- Well pump cleaning and minor repairs

- Which well pump to choose

- We select the unit according to the features of work

- How to choose a pump for a well 20 meters

- Pump for a 20 meter well for irrigation

- Pump for water supply at home

- The best submersible drainage pumps

- Karcher SP 1 Dirt

- Zubr NPG-M-750

- AL-KO Dive 55500/3

- The best pumps for a well from 70 meters

- BELAMOS TF-100 (1300 W)

- Grundfos SQ 3-105 (2540 W)

- BELAMOS TF3-40 (550 W)

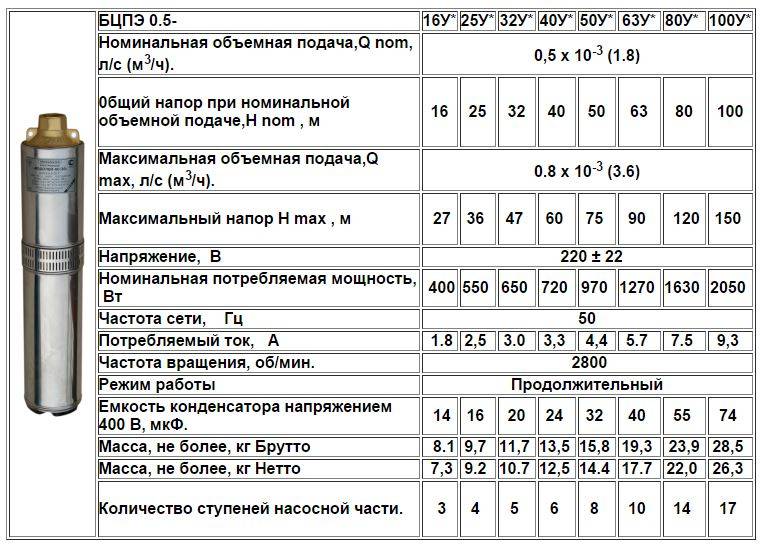

- Aquarius BTsPE 0.5-100U

- UNIPUMP ECO MIDI-2 (550W)

- No less important details

- Surface and submersible well pumps

- Pros and cons of screw and centrifugal pumps for wells

- About the manual rod pump

Well pump cleaning and minor repairs

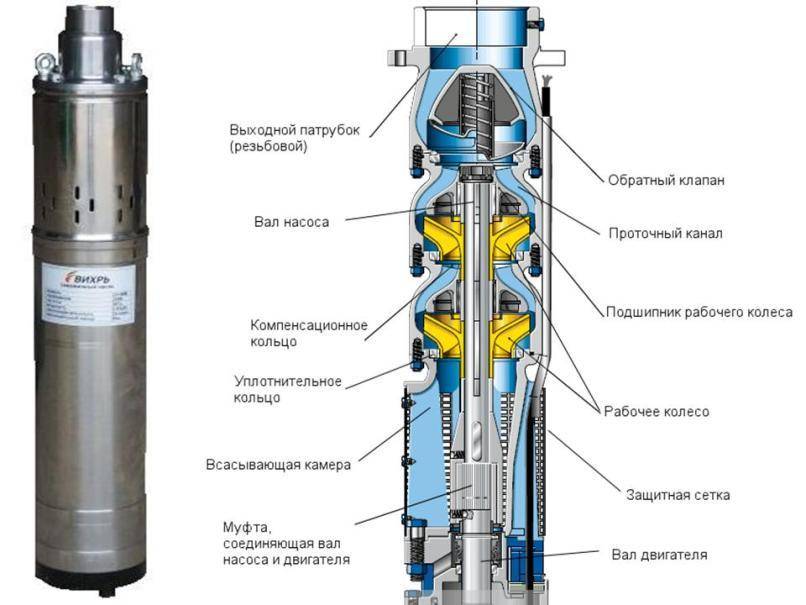

There are times when the downhole pump device does not rotate and its owner needs to disassemble the pump. Please note: the device does not have an internal filter, and a mesh that traps stones and coarse sand is attached outside between the engine and the pump part. For this reason, the cessation of rotation, as a rule, is caused by breakage or clogging of the impellers. Not a large blockage, it is possible to try to eliminate it yourself.

