- Which pipe cutter to choose, mechanical or electric?

- 2 Kraftool 23410-42

- Pros and cons of electric models

- Device and characteristics

- Material

- Dimensions and weight of pipe cutters

- DIY pipe cutter

- Principle of operation and device

- How to choose a pipe cutter for cutting polypropylene pipes

- Technical specifications

- Frame

- What could be the blade

- Mini pipe cutters for copper pipe

- Which pipe cutter is better to buy

- Manufacturing materials

- Selecting the type of tool

- Roller pipe cutters

- Chain pipe cutters

- Guillotine pipe cutters

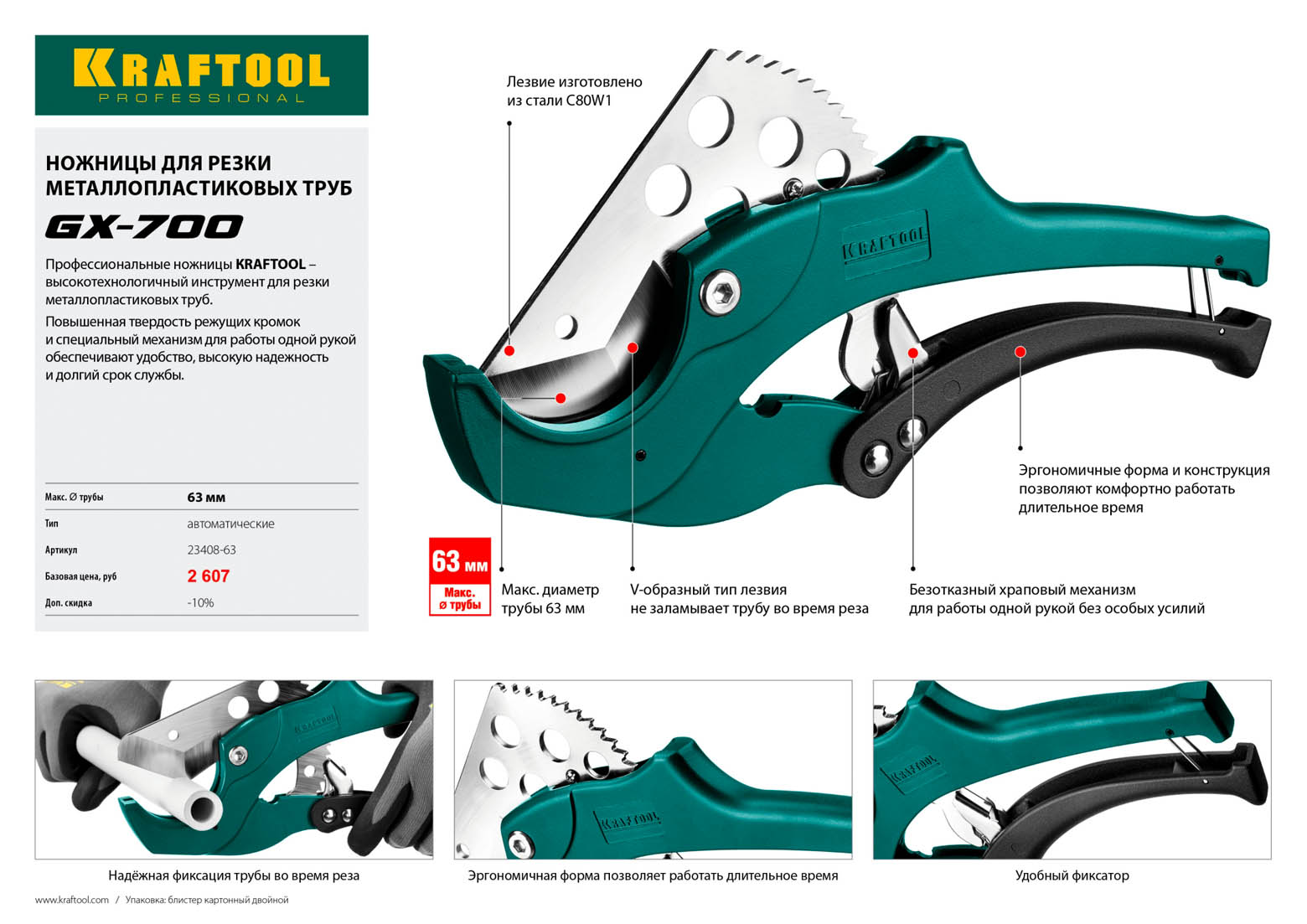

- Ratchet pipe cutters

- Selection principles

- Advantages and disadvantages

- Manufacturers and cost

- How to cut plastic pipes

- Preparation and cutting of steel pipes

- How to cut small diameter pipes

- Cutting steel pipes of large diameter

- Types of tools

- Wall thickness

- Design features

- Operating principle

- How to choose

- Purpose of the tool

- Making a pipe cutter with your own hands

- What you need to work

- Conclusions and useful video on the topic

Which pipe cutter to choose, mechanical or electric?

