- What are the criteria for choosing a heater?

- Comparison of advantages and disadvantages

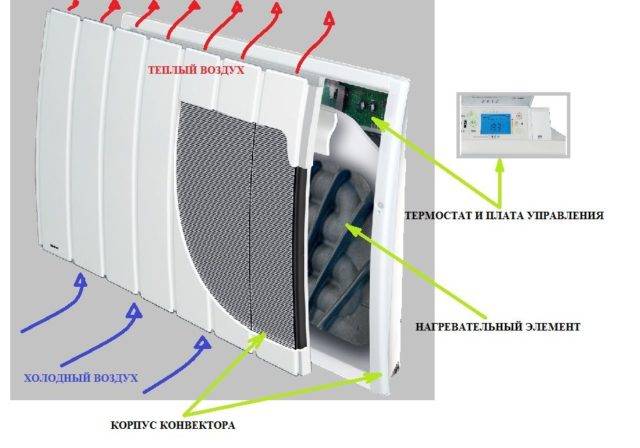

- The principle of operation and design of the convector

- How a convector is arranged and works

- How to choose an oil and convector heater

- The main essence of the article

- How does he work?

- Features of heaters (video)

- Heating area

- Comparison of convectors and oil heaters

- Additional functions

- Comparison of convectors and oil heaters

- Results

What are the criteria for choosing a heater?

In order to understand which devices are better convector or oil, you should compare their main parameters:

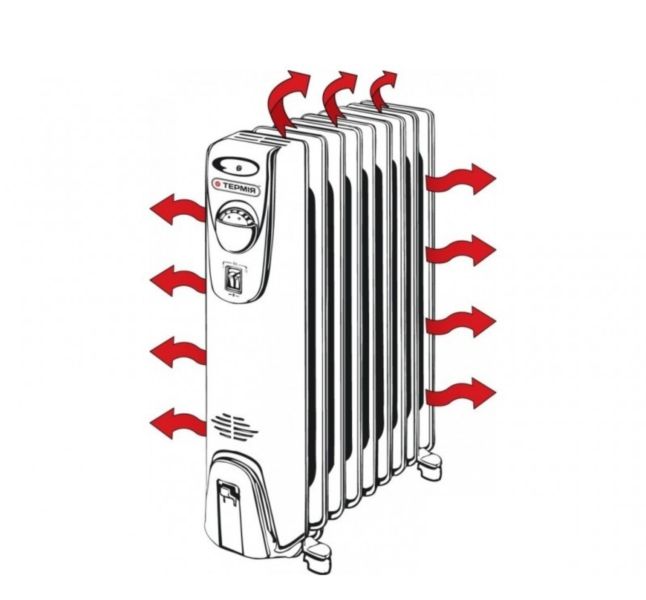

- period of heating the air in the room. In the oil unit, the heating element first heats up, after which it begins to heat the oil, which in turn transfers heat to the body, which warms up the air. The convector starts heating the air immediately. It must be remembered when buying an electric oil heater with a fan, this device is able to heat the air at about the same speed as a convector, and maybe faster. This is due to the relatively low power of the convector;

- electricity consumption. In this regard, the convector is able to consume a quarter less electricity than an oil appliance of the same power.This feature can be decisive, serious energy consumption by an oil unit can hit the budget hard;

- ease of installation and operation. Convectors are lighter compared to large oil models, which makes them much more convenient to move. They are also much easier to install on the wall, although this has a negative effect on work efficiency. All modern devices of both types are equipped with sensors with simple and intuitive controls and displays, so the ease of use is about the same, everything largely depends on the model itself and the manufacturer;

- operational safety. The answer to the question of which oil heaters are more safe can be those that heat up less during operation. The hot oil heats up the body a lot, but the convectors are doing well in this matter, they are absolutely safe. This device can be freely left turned on without supervision, which is highly discouraged with oil units;

- environmental friendliness and safety for health. Devices of both types do not have oxygen-burning elements in their design; in this regard, these devices are completely safe. During the operation of the convector, dust may begin to fly in the room, which is not observed during the operation of oil devices. But the circulation of dust directly depends on the cleanliness of the room;

- durability. The service life of convectors is much longer compared to oil convectors, and their repair is easier. The most common cause of an oil cooler malfunction is the appearance of microcracks through which the coolant flows and evaporates.With such malfunctions, repair is extremely difficult, and in some cases it is completely impossible;

- price. Oil devices are somewhat cheaper than convectors of the same power, but they are seriously inferior to them in terms of performance, so the savings in this case are rather doubtful.