You need to clean in several stages:

– Remove the protective grid. In new models, it is fixed with a special clip that opens by prying with a screwdriver or by lightly pressing in the middle.On the old ones - there are two ordinary bolts that are easily unscrewed

- On wide models of pumps, it is also possible to remove the cable channel - a small metal groove that protects the cord from defects.

– The engine can be dismantled and disconnected from the pump part by unscrewing the four bolts with a 10 wrench. After that, it is necessary to remove the couplings that direct the engine power to the pump.

- The disassembled apparatus is carefully placed on a horizontal surface

It is very important not to damage the cord

- Next, you need to scroll the shaft with a 12 head or a socket wrench, be sure to support the upper part of the device. When the shaft moves, it is necessary to apply a jet of water to the pumping part in order to remove parts from there due to which the device is stuck. After making sure that the shaft can rotate, carefully wash the pump, and assemble it in the reverse order.

Not infrequently, there are cases when the owner of the pump, noticing that the axle in the pump part does not rotate, decides that the bearing is jammed. But in the pump part there is one plain bearing and, accordingly, cannot jam. Here there was a problem with the impellers and it is best to replace them. If you have spare parts, you can try to fix the pump yourself. For this you need:

- Rest against the brass part of the bottom of the apparatus and with force squeeze the shell from below and from above.

- Using narrow teeth, remove the retaining ring. The ring is in a special groove and will loosen if the shell is squeezed hard.

- Remove all impellers one by one, then remove the thrust cover with bearing.

- Eliminate the cause of jamming and fold the parts in reverse order.

Which well pump to choose

one.When choosing a pump for agriculture, graphs are built, according to which the most suitable unit is determined - you can do this work yourself (if you have knowledge) or with the help of designers.

2. You always need to select a device with a small margin, but nothing more - every extra kilowatt will negatively affect the cost.

3. In most cases, you can buy a centrifugal model; with high purity of water, vortex modification is well suited; if the fluid is not of the best quality, the screw version is fine.

4. A vibrating device is more suitable for wells - if necessary, it can also be used as a borehole, but you need to remember that such a pump can be very silted up.

We select the unit according to the features of work

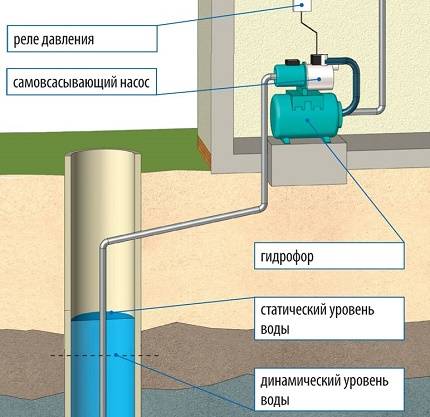

When all of the above has been analyzed, you can begin to familiarize yourself with the types of pumps. Based on the characteristics of the work, all systems are divided into 2 subgroups: surface and submersible (otherwise - deep). Let's consider their differences.

This type of equipment is installed on the ground, without immersion. The pump pumps liquid by suction. The deeper the water column is, the harder it is to lift the liquid, the more powerful the system is selected. It is recommended to buy surface pumps for wells in which the distance to the beginning of the water column does not exceed 8 meters. Do not buy a rubber hose for pumping water. When the equipment is turned on, it will begin to compress the walls due to rarefied air and will not let water through. It is better to replace it with a pipe with a small diameter. The most important plus of the surface pump: easy to install, dismantle.

A surface pump can be installed right next to the well, and to reduce its growl, you can make a box out of wood and hide equipment there

If you have a deep well, then the option with a surface pump will not work. We'll have to look among the submersible units.

