- What are the advantages of liquid fuel boilers?

- 1 Wattek PYROTEK 36

- The best solid fuel boilers for long burning

- Galmet Top

- Buderus Logano G221-25

- Stropuva S15

- TRAYAN TPG-15

- Mounting order

- Stages of operation of solid fuel boilers

- The best models of solid fuel boilers. Overview of the rating of long-burning heating equipment

- Choosing a fuel

- Fuel types

- Classification

- According to the material of the heat exchanger

- By type of fuel

- By way of submission

- By loading direction

- According to the method of burning

- According to the method of regulation of air draft

- By the number of circuits

- Features of long-burning boilers

- Selection of a heat generator according to the burning time

- 1 Lemax Forward-16

- Conclusion

What are the advantages of liquid fuel boilers?

The main advantage of boilers that burn diesel fuel, mining and heavy heating oil is autonomy. The unit is indispensable when there are no other energy sources - firewood, gas and electricity in the required volumes.

There is no need to monitor the combustion process, the device operates in automatic mode until the diesel fuel runs out. Installation does not require any permissions, but the initial start-up and adjustment of the burner should be done by an intelligent master.

This is where the pluses of diesel units end, then there are solid minuses:

- high cost of equipment and fuel;

- constant smell of diesel fuel in the boiler room;

- maintenance - as needed, which occurs quite often due to the quality of the fuel;

- for the same reason, it is necessary to constantly clean the chimney;

- you need to monitor the level of diesel in the tank;

- in terms of weight and dimensions, the unit is comparable to a floor cast-iron boiler.

An example of a diesel boiler house with two heat sources. Fuel tanks and fuel pumps are installed at the end of the room.

If it comes to your mind to heat the house with used engine oil, add to the list of shortcomings the dirt in the furnace and an additional 2-4 squares of area for barrels - sumps.

1 Wattek PYROTEK 36

A pyrolysis boiler of a serious European level, created according to all current quality standards. Czech manufacturers decided to release a line of automatic control units, which at the same time made life easier and more difficult for themselves and users. The fact is that “automation” is a delicate thing, and in some especially unfavorable cases (due to accidents) it can easily fail. Repair and adjustment of the control system on a boiler of this level is expensive, which often causes bewilderment and an angry reaction from people. Perhaps this is the only significant drawback of the system, because in other components it is almost perfect.

Advantages:

- the presence of an automatic control system for temperature and regime parameters;

- availability of emergency, boiler and boiler sensors;

- burning of the wood deposit is 12 hours, briquettes - 15-17 hours;

- high quality assembly materials;

- extended complete base.

Flaws:

adjustment and repair of the automatic control system, in case of failure, will cost the consumer a pretty penny.

The best solid fuel boilers for long burning

The main advantage of solid fuel boilers for long burning is uninterrupted operation for 5-12 days without human intervention. This is very important for summer residents, who rarely appear in the countryside during the cold season. Models of this type are economical and powerful, but have low efficiency and complex maintenance.

