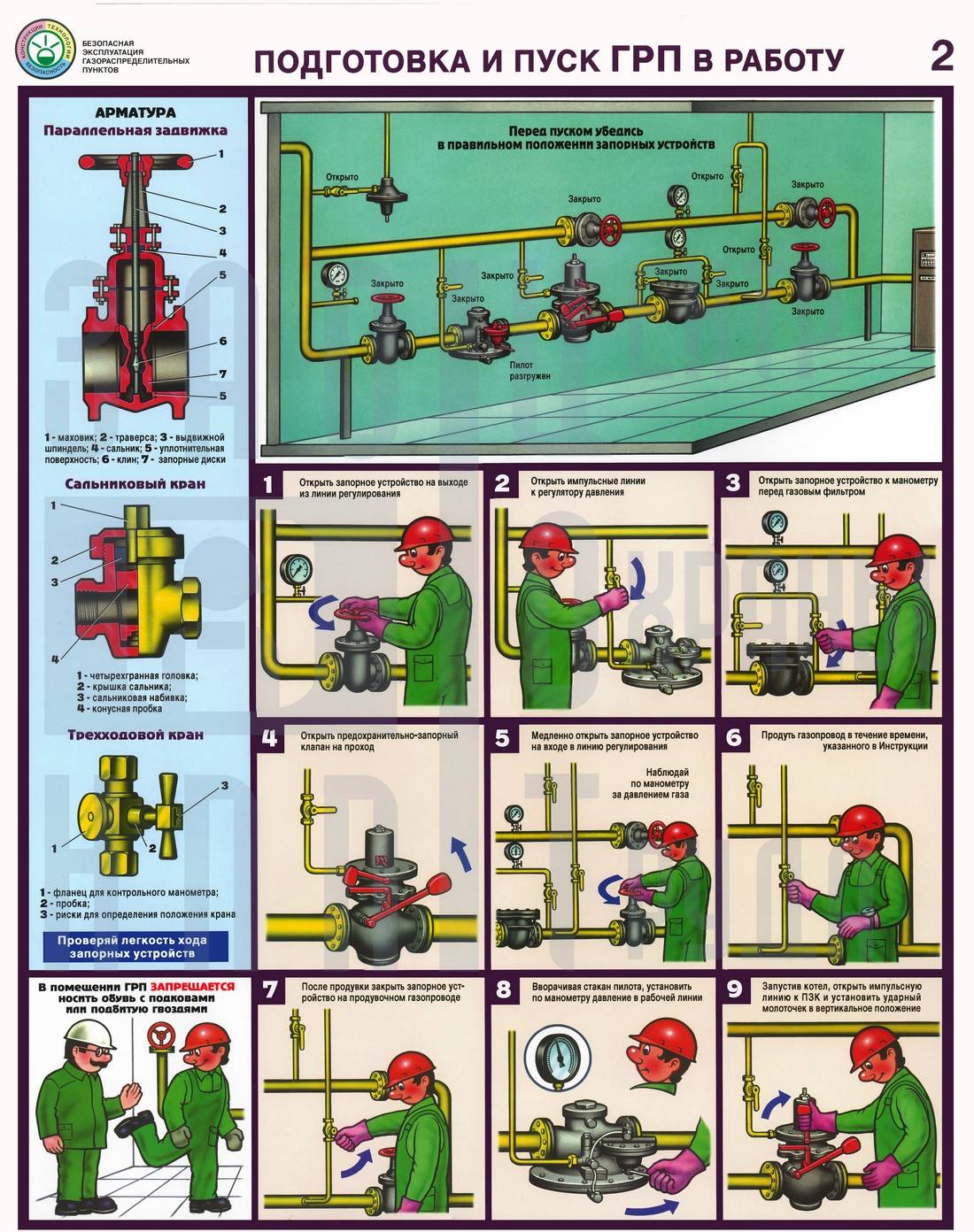

- Gas pressure regulation

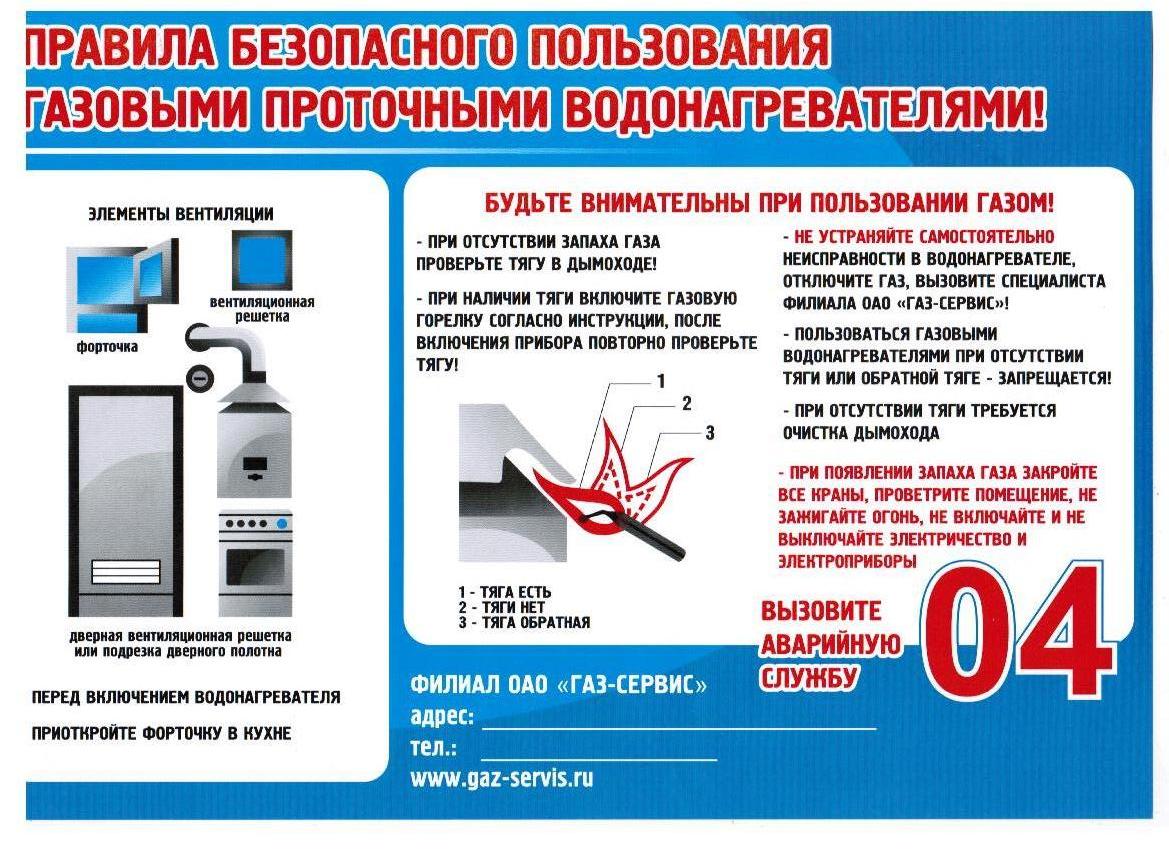

- What rules must be followed?

- What rules must be followed?

- Where do we start?

- Gas boilers

- 5.1. Option 1

- Checking gas equipment

METHODS FOR PRESERVATION OF BOILERS

If the boiler is stopped for a long time, then it is necessary to preserve it. When mothballing boilers, it is necessary to follow the instructions of the manufacturer's instructions for installation and operation.

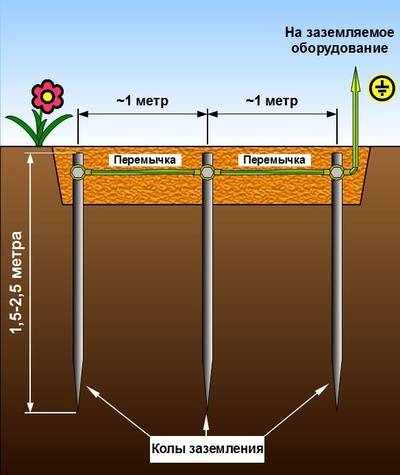

To protect boilers from corrosion, dry, wet and gas preservation methods are used, as well as, in some cases, conservation by the overpressure method.

