- Devices costing from 4 to 5 thousand rubles.

- Features of the operation of the soldering iron

- Operation features

- Best Inexpensive Pipe Soldering Irons

- 1. ELITECH SPT 800

- 2. SOYUZ STS-7220

- 3. Kolner KPWM 800MC

- Bort BRS-1000

- The design of the welding machine for PPR

- Top Producers

- How to weld polypropylene pipes

- Preparatory stage

- soldering process

- The nuances of soldering

- Lists of the best

- Affordable price

- For beginners

- Professional

- Tips for choosing a soldering iron

- Which soldering iron is better rod or xiphoid

- The best mechanical machines for welding polypropylene pipes

- Hurner 315 Weld Control

- BADA SHDS-160 B4

- TIM WM-16

- The best machines for socket welding of polypropylene pipes

- Caliber SVA-2000T

- Sturm TW7219

- Gigant GPW-1000

Devices costing from 4 to 5 thousand rubles.

For most home craftsmen, it is these soldering irons that are most likely the golden mean on which you should choose. Of course, middle-class units are not without flaws, because of which a professional who fulfills customer requests on a daily basis will not want to use them. However, for occasional work at home or with friends, they are quite suitable. Here are some of the benefits of a typical mid-range soldering iron:

- the temperature drop on the tip usually does not exceed 40 ° C, which is quite acceptable for non-professional equipment;

- The “irons” of such devices are made of high-quality aluminum alloys and are equipped with reliable fasteners, the beds are bending-resistant, since they are often made of durable stainless steel;

- some models are equipped with two heating elements at once, which allows you to adjust the temperature of the sting;

- are usually equipped with fairly massive nozzles, the performance of which is many times better than that of models from the "cheap" segment.

The main disadvantage of inexpensive models is still a solid temperature drop on the sting. For home, that is, episodic, use, it is more or less acceptable. But for a professional who is engaged in mass soldering, it can create at least inconvenience. In addition, experienced welders still advise replacing the nozzles from the delivery set of middle-class machines with better ones, for example, manufactured by the Czech company Dytron. Leave much to be desired and network wires of inexpensive models, which are usually devoid of heat resistance.

Speaking about the brands under which good soldering irons of the middle price segment are produced, we should mention such brands as Rosterm, Pro Aqua, Valtec, Candan and Fusion. In the ratings of welding machines for polypropylene pipes, the products of these companies traditionally occupy high positions.

Features of the operation of the soldering iron

The official name of the equipment is a welding machine. However, among the people it is called a soldering iron by analogy with the mode of operation or an iron because of its specific shape. The working part heats up to 300 °C, heats the nozzle-matrices located on both sides.

One matrix is responsible for heating the outer part of the pipe, the second for heating the inside of the fitting. Both elements are held on the soldering iron at the same time, then quickly joined. Polypropylene cools, forming a strong one-piece connection. This is how all sections of the pipeline are connected. Most models are equipped with a stand, so the soldering iron can be installed, soldering on the desktop. This reduces the load on the masters, provides comfort during work.

On weight, it remains only to connect only those pipe joints that are located in hard-to-reach places. Then the device is removed from the stand, soldering is carried out at the place where the pipeline is laid. To prevent burns, the master holds the device by the handle. However, the equipment is quite bulky, it is not always convenient to hold it on weight. That is why it is more often used for stationary work, and the finished sections of the pipeline are laid in accordance with the scheme.

Another type of welding machine is a cylinder on which matrices are fixed. The undoubted advantage of such models is the ability to fix nozzles in any position: at the ends or in the middle of the cylinder. Due to the design features, it is possible to work with the most difficult areas, including places with difficult access, close to the wall, the presence of various obstacles, and complex geometry of the room. The tool itself is compact, so it is easy to get it anywhere. Such models are equipped with a cord of at least two meters, which makes it possible for the master to move freely around the working area. When stationary use is required, the soldering iron can be mounted on a folding bracket.

Subject to the soldering technology, the presence of a good welding machine, reliable ones are obtained, and the life of the pipeline can exceed 100 years. However, before you begin to understand the process itself, you should choose the right soldering iron.

Operation features

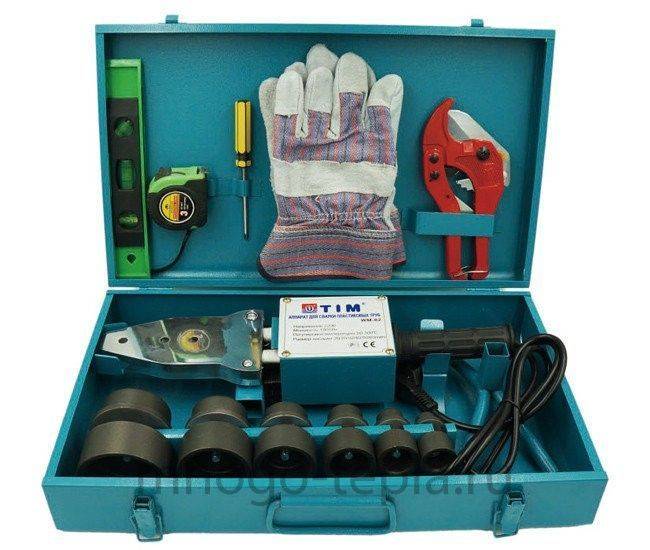

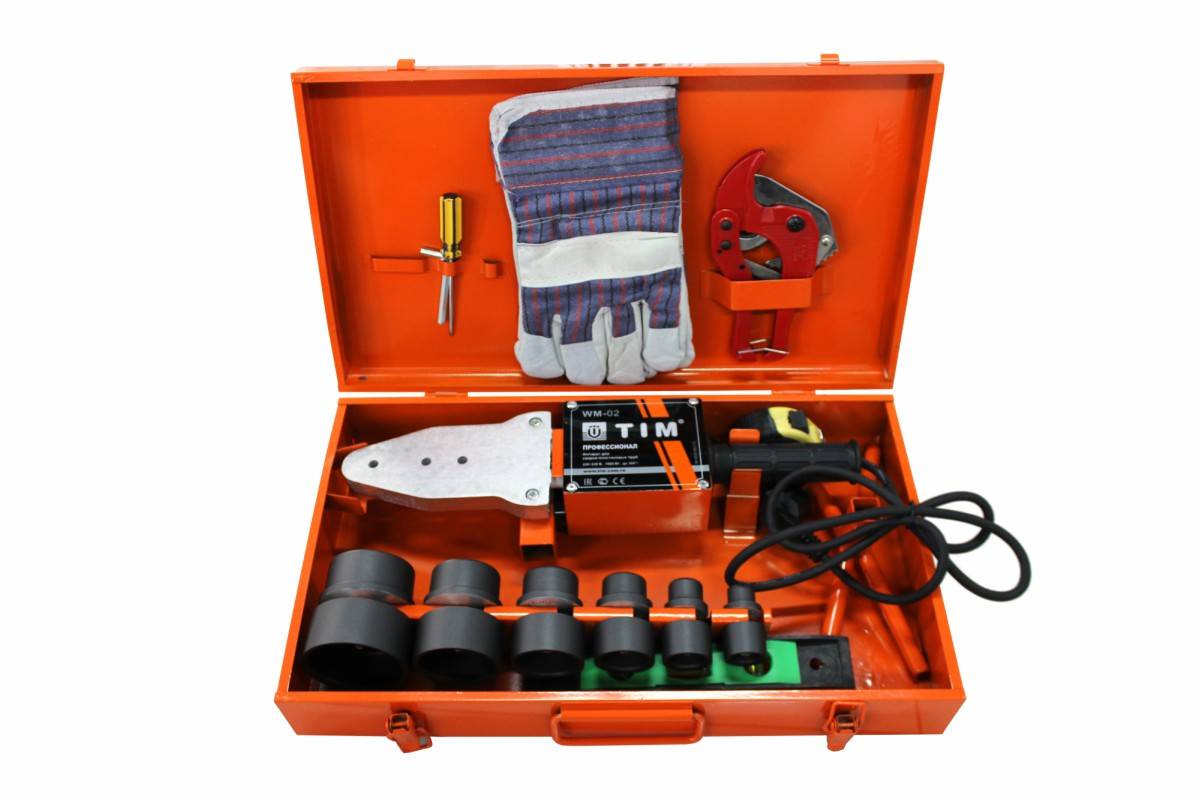

In addition to the soldering iron, welding and installation of polypropylene pipes you will need a number of other tools.

- special scissors for parts made of polypropylene;

- level, screwdriver, tape measure;

- heat resistant gloves;

- chamfering tool.

Included with the soldering iron should be a key for fixing the nozzles on the heating element.

Operating features:

- Prepare in advance the place where the work will be carried out. To do this, you need to choose a flat surface. Clean it from debris, dust. Dirt should not get on heated parts, equipment.

- Welding machines for plastic have legs for installation on flat surfaces. After the equipment is conveniently located, its stability must be checked. Wiggling will create a poor quality connection.

- Pick up the equipment of the desired diameter, fix it on the heating element. Tighten fixing screws.

- Turn on the device. Let him warm up. Heating time - 20-30 minutes. When it heats up, the temperature sensor on the case will turn off.

- After heating the nozzles, pre-prepared pipe ends and couplings are put on them. Before that, they need to be cut with scissors for polypropylene, cleaned of dust, degreased, wait until the degreaser dries.

- The exact heating time of the parts is prescribed in the technical data sheet of the equipment. Overheating will damage the material.

Do not reheat pipes if they do not seem to have warmed up enough.Before installation, you must carefully study the equipment. Nozzles are for the outer, outer side of the parts. Pipe connections are made using couplings, which provide a high rate of tightness and strength.

To assemble a polypropylene pipeline, you need to prepare a number of tools. The main one is a soldering iron for plastic. With it, you can make a tight connection. Any person without practical experience can learn how to use such an apparatus.

Best Inexpensive Pipe Soldering Irons

The group of the best, but inexpensive models includes household-class soldering irons, the welding of plastic pipes with which is limited to domestic conditions (house, garage, cottage or apartment). They are characterized by cheaper prices, "weak" equipment, average power parameters. Minor flaws are not ruled out, such as a slight backlash, a thin platform without additional fasteners. The main parameters, such as temperature conditions, the type of pipes and fittings to be welded, heating adjustment, are not significantly inferior to professional soldering irons.

1. ELITECH SPT 800

The ELITECH SPT-800 soldering iron has a standard, familiar design and typical parameters. The power of the device is 800 W, the equipment is cut down - there are no pipe scissors, a tape measure and a level. A set of nozzles from 20 to 63. This is a good household welder, with which you can lay a pipeline at home, in an apartment, in a country house, in a garage. The resource of the internal mechanism is more than enough for several years of continuous use. However, the household model of the soldering iron is not without its drawbacks - the soldering iron leg may be with curvature and will have to be finalized.The heating indicators are faded and hardly visible in bright sunlight.

Advantages:

- reliable mechanism;

- low cost;

- quality case;

- good selection of nozzles;

- average power consumption - the device can be used without a serious load on the network;

- clear and detailed instructions.

Flaws:

poor equipment.

2. SOYUZ STS-7220

Soldering irons SOYUZ have been very popular among knowledgeable craftsmen for several years. At the lowest possible price, these devices are able to work properly for more than one year, without overloads and failures. Here it is worth noting good protection against overheating, fast and stable heating, high-quality Teflon coating of nozzles. Reduced the price of the soldering iron due to the reduced sole, where there are only two holes for nozzles. The set includes a solid case with metal latches, one screwdriver and six good matrices with a diameter of 20 to 63 mm. The standard diameter of the holes on the iron allows you to purchase matrices of other diameters.

Advantages:

- low price with good workmanship;

- the presence of a case;

- quality matrices;

- long network cable;

- 14 months warranty

Flaws:

- the build quality and parts of the soldering iron are lame;

- high power consumption - 2 kW.

3. Kolner KPWM 800MC

The welder for polypropylene pipes from Kolner is 100% household and is suitable for assembling a water pipe at home or watering in a summer cottage. In confirmation of this, the price is lower than the analogue from SOYUZ, a truncated package and only three nozzles-matrices with diameters of 20, 25 and 32 mm. A soldering iron with the simplest layout does not have a temperature controller, it is equipped with a simple stand, which users often have to “finish with a file”.With its efficiency, the device copes with the tasks and is cheaper than renting a tool.

Advantages:

- the best inexpensive pipe soldering iron on the market;

- familiar design;

- compact dimensions;

- heating rate;

- good thermostat and high-quality heating of workpieces.

Flaws:

- matrices of only three diameters with a budget Teflon coating;

- no temperature control.

Bort BRS-1000

The device for welding with a mobile sleeve with a heating element is designed for joining parts made of synthetic materials and fittings made of PV, PE, PP and PVDF. Heating fittings and bushings must be selected depending on the size of the pipes. They are fixed on the heating element with a wrench with a pin. Two nozzles can be put on one heating element. When connecting the device to the network, one or both heating elements are included. After warming up, the thermostat turns off the current supply, the backlight goes out, informing about the readiness of the soldering iron for work. Socket welding involves soldering a round pipe and a shaped part with an overlap. The welder has many negative and positive reviews.

Among the advantages are:

- speed control;

- Ergonomic handle;

- Affordable cost;

- Quick release cover.

Of the minuses note:

- Inconvenient power key;

- Poor latching.

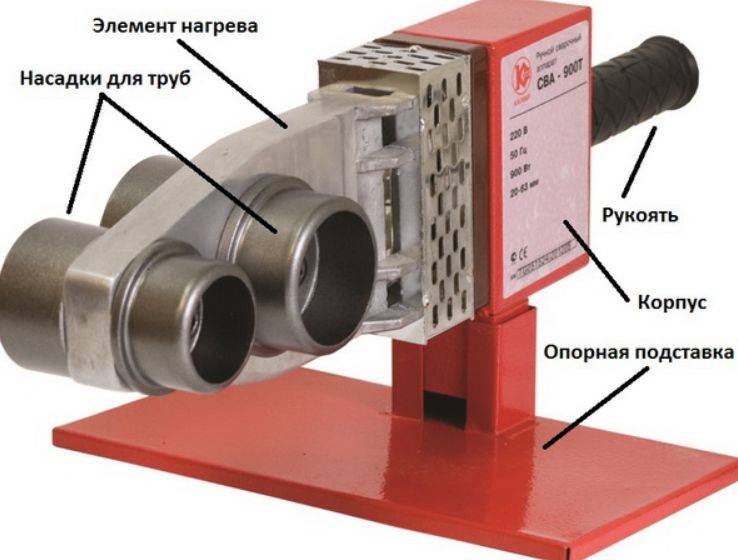

The design of the welding machine for PPR

A manual electric soldering iron (masters call it an “iron”), designed for soldering plastic pipes and fittings, consists of the following parts:

- housing with a transformer unit, thermostat and controls, equipped with a handle;

- a heating element with a power of 500 to 2 kW is installed in front of the case, depending on the model;

- stand and power cable connected to a conventional 220 volt outlet.

Using the regulator, you can set the heating temperature of the mandrel in the range of 0 ... 300 degrees

Heating of polypropylene parts is carried out using nozzles with a diameter of 16 ... 63 mm (household series), coated with a Teflon non-stick layer. The appearance and principle of operation of the device has a certain similarity with a conventional iron:

- The user turns on the heating and sets the required temperature with the regulator, for polypropylene - 260 ° C.

- When the platform with nozzles reaches a predetermined temperature threshold, the thermostat turns off the heating element.

- In the process of soldering pipes, the surface of the “iron” begins to cool, so the automation again activates the heating.

Teflon-coated nozzles consist of 2 parts - a pipe is inserted into one, a fitting into the second

For welding parts from PP-R, a deviation from the established limit of no more than 5 degrees is allowed, polypropylene is heated to the melting threshold. Exceeding the temperature leads to a change in the structure of the material - the plastic "flows" and fills the flow area of the pipe.

Insufficient heating gives a poor-quality connection, which loses its tightness after 3-12 months. How to properly weld a polypropylene joint, read in a separate material.

Top Producers

Having dealt with the selection criteria, you are puzzled by a new question: “Which company is better?”. The modern market is dominated by a variety of brands and pricing that pleases the buyer. If you have a desire to buy a branded item, then you should take a closer look at these manufacturers:

Rothenberger is a well-known European company that produces quality for all kinds of repairs.The goods are popular with the pros of their craft;

In addition to these brands, tools from such companies as CANDAN, ENKOR, RESANTA and other slightly less well-known manufacturers received well-deserved love.

How to weld polypropylene pipes

For the installation of a pipeline at home, the diffusion hot method of coupling connection is usually used. To do this, you need a special tool:

- apparatus with a heating element of any model;

- nozzle of the right size;

- pipe cutters;

- trimmer - a tool for stripping the edge from the foil layer;

- knife for cleaning the cut;

- ruler or caliper;

- marking pencil;

- level.

Preparatory stage

How to get started right:

- the fittings and the ends of the segments are carefully cleaned of dust, dirt, degreased with a swab dipped in alcohol - the adhesion strength depends on this;

- remove all burrs from the edges;

- peel off the foil layer;

- install the soldering iron in working position;

- make markings, mark the heating zone of the upper layer.

To get a high-quality and tight connection, it is important to strictly follow the technology

soldering process

It is important to observe the welding time indicated in the table attached to the tool, these are:

- the term for heating the edge of the segment and the fitting, this is done simultaneously, with two hands on both sides of the soldering iron nozzle;

- the time interval for holding the joint in a fixed position until complete cooling.

Welding table for polypropylene pipes

The heated parts are connected with force until it stops, they do not turn, but only compress. Waiting for the seam to cool. Then the remains of polypropylene are cleaned from the fitting, they spoil the appearance of the system.

The heated parts are connected with force until it stops, they do not turn, but only compress

The heated parts are connected with force until it stops, they do not turn, but only compress

The nuances of soldering

For pipes of large diameter, overheating and an uneven internal seam will be invisible, and for 4 mm it can cause blockage. Beginners have other standard errors that negatively affect the quality of the connection:

- indirect cutting angle;

- insufficient cleaning of the inner surface of the fitting;

- shallow landing after warming up;

- incomplete removal of the foil layer.

Lists of the best

Below you can find out about the best soldering irons in three popular categories:

- affordable price;

- for beginners;

- professional.

Let us dwell in more detail on the description of these categories and the leading devices in them.

Affordable price

Resanta ASPT-1000 65/54 is considered the best soldering iron in the budget category. With its help, any user will be able to connect a large number of pipes of various sizes and materials. In addition to the device itself, the package includes a stand, a screwdriver, a storage case and a key. The device is also equipped with special indicators showing the connection to the network and the temperature mode. Nozzles are able to serve for a long time due to the quality material of manufacture.

Cost: from 1,000 to 1,400 rubles.

Resanta ASPT-1000 65/54

For beginners

ENKOR ASP-1500/20-63 is one of the simplest soldering irons. Suitable for all users who are faced with the task of installing water and heat pipes. The device assumes fast and uniform heating of pipes with various sizes and diameters. It involves the use of three nozzles and a thermostat at once. In operation, it actively uses two heating modes. Additionally, the package includes 6 couplings with different sizes.

The price is around 2500 rubles.

ENKOR ASP-1500/20-63

Professional

The Rothenberger Roweld Rofuse Print+ is a machine with German build quality. The device allows you to connect pipes, the diameter of which can reach 1200 meters. The main difference of the model among most competitors is the logged cooking process. It is possible to save all data on a USB-drive, which makes the control and analysis of the technological chain several times easier.

Cost: from 150,000 to 200,000 rubles.

Rothenberger Roweld Rofuse Print+

Tips for choosing a soldering iron

Professional installers use proven welding equipment, but what are the criteria for choosing an iron for a beginner? First of all, you need to understand that price is not always an indicator of quality.

Due to competition, soldering machines can be produced in plastic or metal cases, with various auxiliary tools (tape measure, level, gloves, screwdriver, etc.). Which affects the final cost, but has nothing to do with quality.

Therefore, in order to understand which machine to choose for welding PVC pipes, you need to build on the following criteria:

- Power consumption;

- working diameter;

- speed and temperature of heating;

- thermostat and stand;

The ironing power can be from 600 to 2500 watts. The higher the power, the larger the diameter of the system can be welded. The heating element heats up faster and has a double hole for softening products.

For home repairs, you can take a tool with less energy consumption and a minimum number of nozzles in the kit (small diameter). Also, for convenience, manufacturers offer a special holder. For everyday work, of course, you will need bolts up to at least 63 diameters.

The heating temperature must correspond to the temperature regime of the material from which the pipeline is made. And it is highly discouraged to purchase a soldering tool without a control panel. Such irons are called disposable, that is, when connected to the network, it will heat up to the maximum temperature.

In most cases, the tool simply burns out and fails. When buying, ask for a warranty card and specify the warranty period.

Which soldering iron is better rod or xiphoid

Also, soldering irons have a different shape of the heating element: rod and xiphoid irons. The shape itself does not affect the quality of fitting fittings

To understand how to choose a welding machine and what to look for when buying, consider their distinctive features:

- With the same characteristics, the rod ones have a lower cost;

- up to three nozzles can be attached to xiphoid ones;

- rod allows you to get to hard-to-reach places;

- xiphoid allow you to simultaneously solder 2 products;

The best mechanical machines for welding polypropylene pipes

The main advantage of this type of tools is their versatility and high welding quality.

With the help of mechanical devices, pipes of various materials with a diameter of up to 400 mm are connected.

However, the use of such models requires certain skills from the operator, and their average market value is significantly higher than that of manual counterparts.

Hurner 315 Weld Control

5.0

★★★★★

editorial score

100%

buyers recommend this product

A feature of the model is the presence in the configuration of a closed hydraulic unit that creates a pressure of 130 bar.

A heating element and a trimmer can be connected to it at the same time. The engine power of the device is 1000 watts.

The ease of use of the device is ensured by the informative user menu and the possibility of dismantling the clamping ring. This allows you to get up-to-date data on the pipe material, wall thickness and work with the tool in hard-to-reach places.

Advantages:

- CNC hydraulic controller;

- the presence of a trimmer and a positioner;

- informative menu;

- USB support for data transfer.

Flaws:

high price.

Hurner WeldControl is used for welding pipes with a diameter of 90 to 315 mm. It is convenient to use on a construction site or at home. Excellent option for professional use on various objects.

BADA SHDS-160 B4

4.9

★★★★★

editorial score

95%

buyers recommend this product

The model will delight you with stable operation in various temperature conditions and a powerful engine. It consists of three main elements: a centralizer, a trimmer and a removable heating element, which allows welding pipes with a diameter of 50 to 160 mm.

