- View overview

- How to use press tongs correctly

- Kinds

- Manual mechanical

- hydraulic

- Electro-hydraulic

- Which type is better for metal-plastic pipes

- The secrets of competent installation of such parts

- How to choose a press tongs?

- Mounting secrets from experts

- Preparing pipes for pressing tongs

- How is crimping done with a hand tool?

- How to work with the tool

- Safety regulations

- Preparing pipes for connection

- How to carry out crimping with manual equipment

- Tips for caring for press tongs

- Press tongs for metal-plastic pipes

- Types of pressing tongs

- The choice of pressing tongs for metal-plastic pipes

- Conclusions and useful video on the topic

View overview

XLPE pipes are widely used due to their remarkable properties:

- the ability to withstand temperatures up to 120 degrees Celsius;

- light weight, pipes made of this material weigh almost 8 times less than steel pipes;

- resistance to chemicals;

- smooth surface inside the pipes, which does not allow scale to form;

- long service life, about 50 years, the material does not rot and does not oxidize if the installation was carried out correctly without violations;

- cross-linked polyethylene is well resistant to mechanical stress, high pressure - pipes are able to withstand a pressure of 15 atmospheres and tolerate temperature changes well;

- made of non-toxic materials, which allows them to be used in the installation of water pipes.

The quality of installation of heating systems or pipelines made of cross-linked polyethylene depends on the tool that will be used for this purpose. It can be divided into two groups.

- Professional, used daily and for large volumes of work. Its main differences are the high price, durability of operation and various additional functions.

- Amateur is used for homework. Its advantage - low cost, disadvantages - quickly fails, and there are no auxiliary options.

To work you will need the following:

- pipe cutter (secateurs) - special scissors, their purpose is to cut pipes at a right angle;

- expander (expander) - this device expands (flares) the ends of the pipes to the required size, creating a socket for securely fastening the fitting;

- the press is used for crimping (uniform compression of the sleeve) at the place of installation of the coupling, mainly three types of presses are used - manual, resembling tongs, hydraulic and electric;

- a set of nozzles for the expander and press, which will be needed to work with pipes of various diameters;

- the calibrator is used to prepare the cut for fitting installation by carefully chamfering the inside of the pipe;

- spanners;

- the welding machine is designed to connect pipes with electrofusion fittings (there are devices with manual settings, but there are also modern automatic devices that can read information from fittings and turn off on their own after welding is completed).

A knife, a building hair dryer and a special lubricant may also come in handy in order to make the coupling easier to fit into place. You can buy the entire tool at retail, but a better solution would be to purchase an assembly kit that will have everything you need.

How to use press tongs correctly

Before operating this tool, it will not be superfluous to familiarize yourself with the standard instructions for its use.

Crimping of fittings of metal-plastic pipes and their connection is carried out in the following sequence:

- First, a chamfer is removed from the side of the pipe trim. To get rid of ovality, a gauge is used that is inserted inside the pipe.

- A sleeve is put on the pipe.

- A fitting with mounted rubber seals is inserted into the pipe. A gasket made of a dielectric material is installed at the junction of the pipe with a metal coupling in order to prevent electrical corrosion.

- Next, the steel sleeve is compressed with any press tongs into which certain liners are inserted.

It is believed that press fittings provide a better connection than the compression type. They are often used in hidden systems that are laid in walls and floors. These, for example, include warm water floors - they hide directly in the screed.However, for crimping couplings, you cannot do without a special tool, which to some extent slows down home repairers, who, naturally, do not want to buy expensive equipment for one-time use.

Kinds

Classification of pressing tongs:

- Manual mechanical.

- Hydraulic.

- Electrohydraulic.

Manual are of two types: mini and standard.

By purpose, the equipment is divided into professional and non-professional (household).