The dry method of conservation is used when the boiler is stopped for a long time and when it is impossible to heat the boiler room in winter.Its essence lies in the fact that after removing water from the boiler, superheater and economizer and cleaning the heating surfaces, the boiler is dried by passing hot air (thorough ventilation) or a small fire is lit in the furnace. In this case, the safety valve must be open to remove water vapor from the drum and boiler pipes. If there is a superheater, the drain valve on the superheated steam chamber must be opened to remove the remaining water in it. After drying is completed, pre-prepared iron pans with quicklime CaO or silica gel (in the amount of 0.5-1.0 kg of CaC12, 2-3 kg of CaO or 1.0-1.5 kg of silica gel per 1 m3) are placed through the open manholes in the drums. boiler volume). Tightly close the manholes of the drum and cover all the fittings. When stopping the boiler for more than 1 year, it is recommended to remove all fittings and install plugs on the fittings. In the future, at least once a month, the state of the reagents should be checked, and then every 2 months, depending on the results of the check, it must be replaced. It is recommended to periodically monitor the condition of the brickwork and, if necessary, dry it.

Wet way. Wet preservation of boilers is used when there is no danger of water freezing in them. Its essence lies in the fact that the boiler is completely filled with water (condensate) with high alkalinity (content of caustic soda 2-10 kg / m Then the solution is heated to the boiling point to remove air and dissolved gases from it, and the boiler is tightly closed.The use of an alkaline solution ensures, at a uniform concentration, sufficient stability of the protective film on the metal surface.

gas method. With the gas method of preservation, water is drained from the cooled boiler, the internal heating surface is thoroughly cleaned of scale. After that, the boiler is filled with gaseous ammonia through the air vent and a pressure of about 0.013 MPa (0.13 kgf/cm2) is created. The action of ammonia is that it dissolves in the film of moisture that is on the surface of the metal in the boiler. This film becomes alkaline and protects the boiler from corrosion. With the gas method, the conservation personnel must be aware of the safety regulations.

The overpressure method consists in the fact that in the boiler, disconnected from the steam pipelines, the steam pressure is maintained slightly above atmospheric and the water temperature is above 100 ° C. This prevents air from entering the boiler and, consequently, oxygen, which is the main corrosive agent. This is achieved periodically by heating the boiler.

When the boiler is put into a cold reserve for up to 1 month, it is filled with deaerated water and a slight excess hydrostatic pressure is maintained in it by connecting it to a tank with deaerated water located above. However, this method is less reliable than the previous one.

With all methods of conservation of boilers, it is necessary to ensure complete tightness of the fittings; all hatches and manholes must be tightly closed; with dry and gas methods, idle boilers must be separated from working boilers with plugs. Preservation of equipment and its control are carried out according to special instructions and under the guidance of a chemist.

4.3. WATER BOILERS

4.3.1. Preparation for conservation

4.3.1.1.The boiler is stopped and drained.

4.3.1.2. Selection of conservation process parameters (temporary

characteristics, concentration of the preservative at various stages) is carried out

based on a preliminary analysis of the state of the boiler, including the determination

values of specific pollution and chemical composition of deposits of internal

boiler heating surfaces.

4.3.1.3. Before starting work, analyze the scheme

conservation (revision of equipment, pipelines and fittings used in

conservation process, instrumentation systems).

4.3.1.4. Assemble a scheme for conservation,

including boiler, preservative dosing system, auxiliary

equipment, connecting pipelines, pumps. The diagram should represent

a closed circulation loop. In this case, it is necessary to cut off the circulation circuit

boiler from the network pipelines and fill the boiler with water. For emulsion supply

preservative in the preservation circuit, an acid line can be used

boiler flushing.

4.3.1.5. Pressurize the conservation system.

4.3.1.6. Prepare the required for chemical

analyzes of chemicals, utensils and instruments in accordance with the methods of analysis.

4.3.2. List of controlled and registered

parameters

4.3.2.1. During the conservation process

control the following parameters:

— boiler water temperature;

- when the burners are turned on - the temperature and pressure in the boiler.

4.3.2.2. Indicators for p. register every hour.

4.3.2.3. Record the start and end times of input and

preservative consumption.

4.3.2.4. Frequency and scope of additional chemical control

in the process of conservation are given in the table.

4.3.3.Instructions for carrying out work during conservation

4.3.3.1. By means of an acid wash pump (NKP)

circulation is organized in the boiler-NKP-boiler circuit. Next, heat the boiler up to

temperature 110 - 150 °C. Start dosing preservative.

4.3.3.2. Set the calculated concentration in the circuit

preservative. Depending on the results of the analyzes, carry out periodic

preservative dosing. Periodically (every 2-3 hours) purge

boiler through the drains of the low points to remove the sludge formed during the

preservation of equipment. Stop dosing during purge.