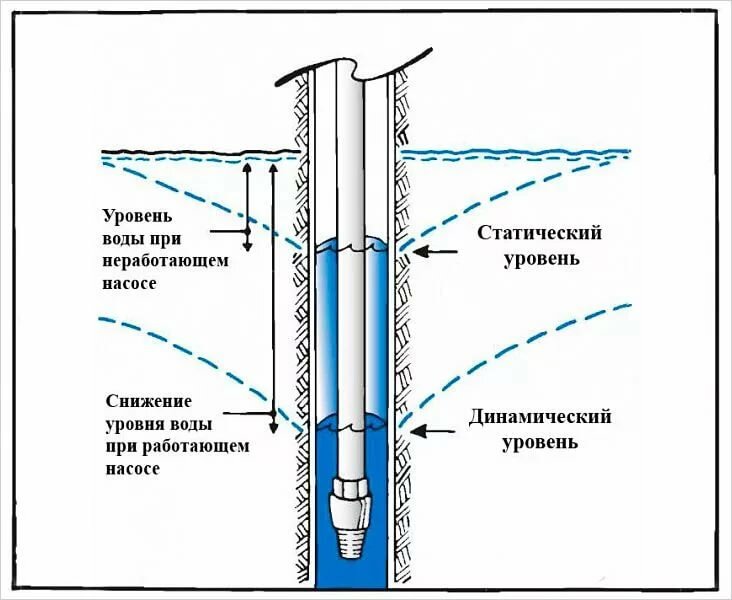

The technique is immersed directly into the pipe, into the water column. The systems work on the principle of liquid ejection. Determine which pump is needed for your well, according to the size of the well. More precisely, it is necessary to calculate to what height the unit will have to push the water jet. To do this, remember the measurements that you took earlier. The length of the dry rope with a weight is the height to which the pump will have to raise the water. Add 3-4 meters to it, because the pump is immersed a couple of meters deeper than the beginning of the water, and you will get the final figure. If it does not exceed 40 meters, then you can buy simple, low-power pumps. Look in the passport for information on the maximum depth at which the system can operate.

It is easy to recognize more powerful submersible pumps: their appearance is larger than that of low-power “brothers”, and they are heavier in weight

By the way, if according to your calculations, the height of the water rise is 60 meters, and this depth is the maximum for the pump, then it is better not to take this model. The equipment will work at the limit of its strength, because with each meter in depth, productivity decreases, and the load increases. Look for pumps designed for 70 meters of depth. This will help the equipment work without unnecessary stress and be better preserved.

Of the two types of deep-well pumps (centrifugal and vibration), it is better to stop at the first. Vibrating ones are too sensitive to dirty water, and in the process they destroy the walls of the well.

The centrifugal pump captures water with blades, and not by vibration of the membrane, like a vibrating one, so it hangs motionless and does not destroy the walls of the well

The pump is selected for a long time, so look for models released by well-known, well-established manufacturers. Then it will be easier for you to find a service center to repair and maintain your system.

How to choose a pump for a well 20 meters

So, you have drilled a 20 meter artesian well (or sandy) and you need to buy a submersible pump for it, what to do. Your first and most important step is to look at the passport for the well, there are already given recommendations on choosing a well pump. Select it by following these instructions and you don't need to do anything else.

Don't have a well permit?

Then let's go point by point, first we will find out which pump diameter is right for you, for this you need to know what diameter of the casing pipe you have.

We have made a small plate for you, this will help you determine the diameter of the pump:

| Casing | Pump diameter |

| Steel 133 mm (without plastic) | 4 inches |

| Steel 133 mm + 110 mm plastic | 3 inches |

| Steel 133 mm + 117 mm plastic | 3" or 3.5" |

| Galvanized 152 mm + 125 mm plastic | 4 inches |

| Steel 159 mm + 125 mm plastic | 4 inches |

All submersible pumps have their own marking (example Grundfos 2-70), in which the first number (2 m3 / h) indicates the performance, and the second (70 meters) indicates the pressure. Simply put, this pump can pump 2 m3/h from a depth of 70 meters. To choose the right submersible pump, you need to know these parameters.

Remember, the performance of a borehole pump should not exceed 90-95% of the well flow rate.

The pressure is easy to calculate on your own, now we will do it.

Pump for a 20 meter well for irrigation

If you are planning a summer arrangement and want to water strawberries near the bathhouse, then ordinary and cheap models will suffice.

Let's pick up a pump for irrigation from a well 20 meters.