When it is planned to carry out installation work on laying pipes on your own, you cannot do without a cutting tool. Therefore, the question of which device is better to purchase, mechanical or electric, is quite relevant.

Cutting pipes with a reciprocating saw. Using a manual guillotine pipe cutter at home.

For work in an apartment, a compact manual mechanical pipe cutter is more suitable, which can be used in small spaces. This will allow cutting pipes directly at the place of their further installation.

In order for the assembly of the pipeline line to be of high quality, any of the pipe cutter models must be learned to use. Therefore, before making a “fine cut”, you should fill your hand a little on a piece of pipe. The cost of polypropylene pipes is low, and you can always afford to buy an extra meter for such a workout, and indeed - just in case. Such an “optional” will help you understand the principle of operation, as well as get at least a small, but for a beginner, invaluable preliminary experience before starting installation.

2 Kraftool 23410-42

Studying the market of pipe cutters, you quickly realize that there is a leader here, which is unlikely to be beaten by anyone. And now he is in front of us. This is a popular German brand, and in its arsenal there are more than a dozen types of different pipe cutters, both scissor and circular type. It is impossible to choose the best option among them, since, regardless of the model, they are all of the highest quality and reliability.

For example, this model has a hardened blade that does not require sharpening and is practically not dull. Very durable tool that does not require replacement modules for many years

The manufacturer pays special attention to ergonomics, and in fact, all of its models differ only in the convenience of the form factor. They always have rubber inserts on the handles, which prevent slipping out of the hands, and convenient locking mechanisms.

Without any dangling brackets and other inconveniences. But the downside here is the price. The tool is quite expensive and it hardly makes sense to buy it for rare home use.

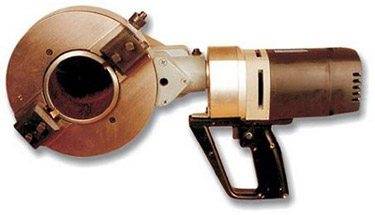

Pros and cons of electric models

Many professional craftsmen prefer manual pipe cutters when it comes to working with copper pipes. Meanwhile, in addition to manual models, there are more technically advanced electric devices.

In this case, the electric drive receives energy either from the built-in battery or from the network. That is, the tool does not lose its mobility properties, which is already an attractive point.

Another new addition to the copper cutter group is the electric pipe cutter. The design is quite convenient, significantly reduces the cost of the user's physical energy. For a quality result requires experience

Another new addition to the copper cutter group is the electric pipe cutter. The design is quite convenient, significantly reduces the cost of the user's physical energy. For a quality result requires experience

The cordless tool is equipped with the mechanism of automatic capture of material. The range of pipe diameters available for the cordless pipe cutter is 12-28 mm. On the body of the device there are elements of illumination, which ensures the convenience of cutting in conditions of poor visibility.

An electric pipe cutter, of course, significantly reduces the physical burden of the user. All that is required for the owner of such a device is to hold the device weighing 1.5 kg in the desired position for several seconds in the cut mode. For example, the MILWAUKEE C12 model, at a working speed of 500 rpm, cuts a piece of pipe with a diameter of 12 mm in three seconds.

But the high cutting speed, and even in automatic mode, somewhat limits the quality indicators. So, the device does not allow cuts of copper pipes shorter than 12-15 mm, according to the instructions.

Such short pieces of copper pipe should not be cut with an electric pipe cutter. Failure to comply may result in tool breakage and risk injury to the user.

In the absence of experience with an electric pipe cutter, it is rarely possible to get a perfect cut due to the presence of vibrations from the engine. Finally, the working mechanism of the electric pipe cutter creates noise at a level of 70 dB (the norm for permissible noise according to SNiP is 55 dB).

Therefore, for craftsmen (especially in the field of refrigeration), manual pipe cutters look like the best tool with all the advantages of electric models. The cutter of manual use gives the master the opportunity to “feel” the course of the blade, set the optimal speed and depth of penetration into the body of the pipe.

As a result, the cut is even and of high quality, ideal for creating rolling or soldering.