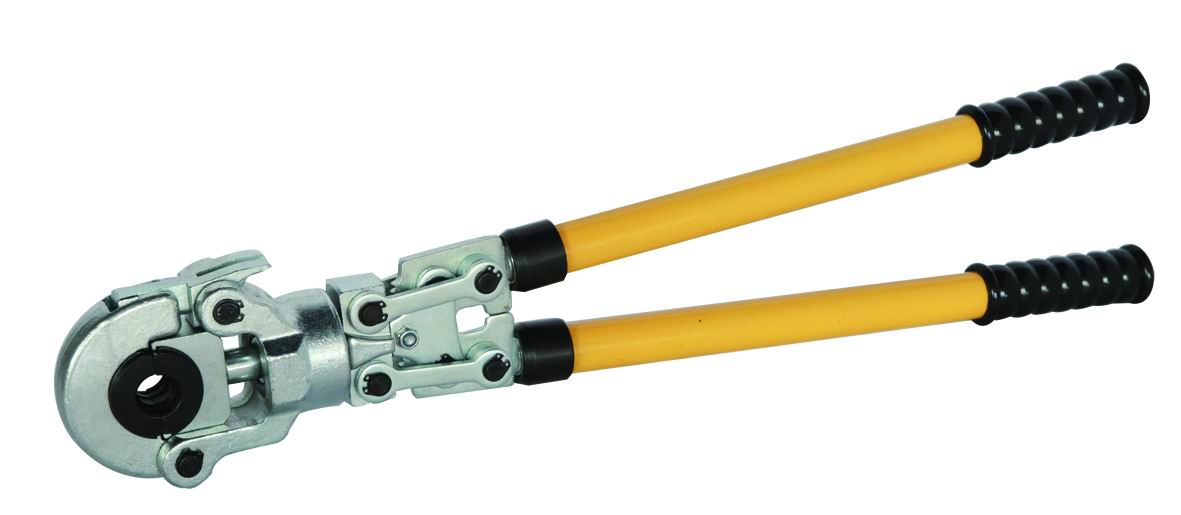

Manual mechanical

The simplest device for crimping pipes of small diameters is manual mini-pliers. Are applied to compression of pipes to 20 mm. Practically such diameters are used for intra-house wiring of hot and cold water. For heating, a larger diameter is already required. The device is compact, weighs about 2.5 kg plus a nozzle, and is inexpensive. Working with a mini-device is easy and simple, but with a large amount of work, the hands get tired. Therefore, it is suitable only for performing small amounts of work in a house or apartment.

The standard device is larger, has elongated telescopic handles. The force on the crimping head is transmitted using a gear transmission - this helps to regulate the force when clamping the fitting. It does not require special skills to work with standard crimping machines. Restriction on application - it is possible to compress pipes with an outer diameter of up to 25 mm (rarely up to 32 mm). With such press tongs, you can mount the wiring of the heating system at home. It is tedious to perform a large amount of installation work with a similar design.

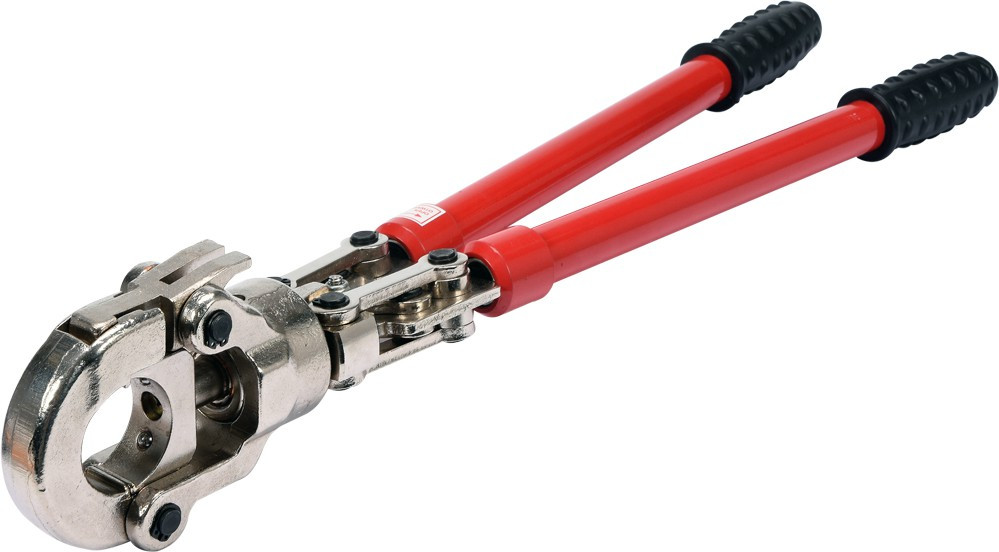

hydraulic

There are hydraulic models of pincers. A hydraulic cylinder is built into one of the handles of the device. When the handles are brought together, a high working pressure is created in the hydraulic cylinder, which transfers the force to the crimping head.Working on such a device requires less physical effort, it can be used to crimp pipes of a slightly larger diameter - up to 32 mm. Disadvantages - significant cost and the need for regular maintenance.