We need to lift water from a depth of about 15 meters, which means that the required head should be 15 meters. Plus, we need a pressure of at least 2 atmospheres (1 atm = 10 meters of pressure).

In total, the required pressure is 35 meters. We select ...

The flow rate of the well is 1.5 m3 / h. For a sand well with a low flow rate, the following pumps are suitable:

- Aquarius 0.32-32U

- Gilex Water Cannon 40/50

- SPERONI STS 0513 or SPS 0518

- UNIPUMP MINI ECO 1 (3 inches)

- Grundfos SQ 1-50 (3")

The flow rate of the well is 2 m3 / hour. A sandy well with a slightly higher flow rate will normally be combined with such pumps:

- Aquarius 0.32-40U

- SPERONI SPS 1009

- Gilex Water Cannon 55/50 or Water Cannon 60/52

- UNIPUMP MINI ECO 1 (3 inches)

- SPERONI SQS 1-45 (3 inches)

The flow rate of the well is 2.5 m3/hour. For such a flow rate, you need one of these pumps:

- 0.5-40U

- Gilex Water Cannon 60/72

- SPERONI SPS 1013

- SPERONI SQS 2-45 (3 inches)

The flow rate of the well is 3 m3 / hour. The following pumps are well suited for irrigation for a shallow artesian well:

- SPERONI SQS 2-60 (3-inch)

- 55/90 or Aquarius 60/92

- SPERONI STS 1010

- UNIPUMP MINI ECO 2 (3 inches)

- Grundfos SQ 2-55 (3")

The flow rate of the well is 3.5 m3/hour.

- SPERONI SPS 1812 or STS 1308

- UNIPUMP MINI ECO 3 (3 inches)

The flow rate of the well is 4 m3/hour.

- Aquarius 1.2-32U

- SPERONI SPS 1815

- Grundfos SQ 3-40 (3")

Such small wells are most likely drilled into the sand, which means that their service life is 5-7 years. Therefore, when choosing a pump, it is not necessary to study it for a long time in terms of reliability. Such a period will work any of the pumps indicated above.Not to mention Grundfos or Speroni.

Pump for water supply at home

Consider the water supply of a one-story and 2-story house from a 20 meter well. To do this, you need to calculate the pressure.

So, let the pump need to lift water from 15 meters, then we need 15 meters of pressure to raise water to ground level. The highest draw-off point is on the 2nd floor, it is another 5 meters in height. In total, to raise water from a well to a tap on the 2nd floor, you need 20 meters of pressure. The tap should have a pressure of 3 atmospheres (1 atm = 10 meters of pressure), which means we add another 30 meters of pressure. Already 50 meters, and we will add 20 meters for losses and for reserve so that the pump does not work at the limit and can quickly create the necessary pressure.

In total, for a 2-storey house and a well of 20 meters, you need a pump with a pressure of 70 meters. For a 1-storey house, we will simply remove 3 meters, because now there is no need to raise water to the 2nd floor. This means that the required pressure will be equal to 67 meters.

In total, for a 2-storey house and a well of 20 meters, you need a pump with a pressure of 70 meters. For a 1-storey house, we will simply remove 3 meters, because now there is no need to raise water to the 2nd floor. This means that the required pressure will be equal to 67 meters.

Experience has shown that the pumps of the following manufacturers are of the highest quality in their price segment:

The best submersible drainage pumps

The submersible drainage pump is designed in such a way that the internal mechanism and the impeller perform stable operation in difficult conditions. This is pumping out dirty water with various impurities: sand, particles of silt, small stones. This is a hardy, working device that helps to drain melt water from basements, cellars during flooding. Perfectly copes with technical liquid from drain holes, ditches.

Karcher SP 1 Dirt

German quality at the most attractive price. Drainage pump with vertical installation, light weight 3.66 kg. The body is made of durable stainless steel. In the lower part there are wide slots for suction of particles with a size of 20 mm.It has a low power consumption of 250 watts. The maximum installation depth is up to 7 m. Throughput speed is 5.5 cubic meters. m/hour. The pressure on the highway is 4.5 m.

