- Types of hydraulic tanks for water supply systems

- Testing and verification of internal and external fire-fighting water supply

- Types of water pipes

- Optimum air pressure

- How to choose the right hydraulic tank

- Calculation of tank parameters

- Advantages and disadvantages

- Expansion tank of open type for heating systems

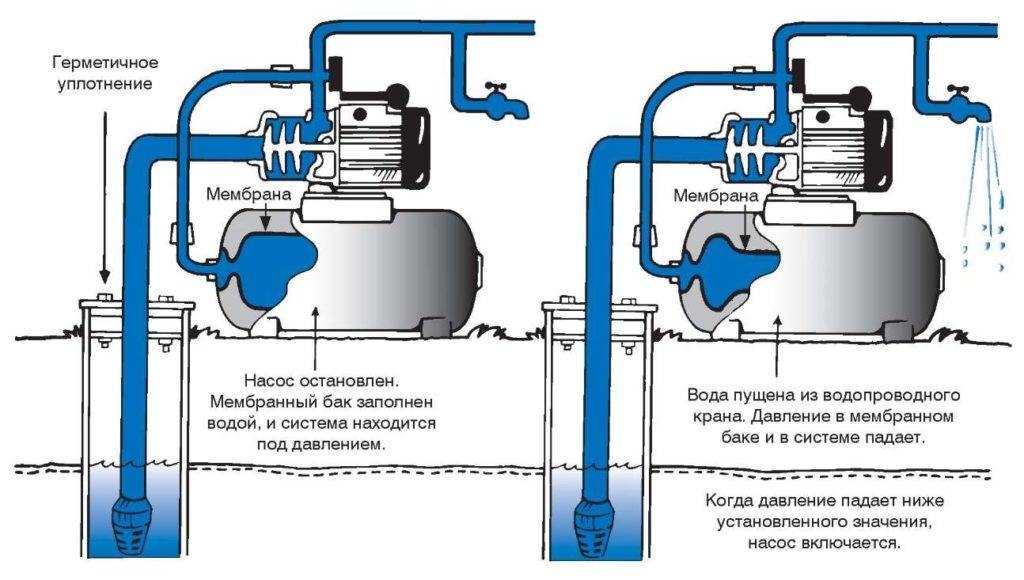

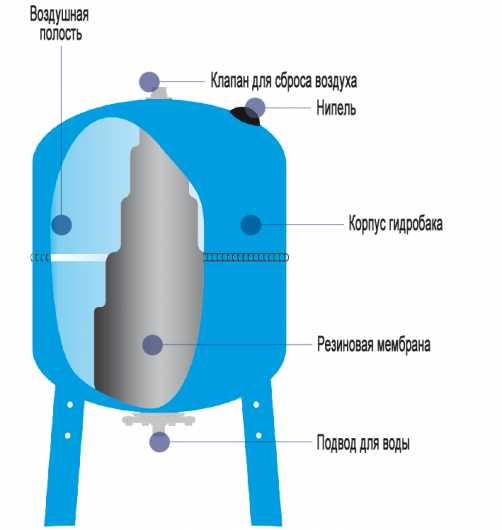

- Operating principle

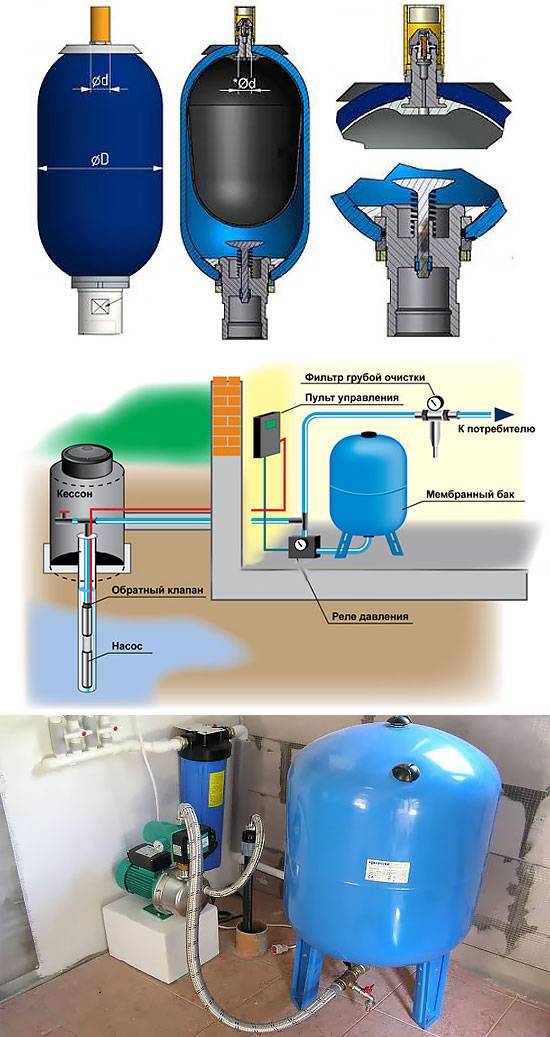

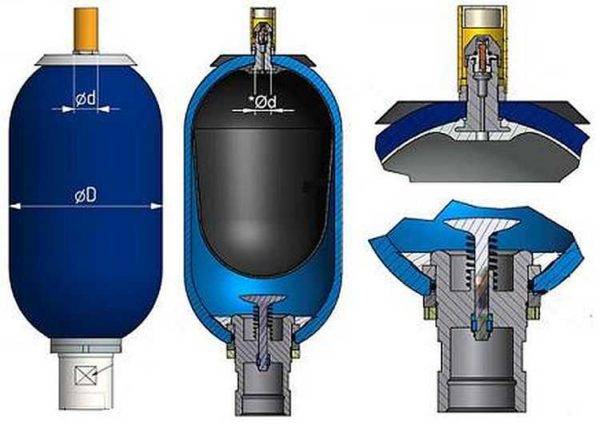

- Design

- Volume

- Appearance

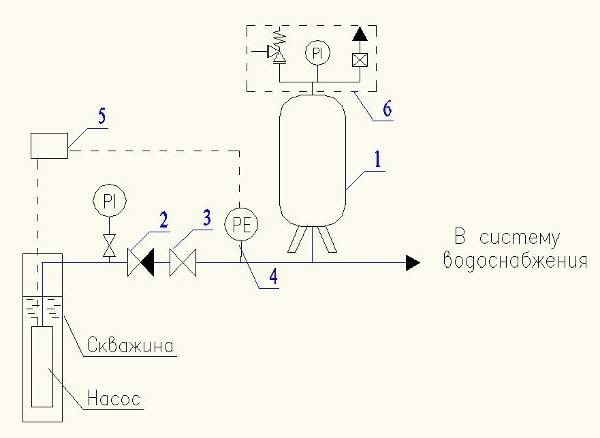

- Tank connection diagram

- How to choose tank volume

- What should be the pressure in the accumulator

- Pre-check and pressure correction

- What air pressure should be

- Tank volume is the main selection criterion

- According to the characteristics of the pump

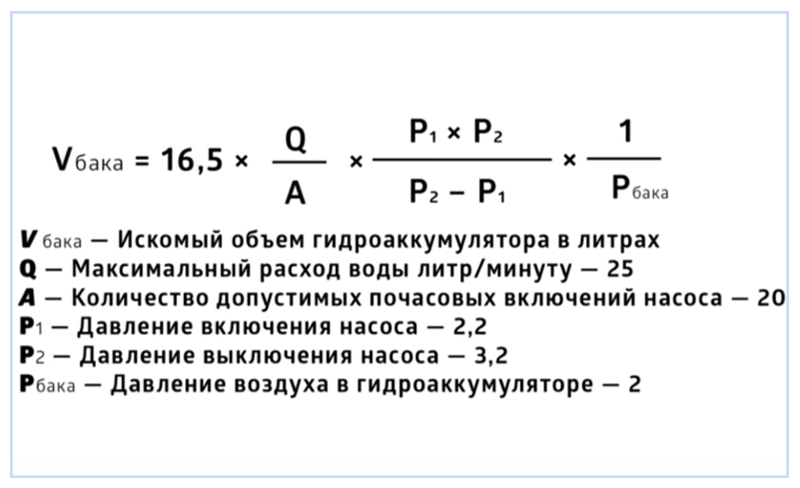

- According to the minimum recommended volume formula

- The best models of water pumps for increasing pressure in an apartment

- Booster pump Wilo

- Grundfos water booster pump

- Comfort X15GR-15 air-cooled pump

- Pump station Dzhileks Jumbo H-50H 70/50

- Jemix W15GR-15A

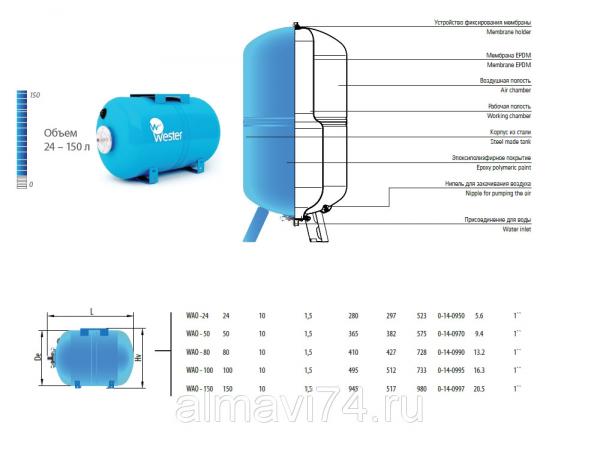

Types of hydraulic tanks for water supply systems