Electro-hydraulic

The most powerful models of pressing tools for metal-plastic pipelines are electro-hydraulic. The muscular effort of the worker in them is replaced by the work of the electric drive and the hydraulic system. Such presses can be used for crimping fittings on Ø 108 mm lines. It should be borne in mind that with increasing diameter, the reliability of the connection decreases slightly. Electric models are sometimes called a press gun - they do not have handles, they are more shaped like an ordinary drill with a nozzle.

Motorized devices perform smooth and very accurate crimping and the highest quality (strong and tight) connection of all types of tools.

Most often there are more compact devices for crimping connectors with a diameter of up to 50 mm and powerful bulky designs for large sizes. All power tools have high productivity, reduce labor costs and speed up the process of pipe installation. The devices are equipped with a set of nozzles for crimping connectors of several similar diameters.

Electric models are divided into three types according to the method of power supply:

Network. They work from a household network of 220 V.

Rechargeable. They are powered by batteries, perform from 50 to 100 compressions depending on the diameter (some models up to 400 compressions). The battery is charged from a 220 V network.It is more convenient to work without a wire, but the performance of the device is lower - the battery requires recharging during a heavy load.

Universal models can work both from a network, and from accumulators.

Which type is better for metal-plastic pipes

Strictly speaking, metal-plastic pipes do not care with which press tongs they were mounted. But it is not all the same to the people who carry out the installation and subsequently operate the heating or water supply system. Ideal quality is obtained when working with an electric tool, but the reliability of the correct crimping with a hand tool is beyond doubt. Therefore, the choice of apparatus depends on the diameter of the pipes and the amount of work.

The secrets of competent installation of such parts

Installation of parts is very fast and quite simple. For its implementation, you will need a special tool, without which it is impossible to compress the fitting.

How to choose a press tongs?

Press tongs for fittings - a device designed to install a part on a pipe. Manual models and more complex hydraulic models are available. For independent work, the first option is quite suitable, since it is the easiest to use and cheapest. And in terms of the quality of the connections made with its help, they are not inferior to those in the process of which a professional hydraulic tool was used.

When purchasing equipment, it must be borne in mind that it is designed to work with a certain pipe diameter. There are models equipped with special inserts that make it possible to work alternately with pipes of several diameters. In addition, on sale you can find improved variations of the tool. They are marked with:

-

- OPS - the device increases the forces applied to it by using step-type clamps.

- APC - during the process, automatic control over its quality is carried out. The press will not open until the crimp is successfully completed.

APS - the device independently distributes the force that is applied to it, depending on the size of the fitting.

Crimping press pliers are a necessary tool for installing fittings. Manual and hydraulic models of special equipment are available

What to look for when buying connectors

The reliability of the connection largely depends on the quality of the parts.

When buying press fittings, experts advise paying attention to the following points:

- The quality of the markings on the case. Companies that produce quality parts do not use cheap molds. All symbols on the body of the fittings are printed very clearly.

- Part weight. For the production of high-quality products, brass is used, which has a fairly large weight. It is better to refuse a fitting that is too light.

- The appearance of the element. Low-quality parts are made of thin metal that looks like aluminum. It is not able to provide a quality connection.

You should not save on fittings and try to buy them "cheaply" at a dubious outlet. In this case, there is a high probability of subsequent alteration of the entire pipeline.

Mounting secrets from experts

Let's start by cutting pipes. We measure the required length and cut the element strictly perpendicular. It is best to use a special tool for this purpose - a pipe cutter. The next stage is the processing of the end of the pipe.We insert a caliber inside the part, straightening a small ovality that inevitably forms during cutting. We remove the inner chamfer using a chamfer for this. In its absence, you can do this operation with an ordinary sharp knife, and then clean the surface with an emery cloth.

At the end of the work, we put the press fitting on the pipe, controlling the tightness of its fit through a special hole. There are models in which the ferrule is not fixed to the fitting. For their installation, such operations are performed. We put the crimp sleeve on the pipe. We insert a fitting inside the element, on which the sealing rings are fixed. To protect the structure from electrocorrosion, we install a dielectric gasket at the contact area of the metal connecting part and the metal-plastic pipe.

For crimping any models of press fittings, we use a tool that is suitable in diameter. We grab the sleeve with a clamp press tongs and reduce their handles to the stop. After removing the tool, two uniform ring strips should remain on the fitting, and the metal should be bent in an arcuate manner. Compression can be performed only once, there should not be any repeated operations. This leads to a broken connection.