Equipped with a float mechanism with automatic water level control. Provided thermal protection against overheating, idle move. Sturdy carrying handle, there is a relay for automatic / manual switching. Warranty period 2 years.

Advantages

- Stable efficiency;

- Minimum power consumption;

- Easily passes 20 mm particles;

- Reliable ceramic sealing ring;

- Small cost.

Flaws

After pumping dirty water, flushing with clean water is necessary.

Due to its design features, low weight, stable performance, Karcher SP 1Dirt can often be found in the private sector. Due to the light weight, compact size, the pump is easy to carry for installation in any place.

The best gasoline walk-behind tractors

Zubr NPG-M-750

The best budget offer of a domestic manufacturer, good quality / cost ratio. Inexpensive model with excellent characteristics. The maximum power along the highway is 9 m, the throughput speed allows you to pump up to 13.5 cubic meters in one hour. dirty water. The optimum size of the passed solid particles is 35 mm. Despite the small immersion depth of only 7 m, the drainer quickly copes with the task.

Light weight of 4.7 kg, comfortable handle make it easy to carry the device without assistance. Average power consumption 750 W. It has built-in thermal protection against overheating. The float mechanism of control of level of water, protects the device from idling. The manufacturer pleased with a long warranty - 5 years.

Advantages

- Excellent price / quality ratio;

- Durable stainless steel body;

- Idle protection;

- Relay for off/on adjustment;

- A light weight.

Flaws

Not detected.

According to experts, this is the only model of submersible drainage, which the manufacturer was not afraid to establish the longest warranty period.

AL-KO Dive 55500/3

The submersible model of the drainage pump of the German manufacturer, is of high quality components. Robust wear-resistant body, high tightness is a distinctive feature. The motor is reliably protected from idling in conditions of critically low water levels. Throughput - 5.5 cubic meters per hour. This is a good indicator for providing water supply, irrigation of the site and other purposes.

The device is designed to work only with clean water, since the size of the passed solid particles is only 0.5 mm. Compact dimensions, light weight of 7.5 kg, maximum head along the line 30 m. Average power consumption 800 W.

Advantages

- German quality;

- Quiet operation of the motor;

- power stability;

- Idle protection;

- Acceptable price.

Flaws

- Does not work with dirty water;

- No thermal protection against overheating.

Since the drain is designed to pass solid particles of only 0.5 mm, it is strictly forbidden to use it for pumping dirty water. Works only with water from sedimentation tanks, storage tanks with rainwater.

The best pumps for a well from 70 meters

BELAMOS TF-100 (1300 W)

Borehole pump BELAMOS TF-100 (1300 W) is used to organize autonomous water supply in private homes and water plants, as well as in agriculture to create irrigation systems.

The 1300 W electric motor is designed for intensive work with increased loads and provides a capacity of 4500 liters per hour.

The thermal relay protects the device from overheating.

The pump part is made of high quality stainless steel.

Main functional characteristics:

- submersible well;

- maximum productivity - 5 m³ / h;

- maximum pressure - 100 m;

- immersion depth - 80 m;

- vertical installation;

- weight - 22.1 kg.

Advantages:

- performance;

- water pressure;

- build quality.

Flaws:

not specified by buyers.

Grundfos SQ 3-105 (2540 W)

The borehole pump Grundfos SQ 3-105 (2540 W) is designed for water supply to private houses, pumping water from tanks, irrigation hydraulic systems and small waterworks.

The single-phase permanent magnet electric motor is capable of high efficiency over a wide power range.

The electric motor is completed with a removable cable connector.

Main functional characteristics:

- submersible well;

- maximum productivity - 4.2 m³ / h;

- maximum pressure - 147 m;

- installation horizontal and vertical;

- weight - 6.5 kg.

Advantages:

- performance;

- water pressure;

- low noise level.

Flaws:

not marked by buyers.

BELAMOS TF3-40 (550 W)

Submersible pump BELAMOS TF3-40 (550 W) is used for pumping clean water from great depths to the house or for watering plants.

The design of the pump part provides the possibility of independent maintenance (cleaning) of the pump part, without going to the workshop.

To disassemble the pumping part, it is enough to unscrew the top cover or the lower flange of the pumping part.