The temperature control system ensures precise setting and maintenance of the set value.

The wide stand facilitates stationary use of the device and guarantees its stability during operation.

Advantages:

- power - 2.2 kW;

- stable work;

- maintaining the temperature regime;

- structural stability.

Flaws:

complexity of transportation.

BADA SHDS-160 B4 will be an excellent purchase for processing large diameter pipes. It has good performance in difficult conditions and can be used for active welding for a long time.

TIM WM-16

4.8

★★★★★

editorial score

90%

buyers recommend this product

The model can be used for both butt and socket welding of polypropylene pipes.

The design of the device allows simultaneous processing of both elements. The power of the device is 1800 W, it is used to fasten pipes with a diameter of 75 to 110 mm.

The device is equipped with a double heating element and a thermostat, which allows the operator to switch between temperature modes without losing the set value.

Advantages:

- powerful engine;

- high performance;

- double soldering iron;

- indication of operating modes.

Flaws:

maintenance demanding.

TIM WM-16 is worth purchasing if you need to quickly build a pipeline. It is distinguished by the reliability of the connection of parts and affordable cost.

The best machines for socket welding of polypropylene pipes

This type of welding is based on the connection of tubular elements using special fittings. The tool consists of a heating element, a set of nozzles and a stand for fixing the device.

The connection of pipes using socket welding devices provides high sealing and reliability of the joint, however, in order to avoid rapid cooling of heated parts, the operator must work quickly and accurately.

Caliber SVA-2000T

5.0

★★★★★

editorial score

98%

buyers recommend this product

The model is equipped with a 2000 W motor and a comfortable rubberized handle. The device sits firmly in the hand and is able to process polypropylene pipes with a diameter of 20, 25, 32, 40, 50 and 63 millimeters.

The device heats up to 300 degrees, has a temperature controller and a stable stand, which allows you to use it in a stationary mode.

High speed of work is provided by the scissors included in the package for cutting of plastic pipes and to the adjusting tool.

Advantages:

- powerful engine;

- Teflon coating of heating elements;

- extended equipment;

- rapid heating.

Flaws:

high price.

Caliber SVA-2000T is used to connect pipes made of polymeric materials of various diameters. The device will be an excellent assistant if you need a quick and efficient installation of the pipeline.

Sturm TW7219

4.9

★★★★★

editorial score

95%

buyers recommend this product

See review

The distinctive characteristics of the model include high engine power and comfort in use.

Special indicators located on the case indicate the current state and temperature mode of the device. Two heating elements are turned on separately, which improves the stability and performance.

In addition to the welding machine, the package includes a metal case for transportation, six nozzles with a diameter of 20 to 63 mm, mounting bolts, an Allen wrench, a screwdriver and other tools. This allows you to start welding work immediately after purchasing the device.

Advantages:

- high power (1900 W);

- rapid heating;

- wear resistance;

- rich equipment;

- stable work.

Flaws:

heavy.

Sturm TW7219 is suitable for professional use in the plumbing industry. Powerful motor and high heating temperature of the elements allow fast and efficient connection of small diameter pipes.

Gigant GPW-1000

4.8

★★★★★

editorial score

90%

buyers recommend this product

A feature of the model is a convenient temperature setting.The rotary regulator is equipped with a special scale that allows setting with an accuracy of 10 degrees.

The power of the device is 1000 watts. It heats up quickly and can process pipes up to 63 mm in diameter.

The compactness and light weight of the instrument guarantee easy transportation and contribute to long-term work without fatigue for the operator.

Advantages:

- Ease of use;

- light weight;

- temperature setting;

- heating time - up to 2.5 minutes.

Flaws:

unstable stand.

Gigant GPW-1000 is used for installation of plumbing or heating systems. An excellent solution at an affordable price for both domestic and professional work.