4.3.3.3. Periodic kindling of the boiler is necessary

maintain in the working circuit the parameters required for conservation

(temperature, pressure).

4.3.3.4. Switch off the system after the end of conservation

dosing, the recirculation pump remains in operation for 3 to 4 hours.

4.3.3.5. Turn off the recirculation pump, switch the boiler to

natural cooling regime.

4.3.3.6. In case of violation of technological parameters

stop the conservation process and start conservation after restoration

boiler operating parameters.

Tips and advice for care

Competent maintenance of the boiler, performed regularly, will help keep it in working condition for a long time and avoid various accidents and accidents. Otherwise, the unit may break down even in the first year of operation. Performing several operations will prevent the following outcome of events:

- even during normal operation of the boiler, you need to contact one of the organizations that carry out work in this area, so that the master inspects the device for gas and water leaks, the condition of the sensors and the chimney, and, if necessary, makes repairs;

- it is always necessary to control the water pressure inside or at the outlet of the system. If it falls below 0.8 bar, then water must be added;

- water is usually added to the system directly through the boiler, where there is a special tap. In this case, the pressure of the added water must be greater than the pressure of the water from the boiler. The refilled water should only be cold (up to 35°C).

Depending on the model and manufacturer, this process will be slightly different due to design differences. It is possible to clarify this in the instructions that came with the device.

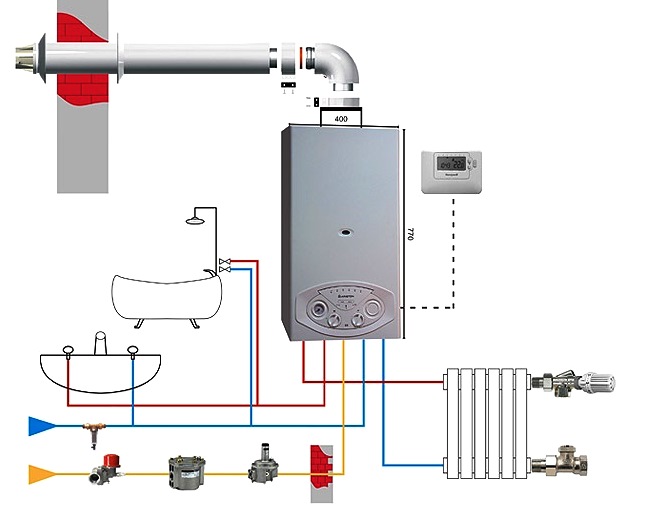

Installation in the heating system of the safety group

In the simplest case security group for the boiler is a showing pressure gauge and a relief (safety) valve. The meaning of installing a safety group is that in the event of an emergency increase in pressure in the system, the safety valve opens when the permissible pressure is exceeded, and the coolant is released from the system. As a result, the pressure in the system decreases and the destruction of the boiler is prevented. In most cases, you can buy a ready-made (factory-made) security group, but you can also make it yourself. The latter will be most relevant for owners of Russian boilers, since it is not easy to buy a factory safety group for a pressure of 1.5 atm. But the photo below shows the safety group that I made and used in my heating system.The installation location of the safety group in the system is immediately behind the boiler (above the boiler).

If you are engaged in modernization on your own, the total costs will not exceed 3-5 thousand rubles, and you can perform work in the summer, when the heating system is not in use. The life of my heating system is about six years. During this time, the following issues emerged:

1. The safety valve leaked, almost in the first week of operation, it was replaced in the store with a new valve (factory marriage). 2. About a year after commissioning, the automatic air vent became clogged. Replaced in the summer with a Mayevsky manual crane. The reason is most likely the wrong choice of containers for collecting and preparing rainwater. 3. Due to large power surges, the gas pollution control system in the boiler room burned out. The case, of course, is non-warranty. I had to buy and install a voltage stabilizer for two outlets and re-buy a gas control system.

There were no other problems associated with the operation of the heating system. For the first year the boiler was operated on solid fuel, currently it is running on natural gas.