Device and characteristics

Structurally, different types of pipe cutters differ markedly from each other, but at the same time they have only two operating principles:

Orbital cutting, when the part is fixed motionless, and the tool wraps around it and turns, due to which the cutting part moves in a circle, forming a furrow deepening with each revolution until the workpiece is divided into two parts

With this method, it is important to leave enough free space at the point of cutting along the diameter of the pipe for the movement of the tool. This principle of operation makes it possible to cut pipe material in confined spaces directly on the installed pipeline.

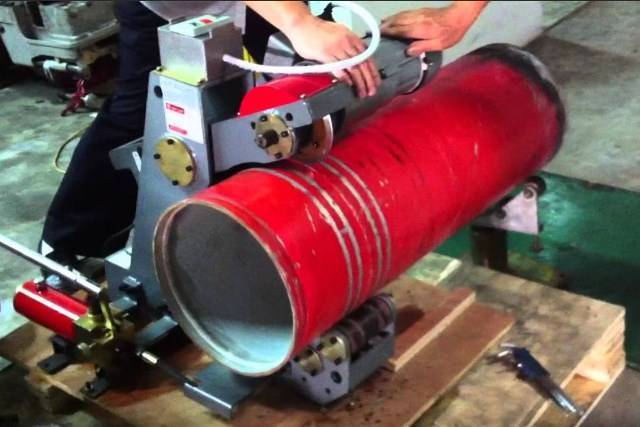

The pipe cutter is in a fixed position, that is, it is permanently installed, and the part itself rotates about the longitudinal axis.For these purposes, a special machine is often used.

The method is used, for example, in the mass production of pipe material, or with a large pipeline diameter.

For these purposes, a special machine is often used. The method is used, for example, in the mass production of pipe material, or with a large pipeline diameter.

From both principles of operation, it can be concluded that a pipe cutter is a kind of tool or mechanism with a body of a specific shape for fixing on a pipe or gripping it.

In most cases, the body resembles a clamp, on the opposite side of which there is a cutting element that performs two functions: directly cutting the material and pressing the body as tightly as possible to the part, resting against it from the opposite side.

At least that's what most manual pipe cutters look like for working with metal blanks.

Material

Depending on the type of pipe cutter, its body can be made of aluminum, zinc alloy, tool steel or impact-resistant plastic.

To ensure corrosion resistance, metal tools are coated with chrome or powder paint resistant to mechanical damage.

A steel pipe cutter is often assembled from parts, some of which are additionally hardened.

This is done for greater stability of rubbing or maximum loaded nodes.

At the same time, the chrome-plated tool easily tolerates high humidity, is resistant to wear, corrosion, and, in addition, has an attractive appearance.

The cutting elements of the pipe cutter are made mainly of high-speed, tool and alloy steel.

Dimensions and weight of pipe cutters

The dimensions of any pipe cutter primarily depend on its design and the maximum diameter of the pipes for which it is intended to cut.

So, for example, scissors for 42 mm products weigh an average of 300 - 500 g, and their length is 250 - 350 mm.

For electric models, the dimensions and weight additionally depend on the power of the installed engine and the mechanism for fixing pipe fragments.

In this case, the indicators are completely individual.

DIY pipe cutter

Consider how to make a pipe cutter for steel and other types of pipes with your own hands. Homemade pipe cutting tools are not uncommon. Craftsmen make pipe cutters from improvised materials, uselessly lying around for years in garages. And many adapt a grinder for this purpose (a pipe cutter from a grinder with their own hands), resulting in a kind of cutting machine.

Aerobatics - making a plasma pipe cutter.

Truck flywheels, Bendix gears and plasma cutters serve as the basis for this design. But for the manufacture of this monster, metalworking machines are needed, so it is difficult to build it in the garage.

Homemade cutting machine

But there are also the simplest models of self-made pipe cutters, for the manufacture of which materials are used that are abundantly available in the home workshop of a thrifty owner.

A do-it-yourself pipe cutter is quite tolerably used for harvesting pipe segments in small volumes.

Principle of operation and device

For a long time, people used a hacksaw to cut metal pipes. The resulting cuts were uneven, installation difficult.To make quality cuts, work faster, a pipe cutter was developed. There are two principles of this tool:

- The pipes are fixed in a vice, cut to the intended size. In this case, the cutting edge of the tool rotates around the surface of the fixed part.

- The tool is fixed motionless, the pipe rotates with the help of a special machine. This principle of operation is typical for industrial models.

The device of pipe cutters depends on the type of tool.