Hydraulic accumulators available on the market, the principle of operation of which is the same, are divided into several types according to a number of features and functional features. First of all, according to the installation methods, they distinguish:

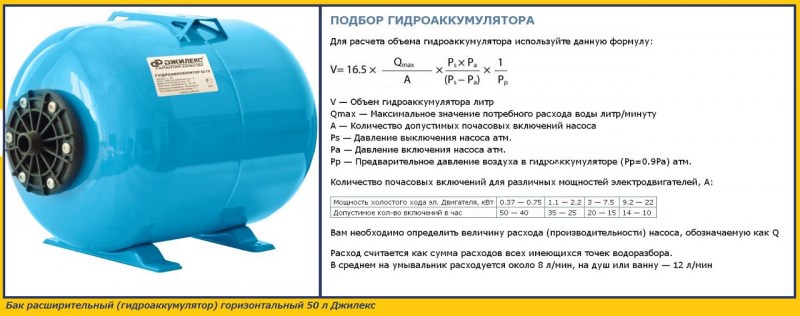

- Horizontal - used for large volumes of water.It is somewhat more difficult to operate due to the low location of the neck (you have to completely drain the water to change or inspect the working membrane or spool).

- Vertical - used for small and medium volumes. Easier to operate, since there is no need to completely drain the water and dismantle part of the piping, as is the case with horizontal tanks.

According to the temperature of the working fluid, hydraulic tanks are:

- For hot water - a heat-resistant material is used as a material for the membrane. Most often it is butyl rubber. It is stable at water temperatures from +100-110 degrees. Such tanks are visually distinguished by red color.

- For cold water - their membrane is made of ordinary rubber and cannot work stably at temperatures above +60 degrees. These tanks are painted blue.

Rubber for both types of accumulators is biologically inert and does not release any substances into the water that spoil its taste or harm human health.