The device is completed with a cable, a plug with a grounding contact.

Main functional characteristics:

- submersible well;

- maximum productivity - 2.7 m³ / h;

- maximum pressure - 42 m;

- immersion depth - 80 m;

- vertical installation;

- weight - 9.4 kg.

Advantages:

- performance;

- build quality;

- water pressure.

Flaws:

not identified by users.

Aquarius BTsPE 0.5-100U

The submersible pump Aquarius BTsPE 0.5-100U consists of a single-phase electric motor and a multi-stage pump part, created in the form of a monoblock, as well as an external condensate box, which is attached to a power cord with a plug.

The electric pump has a thermal relay, which effectively protects it during emergency operation.

The volumetric flow of a submersible pump depends on many factors - the depth of the water, the length and diameter of the operated hose, etc.

Main functional characteristics:

- submersible well;

- maximum productivity - 3.6 m³ / h;

- maximum pressure - 150 m;

- immersion depth - 100 m;

- vertical installation;

- weight - 25 kg.

Advantages:

- performance;

- water pressure;

- build quality.

Flaws:

not specified by users.

UNIPUMP ECO MIDI-2 (550W)

The UNIPUMP ECO MIDI-2 borehole pump (550 W) is used to supply water from sources with a diameter of at least 98 mm.

By means of a deep pump, an automated water supply system can be organized in a summer cottage, in a country house, in production, etc.

"Floating" wheels are made of wear-resistant carbonate.

They minimize the risk that the pump will seize when pumping solids.

A special filter prevents the penetration of large abrasive particles into the pump section.

Main functional characteristics:

- submersible well;

- maximum productivity - 3 m³ / h;

- maximum pressure - 73 m;

- immersion depth - 100 m;

- vertical installation.

Advantages:

- water pressure;

- low noise level;

- performance.

Flaws:

not found by users.

No less important details

When choosing a pump, it is important to consider the quality of drilling work. If professional equipment and a team were involved, this well will be reliable

If you resorted to the help of acquaintances and friends, then this is unlikely. Professional drilling contributes to rare cases of sanding and silting. This will have a positive effect on the functioning of the pump.

If this is an amateur job, then most often, the well will be prone to sanding and silting. For this reason, it is recommended to resort to special pumps that are designed to function in the most difficult conditions. Equipment of this type will cost more, but it will easily endure the situation when water begins to flow into it, in which there is pollution. Under such loads, a simple pump will quickly fail. Owners of professional wells get a higher percentage of equipment selection.

Thus, they will be able to choose a universal or special pump. It will not always be convenient to use a rubber hose to lift water from the depth of the well to a height. During the operation of pumping equipment, the air that is inside the hose will be rare. For this reason, the walls of the hose collapse, the flow of water stops. Stopping this phenomenon is not an easy task.Instead of a rubber hose, plastic structures with the appropriate diameter should be used.

A pipe that is designed for water pressure will be more effective in a 10 meter well and more than a rubber hose that can collapse, preventing water from escaping normally.

The main indicator when choosing a pump is considered to be the approximate water consumption per day. The value is average, as consumption becomes higher in summer and lower in winter. The daily norm for a family of 3-4 people is 60-70 liters. But there is no water for irrigation and the needs of the economic plan. The rate should be increased in view of the number of plants on the site, pets, etc.

The owners, who are prudent about their site, choose 4-inch pipes for a well of 20 meters or more, even though structures of 3 inches in diameter are also used in this capacity. This is due to the fact that a significant part of the equipment is designed for a spacious 4-inch pipe. In order to convert centimeters to inches, it is worth dividing the measurement result with a tape measure by "2.54". This is due to the fact that an inch is equal to this number of cm.

In order for a head to be present at each draw-off point, which is sufficient for operation, it is necessary to apply a hydraulic calculation. The pump must provide all points to the fullest.

Surface and submersible well pumps

To understand which downhole pump to choose for a well, you need to understand the classification of pump equipment.

What are the pumps for wells at the installation site:

- Submersible. They are installed inside the mine, in close proximity to its bottom.