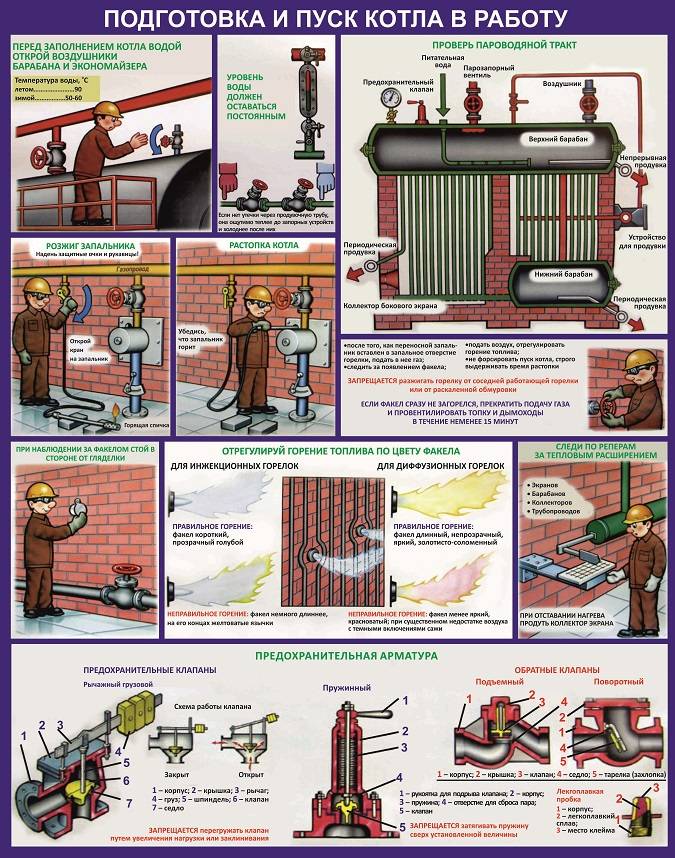

Rules for the use of hot water boilers in a water heating system

The basic rules for the installation, installation and operation of the boiler, as a rule, are prescribed in the instructions. Currently, the choice of boiler equipment is quite large and diverse, and it is almost impossible to take into account all the nuances in one article. Based on my personal experience, as well as the experience of my relatives and friends, I consider it necessary to note a number of general points that can help the proper operation of equipment and heating systems.

one.The first and simplest thing to do, no matter how ridiculous it may seem to you, is to write instructions for the correct use of the boiler and heating system and place it in the room where this equipment is installed. It is far from a fact that only you personally will operate the system, nor is it a fact that all your close relatives are well versed in the nuances of the design and operation of the heating system. This is especially true if gas boiler equipment is used, since erroneous actions can lead to the most unpredictable consequences. 2. Secondly, it is necessary to regularly monitor and monitor the operation of the heating system for the simple reason that certain deviations in the operation of the system can promptly signal to the owner that something is wrong. Unfortunately, I have come across such cases when the owner not only does not know (does not monitor) the operation parameters of his equipment, but does not even have elementary concepts about it.

Recommendations for owners of solid fuel boilers

The main danger in this case is:

1. Boiling water in the boiler and burning the walls of the boiler. This is usually due to the fact that the norms for loading solid fuel into the boiler furnace, prescribed in the passport for the boiler, are violated, and the thermal regime of the boiler is not controlled. 2. The occurrence of smoke or fire. This happens when the chimney is cleaned from time to time. The main danger is that during the combustion of solid fuels, soot forms on the walls of the chimney. In the most "simple" case, it makes it difficult to remove flue gases into the atmosphere, which can disrupt the correct operation of the boiler itself.In this case, there is a danger to the residents of the house (in case of smoke in the dwelling). In addition, if soot ignites, the combustion temperature of which is very high, a fire in the house itself is possible. Therefore, the chimney must be cleaned regularly, at least once a year, before the start of the heating season.

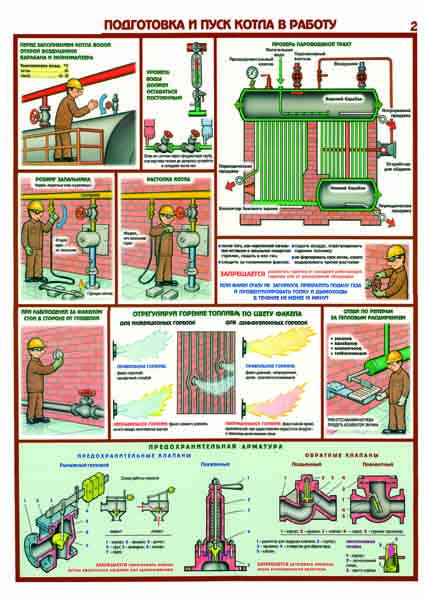

Gas pressure regulation

Measuring and adjusting the minimum and maximum gas pressure will allow not only to achieve the correct operation of the boiler, but also to save money. The exact pressure range is indicated in the instructions. For wall-mounted boilers, it is at least 2 mbar. The maximum pressure is 13 minibar.