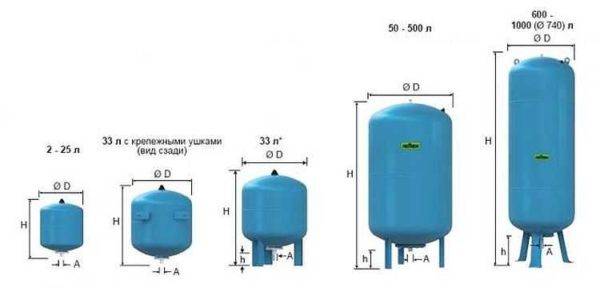

According to the internal volume of hydraulic tanks there are:

- Small capacity - up to 50 liters. Their use is limited to extremely small rooms with a minimum number of consumers (in fact, this is one person). In the version with a membrane or hot water cylinder, such devices are often used in closed-type heating systems.

- Medium - from 51 to 200 liters. They are used exclusively for hot and cold water supply. They can give water for some time when the water supply is turned off. Versatile and reasonably priced. Ideal for houses and apartments with 4-5 residents.

- Large volume from 201 to 2000 liters.They are able not only to stabilize the pressure, but also to provide consumers with a supply of water for a long time in the event that its supply from the water supply is turned off. Such hydraulic tanks have large dimensions and weight. Their cost is also great. They are used in large buildings such as hotels, educational institutions, sanatoriums and hospitals.

Testing and verification of internal and external fire-fighting water supply

To maintain the fire safety of various structures and buildings, it is necessary to constantly check and test the internal fire water pipeline, which is necessary for the supply of water to eliminate the fire, as well as the external fire water pipeline, which is located in underground utilities.

When checking the internal and external fire-fighting water supply, an inspection is carried out, checking the presence of pressure and water, checking the working condition of the device for receiving water from the hydrant, as well as studying the performance of all related structures.

OrderTesting a fire hydrant - from 600 rubles per 1 pc. Testing a fire hydrant - from 2,500 rubles per 1 pc. Tests are carried out 2 times a year. The purpose of the test is to determine the amount of water used in the neutralization of the fire and its compliance with accepted standards. The fire-fighting water supply must be constantly in working condition and provide the volume of water that is necessary to extinguish the fire. According to accepted standards, fire hydrants of such a system are always supplied with trunks and sleeves, and it is also necessary to roll the sleeves to a new roll at least once a year.

The Alliance Monitoring company offers you high-quality and professional services for the inspection of fire water pipelines. Qualified employees of our company will quickly test fire hydrants and cranes using specialized equipment.

Types of water pipes

At the design stage of the building itself and the water supply system, it is necessary to determine where and how the fire water supply system will be located, as well as which system will be used to supply water during extinguishing. Depending on the location, fire water supply can be:

Also, the fire water supply system can be high or low pressure, depending on the strength of the water pressure in the pipes. When using the model of fire-fighting water supply with high pressure, the supply of water pressure is carried out using stationary pumps, due to which the necessary pressure is created, which completely eliminates the fire. The equipment works immediately after ignition is detected.

Low-pressure fire-fighting pipelines are less effective, but are a more economical system. For their use, mobile pumping units are used.

Internal fire water pipelines are divided into:

-

Multifunctional

-

Special

Multifunctional fire-fighting indoor systems are connected to household communication systems. Special fire-fighting systems are autonomous and are used only to extinguish the source of ignition. Testing of the internal fire water supply for water loss occurs immediately after its assembly.

External fire water supply systems are located on the outside of buildings.Often, they go underground and are applied for filling tanks with water various fire equipment.

Regulations governing the installation, use and testing of fire water supply systems

The basis for testing a fire-fighting water pipeline is the Fire Safety Rules in the Russian Federation PPB 01-03:

Paragraph 89: Fire-fighting water supply networks must be in good condition and provide the required water flow for fire fighting needs according to the norms. Checking their performance should be carried out at least twice a year.

Paragraph 91: Fire hydrants of the internal fire-fighting water supply must be equipped with hoses and barrels. The fire hose must be attached to the faucet and barrel. It is necessary to roll the sleeves to a new roll at least once a year.

The list of services for the maintenance of the internal fire water supply network

| No. p / p | Name of works and services) | Periodicity | Foundations |

| 1. | Checking the performance and technical serviceability of fire hydrants | Twice a year |

Optimum air pressure

In order for household appliances to work normally, the pressure in the hydraulic tank must be in the range of 1.4-2.8 atm. For better preservation of the membrane, it is necessary that the pressure in the water supply system be 0.1-0.2 atm. exceeded the pressure in the tank. For example, if the pressure inside the membrane tank is 1.5 atm, then in the system it should be 1.6 atm.

It is this value that should be set on the water pressure switch, which works in conjunction with the accumulator. For a one-story country house, this setting is considered optimal. If we are talking about a two-story cottage, the pressure will have to be increased.To calculate its optimal value, the following formula is used:

Vatm.=(Hmax+6)/10

In this formula, V atm. is the optimum pressure, and Hmax is the height of the highest draw point. As a rule, we are talking about the soul. To get the desired value, you should calculate the height of the shower head relative to the accumulator. The resulting data is entered into the formula. As a result of the calculation, the optimal pressure value that should be in the tank will be obtained.

If we talk about an independent water supply system at home in a simplified way, then its constituent elements are:

- pump,

- accumulator,

- pressure switch,

- check valve,

- manometer.

The last element is used in order to be able to quickly control the pressure. Its permanent presence in the water supply system is not necessary. It can only be connected at the moment when test measurements are being made.

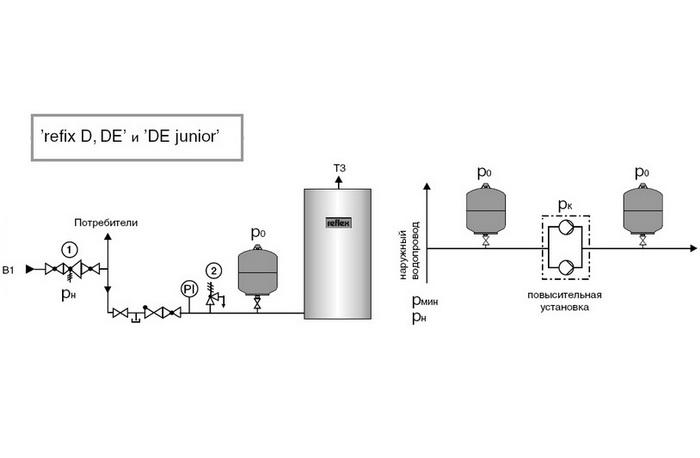

When participating in the surface pump scheme, the hydraulic tank is mounted next to it. At the same time, the check valve is installed on the suction pipeline, and the remaining elements form a single bundle, connecting to each other using a five-outlet fitting.

The five-terminal device is ideally suited for this purpose, since it has terminals of various diameters. The incoming and outgoing pipelines and some other elements of the bundle can be connected to the fitting with the help of American women in order to facilitate preventive and repair work in certain sections of the water supply system.

In this diagram, the connection order is clearly visible. When the fitting is connected to the accumulator, it is necessary to make sure that the connection is tight

So, the accumulator is connected to the pump as follows:

- one inch outlet connects the fitting itself to the hydraulic tank pipe;

- a pressure gauge and pressure switch are connected to the quarter-inch leads;

- there are two free inch outlets, to which the pipe from the pump is mounted, as well as the wiring going to the water consumers.

If a surface pump works in the circuit, then it is better to connect the accumulator to it using a flexible hose with a metal winding.

The accumulator is connected to the submersible pump in the same way. A feature of this scheme is the location of the check valve, which has nothing to do with the issues that we are considering today.

How to choose the right hydraulic tank

A hydraulic tank is a container, the main working body of which is a membrane. Its quality determines how long the device will last from the moment of connection to the first repair.

The best are products made of food (isobutary) rubber. The metal of the body of the product is important only for expansion tanks. Where water is contained in a pear, the characteristics of the metal are not critical.

If you do not pay special attention to the thickness of the flange of your purchase, then in a year and a half, and not in 10-15 years, as you plan, you will have to buy a completely new device or, at best, change the flange itself

At the same time, the guarantee for the tank is only a year with a declared service life of 10-15 years. So the hole will appear just after the expiration of the warranty period. And it will be impossible to solder or weld thin metal. You can, of course, try to find a new flange, but most likely you will need a new tank.

To avoid such misfortunes, you should look for a tank whose flange is made of stainless steel or thick galvanized.

