- Thermostat for heating element and connection of heating element with thermostat

- Video: Underfloor heating temperature sensor, user review

- Mechanical thermostats

- What is a thermostat

- What can thermostats control?

- Device and principle of operation

- What is heating wiring

- How the principle of temperature control works

- Adjustment Options

- Types of floor temperature controllers

- Mechanical Models

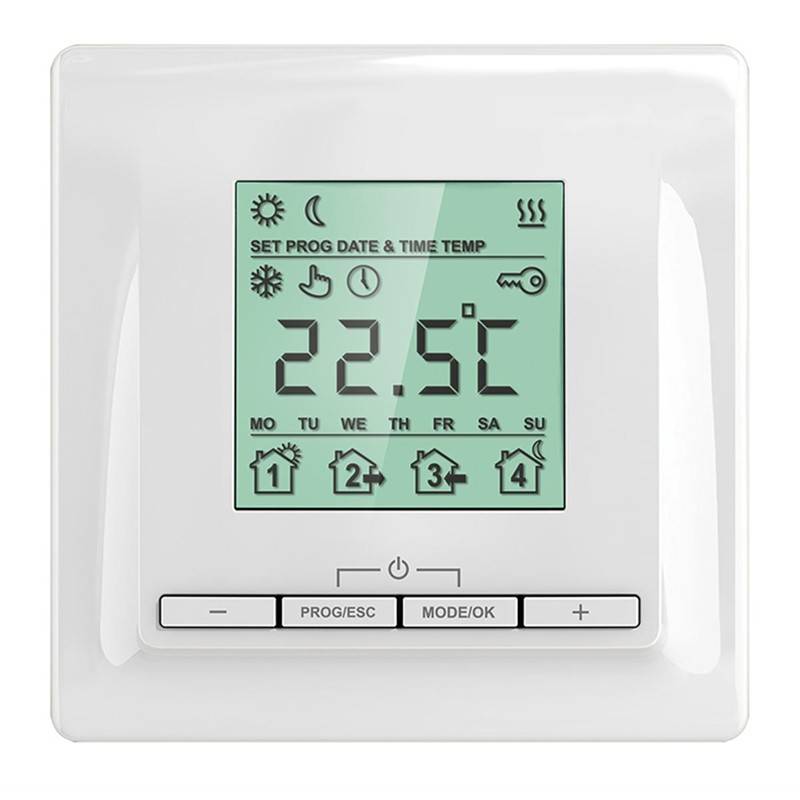

- Programmable Temperature Controllers

- Touch

- Radio thermostats and radio controllers

- Programmable thermostat for underfloor heating

- How to install a floor heating sensor

- Mounting procedure

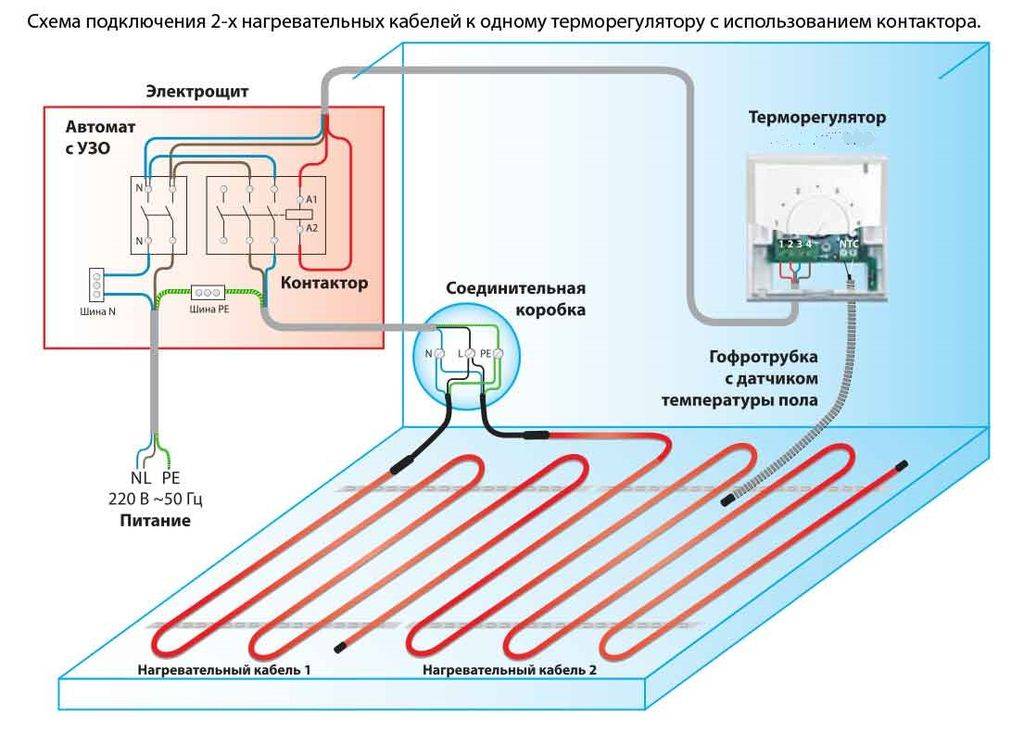

- Wiring diagram

- Selecting the location of the instrument

- Setting

- water floor

- Mechanical thermostats

- Electronic thermostats

- Programmable thermostats (programmers)

- Radio controlled regulators

- How to set up the thermostat?