If there are no errors, start the gas boiler and open the gas valve. Using a differential pressure gauge, we measure the minimum gas pressure in the system. To measure the maximum possible pressure, turn on the boiler in the “chimney sweep” mode and check the pressure in this mode. If necessary, adjust the pressure to passport values.

What rules must be followed?

When carrying out measures for the conservation of boilers in production, they are guided by the requirements set forth in RD 34.20.591-97 "Guidelines for the conservation of thermal mechanical equipment".

The same rules should be observed by the owners of equipment installed in private homes.

If you are unsure of your knowledge or skills, please contact your service organization. Specialists will carry out work to stop the boiler and preserve the equipment in compliance with all safety requirements

What you need to remember if you decide to preserve heating or hot water equipment yourself:

- Before any repair work, turn off the gas. The main valve is installed at the entrance of the gas pipeline to the house.

- Even the slightest ingress of oxygen into the system will cause corrosion of the boiler parts and pipelines, so you need to choose one of the preservation methods and follow it strictly according to the instructions.

- When working with chemicals, it is necessary to protect parts of the body with tight clothing, wear comfortable shoes, gloves and a mask.

- To keep the pipes and components of the unit in working condition, it is necessary to observe the dosage when diluting concentrated formulations and dry chemicals.

- Work with explosive or combustible substances may only be carried out by specialists.

- At the end of the work, it is necessary to turn off the power supply of additional equipment - for example, a pump.

The above rules must be followed to protect your own health and preserve the equipment.

After a long stay of the heating and hot water system, depreservation will be required - a process that also requires compliance with certain rules.

What rules must be followed?

When carrying out measures for the conservation of boilers in production, they are guided by the requirements set forth in RD 34.20.591-97 "Guidelines for the conservation of thermal mechanical equipment".

The same rules should be observed by the owners of equipment installed in private homes.

If you are unsure of your knowledge or skills, please contact your service organization. Specialists will carry out work to stop the boiler and preserve the equipment in compliance with all safety requirements

What you need to remember if you decide to preserve heating or hot water equipment yourself:

- Before any repair work, turn off the gas. The main valve is installed at the entrance of the gas pipeline to the house.

- Even the slightest ingress of oxygen into the system will cause corrosion of the boiler parts and pipelines, so you need to choose one of the preservation methods and follow it strictly according to the instructions.

- When working with chemicals, it is necessary to protect parts of the body with tight clothing, wear comfortable shoes, gloves and a mask.

- To keep the pipes and components of the unit in working condition, it is necessary to observe the dosage when diluting concentrated formulations and dry chemicals.

- Work with explosive or combustible substances may only be carried out by specialists.

- At the end of the work, it is necessary to turn off the power supply of additional equipment - for example, a pump.

The above rules must be followed to protect your own health and preserve the equipment.

After a long stay of the heating and hot water system, depreservation will be required - a process that also requires compliance with certain rules.

