- Device

- What to look for when choosing a pump?

- The best pumps for wells up to 50 meters

- VORTEX CH-135 (1800 W)

- BELAMOS TF3-60 (800 W)

- BELAMOS TF3-80 (1000 W)

- Aquario ASP 1E-30-90 (450 W)

- VORTEX CH-50 (750 W)

- Well pump selection options

- Aquifer characteristics

- Water requirement

- pressure

- The degree of entry into the casing

- Popular well pump models

- Why do you need a pump in the heating system

- The principle of operation of the circulation pump

- Consider an example of calculating a submersible well pump for working with automation:

- Let's calculate according to the available data:

- Selection Options

- Water flow and pump performance

- Lifting height (pressure)

- Immersion depth

- Well diameter

- Design features

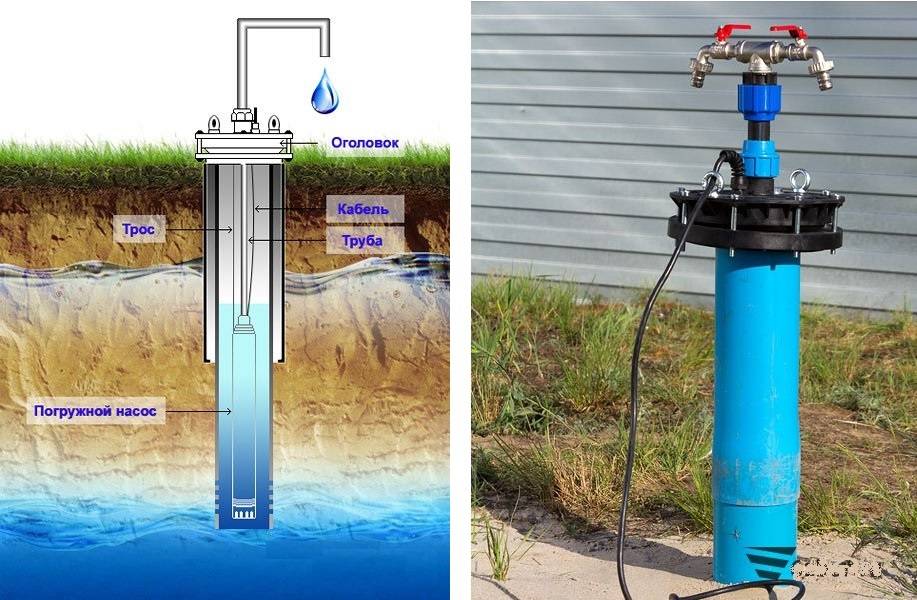

Device

Of great importance for an outboard pump in a well is the cable with which it is installed. An incorrectly selected mount can break at any time and you will need to buy a new one along with a replacement pump. It is almost impossible to extract the loss from a narrow deep well, and this will not affect the quality of the water in the best way. The main thing when choosing a cable is the mass that it is able to hold, along with the water covering the pump.

The load in some cases exceeds 80 kg, but there is no need to be afraid - professional equipment can withstand several times more weight.

If you need to save money, it is recommended to choose cables based on synthetic materials. But even cheapness and immunity to corrosion do not make them an ideal solution. After all, synthetic fiber is gradually stretched, and therefore the load will act more and more on the pipes. You can improve the consumer characteristics of any cable by folding it in half or in four layers. Steel retaining elements, even in very clean water, will last for about a year; zinc coating increases this period, but only slightly.

A more perfect option is a polymer tube around steel. For its manufacture, polyvinyl chloride is used. If you mount the device according to all the rules, the service life will be quite long. But the PVC at the place of attachment to the pump inevitably frays over time and there comes a moment when the cable rusts and breaks. An alternative is the use of stainless steel cables. There is only one problem: the high price of a similar design, approaching the prices of budget category pumps.