The installation of press fittings for metal-plastic pipes takes place in four main stages, which are shown in the figure

Press fittings for metal-plastic provide a very strong, durable connection. Their wide range allows the implementation of pipelines of various configurations. In addition, they are very easy to install. Even a beginner can install press fittings.This requires patience, accuracy and, of course, a careful study of the instructions. The result of the efforts will surely please you with a hand-made pipeline that is reliable in operation.

Preparing pipes for pressing tongs

Immediately before the assembly of metal-plastic systems, i.e. before using press tongs and by carrying out crimping activities, the tubular material is suitably prepared.

During the marking of the metal-plastic pipe material, it is imperative to add a small overlap (2-3 cm) from both ends of the part. Otherwise, after inserting the fitting, the fragment will be shorter than necessary according to the estimate. The position of an incorrectly installed press fitting cannot be corrected. You will have to cut out the entire fragment and install a new one in this place

The sequence of actions is relevant for any type of tool and requires mandatory compliance:

- Using a tape measure, measure the required amount of pipe material from the bay and make a mark with a marker where the intended cut will be.

- Scissors for cutting metal-plastic cut off a part of the required length, making sure that the resulting edge is as even as possible and makes a clear right angle with the conditional central axis of the product.

- When using a guillotine tool for work, its lower edge is kept strictly parallel to the pipe surface, only slightly pressing the cutting part into the pliable material.

- When trimming is done, the resulting end edges are treated with a calibrator. It corrects and aligns the shape of the cut and gently chamfers the inside.

- The crimp sleeve is removed from the fitting and put on the edge of the pipe. The fitting is inserted directly into the cut.

- The end parts of the connection elements are pressed tightly, and the joint area is insulated with a sealing gasket. It protects the material from corrosion and ensures the tightness of the entire system as a whole.

- The control of the placement of the pipe in the sleeve is carried out through a round cut in the edge zone.

When the appropriate preliminary preparations are completed, the press tongs are used and the crimping operation is carried out.

How is crimping done with a hand tool?

The process of crimping a metal-plastic pipe with manual press tongs is not complicated, but it requires attention and accuracy. To work, you need an empty, flat surface that allows you to position the pipe section, connecting fittings and the tool itself.

For correct work with pressing tongs, appropriate conditions are necessary, namely a spacious, even surface and good lighting. At a conveniently equipped place, even a beginner who does not have much repair and installation experience can crimp and correctly install the fitting

When everything you need is prepared, the press tongs are placed on the table and the handles are moved apart by 180 degrees. The upper element of the cage is disconnected from the unit and the upper part of the press insert is inserted into it, corresponding to the size of the section of the pipe that is currently being processed. The lower half is placed in the lower part of the clip, which remains empty, and the tool is snapped into place.

The fitting can only be crimped with press tongs once. The second processing is categorically unacceptable, so each action should be taken responsibly

They make up a joint assembly from the pipe and fitting and insert the structure into the press tongs, carefully making sure that the fitting sleeve is inside the press insert.

It is very important for high-quality crimping to use nozzles that clearly correspond to the diameter of the pipe section. Otherwise, the device will deform the fitting and the part will have to be replaced with a new one. After correctly placing the set of pipes and fittings in the device, the handles are brought together to the stop and crimped

After the operation, two identical arcuate bends and two well-visible annular bands should form on the metal. And the result will be a clearly and firmly installed and fixed fitting, which will be almost impossible to remove with an improvised working tool.

After correctly placing the set of pipe and fitting in the device, the handles are brought together until they stop and crimped. After the operation, two identical arcuate bends and two well-visible annular bands should form on the metal. And the result will be a clearly and firmly installed and fixed fitting, which will be almost impossible to remove with an improvised working tool.

The installation of the fitting must be carried out very carefully, carefully and without haste. Under no circumstances should displacement be allowed to occur. Even 5 millimeters will become critical for the pipeline system and in the future will lead to a violation of the integrity

It is possible to determine incorrectly performed work by a staggering, indistinctly fixed nut, by the presence of an opening more than 1 mm wide visible between the metal-plastic pipe and the nut, and by loose tightening of the nut. If such errors are found, the fitting will have to be cut out of the pipe and re-installed in its place with a new one.

How to work with the tool

The technology of work with the help of press tongs is simple and does not cause difficulties.

Safety regulations

Lighting must be sufficient. You can’t work at the limit of reach when you have to stretch - you need to get closer or change the scaffold. Manipulation from ladders is not allowed.

Do not put your fingers inside the head. It is forbidden to work with a defective power tool. The machine must not be allowed to become contaminated, especially with oil, grease, water and other slippery liquids.