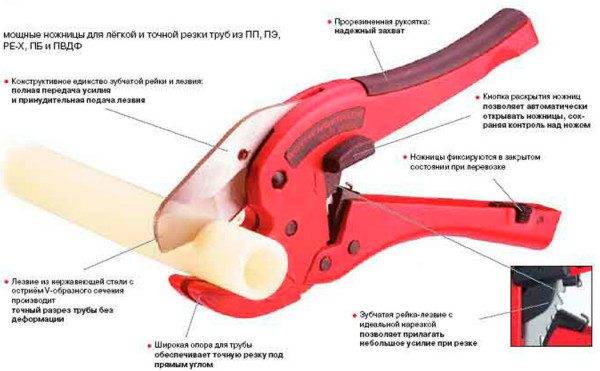

How to choose a pipe cutter for cutting polypropylene pipes

For home use or for occasional use, a mechanical pipe cutter is usually taken to cut pipes. The design is chosen at the same time so that it is "cheap and reliable." Most often they buy a pipe cutter with a ratchet. In principle, a justified choice. They also work with beginners. You just need to choose the right model.

Important structural components of the pipe cutter

In general, the following recommendations can be given for choosing the type of pipe cutters. A thin-walled pipe without reinforcement from any material is cut with a pipe cutter of normal quality or with scissors, regardless of the design. Restrictions on diameter - 32 mm, on wall thickness - up to 4-5 mm. Any pipes, what are they? Yes, all: metal-plastic (MP), polyethylene (PERT, PEX), polyvinyl chloride (PVC), PVDF, low-pressure polyethylene (HDPE), polypropylene (PP, PPR or PPR), including reinforced with fiberglass and even small pipes (diameter 16 -20 mm), reinforced with aluminum foil. For the same pipes, but with a diameter of 4 mm or more, more powerful scissors are needed. They should be larger in size and “harder” in assembly.

Which scissors are best for PVC, PPR, PET, MP pipes

For reinforced polypropylene and PEX with a diameter of 25-40 mm, a good roller cutter is required, and for even larger ones, a guillotine or the same roller shears, but from a professional series, is already needed.

Technical specifications

There is no difficulty at this point. There are two items to keep track of:

- the maximum diameter of the pipes that the scissors can cut;

- which pipes they can cut.

Take a close look at these features. It can be a shame: you buy scissors for polypropylene pipes for a couple of thousand, and then it turns out that they do not cut polypropylene.

First of all, we look at whether the type of material we need cuts, then we pay attention to the diameters

By the way, in a cheap tool, the pipe is declared to have the largest diameter, sometimes it simply does not fit in the holder. So we need to check. If you do not have a part, compare the dimensions of the cutting part with similar ones. Are the sizes more or less the same? Excellent. If the ones you choose look smaller, it's best to set them aside.

Frame

The body of the scissors can be made of silumin or other similar alloy and steel. Inexpensive silumin models can break if you apply too much pressure when cutting large diameter pipe. So if we take silumin ones, then those that look solid and weigh more than a hundred grams. We inspect the body for cracks, cavities, burrs - there are such damages. We immediately put them aside. Let's take a look at the following signs:

- You need a strong strong body.

- Lack of backlash. If the new scissors hang out, then the cut will not be even. And if you also work with them, you will definitely have to hold everything with your hands.

To make it convenient to work, look at the case - The wide lower part where the pipe fits.To get a smooth cut, it must be held firmly. If there is only a thin strip at the bottom, this is not easy to do. So we look to the lower "lip" was large.

Let's look at the handles. The main thing is that they are comfortable. We'll have to squeeze them, so that the sharp edges that are uncomfortable in the hand are also set aside. The best option is rubberized or with rubber pads. But this is already a non-budget series.

What could be the blade

The main working part of scissors for cutting pipes is the blade. It can be made of tool (cheaper and softer type of steel) and alloyed (more expensive and durable) steel. Generally, alloy steel blade can cut plastic and copper pipes. Scissors for polypropylene pipes have a blade made of tool steel.

The type of steel is not everything. You have to look at the thickness of the blade. If it is thin, with a large diameter, the cut goes to the side and cuts the pipe at an angle. And we need something at 90 °.

Pistol pipe cutter mechanism

The thicker the blade, the easier it is to work. By the way, there are models of scissors for polypropylene pipes with a removable blade, there are those in which the blade and the “ladder” of the ratchet mechanism are one. The second option is more durable. The fewer connections, the longer the service life.