- Surface. The location of these models is the surface of the earth, in the immediate vicinity of the water intake point. There is also an option with installation on special floats, when the pumping device floats on the surface of the water. To understand which surface pump is best for a well, it is necessary to measure the depth of the mine. Surface pumps use suction in their work, so their efficiency largely depends on the height of the rise of the water taken from the source.

To understand which well a surface pump is best for, you need to take into account the distance from the water to the surface of the earth. Ideally, it should not exceed 8 m. Popular Abyssinian wells have similar parameters, for which a surface pump is an ideal option. The fact is that the shaft of such a well is very narrow and shallow.

As for filtration or artesian wells, a positive result will not be achieved when using surface models. There is only one way out - to buy a submersible deep-sea pump for a well

Considering both types of pump, it must be taken into account that surface pumps make more noise during operation. For this reason, equipment is usually installed inside a special enclosure or in a separate room. Unlike surface devices that suck in water, submersible devices push it out

Unlike surface devices that suck in water, submersible devices push it out.

When deciding which submersible pump to choose for a well, special attention is paid to the distance from the point where the equipment is located to the surface of the earth. To get it, 2 m is added to the dynamic level.Most of the models on sale are capable of supplying water to a height of up to 40 m.

To equip a well with a greater depth, it is necessary to use a pump of increased power. The accompanying documentation contains an indication of the power of the pump for the well and the maximum height to which the device can pump water. Some people, the old fashioned way, install a manual water pump, which is very economical and practical in some cases.

Most of the models on sale are capable of supplying water to a height of up to 40 m. To equip a well with a greater depth, it is necessary to use an increased power pump. The accompanying documentation contains an indication of the power of the pump for the well and the maximum height to which the device can pump water. Some people, the old fashioned way, install a manual water pump, which is very economical and practical in some cases.

The approximate power of the pump can be found by the appearance of the equipment. Equipment of high productivity is placed in a large housing. Such devices weigh much more than standard pumps with an immersion depth of up to 40 meters.

Taking into account these considerations, it is desirable to purchase devices with a certain margin of performance. For example, for a mine with a depth of 50 m, a unit designed for installation at a depth of 60 m is well suited. At maximum depth, the device will operate in constant overload mode

This will negatively affect the duration of its service due to the rapid wear of internal parts. Wells with a depth of immersion of 60 m must be equipped with pumps for operation at a depth of 70 meters. It is desirable that the pump equipment has automatic protection against "dry running".Sometimes it happens that the water supply to the unit is interrupted for one reason or another.

At the maximum depth, the device will operate in the mode of constant overloads. This will negatively affect the duration of its service due to the rapid wear of internal parts. Wells with a depth of immersion of 60 m must be equipped with pumps for operation at a depth of 70 meters. It is desirable that the pump equipment has automatic protection against "dry running". Sometimes it happens that the water supply to the unit is interrupted for one reason or another.

Pros and cons of screw and centrifugal pumps for wells

| Pump type | Advantages | Flaws |

|---|---|---|

| Screw | with it you can get a lot of pressure; | large in size - it will not be possible to place it everywhere; |

| can be placed at any depth; | there are no screw surface options - they are only submersible; | |

| dirty water is not an obstacle for such a pump; | With such a pump, there is no way to dose the water supply. | |

| it is easy to maintain; | ||

| it is not too expensive, but more expensive than vibration. | ||

| Centrifugal | small size will allow it to be placed even in a small well; | centrifugal pumps are extremely demanding on water quality; |

| extremely reliable device; | all centrifugal options are expensive. | |

| as a rule, practically does not make noise; | ||

| a wide variety of models allows you to find exactly what you need. |

About the manual rod pump

Despite modern technology, thanks to which all the models that will be described below have appeared, in some villages and suburban areas you can still see manual pumping equipment. As a rule, we are talking about rod pumps, since they are easier to use to some extent.

Such pumps are placed at wells or wells, the depth of which is more than 10 meters. At such a depth, the piston "brothers" no longer work properly, but the rod ones do not.

Despite modern technology, the hand pump is still in use due to the simplicity of its design and reliable operation.

Despite modern technology, the hand pump is still in use due to the simplicity of its design and reliable operation.