Do not carry the power tool by the power cord, pull the plug out of the socket with a jerk of the wire, move the power tool that is on (when the “On” button is pressed). Cleaning and adjustment of the power tool is only allowed when disconnected from the mains. Do not connect power tools with damaged cords (and plugs), use unsuitable batteries. When working in wet areas, use battery models or extension cords with a residual current device (RCD). Do not use any power tool in wet rooms and in the rain.

Preparing pipes for connection

Pipe preparation is the same for all types of tongs. Cut the workpiece to the desired length with scissors or a hacksaw. Scissors are preferable - they leave a smooth cut without burrs. The cut must be strictly perpendicular to the pipe, there must be no jams, chips, deformations. Before crimping the connection, they clean the burrs, clean the end of the pipe from dust and dirt. You can process the edge of the pipe with a calibrator, chamfer.

How to carry out crimping with manual equipment

The fitting is dismantled, put on the pipe, the fitting is inserted into the pipe until it stops, the sleeve is pulled onto the section of the pipe with the fitting.There is a hole in the sleeve through which the depth of the pipe entry into the fitting is controlled.

Before crimping, spread the handles of the press tongs by 180 °, check whether the nozzle corresponds to the diameter of the fitting to be crimped. Insert the fitting into the nozzle - the fitting sleeve must be in the nozzle exactly perpendicular to the plane of the tongs. With effort, the handles of the tongs are reduced to the stop - which means that the crimping has occurred. The handles are spread and the fitting-pipe connection is removed from the tongs. There should be two ring dents on the fitting.

All the subtleties of the process can be seen on our video.

If the pipe and fitting are not tightly or obliquely fixed, the fitting stub is loose, the compression was carried out with insufficient force - the fitting will have to be cut and thrown away, take a new one and crimp again. And at the same time, with the help of another fitting, build up the pipe. Or take a new piece. Therefore, you should be careful when carrying out work. A feature of press connectors is that they cannot be reused, the connection will be leaky. The system should be tested at maximum working pressure before starting up or grouting/pouring.

Tips for caring for press tongs

Always clean the pliers from dirt at the end of work with a clean, dry cloth. After use, check the attachment pin of the nozzle and the opening and closing of the nozzle. The nozzle is a working tool, it cannot be repaired. Throw away the damaged nozzle. The pin, if necessary, is lubricated with silicone grease.

The pressing tool is stored in a dry room at a temperature equal to the operating temperature. Batteries are stored separately from tools and metal objects.

On hydraulic and electric models, the pressure in the hydraulic system is checked every few years, gaskets and filters are changed, and the crimp time is measured. These works must be carried out by specialists.