In addition to the parameters already mentioned, it should be mentioned that the improvement of convectors is much faster, due to which oil units are slowly but surely gradually losing the market to convectors. The latest invention in this area is the invention of a monolithic convector heating element, which allows to double the thermal power of the device with the same power consumption.

In addition, when purchasing a convector or an oil unit, it is necessary to take into account the levels of protection, in which the oil cooler loses significantly. It is quite rare to find a modern convector that is not equipped with protection against overheating, power surges and overturning. At the same time, many oil units are not equipped with any protection.

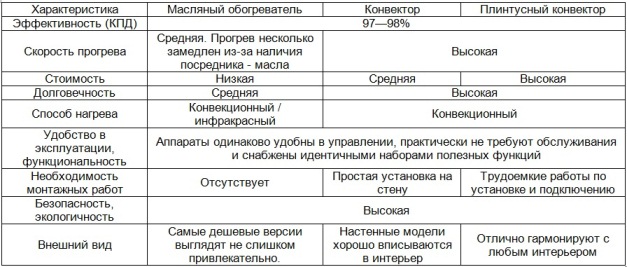

Comparison of advantages and disadvantages

To choose an oil heater or convector for home heating, you need to compare the pros and cons of each type of appliance. This is not so easy to do, since there is much in common between them, in particular, the principle of operation. Let's spend comparison by main characteristics, and for clarity, the results will be entered in the table:

After analyzing all the characteristics, we will present some conclusions that will help you decide which of the heaters is better to choose:

- In terms of efficiency, all devices are the same.If an average of 2 kW of heat is needed to heat a room of 20 m2, then you can take any of the presented devices with a small power reserve - 2.5 kW. For even heat distribution, it is recommended to assign this power to 2 radiators, and not to buy one large one;

- oil heaters have the lowest price, but they lose to convectors in terms of appearance and heating rate. At the same time, these devices do not require installation and are easy to clean;

- wall-mounted convectors are more expensive than oil-filled radiators, but they look more presentable and heat up the room a little faster. Requires simple installation work;

- the most expensive option is skirting convectors. They need to be mounted, wired and connected, which will also cost a pretty penny. It is also difficult to clean the parts of the apparatus from dust. But with high requirements for the interior of the rooms, there is no better solution.

The principle of operation and design of the convector

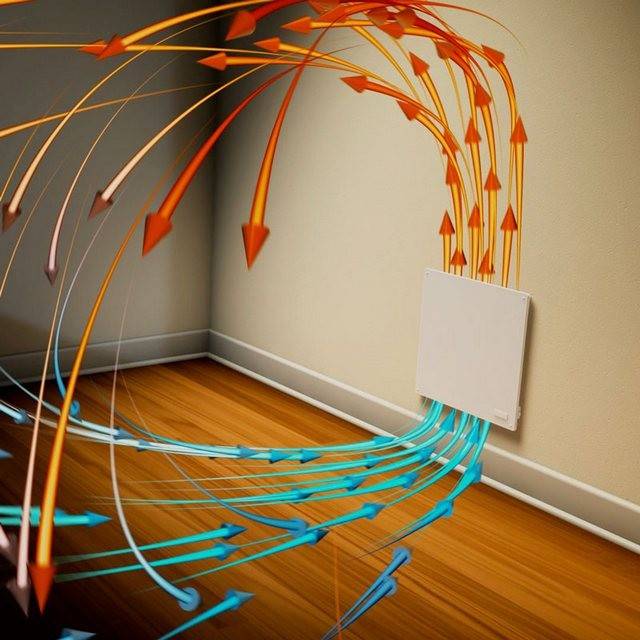

The convector is a heating device, the main part of the heat from which is transferred to the room through convection (from 90%). This is a type of heat transfer in which the streams of the gaseous medium are heated, passing through the device, and rise up, transferring heat to the serviced room. The body of the electric convector does not heat up above 45 degrees.