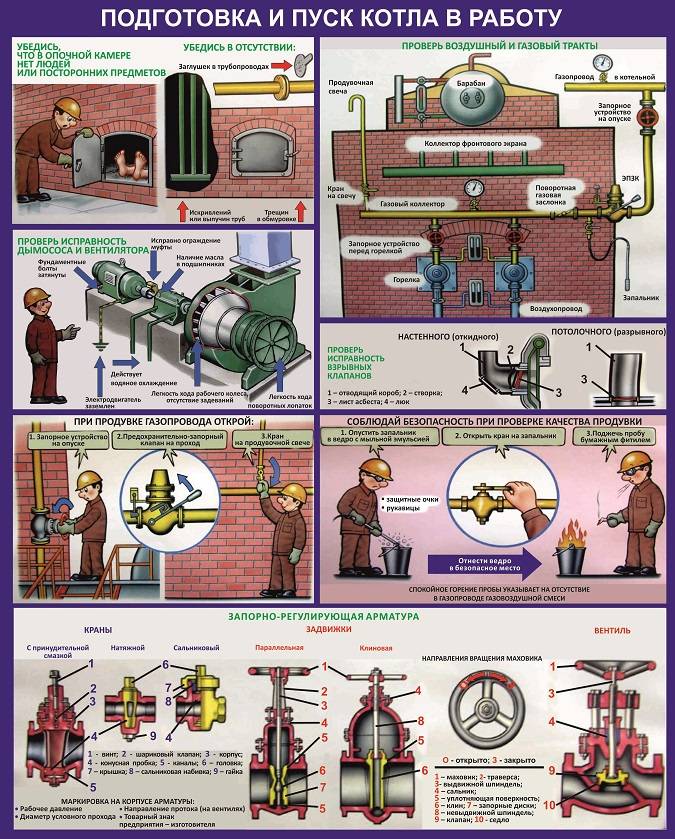

Where do we start?

A household gas boiler is a powerful and productive device designed to heat the coolant and run the heated liquid through the heating system of the house. Modern boilers heat not only batteries, but also tap water in large volumes, have electronic control and various security mechanisms.

When buying a boiler, you should pay attention to the heating area, so that it is slightly larger than your living space.

Naturally, you have already installed the unit itself and completed all the necessary connections and piping of the heating system.We checked the chimney and draft, as well as the device itself for proper operation and the absence of leaks. This stage of work, as a rule, takes place in the presence of employees of the gas industry, who carefully record all the results and "give the go-ahead" to the use of this device.

Before starting the boiler itself, it is necessary to fill the heating system - pipes and batteries, with a coolant, that is, with water. To do this, unscrew the valve at the bottom of the boiler. For different models of boilers, the “appearance” of this supply valve may be different, but it cannot be confused with anything. In extreme cases, check the instructions for your device.

Having opened the valve, we will begin to supply water to pipes and batteries. Be sure to control the pressure level, we are waiting for a mark of 2 - 2.5 atm. This indicator can be measured using the pressure gauge built into the boiler.

When the desired pressure inside the system is reached, it is necessary to bleed the air that may remain inside the batteries and pipes. Air locks significantly worsen the heat dissipation of your battery, is this the result you achieve?

To quickly and efficiently bleed air, it is necessary to unscrew the Mayevsky taps on each battery. At first, you will hear a whistle or hiss - this is normal. If water starts to run from the radiator, it means that there is no air lock here.

When you check all the heating appliances - see what the boiler pressure gauge now shows. It is likely that the pressure will drop a little and you will need to feed the heating system with water.

But in addition to plugs in the pipes, the air inside the circulation pump can interfere with the normal operation of the boiler. This is easy to fix.Some models are equipped with an automatic air release system, but as a rule, this is not effective enough, so it is better to get rid of the air manually for the first time.

To do this, remove the front cover from the boiler body, then look for the pump itself - a cylindrical part with a plug for a flat screwdriver. Sometimes, the pump is located behind the dashboard, which is easily moved or removed from the gates. To release air from the pump, plug the boiler into the socket and start heating the water. The boiler will start up. The pump will also begin to turn on in the working process - this will be confirmed by incomprehensible gurgling sounds inside the unit - do not be alarmed, this is air. We take a flat screwdriver and slowly unscrew the plug. When water flows, we twist the plug back. This procedure should be carried out several times. When you stop hearing the gurgling of water inside the appliance, and your gas boiler starts working, it means that you managed to get rid of the air inside the pump completely. At this stage, you should again check the pressure gauge readings with the instructions for the device. In principle, you can stop there - now your boiler will heat water inside the radiators, and if it is a double-circuit unit, then in the water supply.

But it will not be superfluous to carry out pressure testing and flushing of the heating system. After these procedures, you will be 100% sure that the inside of the radiators is clean and your heating system has no leaks.

Gas boilers

A gas boiler should be selected if there is a gas pipeline passing nearby. Gas is often the most popular and cheapest type of fuel in our country.It should be noted that about half of all heating boilers installed in the Russian Federation use this fuel. For this type of boiler, you can use liquefied gas in cylinders, but this will increase the cost of its operation, due to frequent refueling. This heating option can be taken into account when designing, as a spare. A high level of efficiency allows you to heat houses with a large quadrature. Gas boilers are easy to use and consume economical fuel, this is its indisputable advantage.