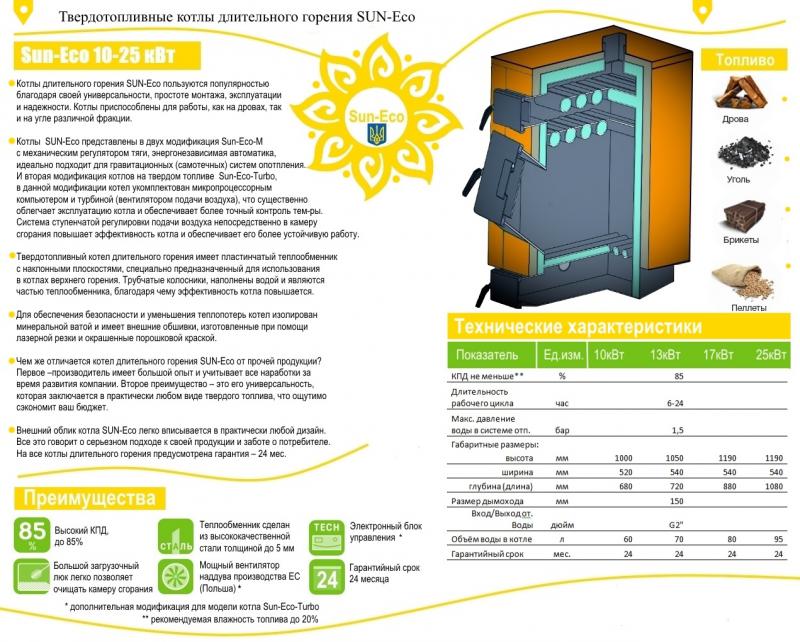

Galmet Top

Rating: 4.9

The Galmet Top 20 solid fuel boiler is widely used as an energy source. It is used in heating systems of private houses, in office buildings and industrial premises up to 200 square meters. m. Experts gave him first place in the ranking for a number of reasons. Firewood, briquettes, peat briquette, lump coal, woodworking waste can be used as fuel. The model is equipped with a reliable steel heat exchanger and automation with great functionality.

A solid fuel boiler compares favorably with competitors due to the possibility of connecting a floor heating circuit. Minimize human participation allows electronic control.

-

high efficiency 85%;

-

overheat protection;

-

the possibility of connecting a warm floor;

-

electronic control;

not detected.

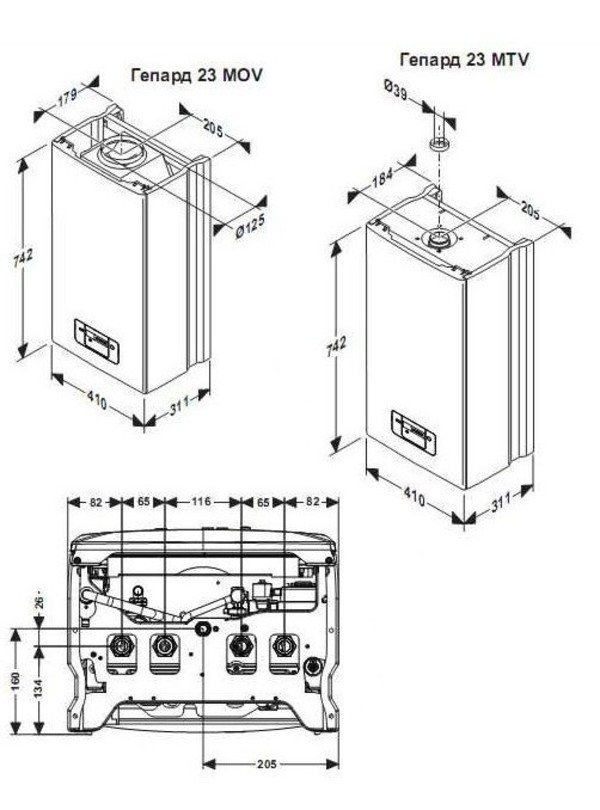

Buderus Logano G221-25

Rating: 4.8

Experts consider German solid fuel boilers Buderus Logano G221-25 to be the standard of quality. The model deservedly took the second line of the podium. It surpasses its competitors in terms of thermal power (25 kW), which allows heating spacious rooms. Boilers are well adapted to the conditions of the Russian winter. Heating of the coolant occurs quickly enough, although some users additionally mount a circulation pump.The model is equipped with a thermometer, pressure gauge, there is protection against overheating.

The manufacturer recommends the use of fuels such as wood, coal and coke. The German boiler loses to the winner in performance (78% efficiency), control (mechanical) and price.

-

capacious firebox;

-

stylish design;

-

unpretentiousness in operation;

-

fast heating of the coolant;

-

high price;

-

low efficiency.

Stropuva S15

Rating: 4.7

The small solid fuel boiler Stropuva S15 is of great interest to summer residents and owners of commercial buildings. It is able to heat rooms of 150 square meters. m. One bookmark of firewood allows you to maintain heat in the house for 30 hours, and when using coal, this time increases to 5 days. Economical fuel consumption is complemented by a high level of efficiency of 85%. The device is capable of heating the coolant to a temperature of 95 ° C, which is more than that of competitors.