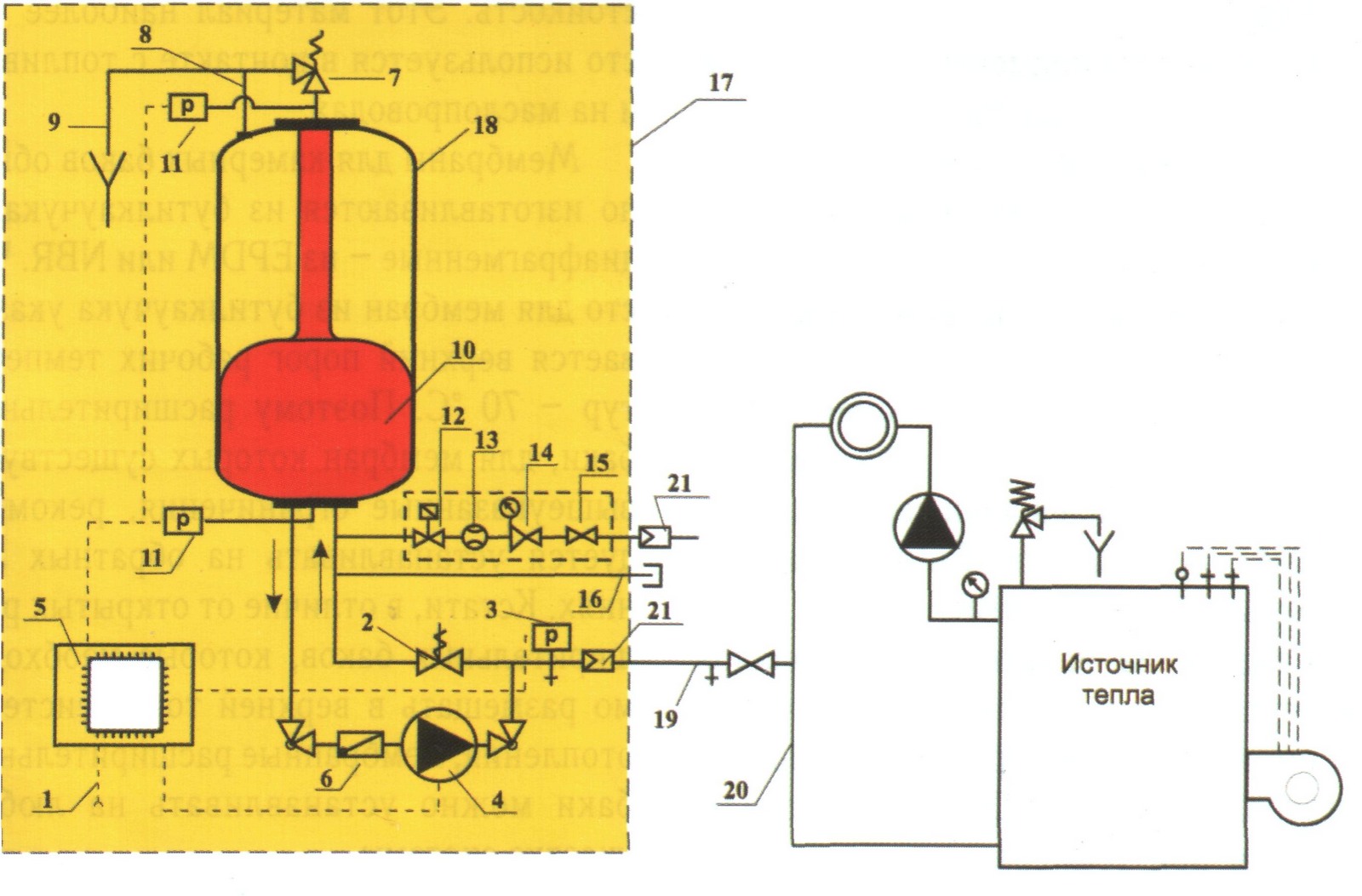

Calculation of tank parameters

In most cases of inclusions, hydraulic tanks for water supply are installed according to the principle: the larger the volume, the better. But too much volume is not always justified: the hydraulic tank will take up a lot of useful space, the water will stagnate in it, and if power outages are very rare, there is simply no need for it. Too small a hydraulic tank is also inefficient - if a powerful pump is used, it will often turn on and off and quickly fail. If a situation arises where installation space is limited or financial resources do not allow the purchase of a large storage tank, you can calculate its minimum volume using the formula below.

How to correctly calculate the volume of the hydraulic tank in the water supply system

Recently, modern high-tech electric pumps with soft start and stop, frequency regulation of the speed of rotation of the impellers depending on water consumption have appeared on the market. In this case, the need for a large hydraulic tank is eliminated - soft start and adjustment do not cause water hammer, as in systems with conventional electric pumps. Automatic control units of high-tech devices with frequency control have a built-in hydraulic tank of a very small volume, designed for its pumping group.

Table of calculated values of pressure and volume of the hydraulic tank depending on the operating modes of the water supply line

Advantages and disadvantages

The main plus of the equipment is the prevention of leaks and other emergency situations that occur during pressure surges.Tanks are needed in long circuits. They contain a significant amount of water, which, when expanded, creates an increased load on joints, radiators and pipes.

Advantages of the equipment:

- the ingress of air into the line is excluded;

- the equipment is designed for water of any quality;

- there is no liquid evaporation;

- emergency pressure increase is prevented;

- installation is possible anywhere;

- system maintenance is simplified, regular refilling of the coolant is not required.

The disadvantages include heat loss and the rather high cost of membrane tanks compared to open tanks.

Expansion tank of open type for heating systems

Large heating structures use expensive closed tanks.

They are characterized by the tightness of the body with an internal rubber partition (membrane) due to which the pressure is adjusted when the coolant expands.

For the full operation of home systems, an open-type expansion tank is a suitable alternative that does not require special knowledge or professional training for the operation and further repair of equipment.

An open tank performs some functions for the smooth operation of the heating mechanism:

- “takes” excess heated coolant and “returns” the cooled liquid back to the system to adjust the pressure;

- removes air, which, due to the slope of the pipes with a couple of degrees, rises to the expansion open tank, located at the top of the heating system;

- The open design feature allows the vaporized volume of liquid to be added directly through the top cap of the reservoir.

Operating principle

The workflow is divided into four simple steps:

- fullness of the tank by two-thirds in normal condition;

- an increase in the incoming liquid into the tank and an increase in the filling level when the coolant is heated;

- liquid leaving the tank when the temperature drops;

- stabilization of the coolant level in the tank to its original position.

Design

The shape of the expansion tank exists in three versions: cylindrical, round or rectangular. An inspection cover is located on the top of the case.

Photo 1. The device of an expansion tank of an open type for heating systems. Components are listed.

The body itself is made of sheet steel, but with a home-made version, other materials are possible, for example, plastic or stainless steel.

Reference. The tank is covered with an anti-corrosion layer to prevent premature destruction (first of all, this applies to iron containers).

The open tank system includes several different nozzles:

- to connect an expansion pipe through which water fills the tank;

- at the junction of the overflow, for pouring out excess;

- when connecting a circulation pipe through which the coolant enters the heating system;

- for connecting a control pipe designed to eliminate air and adjust the fullness of the pipes;

- spare, necessary during repairs to discharge the coolant (water).

Volume

Correctly calculated volume of the tank affects the duration of operation of the joint system and the smooth functioning of individual elements.

A small tank will lead to a breakdown of the safety valve due to frequent operation, and a too large one will require additional finances when buying and heating an excess volume of water.

The presence of free space will also be an influential factor.

Appearance

An open tank is a metal tank in which the upper part is simply closed with a lid, with an additional hole for adding water. The body of the tank is round or rectangular. The latter option is more practical and reliable during installation and fastening, but the round one has the advantage of sealed seamless walls.

Important! A rectangular tank requires additional reinforcement of the walls with an impressive volume of water (home-made version). This makes the entire expansion mechanism heavier, which must be lifted to the highest point of the heating system, for example, to the attic.

Advantages:

- Standard form. In most cases, it is a rectangle that you can install and connect to the general mechanism yourself.

- Simple design without excessive control elements, which makes it easy to control the smooth operation of the tank.

- The minimum number of connecting elements, which gives the body strength and reliability in the process.

- Average market price, thanks to the above facts.

Flaws:

- Unattractive appearance, without the ability to hide thick-walled bulky pipes behind decorative panels.

- Low efficiency.

- The use of water as a heat carrier. With other antifreezes, evaporation occurs faster.

- The tank is not sealed.