Some people use iron chains with a small link or climbing ropes to secure pumping equipment. It is better not to conduct such experiments, because no one will give a firm guarantee of their success. In any design, even the smallest load must not be applied to the network cable, this is extremely dangerous. In many cases, it is better to use not an plug-in motor, but an external device. But this imposes certain restrictions on the hoses used.

In any case, you should not buy a hose that is only good for one watering.It will help only in the warm season of the year, providing:

- car washing (motorcycle, bicycle, paths and sidewalks);

- actually, watering;

- filling containers;

- water supply of a country house.

The rigidity of the hoses taking water from the well is very important. It can be achieved by thickening the walls, introducing reinforcing parts, creating a corrugated structure. The most perfect option are hoses, which are reinforced with steel spirals. They will endure significant pressure for as long as possible. For hoses that will be used all year round, frost resistance is of particular importance.

Flattening and deterioration of characteristics under the influence of negative temperatures are strictly unacceptable. When it is known for sure that the water will be taken for drinking, any rubber hoses become unacceptable. The liquid that has passed through them not only acquires a bad smell, it gradually becomes unsafe for the health and even life of consumers. Therefore, drinking water is allowed to be pumped only through silicone and PVC channels. Silicone is definitely suitable for food use, lasts a long time and does not give off a negative smell.

The objective disadvantage of this material is its unsatisfactory strength and the risk of destruction at the junctions with other sections of the highway, with equipment. PVC is better in this regard and is relatively inexpensive. Regardless of the material of the hose, it is recommended to buy it at a large department store, and even better - at a branded outlet. No one can guarantee the safety of water that has passed through a hose purchased on the market or in an underpass. The same applies to fittings and fasteners.

What to look for when choosing a pump?

Before the final choice, you should pay attention to several key technical characteristics of pumping equipment. One of these characteristics is performance.

It is measured in l/min or cube. m / h and means the volume of pumped water per minute or hour. For a family of 2-3 people, this figure should reach 45 l / min or 2.5 cubic meters. m/h minimum

One of these characteristics is performance. It is measured in l / min or in cubic meters. m / h and means the volume of pumped water per minute or hour. For a family of 2-3 people, this figure should reach 45 l / min or 2.5 cubic meters. m/h minimum.

This indicator can be calculated independently. Sum the water consumption of all points of intake (consumers) in the house and multiply by a factor of 0.6. The number 0.6 means that no more than 60% of all water intake points are used at the same time.

The coefficients for calculating the performance are presented in l / min and in cubic meters. m/hour. For calculations, select only the values of those fence points that are in the house

The maximum pressure is an important indicator. It depends on the pressure force whether the pump will pump enough water for your needs. To calculate it, it is necessary to sum up the dynamic and static water levels. Then add 10% of the amount received.

There are more complex formulas that take into account the distance to the house and the number of water intake points. If you do not want to carry out complex calculations yourself, then seek the advice of a specialist.

The statistical water level or depth to the mirror is the distance between the actual water level and the top of the well. If this distance does not exceed 10 meters, then a surface pump should be selected.

Some experts believe that this figure should be in the range of 2-7 meters. In other cases, focus on the submersible. Note that the latter is more durable, almost silent, and also powerful.

Surface pumps are quite heavy and noisy. They are ideal if a well or well up to 10 meters deep

Surface pumps are quite heavy and noisy. They are ideal if a well or well up to 10 meters deep

Also important is the height of the water column or the dynamic level - this is the distance from the water's edge to the bottom of the well. It is necessary to take into account the depth of the well or well, since this parameter is also prescribed in the passport for the pump. These indicators should ideally match

It is worth taking into account the height of the pump itself in relation to the well

The power of the equipment is fixed in W and means how much electricity the pump will “pull”. Do not purchase a pump with a power reserve, otherwise you will simply overpay for electricity.

Pay attention to the body material, it must have corrosion protection. Details are also important.

Check, at least visually, the quality of the assembly, the wheels. It is best if they are "floating" and made of durable technical plastic.