The cauldron is inferior to the leaders in several respects. First of all, this is a small power (15 kW). In the heating circuit, the maximum pressure is limited to 1.5 bar, which may not be enough for effective heat transfer in a system without a circulation pump.

-

high efficiency;

-

high coolant temperature;

-

prolonged burning of fuel;

-

little pressure;

-

mechanical control.

TRAYAN TPG-15

Rating: 4.7

Solid fuel boiler TRAYAN TPG-15 can be used as the main source of heat in small houses or as a backup energy carrier. With it, you can heat rooms with a total area of up to 130 square meters. m

The model is inferior to the top three in such an important parameter as performance.Subject to the manufacturer's recommendations on one tab of firewood, the device can work up to 24 hours

The role of fuel can be played by firewood, coal and wood waste. There are restrictions only on the length of loaded fuel elements (up to 45 cm). The firebox holds up to 0.2 cubic meters. m of fuel.

The boiler has its advantages. The affordable price deserves special praise, experts note the ease of operation and unpretentiousness of the model.

Mounting order

The boiler belongs to objects of increased danger, it must be installed according to the project of a specialized organization that has licenses for the corresponding types of work.

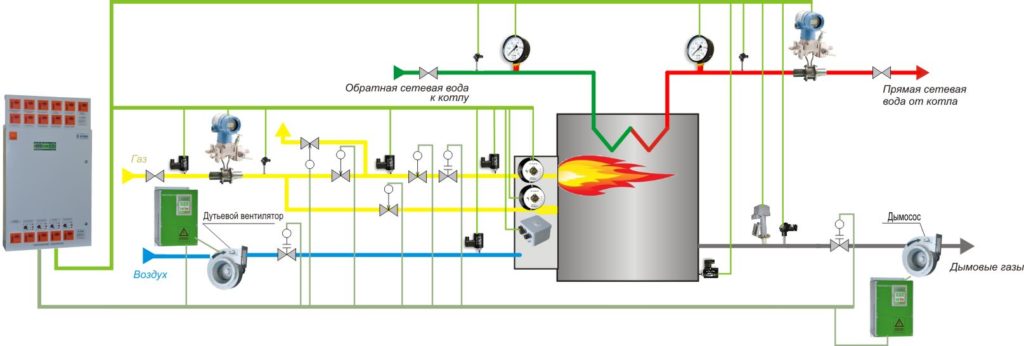

The algorithm for carrying out work during the installation of a coal-fired boiler:

- Preparatory measures are being carried out: Selection of a room for the furnace and concreting of the base for the placement of the unit and auxiliary equipment.

- The boiler is connected to the in-house heating circuit.

- The boiler is connected to the smoke ventilation system.

- Auxiliary equipment is installed: a blower fan, a centrifugal pump, air vents, a safety valve, temperature sensors, a water purification filter and an expansion tank.

- A test run and pressure testing of the system with a water pressure of 1.5 working hours is carried out to check the tightness of the connection of pipe and structural elements.