Press tongs for metal-plastic pipes

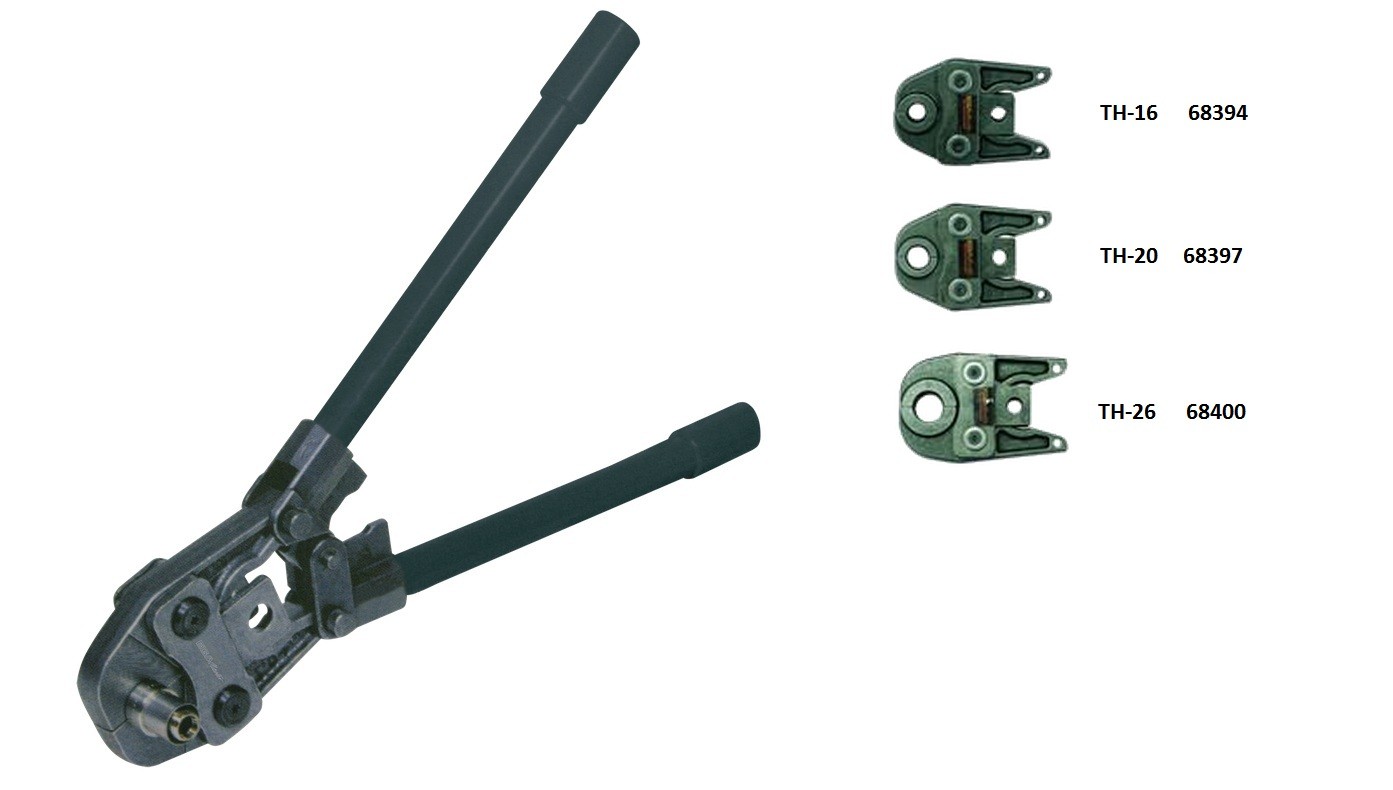

Types of pressing tongs

Most manufacturers of installation tools for metal-plastic pipelines produce, in addition to standard, unified equipment, also professional:

- hydraulic press tongs;

- electromechanical press machines with a set of various clamps, etc.

Appearance of hydraulic tongs

It makes no sense to dwell on specialized types of press tongs, since manual press tongs for metal-plastic pipes are quite suitable for a one-time installation of pipelines in an apartment or cottage. In addition, a professional tool is more expensive, and working with it requires certain skills and abilities, so it is not advisable to purchase it.

According to experts, a manual press for metal-plastic pipes is in no way inferior to professional equipment in terms of the quality of the connection being made. Therefore, cast aside doubts: a hand tool will not let you down.

The choice of pressing tongs for metal-plastic pipes

Range: manual model, battery press and electric press machine

Hand press tongs are easy to operate, they have a simple design. If you have done repairs at home at least once on your own, be sure that working with the tool will not cause any particular difficulties.

Before starting work with pressing tongs, it is necessary to determine the maximum diameter of the pipes from which the pipeline will be mounted.

Pliers for crimping metal-plastic pipes are always equipped with a passport, which specifies the technical parameters, including the maximum diameter value. In addition, the equipment is supplied with a set of inserts, with which you can crimp products with a smaller diameter.

If you are going to work with press tongs, first read the operating instructions for a particular model.

When buying a press tool, pay attention to whether it provides such built-in systems for monitoring and optimizing work, such as:

It is worth giving preference to pressing tongs of well-known brands (for example, Rotenberg)

- OPS-system - improves the quality of the applied efforts through stepped clamps;

- APS-system - evenly distributes the applied forces, based on the size of the clamped fitting;

- APC-system - controls the crimping of the fitting in automatic mode: the tongs do not open until the crimping is complete.

Conclusions and useful video on the topic

Installation of the fittings in question should not cause problems. However, there are still nuances when they connect metal-plastic pipes. And before starting work, we recommend that you watch the video instructions below to avoid beginner mistakes.

Comparison of Compression Compression Fittings and Press Fittings:

Step-by-step instructions for crimping press fittings:

An overview of the pros and cons of compression fittings:

Manufacturers of metal-plastic pipes give a guarantee of up to half a century on their products. However, the pipeline system of them will work all these decades only if the fittings are properly installed. Don't skimp.To assemble a pipeline from metal-plastic, only high-quality connecting parts should be purchased.

The press fittings must be compatible with the pipes to be installed. The best option is when all components are made by one manufacturer. Fortunately, the choice of them now on the market is extensive, there are plenty to choose from.