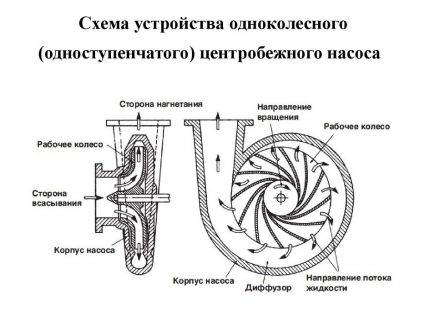

The key working tool of a centrifugal hydraulic pump is the wheel. Most often it is made of an alloy of non-ferrous metals, stainless steel or cast iron.

More tips for choosing the right model well pump we have presented in the next article.

The housing of the centrifugal pump contains impeller with bladesthat carry water. In powerful devices, there may be several such wheels.

The housing of the centrifugal pump contains impeller with bladesthat carry water. In powerful devices, there may be several such wheels.

The wheel is powered by an electric motor. Centrifugal force displaces water to the edge of the wheel from its center.Thus, a zone of high pressure is formed and the liquid flows through the pipes to the points of water intake (kitchen, bath, watering). Then the pressure is reduced and the process starts again.

Some centrifugal pumps have a hydraulic accumulator. This is a tank with a membrane element. It is used to maintain the necessary pressure in the pipes through which water, with the help of a pump, flows from the well and into the house. It is indispensable for wells and wells with a depth of 10 to 30 meters.

Another important element is the check valve. The principle of its operation is that the water does not have the opportunity to move in the opposite direction, that is, from the house through pipes to the well.

It is also worth considering what kind of water the pump can pump. If the water in the well is mixed with lime, clay or sand, then this must be announced before purchase. Otherwise, the pump will clog and fail prematurely.

Before buying, find out the location of service centers and the availability of parts (at least key ones) for the selected pump model.

If you want to install the pump yourself, then be sure to carefully read the instructions for the device and consult with specialists.

Given these characteristics, you can easily select the right pump model.

The best pumps for wells up to 50 meters

VORTEX CH-135 (1800 W)

Borehole pump VORTEX CH-135 (1800 W) is a high-performance device for supplying water from wells.  It is characterized by the ability to lift a large amount of liquid from a depth of 60 meters.

It is characterized by the ability to lift a large amount of liquid from a depth of 60 meters.

The stainless steel housing ensures a long service life of the pump.

Do not pump contaminated fluid. The distance to the bottom should not be less than 0.6 m.

Main functional characteristics:

- submersible well;

- maximum productivity - 5.7 m³ / h;

- maximum pressure - 135 m;

- immersion depth - 60 m;

- vertical installation.

Advantages:

- build quality;

- water pressure;

- performance.

Flaws:

not selected by users.

BELAMOS TF3-60 (800 W)

Submersible pump BELAMOS TF3-60 (800 W) is used to supply clean water located in the well at  depth up to 80 m.

depth up to 80 m.

The presented model is indispensable for any owner of a summer cottage or a country house in which there is no centralized water supply.

Housed in a durable stainless steel case, the device has a well-thought-out design, which includes a special shape of the blades for a stable water pressure, regardless of its flow rate.

This pump is ready to lift water to a height of up to 60 m under optimal operating conditions.

Main functional characteristics:

- submersible well;

- maximum productivity - 2.7 m³ / h;

- maximum pressure - 60 m;

- immersion depth - 80 m;

- vertical installation.

Advantages:

- performance;

- water pressure;

- build quality.

Flaws:

short wire.

BELAMOS TF3-80 (1000 W)

Submersible pump BELAMOS TF3-80 (1000 W) is designed to supply clean water from great depths. used  for work in automated water supply systems for summer cottages, private houses, farms, etc.

for work in automated water supply systems for summer cottages, private houses, farms, etc.

The built-in non-return valve has a stainless steel spring.

A large number of pump stages and a special material and shape of the blades provide a stable head over a wide range of fluid flow.