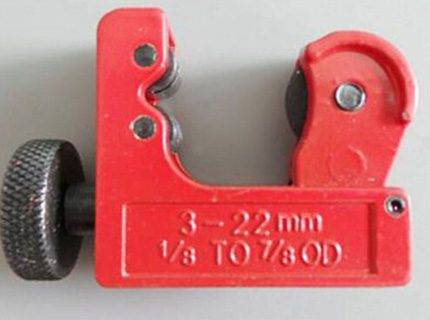

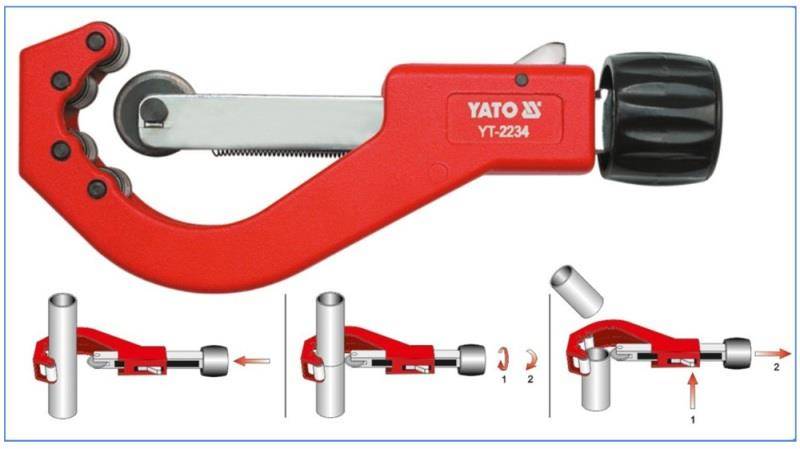

Mini pipe cutters for copper pipe

Rollers are included in the category of compact mini-pipe cutters, which make it easier and more convenient to work in hard-to-reach places. In the same category of tools, you can find slightly different mini-designs, for example, from the MiniCut Pro series of tools from the well-known company Rothenberger.

The same small tool as a roller - a mini pipe cutter of copper pipes.It is very popular in the field of installation of refrigeration systems, in particular, household air conditioners.

Pipe cutters "MiniCut Pro" are available for processing copper pipes with a diameter of 3 to 22 mm. The cutter's working radius of 38 - 45 mm allows you to work with pipes located in close proximity to the walls of buildings or in the presence of other obstacles.

Equipped with two guide rollers with cut-off groove, this type of pipe cutter makes cutting close to the flare easy. The tool is equipped with spare cutting blades in the amount of at least 5 pieces.

On our website there are several more articles that are devoted to the choice of devices for cutting pipes from various materials, we recommend reading:

- Cutting pipes from polypropylene.

- Cutting steel pipes.

- Cutting of metal-plastic pipes.

Which pipe cutter is better to buy

When choosing a pipe cutter, first of all, you should pay attention to its working range. The recommended maximum value depends on the complexity of the tasks to be solved with the tool.

For domestic use, a model is usually enough that can cut pipes with a diameter of up to 50 mm.

For work under heavy load or regular use, it is better to purchase a pipe cutter made of high-alloy or stainless steel. Budget models for domestic use or processing of soft materials have blades made of tool alloys. More durable and resistant to stress are devices that are used in the production of steel containing nickel, vanadium, chromium.

Long service life of the pipe cutter in difficult conditions will be provided by special treatment against corrosion and wear.

The scope of the tool is largely determined by the materials acceptable for cutting. The best choice for professionals will be a pipe cutter capable of processing both metal and plastic. However, it makes no sense to buy such a model for a one-time job.

To maintain the quality of the instrument, follow the recommendations for caring for it. After completion of work, the surfaces of the pipe cutter should be thoroughly cleaned from chips and dirt. Mechanisms must be periodically lubricated, cutting elements regularly inspected for chips and dents, and replaced in a timely manner.

Manufacturing materials

The body of the equipment is made of the following materials:

- impact-resistant plastic;

- zinc alloy;

- composition based on aluminum;

- tool steel.

In order to resist corrosion, individual elements of the body can be coated with a protective layer based on chromium or a special coloring composition (powder). The steel structure is assembled from individual elements, which are also subjected to a procedure such as hardening. This provides significant stability of loaded and rubbing against each other nodes. Chrome-plated components are not afraid of moisture, have a good wear resistance, are resistant to corrosion, and have an excellent appearance. Cutting elements can be steel, tool or made from a special grade of steel (alloyed).

Selecting the type of tool

The following types of pipe cutters are used for cutting plastic pipes:

- roller;

- ratchet;

- guillotine;

- chain.

Roller pipe cutters

The most popular in terms of ease of use and cost are roller pipe cutters designed for sewer pipes, heating or water supply systems made of plastic.

The design of the roller pipe cutter includes:

- a body that is simultaneously a clamp for capturing and holding the pipe during cutting;

- screw or telescopic handle that allows you to cut pipes of different diameters;

- cutting mechanism. The pipe cutter roller, which acts as a knife, is installed at the end of the clamping handle;

- carriage with support rollers.

Roller cutting tool

Some models of roller pipe cutters can be supplemented with a beveler, which facilitates the process of further preparation of the edge for the connection.

The advantages of roller mechanisms include:

- versatility. Using the tool, you can cut pipes of different diameters and with different wall thicknesses;

- ease of use;

- low cost;

- minimal risk of pipe damage.

Among the negative characteristics, one can single out the need to rotate the tool or pipe by 360 °, which practically does not allow cutting off already installed products.

To cut a pipe of a given size with a roller pipe cutter, you must:

- determine the location of the cut;

- install the pipe in the clamp;

- move the knife-roller with a screw handle;

- to cut in a circle;

- if necessary (thick-walled pipes), repeat the work two, three and so on times.

Using a Roller Cutting Tool

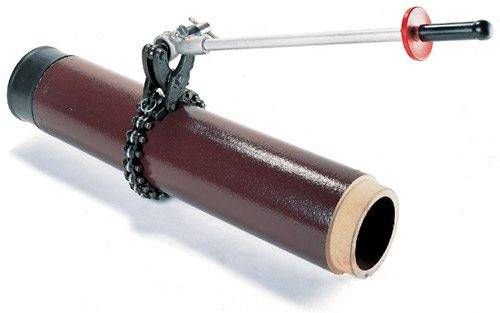

Chain pipe cutters

A variety of roller mechanisms are chain pipe cutters. The device is a tongs on which a chain with roller-knives is fixed.

Chain mechanism for cutting plastic pipes

The advantages of this design are:

- the ability to cut pipes of different diameters. One end of the chain is firmly fixed on the base, and the second can move freely, which allows you to adjust the diameter of the cut pipe;

- high speed of work. Unlike a standard roller tool, a chain pipe cutter has several knife rollers, which is reflected in the cutting speed;

- no deformation of the pipe during the work;

- cutting accuracy.

The main disadvantages of chain tools are the high cost of equipment and the high cost of maintenance and repair.

To cut a plastic pipe with a chain pipe cutter, you need:

- mark the place of the cut to perform the work with maximum accuracy;

Determination of the cut point

- place and fix the pipe so that all cutting rollers are located on the cutting line;

- trim by rotating the tool.

Using a chain cutter

Before connecting the pipe to a fitting or other pipe, it is recommended to process the cut with a facer and beveler.

Guillotine pipe cutters

Guillotine pipe cutters or pipe shears are made in two types:

a hand tool, which is tongs (scissors) equipped with a sharp metal blade;

Manual guillotine pipe cutter

a desktop tool made in the form of a metal frame along which a metal knife moves under the influence of a rotating handle.

Bench guillotine pipe cutter

Guillotine pipe cutters are designed for cutting pipes of certain diameters. As a rule, with a hand tool you can cut the pipe up to 100 mm, and with a table guillotine up to 150 mm.

The advantages of this type of equipment are:

- accuracy and speed of cutting (the device works like ordinary scissors);

- complete absence of pipe deformation;

- no chips;

- the ability to perform cutting in confined spaces;

- low cost.

Negative qualities include:

- the need for periodic sharpening of the cutting mechanism;

- rapid fatigue of the hands.

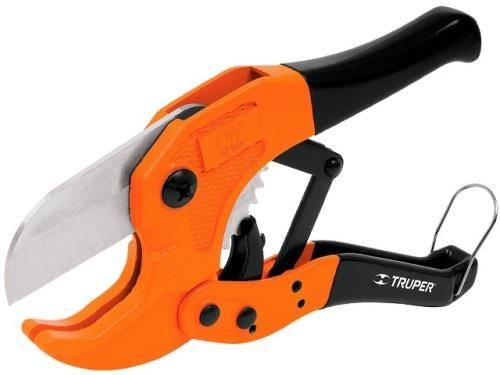

Ratchet pipe cutters

A variety of guillotine pipe cutters are ratchet shears for cutting pipes. The device is a "scissors" with a one-sided cutting mechanism and teeth to fix the cutter in a certain position.

Ratchet scissors for polypropylene pipes

The positive aspects of the tool are:

- speed and ease of work. For trimming, it is enough to install the pipe in the clamp located on the body and press the control knobs;

- low cost.

The negative aspects include:

- the need to make a lot of effort;

- the need for additional processing of the pipe before connection.

Selection principles

Before buying a cutter, you need to decide how to cut a metal-plastic pipe. If you need to make several one-time cuts, you do not need to buy expensive tools, you can use a hacksaw or a grinder for this. To collect the pipeline throughout the house you will need a pipe cutter.

Selection Recommendations:

- In order not to stop working due to dull rollers or blades, you need to choose a complete set with additional working parts.

- When buying tools, you need to consider the diameter of the tube to be cut.

- To facilitate installation work, you can choose a cutter with the ability to chamfer.

Advantages and disadvantages

Positive sides:

- high precision cuts without distortions;

- lack of irregularities, burrs;

- noiselessness;

- no trash.

The disadvantages of pipe cutters include their high price, which depends on the maximum diameter.

Pipe cutters of various types ( / sansvar)

Manufacturers and cost

The price of tools depends on the quality, the availability of additional mechanisms, the maximum diameter of cutting tubes. Manufacturers:

- STURM - the products of this company are suitable for beginners, amateurs. The average price is from 400 to 500 rubles.

- WMT is a company that produces budget cutters. The average price is 300 rubles.

- RIDGID, KALDE, Milwaukee are professional tool manufacturers. The average price is 3000 rubles.

How to cut plastic pipes

Unlike working with polypropylene pipes, when cutting metal-plastic bends, it is important to maintain accuracy. PP pipes will be connected by welding, which will hide small flaws

Metal-plastic parts are joined by fittings, and an extra millimeter here can result in a loose connection and leakage in the future.

Therefore, the mark is applied strictly across the branch. The tool is set so that the blade clearly matches the mark. The machine and retraction must be rigidly fixed. If the operator has a roller pipe cutter in his hands, it is better to make a trial rotation of the device in order to check the accuracy of the installation. Only after that the unit is put into action.

Preparation and cutting of steel pipes

Before opening, the surface of the steel bend is smeared with oil at the place of the intended separation. This will reduce the temperature in the work area, clean the outer perimeter and partially remove scale.

Mark the cut line and fix the workpiece in the tool body.The rod handle regulates the pressure on the cutting edge and moves the device along the perimeter of the outlet. Increasing the pressure, draw a line. If the blades are well sharpened and have the necessary strength, the separation will be smooth and will not require further processing.

How to cut small diameter pipes

The tube is clamped in a vise or otherwise. Make a cut mark. They put the pipe cutter on the end of the outlet and, by rotating the handle of the tool, bring the cutting roller to its contact with the surface of the part.

Turn the pipe cutter one turn, check the correctness and accuracy of the risks. If the line is closed, not forked, the handle is turned another quarter of a turn, pressing the cutting edge against the part. Next, scroll the handle until the walls of the outlet are completely cut through.

Cutting steel pipes of large diameter

Such operations in domestic conditions are practically not carried out. Enterprises dealing with large pipes on an industrial scale acquire powerful and expensive equipment for this.

For example, laser cutting using a special machine and computer equipment will provide fast and high-quality cutting of pipes of huge cross sections.

If it becomes necessary to cut a large diameter pipe, they resort to using an ordinary grinder. The main thing is to make the correct markup, and then make a neat and accurate line along the intended mark.

Types of tools

When choosing a pipe cutter, keep in mind right away that it cannot be considered a universal tool. This is due to the different diameters of the pipes that are installed for the supply of water, heating and drainage of sewage.Therefore, in each case, it should be used according to the material and size of the products. If there are some models suitable for different types of pipelines, but this is most likely an exception to the rule.

There is good news, but it concerns home craftsmen who can easily handle both copper and metal-plastic with a roller pipe cutter for steel.

Portable pipe cutting tool

Wall thickness

Influences the choice and wall thickness of the product with which the tool will work

Taking into account this parameter, we can say that they can be for:

| heavy loads |

|

| Thin-walled pipes | These include the following:

|

| Products from ceramics and asbestos cement | Such pipes are commonly used in sewer and waste systems. |

Cutting equipment ceramic and cement products

Design features

It is fashionable to distinguish the following types of pipe cutters:

- rotary or rotary;

- roller;

- telescopic;

- with ratchet mechanism;

- incisive;

- chain.

| incisive |

|

| Manual type with rollers |

|

| Chain |

|

Operating principle

This is another way to classify a tool, it could be:

- electric;

- manual;

- pneumatic;

- hydraulic.

Most often in everyday life they use a manual version, which is activated by physical force. Typically, such equipment is quite simple, its price is low, it does not require any special skills and qualifications.