Stages of operation of solid fuel boilers

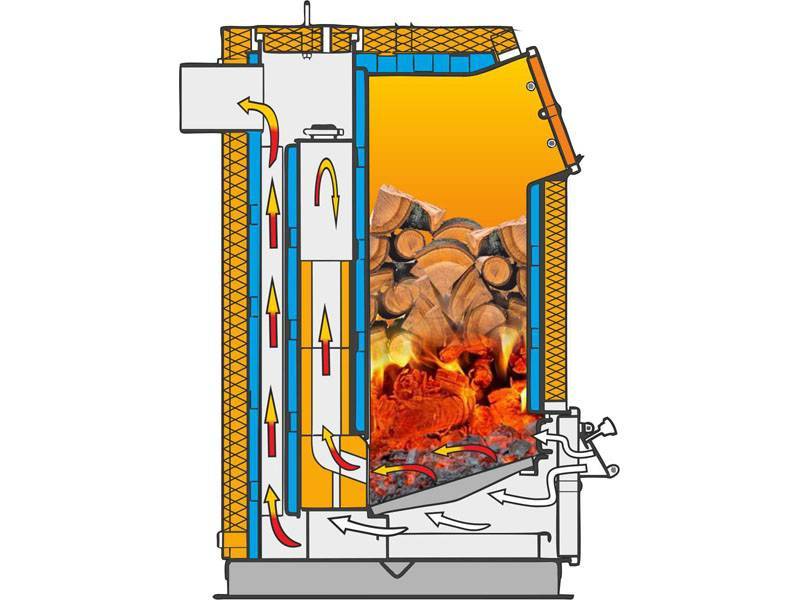

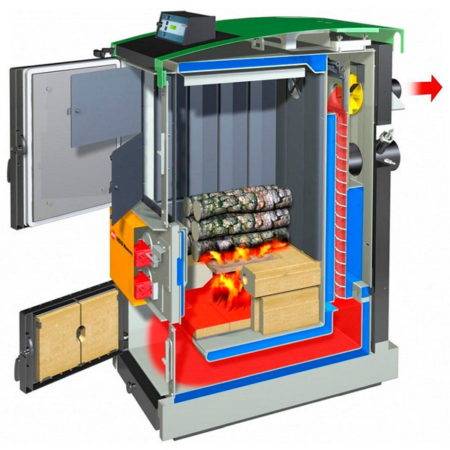

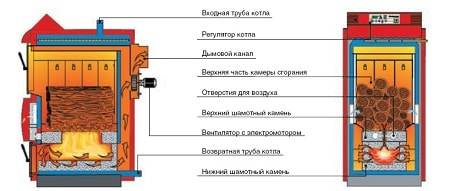

When the temperature rises to 200-800C, the wood decomposes into wood coke and pyrolysis gas. This gas provides most of the thermal energy, and as a result, the quality of the boiler, its efficiency, and temperature conditions increase.

Stages of operation of a solid fuel pyrolysis boiler:

- 100-200C - at this temperature, wood material dries;

- 250-600C - degassing, that is, firewood decomposes into components such as cellulose, resins, oils, and at temperatures above 500C gas already appears. At this stage, 85% of the wood turns into gas, everything else is charcoal;

- 600C and above - at this temperature, the pyrolysis gas is oxidized, that is, it reacts with oxygen and burns out. At the same time, the temperature rises significantly and the charcoal also decomposes.

During combustion, pyrolysis gas interacts with oxygen, as a result of which there are no toxic impurities in the combustion products coming out of this type of boiler. As a rule, water vapor with carbon dioxide escapes.

It is very important that the wood that is used as a fuel material be as dry as possible. This not only makes the operation of the pyrolysis solid fuel boiler much more efficient (more powerful), but also extends its service life.

The best models of solid fuel boilers. Overview of the rating of long-burning heating equipment

Models of solid fuel heating equipment are an excellent alternative to their counterparts that run on liquid or liquefied fuel. Recently, boilers designed for long burning have been in great demand. They are able to work offline for several tens of hours. When choosing the best device modifications, you should be guided by consumer reviews. The rating of equipment included in the top 5 most popular models of 2016-2017 will greatly simplify the task.

Boiler. solid fuel is a good alternative to its counterparts running on natural gas, diesel fuel or electricity.Such equipment is especially in demand in non-gasified areas or remote from regional centers, as well as where there are constant interruptions in the operation of power lines. Solid fuel boilers are available for both industrial and domestic use.

Choosing a fuel

It is also considered an important selection criterion. The functional features of the boiler will depend on its type, which is used by the boiler. The modern market is able to offer several types of fuel. The choice should not be based on the cost of products, but on the natural, climatic and regional characteristics of the region of residence. Wood waste is considered the most budgetary solution in Siberia, as is coal. Pallets, waste from the forestry and agricultural industries can also be used. Combined designs in operation are complex, expensive, but are characterized by versatility.

Fuel types

Fuel selection is often based on cost and market availability. The most common are considered to be:

Varieties

Peculiarities

Pine, birch, oak firewood (other species may also be used)

It is recommended to buy already chopped firewood. The less moisture they contain, the better. Wet pieces of wood will kill a gas generating, solid fuel or pyrolysis boiler in a few years. When choosing a place for subsequent storage of firewood, it is necessary to determine the most protected and dry place. Precipitation and moisture should be avoided at all costs.