Main functional characteristics:

- submersible well;

- maximum productivity - 2.7 m³ / h;

- maximum pressure - 85 m;

- immersion depth - 80 m;

- vertical installation.

Advantages:

- performance;

- water pressure;

- low noise level.

Flaws:

not found by users.

Aquario ASP 1E-30-90 (450 W)

The borehole pump Aquario ASP 1E-30-90 (450 W) is used for pumping clean water from wells and wells.  It is used in private automated water supply systems for irrigation, irrigation and other domestic needs.

It is used in private automated water supply systems for irrigation, irrigation and other domestic needs.

The installation of a submersible multistage pump will allow organizing a system for supplying fluid from a well or other water source with a diameter of more than 10 cm.

The equipment is quite easy to install and connect to the water supply, its installation and connection will take no more than 30 minutes.

Main functional characteristics:

- submersible well;

- maximum productivity - 2.82 m³ / h;

- maximum pressure - 33 m;

- immersion depth - 50 m;

- vertical installation.

Advantages:

- low noise level;

- performance;

- ease of installation.

Flaws:

poor build quality.

VORTEX CH-50 (750 W)

The reliable pump VORTEX CH-50 (750 W) allows you to lift large amounts of water from great depths.  The equipment is specially designed for pumping fluid for various purposes from narrow openings (wells or wells).

The equipment is specially designed for pumping fluid for various purposes from narrow openings (wells or wells).

The device is not designed for contaminated water.

The pump has an elongated cylindrical shape and is similar to a sleeve. The body is made of durable stainless steel.

The device takes in water from the top.

Main functional characteristics:

- submersible well;

- maximum productivity - 2.4 m³ / h;

- maximum pressure - 50 m;

- immersion depth - 60 m;

- vertical installation;

- weight - 13.3 kg.

Advantages:

- low noise level;

- water pressure;

- build quality.

Flaws:

short wire.

Well pump selection options

Aquifer characteristics

The characteristics of the aquifer include:

1. depth - dynamic, changing depending on various factors, and static;

2. debit - the amount of liquid entering the intake per unit of time;

3. the type of soil in which the water is located.

After the work is completed, a passport is drawn up indicating all the necessary data.

Water requirement

In the case of a private house, the need for water is calculated - it should not exceed the debit. When determining it, the number of residents and plumbing fixtures, as well as the mode of operation + the amount of liquid for irrigation, are taken into account.

This parameter, depending on the situation, differs significantly, therefore, with an eye to the norms, it is better to determine it based on consumption habits - under similar conditions, the throughput may need both 2 and 20 m3 / h.

pressure

A mandatory parameter is the head, which can be considered in atmospheres or meters of water column - the ratio between these values is approximately: 1 to 10.

In its simplified calculation, the following are summarized:

1. Geometric lift height (vertical distance from the pump to the highest point of disassembly);

2. Losses on horizontal sections (10 m equals 1 m)

3. Free pressure at the mixer (from 2 or 3 m).

The degree of entry into the casing

The device should enter the casing pipe with a clearance of 1 ... 3 cm. The most common diameters of the latter are 10, 13 and 15 cm. Accordingly, the pumps are produced at 3", 4", more than 4".

Popular well pump models

Among the most common models of the vibrational type of action, one can distinguish "Baby" and "Brook". They are characterized by good performance, reliability and reasonable cost.For simple maintenance and repairs, a general knowledge of plumbing is sufficient. As permanent pumps inside the well, these units are not suitable, the sooner they are replaced, the better.

In the line of submersible centrifugal pumps, the brands "Vodoley" and "Vodomet" have good reviews. Although visually these units are almost indistinguishable, the performance of Aquarius is noticeably higher. This is due to the use of higher quality and durable components. The prices for equipment of this brand are also higher. As for the "Vodomet", this budget model can be successfully used in wells with a small load.

There is a separate subspecies of special pumps for wells on the market. For a pump of this type, you will have to pay a decent amount, but all the invested finances will fully pay off during operation. Among professionals, the 3STM2 and 4STM2 models from TAIFU are especially popular. They are able to work in difficult conditions, pumping large volumes of water.

Why do you need a pump in the heating system

Circulation pumps for heating private houses are designed to create a forced movement of the coolant in the water circuit. After the installation of the equipment, the natural circulation of the liquid in the system becomes impossible, the pumps will operate continuously. For this reason, high demands are placed on circulation equipment regarding:

- performance.

- Noise isolation.

- Reliability.

- Long service life.

A circulation pump is needed for "water floors", as well as two- and one-pipe heating systems. In large buildings it is used for hot water systems.

As practice shows, if you install the station in any system with natural circulation of the coolant, the heating efficiency and uniform heating along the entire length of the water circuit increase.

The only disadvantage of such a solution is the dependence of the operation of pumping equipment on electricity, but the problem is usually solved by connecting an uninterruptible power supply.

Installing a pump in the heating system of a private house is justified both when creating a new one and when modifying an existing heating system.

The principle of operation of the circulation pump

The operation of circulation pumps increases the energy efficiency of the heating system by 40-50%. The principle of operation of devices, regardless of type and design, is as follows:

- The liquid enters the cavity, made in the form of a shell.

- Inside the housing there is an impeller, a flywheel that creates pressure.

- The speed of the coolant increases and, by means of centrifugal force, the liquid is discharged into a spiral channel connected to the water circuit.

- The coolant enters the water heating circuit at a predetermined rate. Due to the swirling of water flows, the hydraulic resistance decreases during fluid circulation.

The principle of operation of a heating system with a circulation pump differs from circuits with natural circulation in that the movement of fluid is forced. The heating efficiency is not affected by compliance with slopes, the number of installed radiators, as well as the diameter of the pipes.

The operation of circulation pumps may differ slightly, depending on the type of construction, but the principle of operation remains the same. Manufacturers offer more than a hundred models of equipment, with various performance and control options.According to the characteristics of pumps, stations can be divided into several groups:

- According to the type of rotor - to enhance the circulation of the coolant, models with a dry and wet rotor can be used. The designs differ in the location of the impeller and moving mechanisms in the housing. So, in models with a dry rotor, only the flywheel, which creates pressure, comes into contact with the coolant fluid. "Dry" models have high performance, but have several drawbacks: a high level of noise is generated from the operation of the pump, regular maintenance is required. For domestic use, it is better to use modules with a wet rotor. All moving parts, including bearings, are completely encased in a coolant medium that serves as a lubricant for the parts that bear the greatest load. The service life of the "wet" type water pump in the heating system is at least 7 years. There is no need for maintenance.

- By type of control - the traditional model of pumping equipment, most often installed in domestic premises of a small area, has a mechanical regulator with three fixed speeds. It is quite inconvenient to regulate the temperature in the house using a mechanical circulation pump. The modules are distinguished by high power consumption. The optimal pump has an electronic control unit. A room thermostat is built into the housing. Automation independently analyzes the temperature indicators in the room, automatically changing the selected mode. At the same time, electricity consumption is reduced by 2-3 times.

There are other parameters that distinguish circulation equipment. But to choose a suitable model, it will be enough to know about the above nuances.

