- Interaction of the pump with the accumulator

- Popular brands

- Which pumping station is better to buy

- The best inexpensive pumping stations for home and garden

- JILEX Jumbo 70/50 H-24 (carbon steel)

- DENZEL PSX1300

- VORTEX ASV-1200/50

- GARDENA 3000/4 Classic (1770)

- Quattro Elementi Automatico 1000 Inox (50 l.)

- First meeting

- A special case

- The device of a typical pumping station

- Pump station hydraulic accumulator

- Station pump

- Comparison of different types of pumps for a pumping station

- Pump station pressure switch

- Pressure switch regulation

- pressure gauge

- Pressure parameters in the accumulator

- Comparison table of characteristics

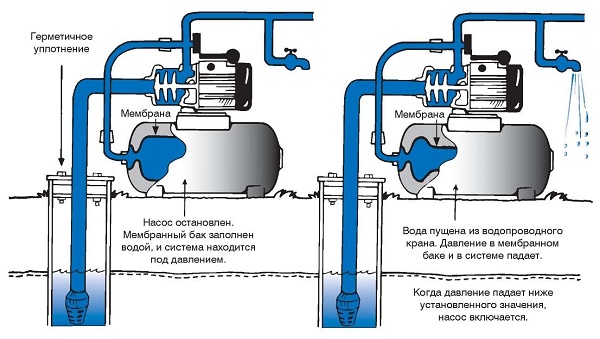

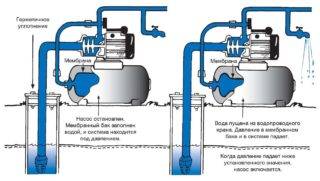

Interaction of the pump with the accumulator

The capacity of the membrane tank is selected taking into account the volume of water consumption. For a couple, a 25–40 liter option is quite enough, and for a family of several people, you will have to select a device from 100 liters.

Tanks less than 15 liters and it is generally recommended to buy only for seasonal use in the country. Due to the constant pumping of water, the membrane in them wears out quickly.

In the initial state, air is pumped into the hydraulic tank through a nipple (air valve), creating a pressure of 1.5 atm. During operation, water is pumped into the membrane under pressure, compressing the air “reserve”. When the faucet is open, the compressed air pushes the water out.

According to the rules, the hydraulic tank is selected on the basis of calculations, based on the values \u200b\u200bof the on and off pressure specified by the manufacturer, the actual water flow when the water intake points are turned on at the same time.

The fluid reserve in a hydraulic tank is usually about a third of the total volume of the tank. All the remaining space is given over to compressed air, which is needed to maintain a constant pressure of water in the pipes.

If a hydraulic accumulator is built into the water supply system to minimize the risks associated with hydraulic shocks, then the tank can be selected in a small size. In this case, it is not the volume of the container that is important, but the presence of a membrane and air behind it. It is they who, in which case, will take the blow, smoothing out its consequences.

The performance of the pump should correspond to the volume of the membrane tank (for a capacity of 20–25 liters, it is recommended to take a hydraulic pump for 1.5 m3 / h, for 50 liters - 2.5 m3 / h, and for a tank of 100 liters - at least 5 m3 / h).

The automatic pumping station operates in two cycles:

- First, water is pumped into the accumulator from the water intake, creating excess air pressure in it.

- When the tap is opened in the house, the membrane tank is emptied, after which the automation restarts the pumping equipment.

The device of a hydraulic accumulator for a water supply pumping station is extremely simple. It consists of a metal case and a sealed membrane that divides the entire space inside into two parts. In the first of them there is air, and in the second water is pumped.

The pump pumps liquid into the membrane tank only when the pressure in the system drops to values in the region of 1.5 atm, when the predetermined maximum high pressure value is reached, the station turns off (+)

After filling the accumulator, the relay turns off the pump.Opening the faucet in the washbasin leads to the fact that the water squeezed out by air pressure on the membrane begins to gradually flow into the water supply system. At some point, the tank is emptied to such an extent that the pressure weakens. After that, the pump is turned on again, starting the cycle of operation of the pumping station according to a new one.

When the tank is empty, the membrane partition is crushed and pressed against the flange of the inlet pipe. After turning on the hydraulic pump, the membrane is expanded by water pressure, compressing the air part and increasing the air pressure in it. It is this interaction of gas-liquid through a changing barrier that underlies the principle of operation of the membrane tank of a pumping station.