The use of wet firewood is undesirable, but it is permissible in designs that do not belong to the category of gas generators (no more than 20%).

Borodino brown, Balakhta or Montenegrin coal

In the process of choosing a material, it is necessary to pay attention to its grade, fraction. The technical conditions for using the boiler should also be taken into account.

There is also a third version of the popular fuel on the market. We are talking about pallets, which are often used in combination with boilers of the same name. In fact, these are pellets, for the manufacture of which agricultural waste, as well as wood, are used. Their choice is a whole science, since the structure, shape and color of the pallets should be taken into account. A wide range on the market only fuels the interest of the average consumer in them, but the price can bite. Their cost exceeds coal and firewood several times, but they will still cost less than electricity or gas.

A great way to heat large rooms. Such boilers can be semi-automatic and automatic. The type of combustion is also different: fireplace, volumetric combustion, or torch. They are characterized by high efficiency and ease of subsequent maintenance of the device.

Classification

Conventionally, boilers are divided according to their characteristic features.

According to the material of the heat exchanger

1. Cast iron - the structure is assembled from separate sections with threaded connections.

Power depends on the number of sections. Smoke usually exits directly without additional ducts with heat exchangers.

Advantages:

- durability and anti-corrosion properties;

- high thermal stability;

- increase in power by increasing the number of sections;

- maintainability.

Flaws:

- increased fragility;

- instability to sudden changes in temperature;

- the need for a foundation or a solid floor due to the weight of the boiler;

- reduced efficiency.

2.Steel - the structure is welded from sheet elements.

The heat exchanger is a "water jacket" that heats the coolant. Installing additional dampers on the gas outlet paths increases heat transfer and efficiency.

Advantages:

- a large assortment;

- serviceability;

- quick exit to work mode

- shock resistance;

- maintainability.

Flaws:

- susceptibility to corrosion;

- the formation of weakly acidic condensate, which limits the service life;

- the possibility of burnout due to low-quality thin steel;

- power is not adjustable.

By type of fuel

1. On firewood.

The main indicators are the density of wood, the amount of smoke emitted, as well as ash. Suitable Breeds:

- oak - the largest heat release during prolonged burning;

- alder - does not require drying, suitable for cleaning the chimney;

- birch - good heat dissipation with long burning, but short storage;

- aspen - suitable for pipe cleaning;

- ash - maximum calorific value:

- poplar or willow - when there is no longer any firewood;

- pine - gives heat, but quickly burns out, leaving a lot of soot.

2. On the corner.

Boilers use:

- coal;

- weakly caking coke;

- brown coal;

- anthracite.

3. On pellets.

Compressed granules up to 10 mm in diameter and up to 50 mm long. Manufacturers usually indicate suitable dimensions, as exceeding the values increases the load on the components of the boiler, reducing the service life. As raw materials for the manufacture are used:

- wood;

- straw;

- sunflower husk;

- reeds;

- peat;

- corn cobs and buckwheat husks;

- municipal solid waste;

- waste paper;

- coal.

4. On wood chips and sawdust.

An effective way to get rid of woodworking residues.

5. On mixed materials.

Possibility of burning different types in one boiler.

By way of submission

1. Boilers with manual loading.

Products in which fuel is added as needed or as it burns. A good option for installation in a private house for maximum heat extraction.

2. Semi-automatic units.

Bookmarking is carried out manually, and the combustion process is controlled by automation.

3. Automatic products.

Modern equipment with automatic supply of granulated fuel in the form of pellets. It is characterized by compactness, high efficiency up to 86%, as well as low ash content.

In addition, they are equipped with automated ignition systems, maintaining the set temperature, as well as emergency protection.