- The need to constantly add water (once a week or once a month) due to evaporation, which, in turn, affects airing and the normal functioning of the heating system.

- The presence of air bubbles leads to internal corrosion of the system elements and a decrease in the service life and heat transfer, as well as the appearance of noise.

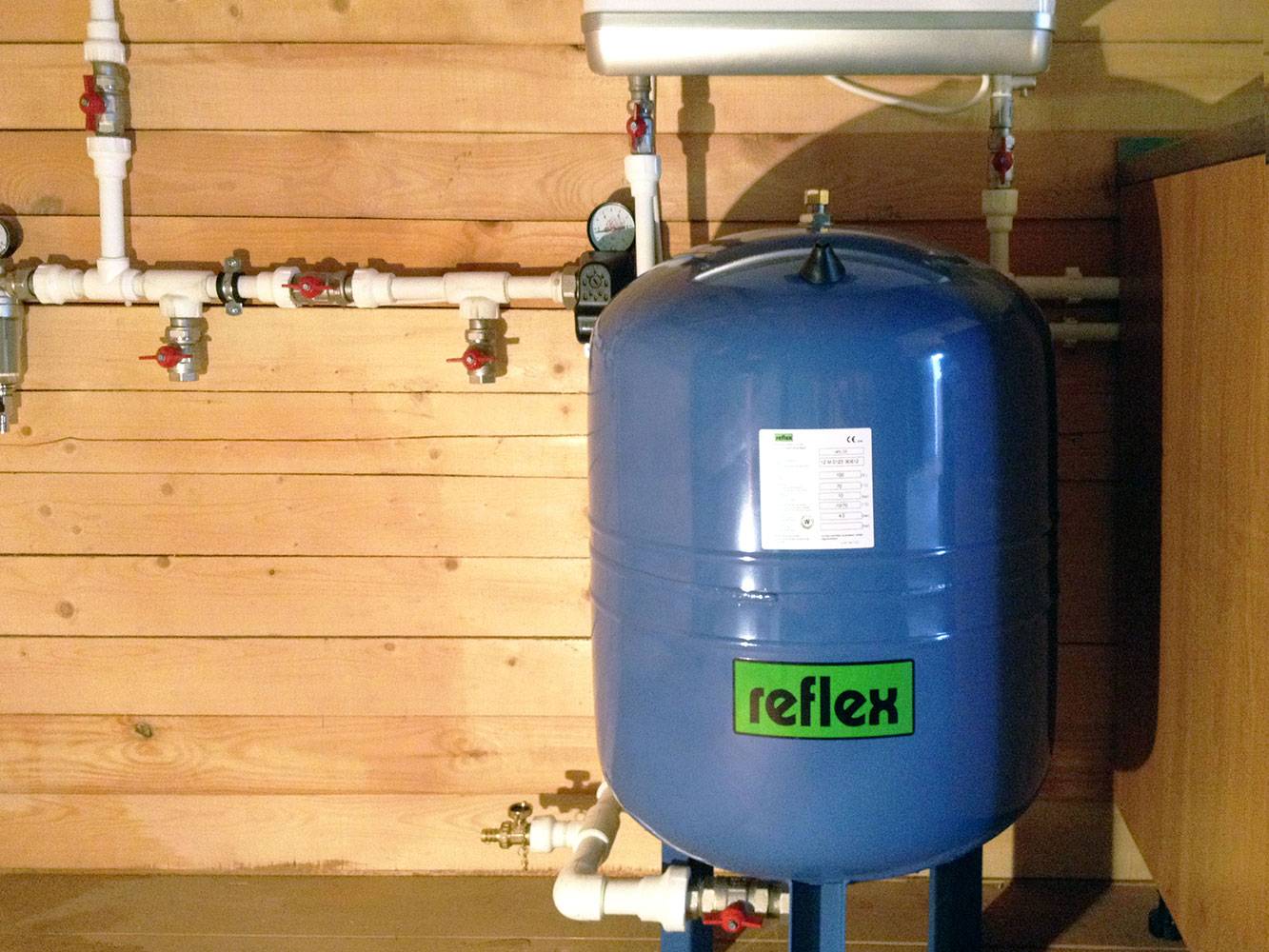

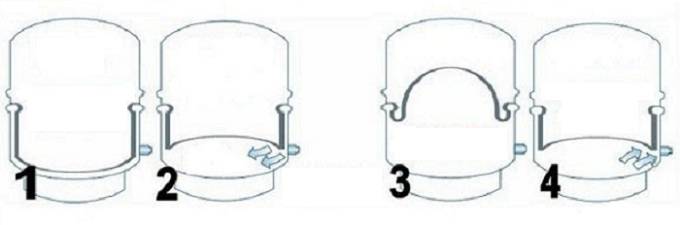

Tank connection diagram

The membrane tank can be installed both vertically and horizontally, but in both cases the connection diagram will be identical:

- Determine the mounting location. The device must be located on the suction side of the circulation pump and before the branching of the water supply. Make sure that the tank has free access for maintenance work.

- Secure the tank to a wall or floor with rubber grommets and ground it.

- Connect a five-pin fitting to the tank nozzle using an American fitting.

- Connect in series to the four free outlets: a pressure switch, a pipe from the pump, a pressure gauge and a branch pipe that supplies water directly to the intake points.

Tank connection

Tank connection

It is important that the cross section of the water pipe to be connected is equal to or slightly larger than the cross section of the inlet pipe, but in no case should it be smaller. Another nuance: it is advisable not to have any technical devices between the expansion tank and the pump, so as not to provoke an increase in hydraulic resistance in the water supply system

How to choose tank volume

You can choose the volume of the tank arbitrarily. There are no requirements or restrictions. The larger the tank, the more water you will have in case of a shutdown and the less often the pump will turn on.

When choosing a volume, it is worth remembering that the volume that is in the passport is the size of the entire container. There will be almost half as much water in it. The second thing to keep in mind is the overall dimensions of the container.A 100 liter tank is a decent barrel - about 850 mm high and 450 mm in diameter. For her and the strapping, it will be necessary to find a place somewhere. Somewhere - this is in the room where the pipe comes from the pump. This is where most of the equipment is installed.

The volume is chosen based on the average consumption

If you need at least some guidelines to choose the volume of the accumulator, calculate the average flow rate from each draw-off point (there are special tables or you can see it in the passport for household appliances). Sum all these data. Get the possible flow rate if all consumers work at the same time. Then estimate how many and which devices can work at the same time, calculate how much water will go in this case per minute. Most likely by this time you will already come to some kind of decision.

What should be the pressure in the accumulator

Compressed air is in one part of the accumulator, water is pumped into the second. The air in the tank is under pressure - factory settings - 1.5 atm. This pressure does not depend on volume - and on a tank with a capacity of 24 liters and 150 liters it is the same. More or less may be the maximum allowable maximum pressure, but it does not depend on the volume, but on the membrane and is indicated in the technical specifications.

The design of the hydraulic accumulator (image of flanges)

Pre-check and pressure correction

Before connecting the accumulator to the system, it is advisable to check the pressure in it. The settings of the pressure switch depend on this indicator, and during transportation and storage the pressure could drop, so control is very desirable.You can control the pressure in the gyro tank using a pressure gauge connected to a special inlet in the upper part of the tank (capacity of 100 liters or more) or installed in its lower part as one of the piping parts. Temporarily, for control, you can connect a car pressure gauge. The error is usually small and it is convenient for them to work. If this is not the case, you can use the regular one for water pipes, but they usually do not differ in accuracy.

Connect pressure gauge to nipple

If necessary, the pressure in the accumulator can be increased or decreased. To do this, there is a nipple at the top of the tank. A car or bicycle pump is connected through the nipple and, if necessary, the pressure is increased. If it needs to be bled off, the nipple valve is bent with some thin object, releasing air.

What air pressure should be

So the pressure in the accumulator should be the same? For the normal operation of household appliances, a pressure of 1.4-2.8 atm is required. To prevent the tank membrane from tearing, the pressure in the system should be slightly higher than the tank pressure - by 0.1-0.2 atm. If the pressure in the tank is 1.5 atm, then the pressure in the system should not be lower than 1.6 atm. This value is set on the water pressure switch, which is paired with a hydraulic accumulator. These are the optimal settings for a small one-story house.

If the house is two-story, you will have to increase the pressure. There is a formula for calculating the pressure in a hydraulic tank:

Where Hmax is the height of the highest draw point. Most often it is a shower. You measure (calculate) at what height relative to the accumulator its watering can is, substitute it into the formula, you get the pressure that should be in the tank.

Connecting a hydraulic accumulator to a surface pump

If the house has a jacuzzi, everything is more complicated. You will have to select empirically - by changing the relay settings and observing the operation of water points and household appliances. But at the same time, the working pressure should not exceed the maximum allowable for other household appliances and plumbing fixtures (indicated in the technical specifications).

Tank volume is the main selection criterion

The most important question is how to choose the volume of the accumulator for water supply systems. To answer it, you need to bring together a lot of data. These are the performance of the pump, and the equipment of the house with water-consuming equipment, and the number of people permanently living in the house, and much more.

But first of all, you need to decide whether you need this reservoir only to stabilize the operation of the system as a whole, or whether there is a need for a supply of water in case of a power outage.

Internal cylinders of different volumes

If the house is small and equipped only with a washbasin, toilet, shower and watering tap, and you do not live in it permanently, you can not make complex calculations. It is enough to buy a tank with a volume of 24-50 liters, it will be enough for the system to work normally and be protected from water hammer.

In the case of a country house for permanent residence of a family, equipped with everything necessary for a comfortable life, it is advisable to approach the issue more responsibly. Here are a few ways to help you determine the size of your accumulator.

According to the characteristics of the pump

The parameters that affect the choice of tank volume are the performance and power of the pump, as well as the recommended number of on / off cycles.

- The higher the power of the unit, the larger the volume of the hydraulic tank should be.

- The powerful pump pumps water quickly and turns off quickly if the tank volume is small.

- A sufficient volume will reduce the number of intermittent starts, thereby extending the life of the motor.

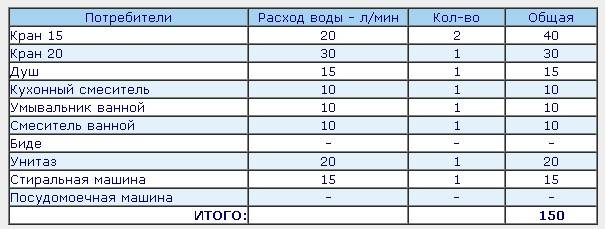

To calculate, you will need to determine the approximate water consumption per hour. To do this, a table is compiled that lists all the devices that consume water, their number and consumption rates. For example:

Table for determining the maximum water flow

Since it is almost impossible to use all devices at the same time, a correction factor of 0.5 is used to determine the real flow rate. As a result, we get that you spend an average of 75 liters of water per minute.

How to calculate the volume of a hydraulic accumulator for water supply, knowing this figure, pump performance and considering that it should turn on no more than 30 times per hour?

- Let's say the productivity is 80 l / min or 4800 l / h.

- And during peak hours you need 4500 l/h.

- With non-stop operation of the pump, its power is enough, but it is unlikely that it will work for a long time in such extreme conditions. And if it turns on more often than 20-30 times per hour, then its resource will run out even faster.

- Therefore, a hydraulic tank is needed, the volume of which will allow you to turn off the equipment and give it a break. At the indicated frequency of cycles, the water supply should be at least 70-80 liters. This will allow the pump to run for one minute out of every two, having pre-filled the reservoir.

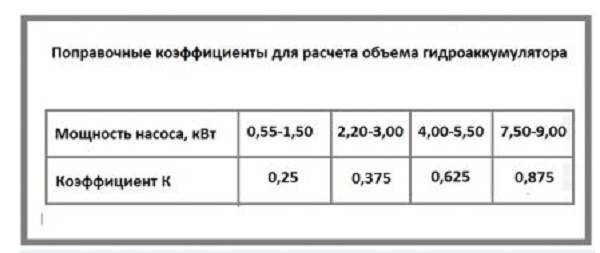

According to the minimum recommended volume formula

To use this formula, you need to know the settings of the pressure switch that turns the pump on and off. The following picture will help you understand:

Changes in pressure in the accumulator when the pump is turned on and off

- 1 – initial pressure Pair (when the pump is off);

- 2 - water flow into the tank when the pump is turned on;

- 3 - reaching the maximum pressure Pmax and turning off the pump;

- 4 - water flow with the pump turned off. When the pressure reaches the minimum Pmin, the pump is switched on.

The formula looks like this:

- V = K x A x ((Pmax+1) x (Pmin +1)) / (Pmax - Pmin) x (Pair + 1), where

- A is the estimated water flow (l / min);

- K - correction factor from the table, determined depending on the pump power.

Table for determining the correction factor

The values of the minimum (starting) and maximum (switching off) pressure on the relay, you must set yourself, depending on what pressure you need in the system. It is determined by the farthest from the accumulator, and the highly located draw-off point.

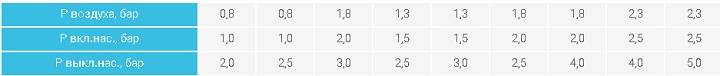

Approximate ratios of pressure switch settings

To adjust the pressure switch, you need to know how to pump up the accumulator for air supply systems, or bleed the extra one. This will require a car pump that connects to the tank through a spool.

Now we can calculate the volume. For example, let's take:

- A = 75 l/min;

- Pump power 1.5 kW, respectively K = 0.25;

- Pmax = 4.0 bar;

- Pmin = 2.5 bar;

- Pair = 2.3 bar.

We get V = 66.3 liters. The closest standard accumulators in terms of volume have a volume of 60 and 80 liters. We choose the one that is more.

It's interesting: How to choose a wood splitter (video)

The best models of water pumps for increasing pressure in an apartment

Booster pump Wilo

If you need to install a reliable pump to increase the water pressure in the apartment, you should pay attention to Wilo products. In particular, the PB201EA model has a water-cooled type, and the shaft is made of stainless steel.

Wilo PB201EA wet rotor pump

The body of the unit is made of cast iron and treated with a special anti-corrosion coating. Bronze fittings provide a long service life. It is also worth noting that the PB201EA unit has silent operation, has automatic overheating protection and a long motor resource. The equipment is easy to mount, however, it should be remembered that only horizontal installation of this device is possible. Wilo PB201EA is also designed for pumping hot water.

Grundfos water booster pump

Among the models of pumping equipment, Grundfos products should be highlighted. All units have a long service life, withstand fairly large loads well, and also ensure long-term uninterrupted operation of plumbing systems.

Grundfos self-priming pumping station

Model MQ3-35 is a pumping station that can solve problems with water pressure in pipes. The installation is controlled automatically and does not require additional control. The design of the unit includes:

- hydraulic accumulator;

- electric motor;

- pressure switch;

- automatic protection unit;

- self-priming pump.

In addition, the unit is equipped with a water flow sensor, which ensures high efficiency in operation. The main advantages of the station include high wear resistance, long service life and silent operation.

Please note that the MQ3-35 unit is designed for cold water supply. Booster pumps are also equipped with relatively small storage tanks, which, however, are enough for domestic tasks.

An operating Grundfos pumping station in a water supply system

Comfort X15GR-15 air-cooled pump

In order for the circulation pump for water supply to work both in manual and automatic mode, we advise you to pay attention to the model of the Comfort X15GR-15 unit. The body of this device is made of stainless steel, so the unit is not afraid of moisture and can function in any conditions.

Comfort X15GR-15 air-cooled pump

An impeller is installed on the rotor, which provides excellent air cooling. The unit has a compact size, does not require special maintenance, and also consumes electricity economically. If necessary, it can be used to pump hot water streams. The disadvantages of the installation include the loud operation of the power unit.

Pump station Dzhileks Jumbo H-50H 70/50

The Jambo 70/50 H-50H pump station is equipped with a centrifugal pump unit, a horizontal accumulator and a sweat pressure switch. The design of the equipment has an ejector and an asynchronous electric motor, which ensure stable operation of the plant.

Jumbo 70/50 H-50H

The housing of the home water pumping station has an anti-corrosion coating. The automatic control unit ensures simple operation of the equipment, and the built-in overheating protection eliminates the possibility of damage to the unit.The disadvantages of the unit include loud work, and there is also no protection against "dry" running. For the device to function properly, it is recommended to install it in a room with good ventilation and low temperature.

Jemix W15GR-15A

Among the models of booster pumps with an air-cooled rotor, Jemix W15GR-15A should be highlighted. The body of the unit has increased strength, since it is made of cast iron. The components of the electric motor design are made of aluminum alloy, and the drive elements are made of highly durable plastic.

Jemix W15GR-15A

Pumping equipment is characterized by high performance, and can also be operated in wet areas. Manual and automatic control of the unit operation is possible. If necessary, the unit can be connected to hot water supply. Significant disadvantages include rapid heating of the elements of the device and noise.