Air flow from the convector.

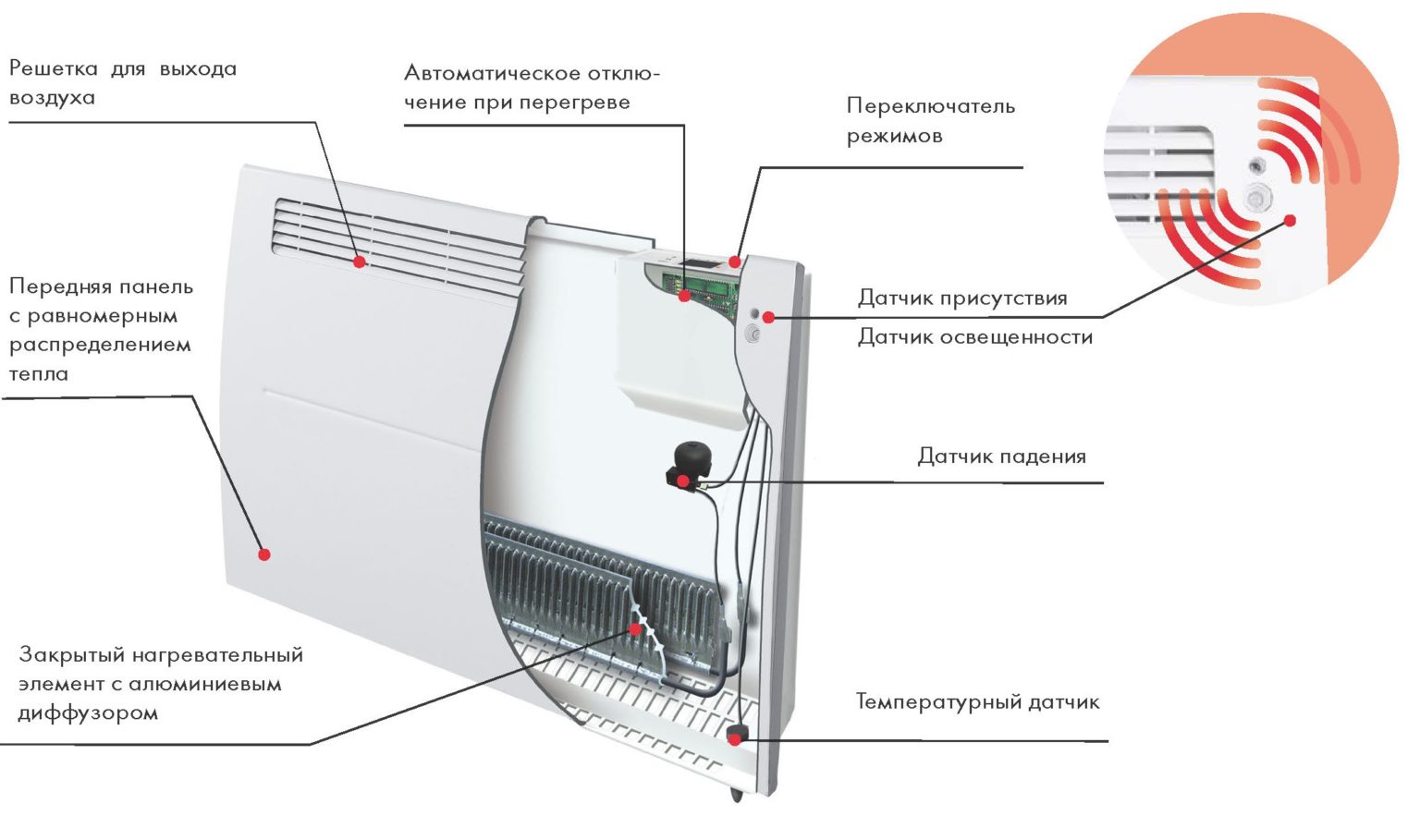

The converter heater consists of several elements that allow you to organize the air flow and protect the device:

- housing with openings for air intake and supply;

- heating element;

- devices to regulate the temperature and protect the device from overheating.