Popular brands

The most popular water supply pumping stations for a private house today are Gileks Jumbo. They are low priced and good quality. They are produced with pumps made of cast iron (the letter “Ch” in the marking), polypropylene (it stands for “P”), and stainless steel (“H”). There are also numbers in the marking: “Jumbo 70-/50 P - 24. It stands for: 70/50 - maximum water consumption 70 liters per minute (capacity), head - 50 meters, P - polypropylene body, and the number 24 - the volume of the accumulator.

Pumping water supply stations for a private house Gileks outwardly similar to units from other manufacturers

The price of a pumping station for water supply at home Gileks starts at $ 100 (mini options with low power and for low flow in a polypropylene case). The most expensive unit with a stainless steel case costs about $350. There are also options with a borehole submersible pump. They can lift water from a depth of up to 30 meters, flow rate up to 1100 liters per hour. Such installations cost from $450-500.

Gileks pumping stations have installation requirements: the diameter of the suction pipeline must be no less than the diameter of the inlet. If the water rises from a depth of more than 4 meters and at the same time the distance from the water source to the house is more than 20 meters, the diameter of the pipe lowered from the well or well must be greater than the diameter of the inlet. This must be taken into account when installing the system and piping the pumping station.

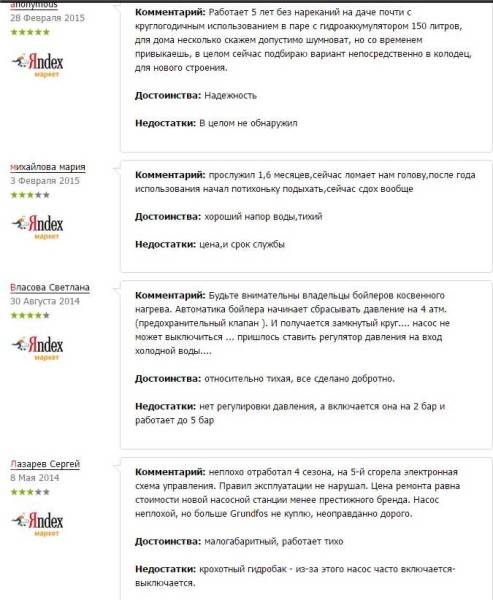

Reviews of JILEX JAMBO 60/35P-24 (in a plastic case, cost $130) you can see in the photo below. This is part of the impressions left by the owners on the trading site.

Reviews of the pumping station for water JILEX JAMBO 60 / 35P-24 (to increase the size of the picture, click on it with the right mouse button)

Grundfos pumping stations (Grundfos) work well with water supply at home. Their body is made of chrome steel, hydraulic accumulators for 24 and 50 liters. They work quietly and reliably, provide stable pressure in the system. The only downside: to the Russian market spare parts are not supplied. If, suddenly, something breaks, you will not find “native” elements. But it must be said that the units break down infrequently.

Prices for pumping stations with surface pumps start at $ 250 (power 0.85 kW, suction depth up to 8 m, capacity up to 3600 liters / hour, height 47 m). A more productive unit (4500 liters/hour with a higher power of 1.5 kW) of the same class costs twice as much - about $500. Reviews of the work are presented in the format of a photo that was taken on the website of one of the stores.

Reviews of Grundfos pumping stations for water supply at home or cottages (to increase the size of the picture, click on it with the right mouse button)

The Grundfos series of pumping stations with stainless steel pump casings is more expensive, but they also have idle protection stroke, overheating, cooling - water. The prices for these installations are from $450. Modifications with borehole pumps are even more expensive - from $ 1200.

The water supply pumping stations for the Wilo house (Vilo) have proven themselves well. This is a more serious technique for ensuring high flow: up to four normally suction pumps can be installed at each station. The body is made of galvanized steel, the connecting pipes are made of stainless steel. Management - programmable processor, touch control panel. The performance of the pumps is smoothly regulated, which ensures a stable pressure in the system. The equipment is solid, but so are the prices - about $1000-1300.

Wilo pumping stations are suitable for the water supply of a large house with a significant flow rate. This equipment belongs to the class of professional

How to make an autonomous water supply in a house connected to a centralized water supply, with poor pressure, or provide yourself on an ongoing basis with hourly water supply, see the following video. And all this with the help of a pumping station and a water storage tank.

Which pumping station is better to buy

For the stable operation of the water supply system or pumping liquid, a pumping station is used. In order to choose the right model that meets the individual characteristics of operation, it is necessary to take into account a number of parameters. To these include the height of the water, the volume of the accumulator, the material of manufacture, technical characteristics and installation method.

Lift height is one of the key criteria for equipment selection. It largely depends on the type of pumping station:

- The productivity of single-stage units is low. Their lifting height is 7-8 m, however, they provide a stable pressure and work silently.

- Multi-stage complexes use several impellers, due to which their efficiency is significantly higher, and the pressure is more powerful.

- Water intake from a depth of up to 35 meters can be carried out by models with a remote ejector, but they are much more expensive than their counterparts.

The main technical characteristics of the pumping station should include performance. It determines the volume of water that the equipment is capable of pumping, and its pressure in the system. It also affects power. To ensure normal water pressure at several flow points at the same time, the power of the station up to 2 kW will be sufficient.

The volume of the storage tank affects the frequency of switching on the pump and the water supply in the event of a power failure. A capacious reservoir contributes to the durability of the electrical windings and the ease of use of the water supply system during power outages. The optimal indicator of the volume of the tank for working in a private house is a value of about 25 liters.

Attention should be paid to the material of manufacture of the pumping station. It largely determines the durability and permissible conditions for maintaining equipment.

For installation in rooms with high humidity, it is recommended to choose a model, the body and main components of which are made of stainless steel. Plastic impellers reduce the cost of the unit, but they are less resistant to wear than steel or cast iron elements.

To extend the life of the pump, it is worth considering the presence of pressure switch protection systems. The functions of protection against dry running and overheating will ensure that the pumping station is turned off if there is no water or the permissible temperature of the power unit is exceeded.

The best inexpensive pumping stations for home and garden

For small houses and cottages, inexpensive pumping stations are suitable. They will provide the kitchen, shower and bathroom with water, will allow you to water the garden and vegetable garden in hot weather. Experts have identified several effective and reliable models.

JILEX Jumbo 70/50 H-24 (carbon steel)

Rating: 4.8

The pumping station JILEKS Jumbo 70/50 N-24 is an automatic installation for a water supply system. It perfectly combines power (1.1 kW), suction depth (9 m), head (45 m) and performance (3.9 cubic meters / h). The station is equipped with a self-priming electric pump and a hydraulic accumulator installed horizontally. The entire structure is mounted on an adapter flange. The main parts are made of stainless steel, aluminum and durable plastic. The model becomes the winner of our rating.

Users are satisfied with the operation of the pumping station. It regularly delivers water from deep wells and wells, has a compact size, and has a pressure boost function. The disadvantages of the owners include noisy work.

- metal case;

- quality assembly;

- wide functionality;

- good pressure.

noisy work.

DENZEL PSX1300

Rating: 4.7

The most productive pumping station in the budget segment is the DENZEL PSX1300 model. The manufacturer equipped it with a powerful electric motor of 1.3 kW, due to which a pressure of 48 m is formed. The throughput is 4.5 cubic meters. m / h, and you can extract water from a depth of 8 m.This performance is enough for many users for water supply at home, baths, as well as for watering a personal plot. Experts note the ease of installation and connection, during operation, the station does not make a lot of noise. The model is inferior to the rating winner only in functional equipment.

The owners of the pumping station speak flatteringly about performance, pressure, and pressure maintenance. The democratic price should also be attributed to the pluses. The built-in filter does a great job of purifying the water.

- high power;

- silent operation;

- quality assembly;

- reliability and durability.

modest functionality.

VORTEX ASV-1200/50

Rating: 4.6

The VORTEX ASV-1200/50 pumping station is of great interest to domestic homeowners. In just 2 months, according to NM data, 15,659 people were interested in it. The model has sufficient performance to provide water to the house and water the garden in the summer. A capacious tank (50 l) allows the pump to turn on less often, which has a positive effect on durability. The model is equipped with automation, so it is able to work without prolonged human intervention. The pumping station ranks third in the ranking due to feedback from consumers who have experienced unit breakdowns.

Most of the complaints come from the unreliability of the model. Some of them break in the first days after connection.

- quality assembly;

- high power;

- capacious tank;

- quiet work.

- high price;

- frequent minor breakdowns.

GARDENA 3000/4 Classic (1770)

Rating: 4.5

A simple GARDENA 3000/4 Classic pumping station can supply water to a 2-storey cottage.Experts note the precise execution of all parts, as well as the high-quality assembly of the device. The model loses to the top three in the rating in terms of electric motor power (650 W) and throughput (2.8 cubic meters / h). But the installation has small overall dimensions and low weight (12.5 kg). The manufacturer took care of extending the life of the pumping station by installing protection against dry running and overheating. You should also highlight the presence of such an option as a soft start of the engine.

In reviews, homeowners praise the system for its light weight, quiet operation, and simple design. The disadvantages of users include the presence of plastic connections with delicate threads.

- ease;

- low price;

- reliable engine protection;

- smooth start.

- low power;

- flimsy plastic joints.

Quattro Elementi Automatico 1000 Inox (50 l.)

Rating: 4.5

The Quattro Elementi Automatico 1000 Inox model closes the rating of budget pumping stations. The advantages of the device experts include a large storage tank (50 l), the presence of a pressure increase function. With an electric motor power of 1.0 kW, the pump is capable of lifting water from a depth of 8 m, creating a maximum head of 42 m. At the same time, the throughput reaches 3.3 cubic meters. m/h The body of the station is made of stainless steel, which becomes a reliable protection against corrosion.

The model also has weaknesses. The electrical part is very sensitive to a decrease in voltage in the network (which often happens in the provinces). Does not like the unit to stay in an unheated room for the winter. Serious problems arise for the owners and with the maintenance of a foreign device.

First meeting

A pumping station is several devices mounted on a common frame.

The list of equipment includes:

- Pump (usually centrifugal surface);

- Hydraulic accumulator (a container divided by an elastic membrane into a pair of compartments - filled with nitrogen or air and intended for water);

- Pressure switch. It controls the power supply of the pump depending on the current pressure in the water supply and accumulator;

Mandatory components of a water supply station

At many pumping stations, the manufacturer installs a pressure gauge that allows you to visually control the current pressure.

Pumping station for giving Alco with a built-in pressure gauge

Let's imagine how a pumping station works for a summer residence:

- When power is applied, the pressure switch turns on the pump;

- He sucks in water, pumps it into the accumulator and then into the water supply. At the same time, the pressure of the gas compressed in the air compartment of the accumulator gradually increases;

- When the pressure reaches the upper threshold of the relay, the pump turns off;

- As the water flows, the pressure gradually drops. The pressure is provided by air compressed in the accumulator;

- When the pressure reaches the lower threshold of the relay, the cycle repeats.

Calculation of the water column at a pressure of 1 kgf / cm2 (760 mm Hg)

A special case

The suction depth limitation is successfully bypassed by surface pumps with an external ejector and stations based on them. For what?

The ejector of such a pump is an open nozzle directed into the suction pipe. The flow of water supplied to the nozzle under pressure through the pressure pipe entrains the water masses surrounding the nozzle.

In this case, the suction depth depends to a large extent on the flow rate (read - on the pump power) and can reach 50 meters.

Scheme of the ejector

Aquatica Leo 2100/25. Price - 11000 rubles

The device of a typical pumping station

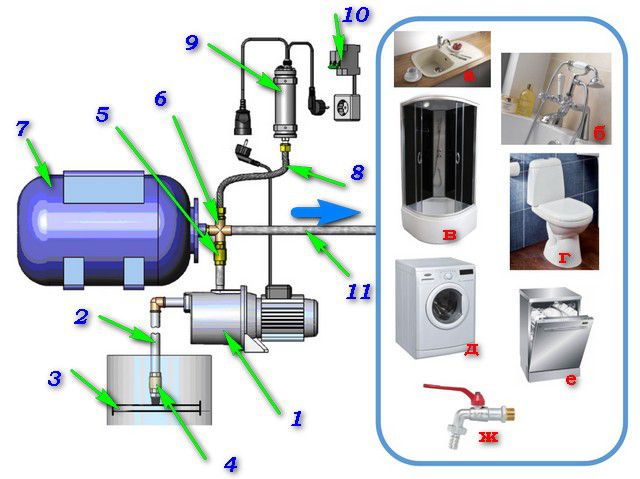

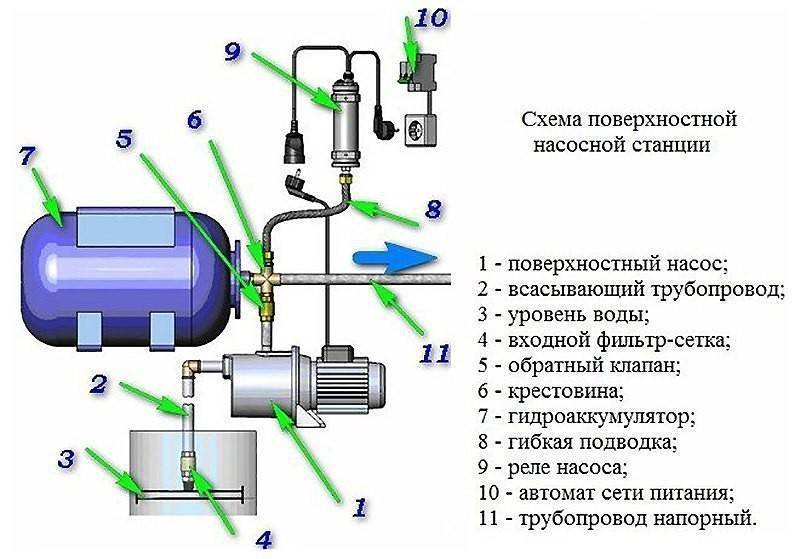

A typical pumping station for a summer residence consists of the following main parts:

- hydraulic accumulator (hydraulic tank with a membrane);

- pump;

- pressure switch;

- manometer;

The device of a typical pumping station

Pump station hydraulic accumulator

A hydraulic accumulator is a hollow tank, inside of which there is a rubber pear, into which the pumped water enters. At the manufacturer's factory, air is pumped into the accumulator under pressure so that the rubber bulb shrinks. When pumping water into the pear, overcoming the pressure in the tank, it can straighten up and even inflate a little. Due to this mobility of the volume filled with water (pears), protection against water hammer is provided, i.e. when you open, for example, a faucet in the sink, the water will flow out of it smoothly, without sharp blows

This is extremely important both for the consumers themselves and for mixers, shut-off and connecting valves.

Injection nipple air into the hydraulic accumulator of the pumping station

The volume of accumulators varies from 1.5 to 100 liters. The larger the tank, topics:

- there will be fewer starts of the pump for pumping water, which means less wear on the pump;

- a larger volume of water can be obtained from the tap, with a sudden power outage (about half a tank).

Station pump

The pump provides the main function of the station - it pumps water from one place to another. But how exactly they do it is an important question. The following types of pumps are used in pumping stations:

- surface pumps:

- multistage;

- self-priming;

- centrifugal.

- submersible pumps:

- centrifugal;

- vibrating.

Surface pumps are installed directly in the pumping station, most often on a hydraulic accumulator.Submersible pumps are lowered under water, and they pump water into a tank at a distance.

Comparison of different types of pumps for a pumping station

| Pump type | Suction depth | pressure | efficiency | Noise level | Installation | Exploitation |

|---|---|---|---|---|---|---|

| Centrifugal pump | 7-8 m | high | short | high | away from home, remotely | difficult: it is necessary to fill the system with water |

| Multistage pump | 7-8 m | high | high | normal | inside the house | difficult: it is necessary to fill the system with water |

| Self-priming pump | up to 9 m (up to 45 m with an ejector) | normal | normal | normal | inside the house | simple: no features |

| Centrifugal submersible pump | up to 40 m | normal | short | normal | in water | simple: no features |

| Vibratory submersible pump | up to 40 m | short | short | normal | in water | simple: no features |

Characteristics of the pumping station

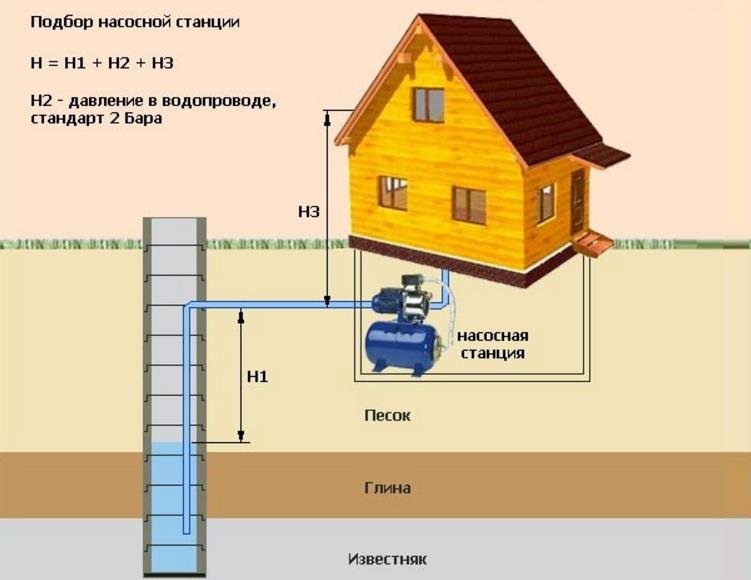

main parameters pumping station selection for giving

If you plan to use a pumping station for sewage, i.e. drainage of fecal and waste water, then you will need special installations. We wrote in detail about all types of pumps in the article.

Pump station pressure switch

The pressure switch signals the pump stations start and stop pumping water into the system. It is necessary to set the relay to the limit values \u200b\u200bof the pressure in the system so that it knows at what point the pump needs to be started and at what point it should be stopped. The standard values of the lower pressure in the system are set to 1.5-1.7 atmospheres, and the upper ones to 2.5-3 atmospheres.

Pump station pressure switch

Pressure switch regulation

Remove the plastic cover with pressure switchby unscrewing the fastening screw with a flat screwdriver. Inside you will find two springs and nuts that compress them.

Remember two things:

- The large nut is responsible for the lower pressure, and the small one is responsible for the upper.

- By turning the nuts clockwise, you will increase the boundary pressure to which the relay will be oriented.

By turning on the pumping station (Attention, follow safety precautions!), You can evaluate the values of the upper and lower pressure limits set in the pressure switch using a pressure gauge

pressure gauge

A pressure gauge is a measuring device that shows the pressure in the system at the present time. Monitor pressure gauge data to adjust pressure switch settings pumping station.

The pressure gauge of the pumping station shows the pressure in the water supply system of the cottage

Pressure parameters in the accumulator

For the proper operation of household plumbing fixtures in the water supply of the cottage, it is necessary to maintain a pressure of 1.4–2.6 atmospheres. To prevent the accumulator membrane from wearing out too quickly, manufacturers recommend setting the pressure in it to 0.2–0.3 atm higher than the water pressure.

The pressure in the water supply of a one-story house is usually 1.5 atm. From this figure, and should be repelled when adjusting the hydraulic tank. But for larger residential buildings, the pressure must be increased so that water is in all the taps farthest from the riser. Here, more complex hydraulic calculations are needed, taking into account the length and configuration of pipelines, as well as the number and type of plumbing fixtures.

Simplified, you can calculate the required pressure for the intra-house water supply using the formula:

(H+6)/10,

where "H" is the height from the pump to the highest point of water supply to the plumbing on the top floor of the house.

However, if the calculated pressure indicator in an autonomous water supply system exceeds the permissible characteristics of existing plumbing and household appliances, then when such pressure is set, they will fail. In this case, it is necessary to select a different scheme for distributing water pipes.

The pressure in the air part of the accumulator is regulated through the spool by bleeding excess air or pumping it with a car pump

Comparison table of characteristics

The table below presents the key characteristics of the models under consideration. By comparing them with each other, it will be easier for you to navigate the variety of devices and choose the one that best suits your wishes and needs in the device.

| Name of the pumping station | Power, in W | Tank volume, in l | Mechanism device |

| JILEX Jumbo 70/50 Ch-24 | 1100 | 24 | centrifugal |

| Grundfos MQ 3-35 (850 W) | 850 | 35 | surface |

| VORTEX ASV-1200/24N | 1200 | 24 | vortex |

| JILEX Poplar 65/50 P-244 | 1100 | 50 | surface |

| DAB E.sybox Mini 3 (800W) | 800 | 24 | centrifugal |

| AL-KO HW 4000 FCS Comfort | 1200 | 30 | centrifugal |

| DAB AQUAJET 82M (850W) | 850 | 24 | surface |