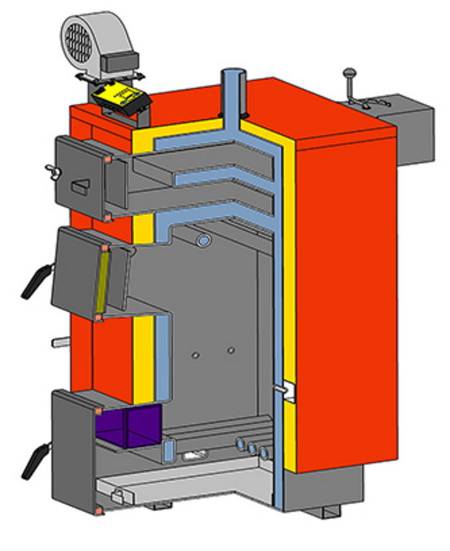

By loading direction

- With horizontal (front) loading - for products with cast iron heat exchangers. In the process of work, it is convenient to lay logs of firewood.

- With vertical (top) loading - for models with steel heat exchangers and characteristic combustion at the lower level with simultaneous drying in the upper part. Efficient work requires careful stacking of logs.

According to the method of burning

1. Traditional - differ in the absence of any electronics or elements that depend on the power supply. The entire fuel line is used. The dimensions of the furnace and the principle of combustion determine the frequency of loading the boiler and the regularity of cleaning. The product is a good option for equipping a wooden house or cottage.

2. Pyrolysis - differ in the use of the principle of separate combustion of materials and gases generated during combustion. Heat is released in large quantities when mixed with incoming oxygen. Waste in the form of ash and soot is practically not formed, and the efficiency of the device is very high.It is imperative to comply with increased requirements for the moisture content of firewood, which should not exceed 15 percent.

3. Long burning - simple devices with loyal requirements for humidity and the possibility of maintenance once or twice a day. There are:

- single-circuit;

- double-circuit;

- combined.

According to the method of regulation of air draft

- Non-volatile - mechanical adjustment of the air flow.

- Volatile - the use of a blower controlled by an electronic unit.

By the number of circuits

- Single-circuit - only for the heating system.

- Double-circuit - provide space heating and hot water supply.

Features of long-burning boilers

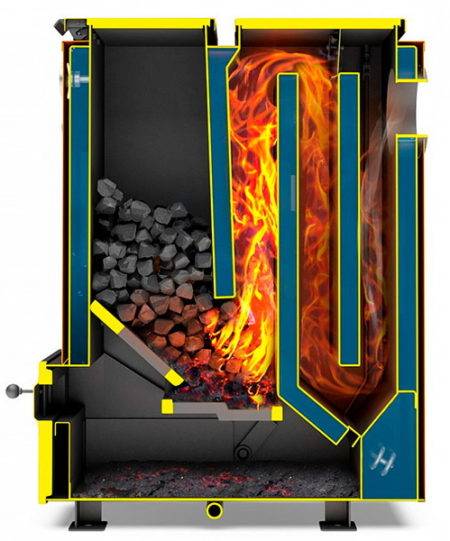

The first and most important fundamental difference is the way the fuel burns. In these units, the technology of the combustion process differs significantly from the traditional classical “bottom-up” scheme, as is customary in conventional furnaces and furnaces, and which covers the entire portion of the fuel with flame at once. In this case, everything happens exactly the opposite - “from top to bottom”, like a candle. A stable effect is achieved due to the telescopic design of the flow air distributor, which, under the influence of its own gravity, presses on the flame source and gradually shifts it downwards. As a result, the fuel slowly burns out in layers, along the entire height of the vertical combustion chamber, starting from the upper level - a type of upper combustion boilers.

This design makes it possible to burn the material evenly, evenly and with better quality, increasing the efficiency and duration of a single load mode.In addition, - this feature allows: to increase the service life of the unit, since the movement of the source of thermal energy in time reduces the "fatigue strength" of the steel heat exchanger compared to traditional furnaces, in which the hearth is located stationary and motionless; and completely abandon the use of additional heat accumulators.

Mechanical adjustment of the coolant temperature is carried out by a thermomechanical draft regulator (based on bimetal), which directly acts on the air valve. Therefore, they can be used in systems with both natural and forced circulation of the coolant.