Converter heaters use electricity, gas or liquid from the heating system as an energy source.Since the comparison is made with an electric oil heater, we further consider the same type of convector.

How a convector is arranged and works

Outwardly, it is very easy to distinguish a convector from an oil cooler. If the latter looks like an "accordion on legs", then the former has a flat, smooth body with slots at the top and bottom. The main difference between these devices is the method of heating the room. The radiator first heats the oil, and the convector directly heats the air masses.

The principle of operation of the convector is based on the physical properties of cold and hot air. The second one is known to be easier. In the hollow body of the convector there is only a heating element (spiral) and a temperature sensor. Cold air enters the convector through slots located at the bottom of the appliance. Then the air masses, heated by the heating element, naturally exit through the holes located in the upper part of the housing. And their place is again taken by cold air, the process repeats.

Each convector heater is equipped with a temperature sensor that turns the device on and off depending on whether the air in the room has reached the set temperature. This is very convenient since there is no need to monitor the device. Automation independently maintains a comfortable temperature in the room.

Almost all models of convectors have two ways of placement. They can be hung on the wall or installed on special legs and placed in a convenient place on the floor.

How to choose an oil and convector heater

When choosing a heater for the home, it is important to focus not so much on what is better - an oil or convector type of device, but first of all, pay attention to the performance and functionality of specific models. The basic specifications here are:

The basic specifications here are:

The basic specifications here are:

- power: the higher this indicator, the larger the area the device can insulate. It is necessary to calculate the required level of performance of the unit, taking into account not only the square meters of the room, but also the height of the ceilings, the number of windows and the degree of thermal insulation of the outer walls;

- mounting/installation type: universal, ceiling, wall, floor, plinth, which significantly affects the ease of use of the heater, the quality of its work, durability and safety;

- frequency of use: the best choice as an auxiliary or backup heat source is oil radiators, but for permanent operation, especially in the winter season, it is recommended to purchase convector units.

Regardless of the type of climate technology, each heater needs to provide conditions for the uninterrupted realization of its capabilities, including competent maintenance throughout the entire period of operation.

The main essence of the article

- Electric oil-filled heater - a device for heating residential, administrative and industrial premises. The oil unit has been produced for several decades, so its design today is quite perfect and safe, which leads to the wide popularity of this device in everyday life.

- The demand for an oil electric heater is due to a number of advantages with the only drawback - increased power consumption.

When choosing an oil-filled heater, you can be sure of the convenience and ease of operation, as well as the reliability of several levels of security.

- electric heating element placed in a hermetic case filled with mineral oil

But there are several varieties of these heaters, which differ not only in power and design, but also in the design installation site - floor, wall and universal units.

When choosing an oil heater, you need to focus on the degree of need for heating, so it is important to be able to calculate the required power of the heater, to know the factors that affect the efficiency of operation of this device. The best oil heater is the right unit for specific conditions.

In addition to technical characteristics, models of oil-filled heaters have an individual rating, determined by consumer reviews and the compliance of the price of the heater with its quality.

When choosing a heater, you need to know which company's products have proven themselves well in the Russian market, and the rating of manufacturing companies.

With the necessary knowledge and professional skills, you can make an oil electric heater yourself. There are not many ways to manufacture these devices, but the technologies contain a number of points directly related to the safe operation of such heaters - the material for the manufacture of radiators, methods for ensuring their tightness, and requirements for the used oil.

The safety of use of household electrical equipment is the most important factor in evaluating the device. Therefore, when making handicraft heaters using used oil, it is necessary to objectively assess your capabilities to ensure the safety of operation of the manufactured heater. If you have doubts about your abilities, it is better to abandon these plans and purchase a reliable and safe industrial production unit.

How does he work?

Consider the principle of operation of a convection heater. The principle of operation of an electric convector is based on the natural circulation (convection) of air. The convector, as a rule, has a rectangular shape, an electric heating element is located inside it.

On the surface of the convector there are holes designed for air circulation. The convector is designed in such a way that the air coming from the bottom and side openings is heated after passing through the heating element and then exits through the openings located on the front panel of the convector.

