- How to choose a welding machine?

- Top Producers

- Choice by power

- Nozzle dimensions and their number

- How to perform diffusion soldering

- How to choose a soldering iron for polypropylene pipes

- Soldering iron specifications

- Power

- Nozzle set

- Manufacturer and brand

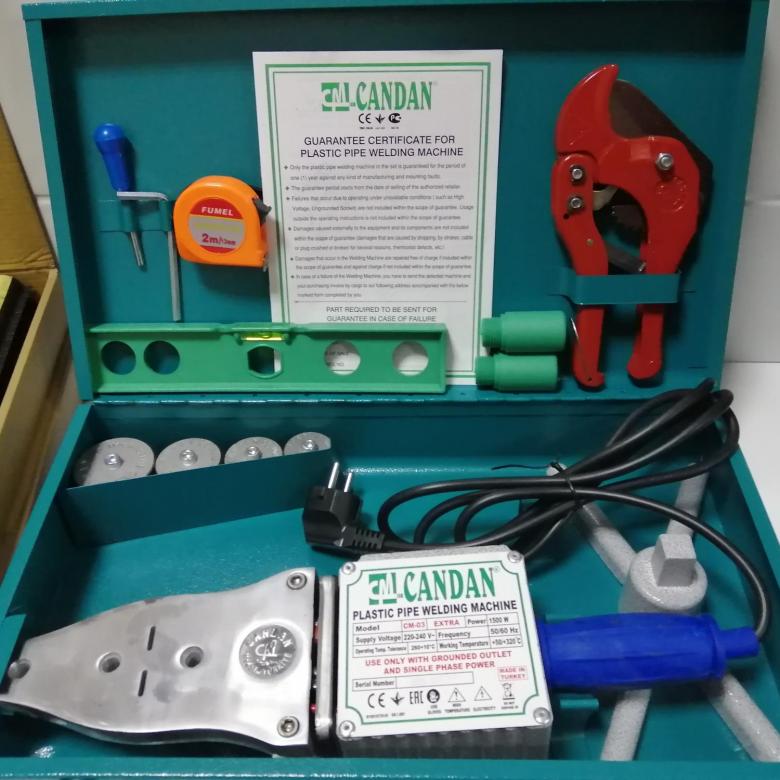

- Equipment

- How to choose a soldering iron for polypropylene pipes

- The best machines for butt welding of polypropylene pipes

- Rothenberger Roweld HE 200

- Brexit B-Weld G 315

- Rijing Makina HDT 160

- What is a soldering iron for PP pipes

- Cylinder or "iron"

- nozzles

- thermostat

- Pipe shears

- How to solder polypropylene pipes

- What to look for when choosing a plastic soldering iron

- Heating time for pipes and fittings

- Sword soldering irons for welding plastic pipes

- Soldering rods for polypropylene

- soldering technology

- The principle of operation of the soldering iron and design features

- The principle of operation of the soldering iron

- Recommendations for choosing soldering equipment

- Candan CM05 2400W

- Dytron SP-4a 1200W TraceWeld Profi blue (63-125)

- WRM-160

How to choose a welding machine?

To choose the right soldering iron for polypropylene pipes, you need to take into account a number of nuances, conditions of use (for soldering in hard-to-reach places, you need to choose cylindrical models).Difficulties in choosing may arise due to the large range of heating equipment.

Top Producers

Among the companies that produce soldering machines, there are 10 best manufacturers. Top 10 manufacturers:

- Candan is a Turkish company whose products have improved technical characteristics.

- REMS - equipment from this manufacturer is valued among professionals. Models of soldering irons have an accurate heating regulator, they work for a long time without breakdowns.

- Valtek is a Russian-Italian brand whose products are distinguished by reliability and durability.

- Prorab - the manufacturer produces compact soldering machines.

- Gerat Weld is a company that produces inexpensive but high-quality soldering irons. It is possible to fix two different nozzles for heating plastic.

- Aqua Prom - under the brand name of this brand, powerful equipment is produced.

- Sturm - professional devices for the simultaneous implementation of two types of welding.

- Bosch - the company produces the best soldering irons for polypropylene pipes, used among beginners. The devices are reliable, a large number of nozzles of different diameters.

- Electromash - with the help of such tools, manual welding of polypropylene is performed. They are reliable, easy to use.

- Rotorica are versatile devices that are appreciated by professionals and beginners. For convenience, soldering irons are equipped with digital temperature controls.

The equipment rating was compiled based on the opinions of buyers.

Choice by power

When buying a polypropylene soldering iron, you need to pay attention to the power of the device. Recommendations:

- If it is necessary to solder tubes up to 50 mm in diameter, it is enough to choose a tool with a power of 1 kW.

- For parts with a large cross section, the optimal power is from 1.7 to 2 kW.

For professional installers, the best choice is a PPR universal soldering iron with high power.

Professional high power soldering iron

Nozzle dimensions and their number

The nozzle for a soldering iron is an indispensable element when heating polypropylene pipes. The end of the pipe is put on it, which will be connected to the coupling or other connecting part. Selection Guide:

- For low power devices, you need to buy nozzles of small diameter, since they cannot warm up large parts.

- For professional installers, you will need a set of nozzles from 10 to 110 mm. At home, parts in sizes 16, 24, 32 are suitable. This is enough for welding domestic pipelines.

- It is advisable to choose nozzles with a Teflon coating.

How to perform diffusion soldering

Docking of the ends is carried out directly by socket soldering or with the help of couplings. The coupling is a shaped piece that is used as a connecting link. It is appropriate for pipes with a diameter of up to 63 mm. Instead of a coupling, cutting pipes of a larger diameter than the welded area are suitable. The section of the pipe and the coupling at the junction is melted, providing a reliable fastening.

Pipe cutting

The socket connection requires precise joining of the pipe elements. The edges must be perfectly protected. Irregularities and burrs after trimming are not allowed. After the ends are melted by the apparatus, their diffuse connection occurs. If errors occur during trimming, a leak or a gap in the joint will form when the water is supplied.

How to choose a soldering iron for polypropylene pipes

Soldering devices are divided into 2 groups. Devices with power up to 1000 W have one heating element.It takes time to reach the required temperature for bonding. Models with power up to 2000 W are distinguished by the presence of two heating elements. Operating temperature is reached faster. For one-time use at home, you can buy an inexpensive low-power soldering iron.

Standard machines are heated up to 260-300°C. The possibility of thermal control helps to adapt to the materials being welded. 260°C is enough to melt polypropylene. When buying, consider the specifics of the upcoming activity. Large investments are required only when soldering is a professional activity.

Soldering iron specifications

Power

The power depends on the warm-up time, the soldering time of one joint, in rare cases, the tightness of the joint. It seems that the more power, the better, but in fact, a soldering iron with a power of about 1000-1200W is enough for home use. If a soldering iron for polypropylene pipes has high power, but the nozzles do not exceed a diameter of 63mm, the stock can be safely considered a waste of money.

Nozzle set

On the one hand, the more attachments, the better. Unscrupulous manufacturers are trying to lure buyers with quantity.

Ideally, you need to know in advance what diameters of polypropylene pipes will be in operation. But this is only possible when buying a soldering iron for one project, that is, for a home craftsman. Therefore, it is easiest to focus on the qualities of the instrument itself, not paying attention to the rest.

Manufacturer and brand

Does the manufacturer and brand matter? For the purchase of equipment for a construction site - definitely.For home construction, where the soldering iron will be used to assemble the polypropylene plumbing of your home and several times with relatives, choose a model according to its characteristics and reviews.

For construction, soldering irons of the German brand Rotenberger are better suited. For several years now, this company has been a reliable supplier of equipment for welding polypropylene pipelines from a wide variety of materials.

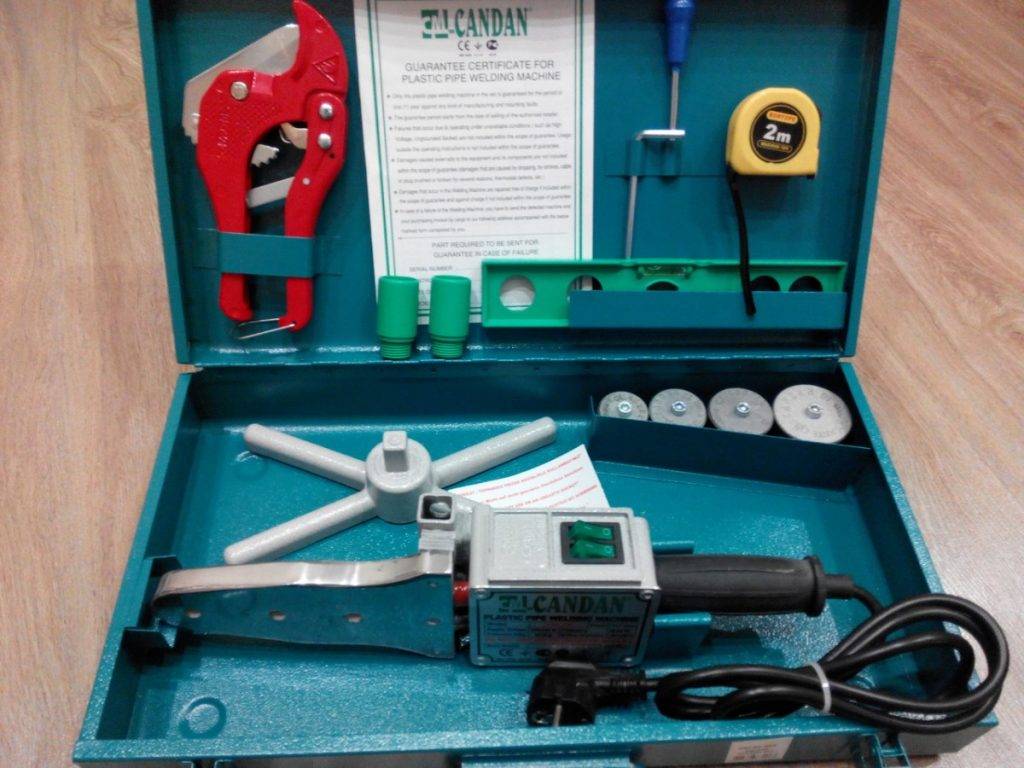

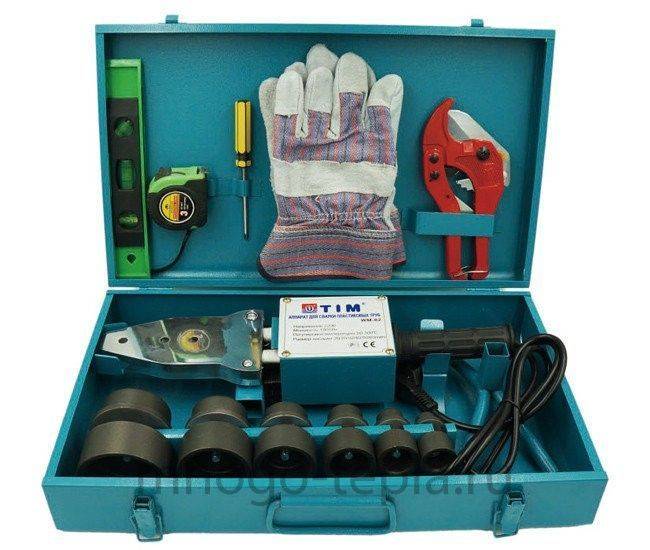

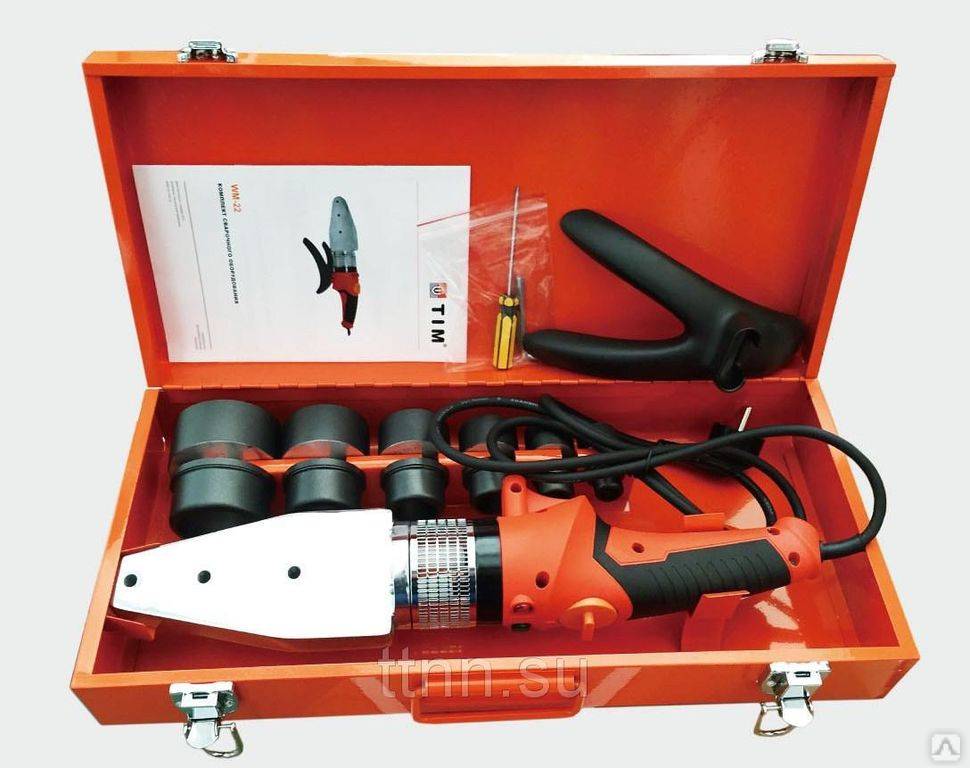

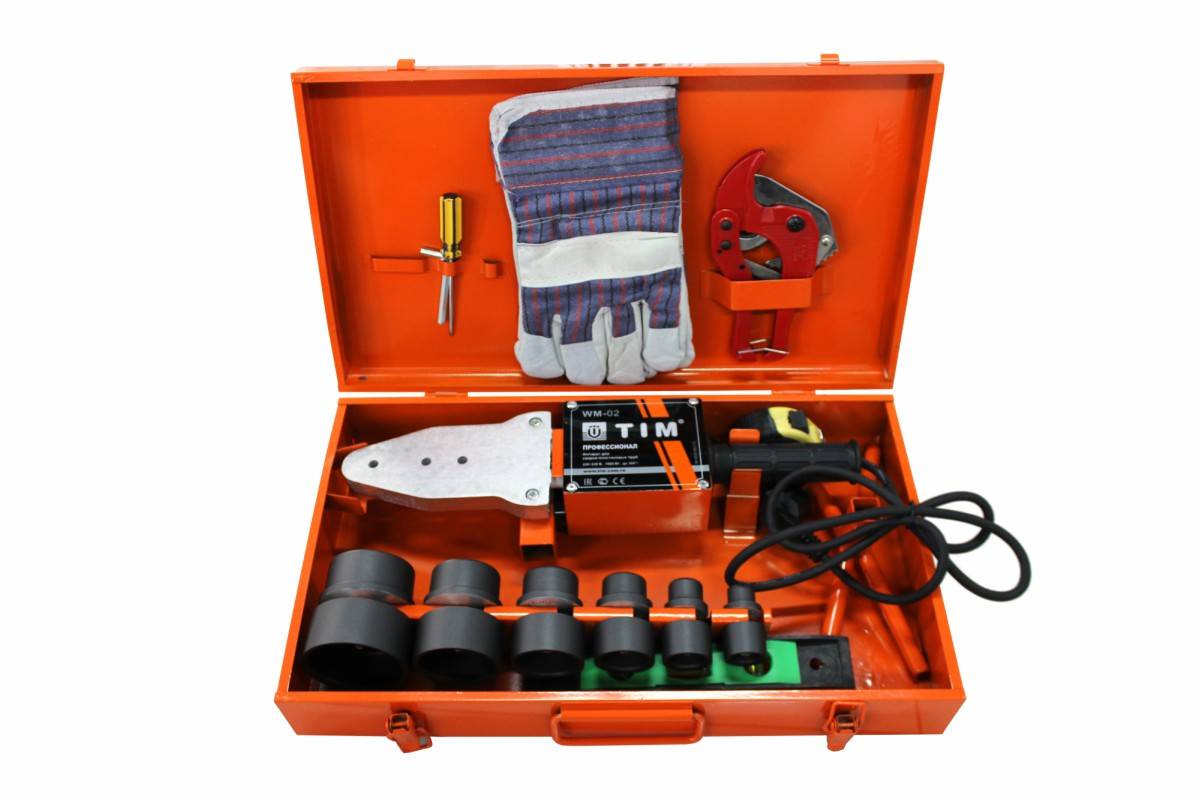

Equipment

What is important and what is not very important in a soldering iron kit?

- The main thing is the soldering iron for pipes. If you are not satisfied with its characteristics, reviews, price, power or any other factor, you do not need to take this tool.

- The second factor is the stand and soldering iron handle. The stand can be in the form of a table mount or a cross. A cross is not the best option, but if there is no other choice, then you need to choose a massive, heavy base. We recommend mounting on the table with a screw that securely fixes the tool on the tabletop. The handle must be rubberized.

- The third factor is the case. Kits in a plastic box are not very convenient and you need to be prepared in advance for the fact that the case will crack, and half of the nozzles will be lost. The best choice is a metal box.

The remaining parts of the kits are a way to attract a client. If nozzles and scissors for polypropylene pipes still justified, then screwdrivers, tape measures, gloves - a cheap trick to get your attention. First of all, you need to look at the soldering iron. Other items can be purchased separately. It will come out a little more expensive, but each part of the kit will be matched to a specific master. Homemade welding machine or a waste of time

A soldering iron for plastic pipes is inexpensive.Despite this, many home craftsmen still want to make a tool with their own hands. We note right away that it is much easier to buy a budget soldering iron at a time than to suffer from a household one with an iron for pipes.

To make a tool with your own hands you will need:

- Iron. The sole is twisted from it. In shape, it resembles sword-shaped soldering irons and will just be used as a heating element. It is better to take ready-made nozzles, rather than trying to carve round objects from household trash

- Temperature controller. You can buy it or build it yourself.

- Handle (preferably rubberized)

- Stand made of metal (can be welded from metal rods).

The nozzles cling to the sole of the iron with bolts. On this, the assembly of an unreliable design, which for some reason is called a soldering iron, is over.

Let's say right away that there is not much point in wasting energy on assembling such a tool. The assembly itself will take several hours, and the result will be enough for one repair. Therefore, such homemade products can only be considered as extreme measures or a hobby, but not an independent tool.

Instead of a conclusion, we note that the choice of a soldering iron for polypropylene pipes should take into account 3 factors:

- It makes no sense to overpay if the device is needed for 2-3 repairs.

- Do not be fooled by the number of components in the kit. You need a tool, gloves or a screwdriver alone won't solder anything.

- Excessive power is not needed for home plumbing repairs. Focus on the power of 1000 watts.

How to choose a soldering iron for polypropylene pipes

The main criteria for choosing a soldering iron for polypropylene pipes are as follows:

- In the power of the tool;

- The shape of the heating element;

- In the number and size of nozzles for a soldering iron;

- In a complete set;

- From the manufacturer.

The greatest attention when choosing a soldering iron for pipes deserves the power and shape of the heating element. The maximum diameter of the pipes to be welded is directly related to the power of the soldering iron, so this selection criterion should be approached as responsibly as possible.

So, for example, for domestic needs and minor repairs of apartments, a soldering iron for polypropylene pipes, the power of which varies between 700-900 watts, will be quite enough. In the kit of a household soldering iron for welding pipes, there are nozzles ranging from 20 to 40 pipe diameters.

In the event that from time to time you have to weld water pipes of 63 diameters and above, then you will need a more specialized soldering iron with a power of at least 1100 watts.

Choosing a soldering iron for pipes is easy, based on the tasks. At the same time, it is worth giving preference only to trusted manufacturers that have been on the power tool market for more than a year.

The best machines for butt welding of polypropylene pipes

This type of welding does not require special couplings. The process of connecting tubular elements is based on heating their end parts and bonding under pressure.

Apparatus for butt welds are distinguished by a large range of machined diameters and high productivity.

Rothenberger Roweld HE 200

4.9

★★★★★

editorial score

96%

buyers recommend this product

The distinctive characteristics of the model include PTFE-coated heating elements and easy replacement of nozzles.

Thanks to this, melted areas do not stick to the device, and switching between pipes of different diameters takes place in a matter of minutes. The power of the device is 800 watts. A long service life is ensured by a mechanism that protects against overheating.

The temperature is electronically controlled and distributed evenly over the entire surface of the soldering iron.

Advantages:

- durability;

- status indication;

- ease of setup;

- quick nozzle change.

Flaws:

high price.

Rothenberger Roweld is used when connecting pipes made of synthetic materials with a diameter of not more than 20 mm. It can be bought for fast and efficient butt welding.

Brexit B-Weld G 315

4.9

★★★★★

editorial score

94%

buyers recommend this product

The heating element of the model is coated with Teflon and has a removable design, which makes it easy to replace.

The device is equipped with a high-precision temperature control system and a two-channel timer that allows you to keep statistics of the time spent on heating and cooling.

The motor power of the device is 3800 W, which guarantees efficient processing of pipes with a diameter of up to 315 mm. Low starting pressure and hydraulic drive ensure high welding quality.

Advantages:

- precise temperature control;

- powerful engine;

- welding of large diameter pipes;

- built-in pressure gauge and timer.

Flaws:

great weight.

Brexit B-Weld G 315 is used in the construction and manufacturing sectors. This is a professional tool for welding polypropylene pipes of various diameters. An excellent choice for quality and productive work.

Rijing Makina HDT 160

4.8

★★★★★

editorial score

88%

buyers recommend this product

The main features of the model are small dimensions, stability and reliability of the design. Clamping inserts of the device are equipped with force and fixation regulators.

The temperature of the heating element can be precisely adjusted, evenly distributed over the entire surface and maintained throughout the entire operation time.

The motor power is 1000W. The package includes reducing inserts for fixing pipes with a diameter of 40, 50, 63, 75, 90, 110, 125 and 160 mm. The high speed of processing is reached by means of the electric facer installed on the case.

Advantages:

- rich equipment;

- stability;

- compactness;

- the presence of a trimmer.

Flaws:

short cable.

Rijing Makina HDT 160 is worth buying for welding in hard-to-reach places, such as basements or wells.

Ease of use and ease of setup make it possible to successfully use it both in the professional field and in domestic work.

What is a soldering iron for PP pipes

Cylinder or "iron"

A device for welding polypropylene pipes is often called a soldering iron, sometimes an iron. It really has a lot in common with a household iron:

- powerful electric heater;

- a heating surface similar, in some products, to an iron sole (sword-shaped);

- thermostat;

- handle.

The heating surface of the devices may have a cylindrical (rod) shape. Such devices are more compact. They are more convenient to use in hard-to-reach places, since the nozzles can be placed on the heating element at any angle.

nozzles

Soldering irons are equipped with nozzles that are attached to the heater and transfer heat to the workpiece and fittings (connecting parts). The cross section of these devices corresponds to the cross section of pipes and is indicated in the technical documentation by the letters Du (nominal diameter). So that the molten polymer does not stick to the metal and does not complicate the work of the master, the nozzles are made with a Teflon coating.

thermostat

The working surface of the soldering iron is usually heated up to 260ºС. The duration of heating depends on the diameter of the product. In case of overheating, connections may lose bandwidth. Molten polypropylene melts part of the internal section, creating an obstacle to the flow of water.

As a result, water consumption is drastically reduced. For heating and hot water systems, this is accompanied by a decrease in water temperature, or complete freezing in winter.

Insufficiently heated elements do not ensure the tightness of a non-separable connection. Simply put, the installed water supply will leak at the joints and will have to be redone.

To eliminate problems with the heating temperature, the devices are equipped with manual or microprocessor thermostats. In the first case, by turning a special knob on the scale, the set temperature is set, upon reaching which the thermal relay or thermostat is triggered.

In the second, the temperature is controlled by a microprocessor.

Pipe shears

If necessary, prepare a workpiece of a certain size for soldering, mark it and cut it off with special scissors. Of course, you can use a hacksaw for metal or a grinder. However, it is better to perform a high-quality cut with special scissors.

Good hand shears should be equipped with a ratchet or ratchet mechanism, have a sharp and hard stainless steel blade and a wide base that provides a smooth cut at an angle of 90 degrees. The quality of the connection depends on this. In the case of an uneven cut, the joint may be leaky.

How to solder polypropylene pipes

Nozzles are attached to the sword-shaped heating surface of the soldering iron with screws. In devices with a cylindrical heating surface, they are put on the working body like clamps and are also tightened with screws. The blank is inserted, and the fitting is put on the nozzle.  The device is connected to the mains with a voltage of 220 volts. The surface is heated, the polypropylene softens to a certain extent. Then the heated billet is inserted into the heated fitting until it stops and allowed to cool.

The device is connected to the mains with a voltage of 220 volts. The surface is heated, the polypropylene softens to a certain extent. Then the heated billet is inserted into the heated fitting until it stops and allowed to cool.

Thus, diffusion welding of parts occurs. In the instructions attached to the soldering iron, the heating time of the parts for each diameter in seconds is described.

What to look for when choosing a plastic soldering iron

According to the reviews of masters specializing in heating and plumbing systems, all the components of the heater are important. First of all, the quality of the steel and the coating of the nozzles are checked, as they bear a constant load on the temperature difference and ensure the quality of welding.

First of all, the quality of the steel and the coating of the nozzles are checked, since they bear a constant load on the temperature difference and ensure the quality of welding.

Heating time for pipes and fittings

| Diameter, mm | Heating time, sec | Relocation time limit (no more), sec | Cooling time, sec |

| 16 | 5 | 4 | 2 |

| 20 | 5 | 4 | 2 |

| 25 | 7 | 4 | 2 |

| 32 | 8 | 6 | 4 |

| 40 | 12 | 6 | 4 |

| 50 | 18 | 6 | 4 |

| 63 | 24 | 8 | 6 |

| 75 | 30 | 10 | 8 |

The heating time of a good household appliance is about 5 minutes. If you have to work with a budget soldering iron, which does not hold the heat regulator tightly, then smart craftsmen advise you to fix it with tape to avoid accidental drop and spoil the influx on the pipe.

When evaluating the quality of tips, it is important to check that the Teflon is of good quality, otherwise it will fail after a few uses. Pieces of plastic will remain in the nozzles; when turned on, strong smoke with harmful impurities will go out

Another subtlety is the location of the nozzles on the canvas. If this is an iron, then it is best to select a configuration with nozzles along the very edge of the heating plate, as this will make it possible to work in hard-to-reach corners.

The second sensitive factor is the guarantee of constant heating. In expensive professional devices, the deviation of heat indicators ranges from 1.5-3 °. Moreover, the electronic display not only controls the set heating temperature, but also shows it on the screen.

If an inexpensive manual device is used, then you will have to test its operation on pieces of pipes and fittings in order to achieve a good result. Experienced craftsmen advise using a template to mark the distance the pipe must enter the nozzle and heat up. With a smooth introduction to the desired segment, the influx will turn out to be even and will not bend inward, reducing the conductivity of the liquid in the future system.

| Diameter, mm | Entry into the nozzle/fitting, taking into account the space for the internal influx, mm | Distance to the outer, visible influx, mm | Mark distance (template), mm |

| 20 | 13 | 2 | 15 |

| 25 | 15 | 3 | 18 |

| 32 | 16 | 4 | 20 |

| 40 | 18 | 5 | 23 |

Thus, the third criterion for choosing a soldering iron will be electronic or manual control.And here we have to solve a dilemma. If you have significant work experience, then you are able to control the correct preparation and soldering process on a manual apparatus. But when you plan to weld for the first time, you will either have to learn from test material or buy an expensive electronic device to take control of the process for you.

And the last fourth criterion is the stand for the soldering iron. Since the device will operate at high temperatures, elementary safety precautions are extremely important. The stand or support under the heater should not be flimsy, otherwise it will not only turn over, but may also cause burns to you.

Sword soldering irons for welding plastic pipes

The most common options for a heating element with a wide platform and the ability to mount several nozzles at once. Popular for high volume work at large facilities. They have their own form of fastening nozzles with a key.

Soldering rods for polypropylene

They are characterized by a rod on the handle, to which nozzles are attached according to the clamp principle. The quality of heating does not differ from sword-shaped "irons" and depends only on the method of heating and adjustment. A feature is the ability to work not only on a horizontal surface, but also on weight in corner joints.

soldering technology

Using a device for soldering propylene pipes does not have any difficulties. It is necessary to follow the actions recommended by the instructions and follow the safety rules.

Using a device for soldering propylene pipes does not have any difficulties. It is necessary to follow the actions recommended by the instructions and follow the safety rules.

The soldering iron is installed on the legs, which are included in the kit, and connected to the mains. Choose nozzles that are the same as the diameter of the pipes to be mounted. The edges of the pipes are heated, connected and squeezed, applying a little effort.

Before you start working, you need to let the device warm up well. The correct temperature will make it possible to solder the pipes with high quality - this is the key to the future operation of the pipeline. Based on the power of the soldering iron, warming up can last from 10 to 30 minutes. The extinguished indicator light provided on the case will tell you about the readiness of the device.

Read the technical data sheet, there you will find the exact time required to warm up the connection elements. If the connection attempt fails, do not try to warm up the element again. Polypropylene stretches after heating, and when stretched, it does not match the size of the nozzle. Simply remove the pipe section and reheat.

Having a good soldering iron and knowing how to handle it, you can install a water supply or heating system in an apartment and house quickly enough.

Masters recommend following two rules to obtain high-quality soldering of polypropylene:

- Maintain the required temperature.

- Warm up the pipe for the time recommended by the instructions.

A coupling is used to connect pipes, so the nozzle from different sides has a different diameter. One edge is for heating the pipe from the outside, and the second is for heating the inner diameter of the coupling.

A coupling is used to connect pipes, so the nozzle from different sides has a different diameter. One edge is for heating the pipe from the outside, and the second is for heating the inner diameter of the coupling.

Further actions occur according to the following scenario. The coupling is put on the heated nozzle of the device on one side, and the pipe is inserted into the nozzle on the other side. The fixation time of the elements is recorded, as a rule, from 30 to 60 seconds. After that, the coupling and pipes are removed from the nozzle and connected together.

To obtain an uninterruptedly working water main, all actions are carried out very accurately and carefully.The quality of the connections is very important when working with hot water or heating systems.

One obvious conclusion suggests itself: in order to get a water main consisting of polypropylene pipes that will work smoothly for many years, it is not enough to buy an expensive soldering iron for polypropylene pipes. Experience with the device is required. You should master the rules for working with polypropylene pipes, understand the installation and design of water supply and heating systems.

A combination of skills, knowledge and professional experience can give the desired result.

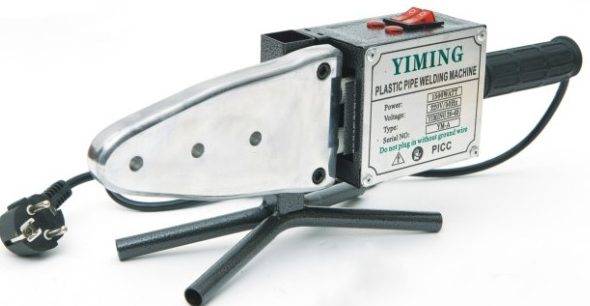

The principle of operation of the soldering iron and design features

In most cases, the appearance and design of various models of devices is the same, the most important differences are in the methods of attaching nozzles to the device itself. Device composition:

- Frame.

- Lever.

- Tubular electric heater.

- Temperature controller.

- And the nozzles themselves.

The main components of both devices are the heating element and the thermostat. Manufacturers embed the heating element in a variety of housings - flat or round. The variation of the case determines which nozzles will be used when working with the device.

The principle of operation is not distinguished by any difficulties and difficulties: a tubular electric heater heats up the surface that heats the nozzles to the required temperature. Polypropylene softens under the influence of temperature, which makes it possible to create a high-quality connection of elements.

The thermostat controls the optimum temperature (usually it is two hundred and sixty degrees Celsius).Otherwise, polypropylene can overheat and leak - this does not lead to anything good. Either the diameter of the pipes will be reduced, or the plumbing will be damaged.

In another case, if the polypropylene is not heated enough, it will not be possible to create a tight connection. It should be noted that the thermostat acts as a protection for the heating element, at the same time saving it from overheating and preventing the metal head from melting.

A separate place is occupied by nozzles for a soldering iron. First of all, they should be of the highest quality, because it is the nozzles that guarantee the quality of the joint when soldering elements. They have a variety of finishes.

There are Teflon-coated nozzles, according to experts, they are considered the most durable. You can also find products with a metallized Teflon coating (even stronger) - they help to produce uniform heating.

The principle of operation of the soldering iron

The standard device is a design consisting of: a body with a handle, a thermostat, a heating element, a platform and a hole for nozzles. Some may come with a stand, and some may not have a control panel. It all depends on the manufacturer.

When connected to the network, the heating element begins to heat up the work area (platform or iron, which comes after the handle). Plastic products are mounted with their ends on heated bolts and melted during the standard time. When the soldering machine softens the inner and outer surfaces of polypropylene pipes and fittings, they are fastened together and a strong, inseparable connection is obtained.

The melted edges are easy to connect and harden tightly. If you overexpose the plastic on a hot surface, it will begin to spread and become unusable.The handle prevents burns, and the stand allows you to fix the soldering iron and joining plastic products.

This welding tool can be used for HDPE, PE and PVC pipes. Also with high-temperature welding, you will need scissors for cutting products. Before self-assembly, we recommend that you familiarize yourself with all the nuances of welding plastic products.

Recommendations for choosing soldering equipment

Before buying equipment, it is important to determine for yourself how often you plan to use it, what volume of pipes you will solder, and what maximum level of heating is required. Having decided on the main points, you can proceed to the main technical indicators:

Power - all equipment for welding polypropylene pipes should be divided into two large categories. Soldering irons with a power of up to 1000 W are equipped with one heating element, so you will need to wait a little before starting work. Equipment with a power of up to 2000 W is equipped with two heating elements. Depending on whether one or two heating elements are connected, the warm-up time of the equipment changes. For professional use, high speed is required, so it is worth choosing more powerful models. For a home craftsman who decides to replace the pipeline on his own, a soldering iron with one heating element will suffice.

soldering diameter. Depending on the purpose, polypropylene pipes come in different diameters. To create a pipeline for various purposes, it is necessary that the soldering iron kit contains matrices of the right size. The greater the number of nozzles, the wider the scope of the equipment.The presence of matrices with a diameter of 20-63 mm allows you to work with the water supply, as well as the sewage disposal system in the apartment. For a wider use of equipment, it is worth purchasing a professional model, the diameter of the nozzles in which will reach 110 mm.

The maximum heating temperature of most soldering irons varies between 260-300 ° C

When choosing a tool, it is important to consider not only the maximum rate, but also the ability to adjust the heat. It is convenient when it is possible to set the temperature from 50 ° C, adjusting the degree of heating of the tool to the materials that need to be welded

For example, a polyethylene pipe melts perfectly at a temperature of 200 ° C, while polypropylene requires a minimum of 260 ° C.

When choosing a soldering iron, you should pay attention to the presence of additional elements. Additional comfort of operation is provided by the presence of light indication of power, heating level

Professional soldering irons are equipped with a special display that allows you to set the heating temperature at the selected level. This provides a definite plus, compared to cheaper models, since in the latter the level of heating of the working part is determined intuitively by the master.

Models equipped with a built-in thermostat are more economical to use, able to maintain the temperature at the same level, periodically turning off the heating elements. Cheaper soldering irons have to be periodically disconnected from the network on their own. It is not always convenient, it constantly distracts from cutting, installation, welding of the pipeline.

The best professional soldering irons

When you have to connect plastic pipes every day, only professional devices can withstand a serious load for a long time.They are characterized by high performance, temperature accuracy and durability. Experts speak flatteringly about the following models.

Candan CM05 2400W

Rating: 4.9

The Turkish Candan CM05 pipe soldering iron is popular with professional plumbing installers. The model has an optimal ratio of price and performance. Experts appreciated the high power of the device (2.4 kW), quick heating up to a temperature of 320°C, the ability to connect pipes with a diameter of 50 to 160 mm. The device is equipped with two heating elements, which can be turned on simultaneously or separately (1.2 kW each). When the required temperature is reached, the master will be informed by 2 light indicators. The thermostat helps to maintain the set temperature (from 50 to 320°C).

Together with the device, the manufacturer includes a key for nozzles, a tripod stand and a metal case.

-

high power;

-

affordable price;

-

light indicators;

-

good equipment.

a modest assortment of nozzles.

Dytron SP-4a 1200W TraceWeld Profi blue (63-125)

Rating: 4.8

The Czech soldering iron Dytron SP-4a is distinguished by excellent quality, durable and trouble-free operation. In the device, the microprocessor is responsible for the optimal temperature regime, which makes it possible to achieve an accuracy of 1.5 ° C. A professional device is able to cope with a wide range of pipes, from 16 mm to 125 mm. The welding time is determined automatically. Thanks to a set of these characteristics, the model falls into our rating. But the high price did not allow to become a winner.

Complete with the device, the manufacturer includes 5 nozzles, a key for attaching nozzles, a clamp, a metal case. You can use the soldering iron not only indoors, but also outdoors.In addition to polypropylene and polyethylene pipes, the device also welds materials such as PVC and HDPE.

-

temperature setting accuracy;

-

high performance;

-

work durability.

-

high price;

-

tight case.

WRM-160

Rating: 4.8

The WRM-160 soldering iron is a real welding machine capable of solving the most difficult tasks. Professionals value the device for its exceptional performance and ease of use. The device is designed for connecting pipes with a diameter of 50 to 160 mm. The welding machine does not have record power (1.2 kW) and high heating temperature (260°C). But experts note the outstanding accuracy of setting the temperature regime. This is achieved by an electronic thermostat. The machine is installed on high legs, which makes work more convenient and less tiring. The model deserves the third line of our rating.

The unit is intended for large companies, a very high price hints at this. Together with the machine, the consumer is offered a wooden box, replaceable nozzles and bushings, 3 legs.