Unlike the previous electric pipe cutter, it is significantly more expensive, but its performance is much higher. The device eliminates the use of physical force, has a high efficiency, so it is usually purchased for large-scale work.

Scissors for cutting plastic pipeline

How to choose

The most popular and numerous are pipe cutters for steel pipes.

With respect to other materials, things do not look so rosy.

- When working with copper, do not forget that it is a soft metal that can easily be deformed. Therefore, to work with it, a special pipe cutter for copper pipes is used.

Pipe cutter for plastic pipes of large diameters

- To work with thin-walled plastic pipes, special scissors are used, which completely replace the pipe cutter for plastic pipes. Their main advantage is low cost and ease of use. Of the minuses - hands get tired quickly when cutting a large number of products, low-quality models come across.

Use roller and battery models:

- the first - cut with one cutting roller, rolling through several guides, usually they are not "hurried";

- the second ones do the job much faster, but its maximum diameter is 42 mm.

Cordless pipe cutter for polypropylene pipes

- It is better to cut thin metal-plastic pipes with scissors, and use a pipe cutter for products whose Ø40 mm or more. A good choice would be a telescoping tool or a ratcheting version that resembles scissors in appearance. The process is performed by closing the handle.

Then it is necessary to restore the section of the product using a calibrator, which will simultaneously chamfer. The instruction allows the use of a tool for cutting steel pipes.

Pipe cutter for metal-plastic pipes such as scissors

Purpose of the tool

Copper is a rather soft material, lends itself well to any type of processing, including cutting. It can be cut with a hacksaw, grinder.

However, a real pro will never do this. And the point is not only that these sawing units will make a rough cut with burrs, and after them chips will get into the tube. The cut itself is unlikely to turn out to be even, strictly at a right angle. Namely, this is required when cutting a copper tube.

The material is expensive enough to save yourself from mistakes when cutting it, unnecessary costs, it is more reliable to use a pipe cutter when cutting copper pipes.

It will come in handy for:

- Installation of home communications for heating and water supply, laying underfloor heating.

- Repair of refrigerators, air conditioners and other household appliances containing copper pipe parts.

- For plumbing and other types of household work.

Making a pipe cutter with your own hands

If for some reason it is not possible to purchase a professional device, then it is quite possible to make it yourself from ordinary materials available to almost everyone. The advantages of this option are as follows:

- such a device will cost less than a store;

- it can be adapted specifically to your needs (cutting pipes of given parameters);

- in its manufacture, you can learn new things and gain valuable experience that will be useful in other areas.

What you need to work

To make a tool yourself, you need a small set of tools and materials:

- set of wrenches;

- screwdrivers;

- hacksaw for metal work;

- square rod;

- spring;

- hacksaw blades.

Also in the work you will need a bolt and screws of special sizes, which depend on the parameters of the device itself. Metal rivets are selected in regular sizes (diameter 0.4 cm).

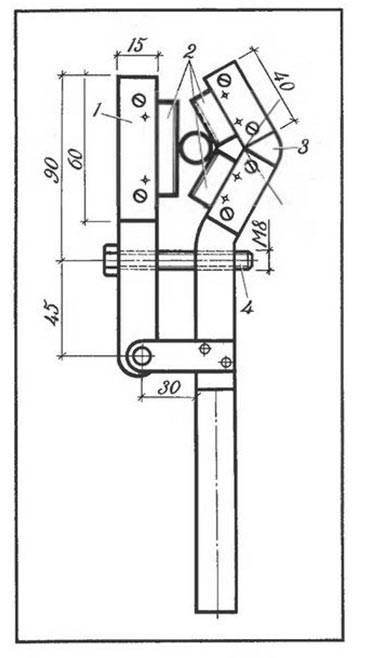

The sequence of work is associated with the stages of manufacturing the left (1), right half (3) of the tool and their assembly. An example drawing is shown below.

The number 2 indicates the cutting of the canvas, 4 - the clamping screw. Dimensions are in millimeters and can be proportionally recalculated for your specific model.

Conclusions and useful video on the topic

In a short video, the process of cutting a copper pipe is clearly presented, as well as tips on how to properly perform the steps.

Selecting the right tool from the existing range of copper pipe cutters is easy. The market offers a lot of models of different designs, among which you will always find the best option. The main thing is to have an idea of what criteria to select a device for and to work with which pipes a pipe cutter is needed.

Still can't decide on a pipe cutter for copper pipes? Or do you already use similar equipment? Please tell us about the advantages and disadvantages that you noticed while working with the device. Leave your comments, ask questions in the block under the article.