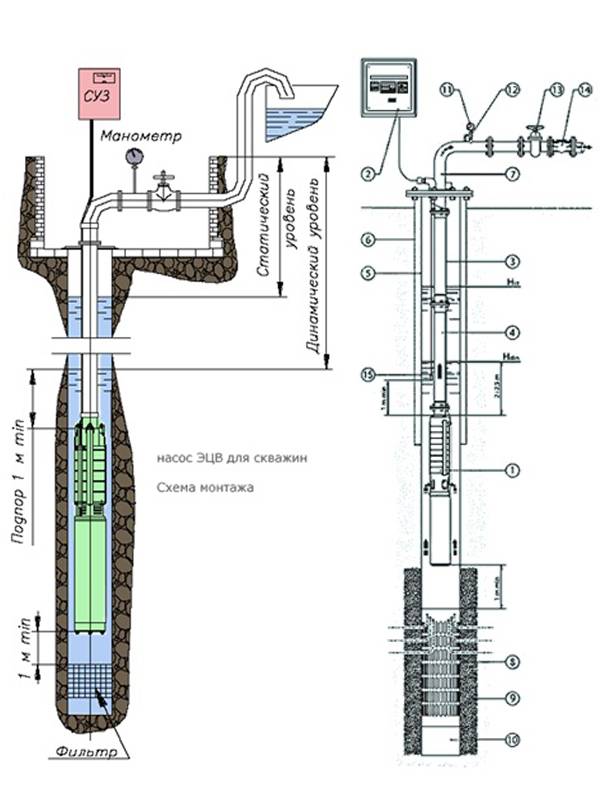

Consider an example of calculating a submersible well pump for working with automation:

Well depth: 30m (A)

The pump is always raised from the bottom of the well by 2-3 meters.

Let's take a rise of 2m. As a result (A = 28m).

Horizontal pipe section (B):

From the well to the house: 20 m or 0.2 atm along the horizon, (B = 20m)

Pressure resistance (V) :

The presence of 5 pipe turns (0.5atm = 50m);

check valve (0.39 atm = 39m) and filter (0.4 atm = 40m), (H = 129m)

It should be noted that if the well depth is more than 60m, then it is necessary to install 2 check valves - one is placed directly after the pump, and the second at a height of 45-50m.

Also, most manufacturers recommend installing a check valve after the pump through a distance of 1 to 5 m, but this can be neglected at shallow depths.

Let's take a mirror of water: 5m (G)

We take into account the water mirror and get a water column in which the pump will be 28m-5m = 23m (A=23m)

Did you know that the pump experiences a liquid lifting load starting from the end of the water column.

In this example, the mirror is 5m, so the pump will need to overcome the vertical resistance of a 5m water column. Thus, the pressure resistance will be 0.5 atm (10m = 1 atm).

However, it is necessary to take into account seasonal fluctuations in the water column - this is about 10 m, i.e. add another 1 atm loss.

As a result: D=5+10=15m (D=15m)

Debit: 1.8 cubic meters / hour (D)

If you do not know the debit of your well, then you can safely take 1.2-1.4 cubic meters / hour

Let's calculate the amount of water produced by the well:

D \u003d 1.8 * 1000 / 60 \u003d 30 l / min

Water points: take one (T)

D = 30l/min; T= 10l/min ===> D>T

D>T - means water does not decrease in the well, therefore, the pump does not need to work on the water column in the well, when it is empty ==> (A = 0)

Let's calculate according to the available data:

We translate the values of horizontal losses into vertical ones (10m horizontally = 1m vertically):

(B + C) / 100 ==> (20m + 129m) / 100 = 1.49m; D=15m

A + B + C + D \u003d E, provided D < T; B + C + D \u003d E, provided D >= T

15m + 1.49m = 16.49m =>

E \u003d 16.49m (16.49m / 100 \u003d 1.649 atm)

1,649m (2atm) this height will be spent only on the ascent water to the pressure switch. those. we will get a water pressure of not more than 0.1 atm at the outlet of the pipe.

Based on this, we need to get the output, i.e. at the point of water parsing about 2.6 atm (26m).

It should be remembered that if you use automation, then the pressure in the accumulator is always set to 0.1 atm less than the pressure to turn on the automation !!! It is also necessary to know that the accumulator stabilizes the pressure in the system and its resistance can be neglected.

A properly tuned accumulator will last longer.

If you have a multi-storey building, then you need to take into account the rise to the highest point of analysis, taking into account 10m = 1 atm of losses.

As a result, we get: 2.6 + 2 + Htop point = 4.6atm (46m).

We conclude that the pump lift must be at least 46 meters.

46m + 10% = 50.6m => The ideal option would be a pump with a lift of 50 meters.

We always make a minimum margin of 5-10% in terms of pump power. This will reduce its wear and allow the engine to work more stably during voltage drops and pump starts.

From the calculation obtained, we obtain a list of suitable pumps:

Aquario ASP 1E 45-90 (head 45 m, CABLE 35 m.) - Pressure margin 24%

Aquatech SP 3.5″ 4- 45 (head 45 m, cable 25 m) - Pressure margin 14%

BELAMOS Borehole pump TF3-60 (head 60 m, cable length 35 m) - Pressure margin 62%

WWQ Borehole pump 3NSL 0.5/30P (head 53 m, cable length 30 m) — Pressure margin 34%

The most minimal suitable option and at the same time financially attractive:

WWQ Borehole pump 3NSL 0.5/30P (head 53 m, cable length 30 m) — Pressure margin 34%

Aquatech SP 3.5″ 4- 45 (head 45 m, cable 25 m) - Pressure margin 14%

The most ideal option:

WWQ Borehole pump 3NSL 0.5/30P (head 53 m, cable length 30 m) — Pressure margin 34%

With such borehole pump and the pressure will be good and in the future you can slightly expand the length of the horizontal water supply or add more points of analysis, without critical loads for the engine.

Selection Options

Well pumps are easy to distinguish even by their appearance. They are an elongated cylinder made of stainless steel or plastic. Naturally, stainless steel models are more expensive - the steel must be of high quality (usually food grade AISI304). Pumps in a plastic case are much cheaper. Although they are made of a special impact-resistant plastic, they must be handled with care - it still does not tolerate shock loads very well. All other parameters will have to be selected.

Brief technical characteristics of the pump for the well

Water flow and pump performance

In order for the water in the house or in the country to be with sufficient pressure, equipment is needed that can deliver the required volume of liquid. This parameter is called pump performance, measured in liters or milliliters (grams) per unit of time:

- ml/s - milliliters per second;

- l / min - liters per minute;

- l / h or cubic / h (m³ / h) - liters or cubic meters per hour (one cubic meter is equal to 1000 liters).

Downhole pumps can lift from 20 liters/min up to 200 liters/min. The more productive the unit, the greater the power consumption and the higher the price. Therefore, we choose this parameter with a reasonable margin.

One of the key parameters for selecting a well pump is performance

The required amount of water is calculated by two methods. The first takes into account the number of people living and the total expense. If four people live in the house, then the water consumption in day will be normal 800 liters (200 l/person). If there is not only water supply from the well, but also irrigation, then some more moisture must be added. We divide the total amount by 12 (not by 24 hours, because at night we use water supply to a minimum). We get how much we will spend on average per hour. Dividing it by 60, we get the required pump performance.

For example, for a family of four and watering a small garden, it takes 1,500 liters per day. Divide by 12, we get 125 liters / hour. In a minute it will be 2.08 l / min. If you often have guests, you may need a little more water, so we can increase the consumption by about 20%. Then you will need to look for a pump with a capacity of about 2.2-2.3 liters per minute.

Lifting height (pressure)

When choosing a pump for a well, you will inevitably study the technical specifications. There are parameters such as lifting height and immersion depth. Lifting height - also called pressure - is a calculated value. It takes into account the depth from which the pump will pump water, the height to which it must be raised in the house, the length of the horizontal section and the resistance of the pipes. Calculated according to the formula:

The formula for calculating the pump head

An example of calculating the required pressure.Let it be necessary to raise water from a depth (pump installation site) of 35 meters. The horizontal section is 25 meters, which equates to 2.5 meters of elevation. The house is two-story, the highest point is a shower on the second floor at a height of 4.5 m. Now we consider: 35 m + 2.5 m + 4.5 m = 42 m. We multiply this figure by the correction factor: 42 * 1.1 5 = 48.3 m. That is, the minimum pressure or lifting height is 50 meters.

If in the water supply system of the house has a hydraulic accumulator, it is not the distance to the highest point that is taken into account, but its resistance. It depends on the pressure in the tank. One atmosphere is equal to 10 meters of pressure. That is, if the pressure in the GA is 2 atm, when calculating, instead of the height of the house, substitute 20 m.

Immersion depth

Another important parameter in the technical specifications is the immersion depth. This is the amount with which the pump can pump out water. It varies from 8-10 m for very low-power models to 200 m and more. That is, when choosing a pump for a well, you need to look at both characteristics at once.

For different wells, the depth of immersion is different

How to determine how deep to lower the pump? This figure should be in the passport for the well. It depends on the total depth of the well, its size (diameter) and flow rate (the rate at which water arrives). In general, the recommendations are as follows: the pump should be at least 15-20 meters below the water surface, but even lower is better. When the pump is turned on, the liquid level drops by 3-8 meters. The amount remaining above it is pumped out. If the pump is very productive, it pumps quickly, it must be lowered lower, otherwise it will often turn off due to lack of water.

Well diameter

An important role in the selection of equipment is played by the diameter of the well. Most domestic well pumps have sizes from 70 mm to 102 mm. In general, this parameter is usually measured in inches. If so, then the easiest way to find three and four inch specimens. The rest are made to order.

The well pump must fit in the casing

Design features

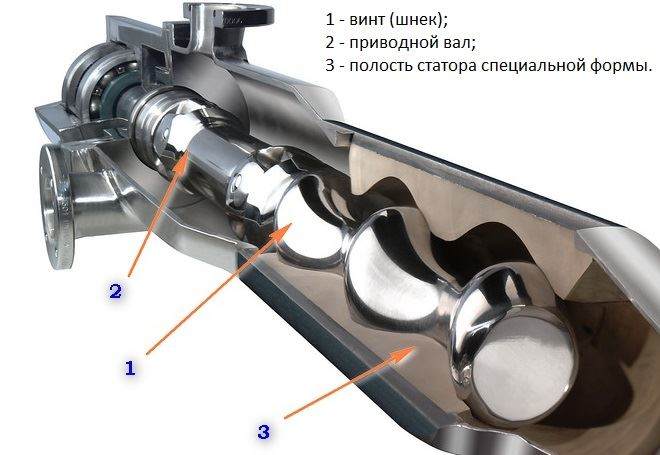

Screw well pump consists of cylindrical or conical housing and a motor attached to the flange through sealing washers. Inside the casing there is a working shaft having a screw configuration.

When the working element rotates, the liquid is supplied to the outlet; hermetic seals do not allow backflow of water. Due to this, a constant pressure is achieved in the water supply system and the working chamber of the pump. The performance of the device depends on the angle of twist of the screw and the rotational speed of the rotor of the electric motor.

There are pumps with an engine integrated into the housing. The power drive passes through a sealed channel to the stator windings; the design of the product provides for an oil tank for automatic lubrication of the screw bearings and the motor rotor.

Water is supplied to the pump cavity through a mesh grate mounted around the screw housing. The pressure fitting allows you to connect a flexible rubber hose, which is connected to the storage tank of the water supply system.

Schematic representation of a downhole screw pump device

Schematic representation of a downhole screw pump device

For the pump to work, it is required to lower the equipment into the working environment; the use of the pump in wells or wells is allowed. When air is drawn in, the deep pump begins to wear out; automation ensures that the auger drive is turned off.

The equipment allows you to supply not only water, but also pump oil products or solutions containing impurities of aggressive substances (provided that chemical-resistant materials are used in the pump design).

The design of the equipment allows pumping water with impurities in the form of sand or silt. Foreign particles are fed together with the liquid into the pressure hose and then separated in a sump or by means of a filter element. A coarse filter is installed on the intake pipe of the pump, which does not allow large stones or algae fibers to pass through. The screw type pump has a diameter corresponding to the size of the well; reduction of dimensions allows to improve the technical characteristics of the equipment.