And the second distinctive feature is their "unpretentiousness and omnivorousness"

And what is especially important in the heating system is the most economical fuel consumption. For example, for a power output of 20 kW, their performance indicators are (fuel type / one-time load, kg):

- firewood (≤ 50 kg);

- fuel briquettes - wood (≤ 110 kg) and peat (≤ 119 kg);

- coal - stone (≤ 145 kg) and anthracite (≤ 170 kg).

Due to specific design features, they are single-circuit, and have an efficiency of about 91-93%, one of the highest in its class. It takes them up to about 30 hours to completely burn out a single load of firewood, and the amount of heat released during the combustion of coal is enough for four days (for a private house with a daily need of 150 kW / h), depending on the temperature difference inside and outside the house.Their few shortcomings can only be attributed to the restriction on the use of pellets, manual loading of fuel and ash removal.

However, today solid fuel boilers are considered one of the most promising alternative sources of heating. Convincing evidence of this is the popularity ratings and the constant trend of growing interest in this particular segment of equipment for heating a private house.

TOP 3 most popular solid fuel boilers

- Lemax Forward-12.5

- NMK Siberia-Gefest KVO 15 TE

- Protherm Beaver 20 DLO

Selection of a heat generator according to the burning time

You can visually distinguish a real long-burning TT boiler from others by the following features:

- The product passport indicates the duration of work from 1 load at least 8 hours.

- The increased volume of the firebox increases the overall height of the unit, which is why such boilers are higher than their "brothers" with the same heat output. Another option is to increase the depth of the furnace, which is why the body "grows" in length.

- For high models, the distance between the loading and ash door is about 500 mm, no less. Some manufacturers provide their products with a third intermediate door for ease of use.

Example. A solid fuel hot water boiler, operating according to the usual scheme, has a furnace volume of 50-65 liters with a power of 22 kW and a nameplate burning time of 6 hours on wood. The total volume of the firebox of a long-burning heat generator is 100 liters or more, and the useful volume (up to the level of the loading door) is 80 liters at a power of 20 kW (for example, ATMOS D30 and VIESSMANN VITOLIGNO 250-S). If we consider boilers with upper combustion of firewood such as the Baltic Stropuva, then the volume of the chamber reaches 260 liters (power 20 kW).

Top-burning heaters are capable of operating for 12-15 hours on wood and up to 3 days on anthracite, but have a number of disadvantages:

- logs cannot be thrown “on the go”, but only after the previous portion of firewood has completely burned out;

- it is difficult to do short-term heating at home;

- fine fraction fuel like sawdust or debris sometimes hangs on the walls.

More information about these heat generators is described in the video:

1 Lemax Forward-16

16 kilowatts of power of the Lemax Forward-16 boiler is enough for heating premises of the administrative and domestic levels, private residential buildings and even cottages, by independent or forced (with the installation of a pump) circulation of the coolant through the heating water system. This is one of the most successful examples of small but productive installations with an uncharacteristically high (about 75-80 percent) level of efficiency. The uncomplicated design contains the solution to many operational problems. From the point of view of the technologist, such measures as, for example, "tamping" the heat exchanger with channels to increase the ultimate tensile strength, look redundant, but justify themselves in terms of durability of use. Such a boiler can last a good seven to nine years, provided that all measures of proper operation are observed without exception.

Advantages:

- the presence of additional elements that positively affect the durability of the installation;

- optimal cost with acceptable quality;

- sufficiently high (atypical) level of efficiency;

- the ability to connect a pump to increase the circulation rate of the coolant;

- the possibility of converting the boiler to work with gas (carried out by installing a gas burner).

Flaws:

no serious deficiencies were found.

Conclusion

Choosing a good solid fuel boiler is not difficult at all. The main thing is to determine those criteria that will be a priority for you. So, for some, the most important parameters may be the dimensions of the boiler, if there is no space for its installation. Basically, when choosing, they rely on the type of fuel, power and percentage of efficiency. Remember that solid fuel boilers are a convenient and modern source of autonomous heating.

When buying, pay attention to the material of the unit. So, cast iron boilers are considered the most reliable, while steel boilers are considered easier to maintain, but require regular cleaning.

This rating is subjective and is not an advertisement.

The most interesting in the sequel: