- Prevention

- Types of sealing products

- Seal form

- Material

- How to fix a leak between the tank and the toilet

- Causes of leaks

- Causes of a leak

- leak inside

- Wet outside

- Types of sealing products

- Seal form

- Material

- cistern structure

- The main malfunctions that occur in the drain tank

- Toilet replacement

- Installation nuances

- Gasket for drain mechanism

- Testing

- Fundamentals of total tightness

- Screed features

- How to install a gasket between the tank and the toilet

Prevention

On modern plumbing kits, it is customary to install polymer studs. In terms of fastening, they are, of course, inferior to metal ones, but they also have their advantages. The main advantage is the resistance of the material to corrosion, because metal bolts are guaranteed to rust over time, and the tank leaks because of this.

Preventive measures also include regular inspection of the toilet bowl and all elements of its fastening. If you notice malfunctions and wear of parts in time, you can avoid a number of unpleasant moments, such as a leak.

How to fix a leak in the toilet, see the following video.

Types of sealing products

Known types of sealing products differ both in their configuration and in size and material from which they are made. Each of these features has its own characteristics.

Seal form

In accordance with this feature, cuffs for toilet bowls are divided into the following groups:

- oval, resembling a regular ring;

- trapezoidal seals;

- cone products;

- gaskets of complex multi-circuit configuration.

O-rings for toilet bowls are the most common type of cuffs used to articulate the bowl and tank.

They are used in most classic old-style designs. In modern models, gaskets of a more complex shape, resembling a truncated cone, are usually installed.

Recently, trapezoidal seals have become increasingly common in foreign-made products, resembling a triangle with cut-off corners.

In addition to the shape of the cuffs, all of them are characterized by another important property that determines the performance characteristics of the product. It involves a classification according to the type of material used in the manufacturing process.

Material

On this basis, all known samples of seals are divided into the following types:

- elastic cuffs, belonging to the category of the most popular and cheapest products;

- silicone blanks, characterized by increased elasticity and higher cost;

- polyurethane seals, which are the most expensive in their class.

Rubber cuffs are easy to manufacture and have a relatively low price. You have to pay for this with poor wear resistance and the need for frequent replacement.In contrast, expensive polyurethane products are very elastic, retain their shape well and have a long service life.

How to fix a leak between the tank and the toilet

If there is a leak between the tank and the toilet, then the reason is the depressurization of the device. Most likely, the problem is the deformation of the seal, a special rubber gasket. To fix the problem, you will need to replace the gasket.

Gasket replacement steps:

- First, shut off the water supply;

- The liquid from the tank will need to be drained, possible residues are also removed;

- Under the descent hatch there is a drain nut, it should be loosened;

- Then you should remove the tank by unscrewing the corresponding nuts at the place of fastening;

- You will also need to unscrew the drain;

- Next, you need to replace the gasket;

- Then reinstall all parts in place.

But the old rusty bolt that holds the container to the bowl can also be the cause of the problem. Next, you need to replace the damaged part. Also, the water is first shut off and the water is drained. Bolts will need to be removed and replaced with new ones. Sealing washers are required.

Sometimes you can only tighten loose bolts. To do this, just fix the element with a key and turn it with a screwdriver. But you need to be careful not to ruin the ceramic bowl. That is why it is better to replace parts, and not constantly twist.

Causes of leaks

To begin with, it is worth considering the signs of a leak that should alert owners. These include the following points:

Constantly flowing water in the toilet.

- Significantly increased monthly water consumption.

- When draining, the water flows in an insufficiently intense flow, since it constantly drains and does not have time to accumulate in the tank.

- There is a constant, never-ending sound of pouring water.

- The appearance of rusty streaks or salt deposits in the toilet bowl at the point where the water is drained.

- The surface of the toilet in the cistern area is constantly damp, even if the toilet has not been used for a long time.

- There are constant traces of condensate on the outer surface of the tank and on the pipes.

If at least one of the above signs appears, an audit of the tank and the connection points of the water supply and drain pipes should be made. These steps will help determine the area and cause of the leak. To make it easier to understand this issue, the following will be a list of possible causes that can lead to a leak.

The most common phenomenon is the constant leakage of water into the toilet. In this case, water, of course, will not flood the room, but its consumption will increase significantly. There are several reasons that can lead to this phenomenon.

Most often, a leak occurs due to a loss of tightness in the exhaust valve.

- The rubber gasket on the outlet valve that seals the drain hole has lost elasticity due to long-term use. The pear, cork or membrane does not fit snugly, even under the pressure of water, and there is a constant, sometimes not even visually noticeable leak.

- The rubber gasket, due to shearing or improper installation, does not fit snugly against the drain hole, so water constantly flows into the toilet.

- The pear or cork itself has lost its elasticity or has received mechanical damage, broken through or deformed.

- At the edges of the drain hole, to which the plug should fit, irregularities appeared due to silt contamination, a small solid fragment that got in, or from a salt build-up.

- Damage to the water release mechanism preventing the valve from returning freely into place - this can be a real cause of leakage, as parts are almost always made of plastic.

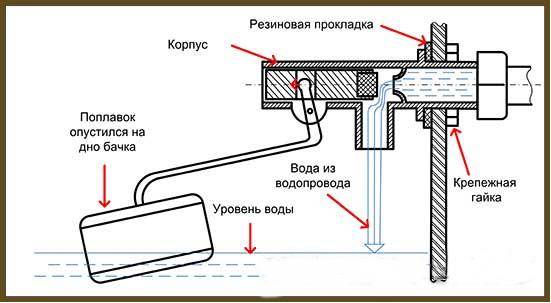

Another common problem is that the tank is constantly overflowing, water constantly flows out through the hole (tube) of the safety overflow. It is clear that such a phenomenon is caused by a malfunction or misadjustment of the float valve.

The rod (lever) connecting the valve to the float has become unusable. A metal part during operation can rust, deform or be damaged by mechanical stress. There can also be problems with plastic levers - cracks, fractures, deformations,

Float valve in brass body

- Damage to the float valve body can also cause permanent water leakage. If the valve is made of brass, then the risk of such a problem is significantly reduced, since such products are distinguished by their strength. What can not be said about plastic.

- Wear of the valve assembly itself - even when fully pressed, the water flow is not completely blocked.

- Loss of tightness of the float - water gets inside it, while it naturally becomes heavier and incorrectly controls the level of water in the tank. And sometimes it does not change its extreme lower position at all, that is, it simply sinks.

These were all leaks, as they say, internal.Water runs uncontrollably into the toilet, but there is still no risk of flooding the room. Worse, if the water starts to ooze from the outside. The reason for this may be the following malfunctions.

Damage to the connection that pulls together the drain tank and the toilet bowl. Most often associated with deformation, loss of elasticity of the sealing parts installed between them.

Docking cistern and toilet bowl - leaks can be here.

- Damage to the hose supplying water to the tank, or depressurization of the assembly of its connection with the pipe of the float valve.

- For hanging-type tanks - depressurization of the connection points of the pipe connecting the tank and the toilet.

- The occurrence of a crack in the tank body.

Any of these causes of leakage requires a quick response. It is not necessary to call a plumber to fix it - most problems can be dealt with on your own.

Causes of a leak

To establish the causes of a leak and eliminate it, you must first clearly identify the place where it flows. Such leaks are internal and external. Let's consider in order.

leak inside

Such a leak is manifested in the constant outflow (of greater or lesser intensity) of water through the drain valve or overflow pipe of the tank directly into the toilet. This leak is safe, but leads to water overruns. You can visually establish such a leak of low intensity by a thin stream of water that constantly flows through the toilet.

Options for troubleshooting this problem:

- Change gaskets between check valve and seat.

- clean the place of its junction with the seat.

- raise the level of the overflow pipe.

- adjust the float and filling valve system.

- Replace fill valve and float.

Advice! In most of these cases, water flows through the overflow pipe, so you need to start the repair by adjusting the water level in the tank.

A properly adjusted system closes the inlet valve when the water level in the tank is below the top edge of the overflow tube. As a rule, this is enough to eliminate such a leak.

Wet outside

If you have water on the floor under the toilet, you should take a very responsible approach to finding out where it flows and for what reasons. With some faults of this type, there is a significant risk of a major flood. According to the law of meanness, this happens, as a rule, at night or in your absence, therefore it causes maximum harm.

Perhaps there is nothing with your tank at all. Just because of the temperature difference between the water entering the tank and the room, a rather powerful condensate can form, which flows to the floor and forms puddles.

This effect is observed in cold weather with intensive draining - the water is constantly updated and does not have time to warm up.

To eliminate this phenomenon, you can install a partial drain system - half the volume of the tank is poured at a time. The incoming cold water is mixed with warm water and much less condensation is formed.

Another reason is a strong internal leak. Solutions are described in the previous chapter.

Leak in flexible hose.

Probably the most dangerous defect that can lead to catastrophic consequences.

If during inspection you find that water is flowing from the water supply connection, then you need to tighten it or replace the gaskets in it.

Flexible hoses made of rubber with external reinforcement, as a rule, are of rather poor quality.Over time, in addition to cracks on the hose itself, the bushings into which this hose is compressed are also subject to corrosion, so there is a possibility, when the gasket is compressed, to break the fitting and arrange a fountain. And this is not the worst option, the fitting can burst even in your absence.

Advice! Do not take risks - change such hoses for special plastic, metal-plastic or stainless steel pipes.

Leak from under the tank.

Another type of external leak. It occurs when the seal between the cistern and the toilet is broken. The intensity of such a leak depends on the degree of damage and can be quite dangerous.

There are two main types of cistern-toilet connection - a hinged cistern connected by a pipe to the toilet drain hole and a cistern installed directly on its bowl. Consider the options for eliminating leaks on the second, modern type of installation.

Loose fastening threaded connections. When the tank is installed on steel threaded rods, they corrode over time, up to destruction. In this case, distortions and, accordingly, the appearance of cracks and leaks are possible.

If you find such a defect, you need to replace the fasteners, and, if necessary, the seal between the tank and the toilet.

Damage or physical deterioration of the rubber seal.

Rubber is a material that is not particularly resistant to temperature changes and fluctuations, therefore, over time, it loses plasticity, becomes covered with cracks and ruts. Such a gasket can no longer reliably perform its functions and must be replaced with a new one.

Crack, cracks on the body of the tank and or toilet bowl.

Quite rarely, but still there are cases when, during non-professional installation, as a rule, with excessive tightening of the fasteners, cracks appear on the faience. This situation is very unpleasant and its resolution is the replacement of a cracked device with a new one.

Advice! The drain system is a low pressure system, therefore it does not require increased strength of the connections.

If the cracks are small and do not significantly affect the strength of the structure, it is worth trying to seal them with silicone sealant. To do this, you need to thoroughly clean, degrease the treated area and apply a layer of sealant on it from the inside. A strip of plaster mesh of a small cell additionally reinforces such a seam.

Types of sealing products

Known types of sealing products differ both in their configuration and in size and material from which they are made. Each of these features has its own characteristics.

Seal form

In accordance with this feature, cuffs for toilet bowls are divided into the following groups:

- oval, resembling a regular ring;

- trapezoidal seals;

- cone products;

- gaskets of complex multi-circuit configuration.

O-rings for toilet bowls are the most common type of cuffs used to articulate the bowl and tank.

They are used in most classic old-style designs. In modern models, gaskets of a more complex shape, resembling a truncated cone, are usually installed.

Recently, trapezoidal seals have become increasingly common in foreign-made products, resembling a triangle with cut-off corners.

In addition to the shape of the cuffs, all of them are characterized by another important property that determines the performance characteristics of the product. It involves classification according to the type of material used in the manufacturing process.

Material

On this basis, all known samples of seals are divided into the following types:

- elastic cuffs, belonging to the category of the most popular and cheapest products;

- silicone blanks, characterized by increased elasticity and higher cost;

- polyurethane seals, which are the most expensive in their class.

Rubber cuffs are easy to manufacture and have a relatively low price. You have to pay for this with poor wear resistance and the need for frequent replacement. In contrast, expensive polyurethane products are very elastic, retain their shape well and have a long service life.

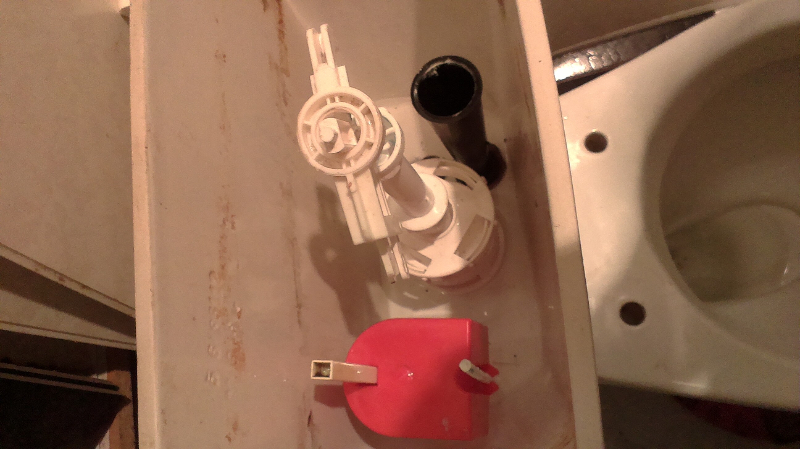

cistern structure

The components that make up the drain tank.

For several decades, the device of the drain tank has undergone a minimum of changes. Just like half a century ago, in parallel with the filling, the float rises, resulting in the blocking of the water flow.

The operation of modern drain systems is ensured by three components, which include:

- Float.

- Leverage.

- Pad.

The operation of the mechanism is carried out as follows: when entering the tank, water, upon reaching a certain level, is blocked by a shut-off valve. When you press the drain lever, the water will drain.

The main malfunctions that occur in the drain tank

The gasket of the toilet bowl is far from always to blame for the occurrence of a leak.Therefore, before starting work, you need to determine the nature of the leak. The table below will help you with this.

A leak in the toilet is not always the fault of the gaskets. In the photo - setting the level of the float.

| Type of malfunction | Cause | Remedy |

| Water flows into the tank continuously. | There may be several reasons for this phenomenon:

| The problem is solved by installing the float horizontally (if we are talking about skew) or by replacing it. If there is no possibility for replacement, then for a while you can tightly wrap the float with a plastic bag in order to protect it from water ingress. |

| The toilet won't stop flowing. | Most likely, you have a damaged drain valve membrane. | The problem is solved by replacing the membrane. To do this, it is necessary to disconnect the drain pipe from the product, after which the membrane is replaced. A new gasket for the toilet bowl is also needed here. |

| The tank is leaking. | This can also be caused by:

| In the first case, the leak is eliminated by replacing the pear. In the second, it is necessary to disconnect the pear by cleaning its saddle with sandpaper. Your goal in this case is to eliminate corrosion and deposits. |

| Leak between cistern and toilet. | This problem can also be caused by the fact that the gasket between the cistern and the toilet is cracked or was not installed correctly. Technicians refer to this phenomenon as a “chewed pad.” | First of all, you should check the rubber lining under the toilet.If it is installed incorrectly, give it the correct position and reconnect the structure. If the reason is that it is cracked, then it must be replaced. The price of gaskets is low, and therefore such a replacement will not hit your wallet. |

| Water flows out. | There can be several reasons for this problem:

| In the first case, it is only necessary to tighten the nut. This is a fairly common problem with the occurrence of such leaks. A cracked nut must be replaced. If you find a crack in the tank itself, then it must be replaced. |

| Water is leaking from the drain tank. | Perhaps the reason for this is the incorrect height of the button, in which the valve is above the drain hole. Because of the gap formed, a leak occurs. | The problem is fixed by adjusting the height of the button. |

| Leakage of water in the toilet when filling the tank. | Most often this occurs due to the fact that the shut-off valve simply does not shut off the water. | The first step is to establish a valve defect. To detect it, press the valve with your hand - the water flow should stop. If so, do-it-yourself gasket for the hanging toilet is changing. If this does not help, change the valve. |

Toilet replacement

Assembly of sanitary ware. The lining is set correctly.

If you have an old toilet, then sooner or later it will have to be replaced.

And the following instructions will help you to do everything right:

- First you need to determine the shape of the release, which can be horizontal, floor or inclined. You need to purchase the type of product that you had before.

- The simpler the design of the tank, the more durable the plumbing will be.

The simpler the armature, the less likely it is to fail.

- Do not forget to purchase an additional set of gaskets, in this case, if a leak is detected, you will not need to go to the store, and you can quickly fix the problem.

Various types of plumbing gaskets that should always be at hand.

- If you do not have experience in changing the toilet bowl, then it is better to trust a specialist.

Installation nuances

Pay attention to these details:

- which drain - oblique or straight;

- body symmetry;

- there should be no distortions on the seating surfaces of the body of the tank and the toilet bowl;

- when buying, check all accessories, seals, elastic bands;

- fixing bolts must be equipped with conical washers and rubber bands;

- during installation, it is advisable to treat the connection between the drain and the sewer pipe with liquid silicone;

- the place where the toilet bowl is attached to the floor is treated with white or transparent silicone.

The toilet body must be installed horizontally without distortion. The tightening of the tank mounting bolts occurs gradually by half a turn in turn.

The visor bowl is an intermediate option in the design of the toilet bowl between the dish-shaped and funnel-shaped. It features 100% protection against splashing water on the body. But men need to remember that the angle of incidence of the liquid on the bowl is equal to the angle of reflection.

Gasket for drain mechanism

The drain gasket is a wear part.

The time for a replacement comes when water begins to seep into the bowl in a continuous stream, and with it your money.

Silicone and polyurethane gaskets last longer than rubber ones.

Testing

Before putting the toilet into operation, check the tightness of all connections. Flush testing can be done at home. To do this, apply ink drops around the edges of the bowl around the perimeter and try to wash them off. If the ink is washed off the first time, then the result is excellent. Best of all, toilets with a circular flush cope with this task. To prevent water from getting on the body, it is better to buy models with an inclined visor bowl.

Fundamentals of total tightness

The complete tightness of the toilet bowl means the tightness of all connections:

- between the bowl and the tank;

- sewer pipe and housing;

- tightness of the lateral water supply;

- tightness of the trigger mechanism.

The lack of tightness entails not only problems with the neighbors on the floor below. But also financial losses. Worn stop valve gasket increases water consumption and charges.

Screed features

It would seem that it could be easier than the process of tightening parts, when all the manipulations with the gaskets are behind. However, the procedure for fastening toilet parts has certain features.

Screwing nuts onto the threads of bolted studs must be carried out evenly, acting alternately with bolted connections. The pressure force should be moderate, the tightening intensity correctly calculated. You should not overtighten the connections, it is enough to stop at the stage when the gasket is visually and to the touch tightened to the desired level.

Tightening is especially not recommended in places where polypropylene screws are used.Experts recommend replacing plastic fasteners with metal ones: this way you can achieve reliability guaranteed by the manufacturer.

How to install a gasket between the tank and the toilet

If you need to replace the toilet seal, you must first remove the cistern. To do this, follow the sequence of actions:

- Shut off the water supply.

- Remove cover.

- Drain the water.

- Wipe the tank dry.

- Unscrew the pipe supplying water.

- Unscrew the locknut that holds the siphon in the tank.

- Loosen the tank fixing screws.

- Remove tank.

On older models, the toilet and cistern were fastened with metal bolts. Metal, unlike modern polymers, is subject to corrosion. This leads to difficulties when trying to unscrew them. To facilitate the task, it is necessary to spray WD-40 on the surface of the bolts. Better than this composition, kerosene is cracking down on rust. After removing the tank from its place, the following actions are necessary:

- Remove the old cuff.

- We are preparing a place for the installation of a new gasket. The installation site should be free of dirt and dry.

- We put on a new gasket.

- To strengthen the tightness, we process the gasket with a sealant.

- We put the tank back and fix it. Tighten the screw slowly so as not to damage the toilet. First, we tighten the first screw a few turns, then the second one in the same way. If you immediately tighten the screw to the full force, then the gasket may be displaced or the drain tank may be damaged.

- We connect the internal fittings of the tank and fix it with a lock nut.

- We connect the water supply hose, but do not supply the water itself.

- After two hours, which are necessary for the sealant to harden, we turn on the water supply to the drain tank.

- Check if there are any leaks at the joints.

As you can see, there are no questions about replacing the old gasket with a new one between the drain tank and the toilet. The whole process of work can be carried out without the involvement of extraneous forces and using a minimum of tools. It is only necessary to periodically carry out preventive inspections to reduce the risk of leakage.

There are several options:

- You need to cut a small strip of fabric and moisten it with paint. The paint needs oil. The drain tank must be raised (an assistant will be needed here) and, while it is raised, wrap the fabric around the damaged area. To have a more effective result, the fabric is fixed with a rope or a collar, after which the tank can be lowered. Once the paint is dry, you can use the toilet.

- A rubber band can be applied to the damaged element. You can buy it at a pharmacy. The tape is stretched and applied to the damage. You can fix it with wire.