For example, an oil-type heater heats the room due to the heat radiation that comes from heated radiators. The convector has a different principle - the heating of the room is carried out due to the directed flow of heated air

Due to this, the convector heats the room much faster and, no less important, evenly over the entire area.

The heating element of a modern convector is low-temperature, it is made of a special alloy, due to which it heats up much faster than conventional tubular heating elements. As a rule, after 30-60 seconds after being connected to the network, the convector already begins to give off heat to the room.

The efficiency of this type of heater reaches 90% due to the fact that almost all the energy goes to warming up the room, unlike other types of heaters, for example, oil heaters, which does not begin to give off heat to the room immediately, but only after its heat-conducting medium warms up - oil, and then its metal case (radiator).

There is an opinion that heaters, including electric convectors, burn oxygen. But is it really so? As mentioned above, low-temperature heating elements are installed in an electric convector, the maximum heating temperature, as a rule, does not exceed 60C.

At this temperature, oxygen is not burned, which is a significant advantage of the convector compared to other types of electric heaters, the heating elements of which heat up to several hundred degrees. In addition, the low operating temperature of the convector allows it to be installed almost everywhere, including near fire hazardous surfaces, for example, on a wooden wall.

And how can a convector effectively heat a room if the operating temperature of its heating elements is much lower than in other types of heaters?

The heating element of the convector is much larger than the heating elements, which have a higher operating temperature. Due to this, the convector emits a sufficient amount of heat and, despite the low operating temperature of its heating elements, is able to heat a large area. Depending on the power, one convector can heat a room up to 30 square meters. m.

Features of heaters (video)

These devices have a low price, which makes them accessible to a larger number of consumers. Devices of various power are produced, which can fluctuate over a wide range. More powerful units are placed on the floor, devices with less power are very compact and can be installed on various surfaces.

The principle of operation of a fan heater is extremely simple. The device consists of a heating element and a fan that moves a large volume of air.

Tubular fan heater

- Electric coil heated up to 800°C.

- Tubular electric heater having an operating temperature of about 200°C.

- Ceramic tiles with heating temperature up to 200°C.

The cleanest air is provided by devices having a ceramic heating element. Fan heaters of other designs, especially those with an open coil, pollute the air with their combustion products. Also, heaters can cause an unpleasant odor that occurs when debris and dust get on the heating element. This is also most common with open coil devices, especially given their high heating temperatures.

The principle of operation of the fan heater

- Low price.

- Compact dimensions, even for high power devices.

- Fast heating of air and its uniform distribution throughout the room.

- Elegant design that allows you to integrate the device into almost any room.

- Ability to perform additional functions.

Proven manufacturers of fan heaters are such brands: Ballu, Bork, Climate, De'Longhi, General, Electrolux, NeoClima, Polaris, Rolsen, Saturn, Scarlett, Supra, Timberk.

Also, when buying, you can use the following tips:

- Models with ceramic heating elements are better in operation, although they are more expensive.

- Appliances with a coarse sponge filter on the rear panel keep the air clean.

- The optimal power of a household appliance is from 1 to 3 kW; for ease of use, it should be smoothly regulated.

- It is recommended to purchase appliances with a well-thought-out safety system, having protection against overheating and equipped with an automatic shutdown in the event of a rollover.

The convection heater also heats the air, but its movement occurs with the help of natural convection, and not forcibly. Cold air enters the unit from below, passes through the heater and exits from above. After that, the air is distributed throughout the room also due to natural processes.

Convection heater device

Various types of convectors are produced - floor, wall and combined. Floor units have wheels for easy movement. When placing the convector on the wall, it is recommended to place it a few centimeters above the floor. This will provide the best heating of the room.

If the device is used in a bathroom or other rooms with high humidity, then you should pay attention to the electrical and moisture protection class. A somewhat special design have devices built into the floor

The advantages of convectors are as follows:

- Ability to work for a long time.

- Multiple placement options in the room.

- The presence of thermostats that allow you to maintain a certain temperature in the room.

- The possibility of combining devices into a heating system;

- Safety of use.

- Quiet operation.

The only significant drawback of converter heaters is the slow heating of the air in the room. This is due to the limited possibilities of natural convection.

Having familiarized yourself with the types of heating devices and their features, you can make an informed choice. If the device requires quick and short heating, then the fan heater will be optimal. If you need a long-term operation of the device, you should purchase a convector. The choice of model is recommended to be carried out according to the technical characteristics of the product.

Heating area

How often do I hear from customers the question: “Is one device enough for me?”. I immediately ask in response: “Do you want to save money or keep warm?” If the first option, one fireplace is enough.

Both oil and convector heaters are able to heat a room of approximately the same area. But it would be a mistake to assume that one fireplace = one room. First, a lot depends on the power of the device. Secondly, it is better to navigate by footage. For example, you have a device with a power of 1 kW. It is enough to heat 10-12 sq.m. So better plan your purchases, taking into account the features of your own home.

Comparison of convectors and oil heaters

So, let's see how a convector differs from an oil cooler. Convectors have a simpler and safer design. They do not have any coolant, they heat the air directly, without intermediaries.In addition, mineral oil can leak out as a result of corrosion of the hull - it will flood floors, damage carpets and can cause burns. It should also be noted that the presence of oil significantly increases the time the device reaches full power.

Another difference between a convector and an oil cooler is its efficiency in terms of electricity consumption. Depending on the model, it consumes up to 15-25% less than the oil model for the same area of heated rooms

Electric heating is distinguished by its high cost, so we recommend that you pay special attention to this property of convectors.

We recommend using oil convectors as an auxiliary equipment - to help convectors or hot water heating. This is how most consumers use them.

The body of the electric convector does not heat up to high temperatures and is safe even for children.

Another difference between a convector and an oil heater is the body temperature. Convectors are made so that they heat the air, but they themselves remain as cold as possible. Usually the temperature of their cases is + 60-65 degrees, and the back wall remains cool at all. Thanks to this, convectors can be installed without any particular fear in any premises, for example, in children's rooms.

Oil heaters are hotter because they heat the air with their casing. If you set the maximum power and maximum temperature, then you can get burned on the metal. And if an adult can still survive such a burn (as a rule, his temperature does not exceed +100 degrees), then for young children it will be more noticeable.

Oil heaters endowed with special plastic protection have the greatest safety. Such protection passes air masses without problems, but prevents burns. True, you have to pay for this option.

There are practically no differences between oil heaters and convectors in terms of heating speed. Oil models may seem slower, but convectors are about the same slowness. The difference can be and can be measured, but it will be insignificant. Therefore, it is not worth considering this as a selection factor. If you want to experience faster heating, we recommend choosing from equipment equipped with fans for forced convection.

An important factor determining which is better, oil coolers or convectors, is the service life of the presented electrical appliances. Convectors are more enduring, because apart from air heating elements there is nothing in them - no heat carrier, no mineral oil. The devices serve for a very long time, showing a high level of reliability. Oil heaters are prone to breakage - they often start to leak, and a faulty heater is easier to throw out than to repair.

If the breakdown of the oil cooler is not associated with an oil leak, then a competent specialist will be able to bring it back to life.

As for the combustion of oxygen and other environmental factors, nothing like this is observed in either equipment. Convectors and oil heaters do not burn oxygen, unlike fan heaters and other appliances with exposed heating elements.True, they can dry the air somewhat, which is compensated by using a humidifier or a container of water installed next to the equipment.

Some allergic consumers scold convectors for kicking up dust. For such people, we recommend that you look at devices with built-in dust filters. As for oil heaters, they even win here - it is easy to brush off the dust from them with a damp cloth.

Additional functions

Let's now look at the additional features that can be found in electric convectors. Moreover, they are most often endowed with electronically controlled models. Let's put them in the form of a list:

The remote control is a great addition to a standard convector heater.