One of the rules for operating boiler rooms sounds: To install a gas boiler, you need to obtain permission from Gazgortekhnadzor, which is not so easy to do. It will be necessary to obtain not only permission to install, but also to achieve agreement and pay a fee. When arranging such a boiler room, it is necessary to use the services of specialists in the design and installation of the chimney, since the safety of the structure itself depends on it. The room in which the boiler will be located must be equipped with an exit to the street and have good ventilation. Otherwise, the gas boiler may smoke.

Basic rules for the operation of boiler rooms with a gas boiler:

- The presence of a separate room (boiler room);

- the boiler room must be at least 4.5 m2 in area, with a ceiling height of 2.5 m and above;

- the chimney must be made of acid-resistant and heat-resistant material;

- the upper edge of the chimney (head) must be raised above the level of the roof ridge by at least half a meter;

- horizontal sections of the chimney pipe should not exceed 1 m in length;

- the width of the entrance doors is made at least 80 cm;

- be sure to equip the room with a sufficient ventilation hole;

- it is necessary to have natural lighting at the rate of at least 0.3 m2 per 10 m2 of the boiler room area;

- the presence of a gas analyzer is a must, as it is responsible for analyzing the environment and controls the gas content of the air in the room. In case of exceeding the norm, it automatically blocks the gas supply to the boiler.

- the boiler must be located at least 20 cm from the nearest walls, the surface of which must be protected with fire-resistant material.

5.1. Option 1

5.1.1. The most favorable conditions for

conservation of the turbine is the combination of the regular mode of wet-steam washing

turbine flow path (where provided) with simultaneous dosing in

steam preservative or by dosing an aqueous emulsion of preservative in

slightly superheated steam in front of the turbine with condensate discharge (by open circuit

scheme).

5.1.2. Volumetric steam passes are selected from the conditions

maintaining reduced turbine rotor speed (taking into account critical frequencies).

5.1.3. The temperature of the steam at the turbine exhaust

maintained at least 60 - 70 ° C.

Checking gas equipment

According to the requirements of the housing code, to prevent accidents, possible leaks and failure of gas equipment, technical services conduct regular checks. The owner of the accommodation is obliged to provide employees with unhindered access to examine the condition of the devices.

For the safe operation of gas equipment available in residential buildings, test standards have been established. Gas stoves should be checked every three years, boilers and water heaters once a year.Faulty and obsolete equipment must be replaced in a timely manner.

Tenants are notified in advance in writing about the time of equipment inspection. This deprives the homeowner of the opportunity to challenge the violations identified as a result of the inspection.

During the inspection, experts must:

- check the tightness of the fasteners in the places of all joints;

- make sure that there are no leaks in places where the gas pipeline connects to the gas shut-off point (if necessary, a liquid pressure gauge can be used);

- make a visual inspection of the chimney and hood in residential buildings;

- check the quality of gas supply to stoves and water heaters;

- if necessary, adjust the intensity of the supply of blue fuel;

- check the operation of automation and electronic devices.

In case of detection of serious violations, the service organization repairs the equipment, replaces gas valves, pipeline sections. If breakdowns and emergencies occurred due to the fault of the owners, the gas supply may be stopped.

Other possible reasons for shutting off the gas supply:

- the user independently carried out the installation of gas equipment (additional equipment);

- upon detection of malfunctions (poor ventilation, lack of exhaust, insufficient gas concentration);

- illegal connection to the gas supply network;

- an emergency has occurred;

- during the repair of gas communications or equipment;

- in the absence of an agreement with the gas service;

- the debt for the used blue fuel exceeds two settlement periods;

- the consumer does not transmit data on the actual volume of gas used and interferes with the work of regulatory authorities;

- equipment is used that is not specified in the contract.

20 days before disconnection from the gas supply, the consumer must be informed by the gas service with which the service contract has been concluded. The notice must come in writing with a detailed explanation of the reasons.

If an emergency occurs, the gas is shut off without warning

The total shutdown of gas per month for the purpose of repair work is 4 hours. If this condition is violated, for each extra hour the amount of payment for blue fuel should be reduced by 0.15%.

In case of an emergency shutdown, the gas can be shut off without warning for a maximum of a day. Gas is supplied within 48 hours. If the subscriber is disconnected gas for non-payment, the first notification is sent to him 40 days in advance, and the second 20 days before the outage.

About where, to whom and how to complain about representatives of GorGaz is detailed in the following article on this important issue.