- Anti-freeze - the technique maintains the temperature at +5 degrees, preventing buildings from freezing. The function is relevant for owners of country houses and cottages, where accommodation is carried out only on weekends. Thus, users can not worry about the complete freezing of the house and the unnecessarily high power consumption;

- Work according to the program is an interesting function that allows you to set the operating modes by the hour. For example, at night the temperature may drop to rise again in the morning. It is also possible to set other operating modes;

- Timer - electric convectors turn on and off according to the timer. Devices with this function are best suited for those who are at work during the day;

- Remote control - heaters are supplied with remote controls that allow you to adjust the temperature directly from the sofa;

- Work as a slave and master equipment - the function is useful when it is necessary to implement complex temperature control in rooms. In this case, only one control unit is used, and the rest operate in the modes specified by it;

- Humidification is a great option. If you care about your health, it is best to look at equipment with this function. The humidification module will make indoor air healthier;

- Bluetooth control is another option for remote control of equipment from a tablet or smartphone. A dubious feature, and hardly better than a classic remote;

- Air ionization is one of the most useful options. We recommend these heaters to those who care about their health and well-being. If you feel a breakdown and weakness, it is best to install at least one such device in the room.

The presence of additional functions is better because you get heating equipment that is easy to manage and operate. And simple devices are better for their reliability and reliability.

Please note that each additional function is an increase in the cost of electric convectors.

Comparison of convectors and oil heaters

So, let's see how a convector differs from an oil cooler. Convectors have a simpler and safer design. They do not have any coolant, they heat the air directly, without intermediaries. In addition, mineral oil can leak out as a result of corrosion of the hull - it will flood floors, damage carpets and can cause burns. It should also be noted that the presence of oil significantly increases the time the device reaches full power.

Another difference between a convector and an oil cooler is its efficiency in terms of electricity consumption. Depending on the model, it consumes up to 15-25% less than the oil model for the same area of heated rooms

Electric heating is distinguished by its high cost, so we recommend that you pay special attention to this property of convectors.

We recommend using oil convectors as an auxiliary equipment - to help convectors or hot water heating. This is how most consumers use them.

The body of the electric convector does not heat up to high temperatures and is safe even for children.

Another difference between a convector and an oil heater is the body temperature. Convectors are made so that they heat the air, but they themselves remain as cold as possible. Usually the temperature of their cases is + 60-65 degrees, and the back wall remains cool at all. Thanks to this, convectors can be installed without any particular fear in any premises, for example, in children's rooms.

Oil heaters are hotter because they heat the air with their casing. If you set the maximum power and maximum temperature, then you can get burned on the metal. And if an adult can still survive such a burn (as a rule, his temperature does not exceed +100 degrees), then for young children it will be more noticeable.

Oil heaters endowed with special plastic protection have the greatest safety. Such protection passes air masses without problems, but prevents burns. True, you have to pay for this option.

There are practically no differences between oil heaters and convectors in terms of heating speed. Oil models may seem slower, but convectors are about the same slowness. The difference can be and can be measured, but it will be insignificant. Therefore, it is not worth considering this as a selection factor. If you want to experience faster heating, we recommend choosing from equipment equipped with fans for forced convection.

An important factor determining which is better, oil coolers or convectors, is the service life of the presented electrical appliances. Convectors are more enduring, because apart from air heating elements there is nothing in them - no heat carrier, no mineral oil. The devices serve for a very long time, showing a high level of reliability. Oil heaters are prone to breakage - they often start to leak, and a faulty heater is easier to throw out than to repair.

If the breakdown of the oil cooler is not associated with an oil leak, then a competent specialist will be able to bring it back to life.

As for the combustion of oxygen and other environmental factors, nothing like this is observed in either equipment. Convectors and oil heaters do not burn oxygen, unlike fan heaters and other appliances with exposed heating elements. True, they can dry the air somewhat, which is compensated by using a humidifier or a container of water installed next to the equipment.

Some allergic consumers scold convectors for kicking up dust. For such people, we recommend that you look at devices with built-in dust filters.As for oil heaters, they even win here - it is easy to brush off the dust from them with a damp cloth.

Results

Oil heaters by all indications should gradually disappear from the market. After all, they are being replaced by more efficient and economical types of devices. However, manufacturers do not give up and improve designs in order to increase efficiency and reduce energy costs. Various add-ons like a humidifier or access via a smartphone also help in this matter.

Soft heat, noiselessness and an affordable price tag allow the radiators to remain a favorite among many buyers. It is too early to write them off: with modern solutions, they can compete with more advanced technology.

Tell me, do you use a heater? If so, what type of heater did you choose for yourself and why?