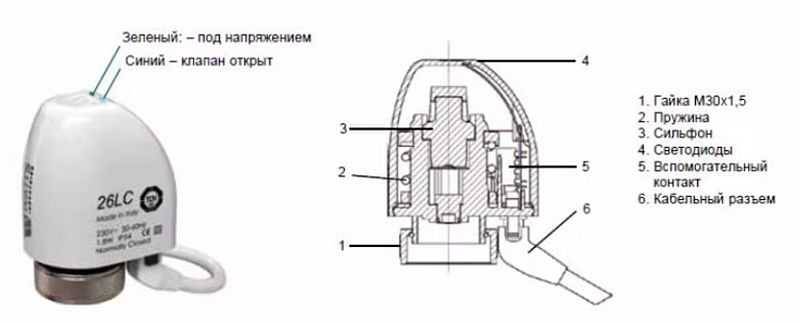

- Water floor servos

- How to connect servos

- Tips for installing thermostats

- Temperature error

- Summing up

Thermostat for heating element and connection of heating element with thermostat

At low temperatures outside the window, this is good. Control method It can be of two types: Mechanical, when the physical characteristics of the opening contacts change.

Plugging in.For electric boilers, such thermostats are a mandatory addition. Depending on the installation location - directly on the unit or in the actual area of the room, remote devices, the thermostat responds to changes in the temperature of the heater case or the air in the room and switches the heater on and off, maintaining the preset mode.

At the same time, it is imperative to control the area in which the heating equipment is located and not leave it unattended.

The design of controlled temperature controllers can be of two types: capillary - a special relay in the form of a narrow cylinder, in which there is a cylindrical capsule with a liquid having a high coefficient of thermal expansion - the capsule closes and opens contacts with a change in temperature using a drive of a special design; used in liquid-filled radiators; bimetallic plate - an element combined from two dissimilar metals with a significant difference in the coefficients of thermal expansion - the halves of the plate, when heated, elongate so much that they bend in the landing socket and open the electrical circuit, and after cooling, they again take their dimensions and close the contacts. In both cases, the control is carried out manually, by setting the required temperature on the controller case. Group 3: electronic This kind thermostats for hot water boilers belongs to the volatile category.

The lever mechanism of the thermostat, which is located in the box, when cooled, acts on the contact group - the thermostat opens. This option is the most expensive of all presented. Range adjustment is done by resistor R3.

The best option would be to buy the same device that has become unusable. With its implementation, many of the most important shortcomings of the previous methods are eliminated. Having assembled the adjustment-switching unit, you must first check the correctness of the installation, and only after that proceed with setting up the entire system.

Let us consider in more detail the temperature-regulating devices, standard and remote, installed on infrared heaters.

When choosing devices in this category, it is necessary to pay attention to the following points: Housing material. The maximum current that the new thermostat will have to handle

For example, the use of an outwardly similar temperature sensor K.5 instead of K.5 will result in freezing of the rear wall in the refrigerator chamber and a change in the temperature regime of the refrigerator. In addition to standard regulators, mandatory for installation and optimizing heater control, controllers are produced for additional equipment of heaters in order to increase their efficiency and functionality.

Three-wire switching is used when heaters or any other load are designed for operating voltage V. The load of this microcircuit is a PC fan. The control device, whose power is usually 3 kW, has 4 terminals - two for connecting to the circuit breaker on the electrical panel, and two for connecting to the heating unit. As the amount of steam increases, so does the pressure inside the tank. The outdoor thermostat has a thicker body, which is closed on all sides with plastic plates.

Connecting a Chinese thermostat

Video: Underfloor heating temperature sensor, user review

Secrets of the treatment of joint pain from our regular reader.

My name is Gennady Alekseevich. I am a baker with over 20 years of experience. I am engaged in both repair and construction of Russian stoves and fireplaces. I always perform the work very efficiently and carefully, which negatively affects the condition of the joints. As I got older, the pain got worse and worse, to the point where I could no longer work. Having tried a lot of both medicinal and folk methods of treatment, I realized how serious my disease was, since there was no positive effect. Until I came across one tool, which I want to tell you about.

It is a unique blend of the rarest and most powerful natural healing substances. This tool has proven its effectiveness not only to patients, but also to science, which has recognized it as an effective drug. Pain in the joints and back go away in 10-15 days, studies have shown. The main thing is to strictly follow the instructions in the methodology. Order the product in the original packaging. with a guarantee of quality can be on the official website.

Mechanical thermostats

The simplest and perfectly coping with its task of controlling the heating temperature is a mechanical thermostat for underfloor heating.

On their panel there is a rotary regulator, with a scale in a circle. The device is turned on and off with the key. There is no electronics included. They are not powered by electricity. However, some models are equipped with indicator lights, thanks to which you can find out the status of the heating system.

There are also models of mechanical regulators with timers. With their help, you can set the time period for the operation of underfloor heating.

The principle of operation of the temperature sensor is based on the special property of gases and bimetallic elements that change their shape and volume under the influence of temperature. Thus, the electrical circuit closes and opens at the right time. The temperature level of the heating elements is not controlled.

In order to better understand the device of a mechanical thermostat, many compare the principle of its operation with a conventional iron, where the set heating temperature is simply set and then maintained. You can change the temperature at any time. Usually, each owner of the house selects the most comfortable temperature level in the rooms.

What is a thermostat

The underfloor heating system involves the installation of heating elements under the floor covering, followed by connection to the mains. This is not done directly, but through a control device - a thermostat.

Naturally, this heating system is equipped with a temperature sensor. The installation of this device is carried out using a flexible plastic tube installed directly in the floor screed.

The latest models of thermostats are equipped with a programming system, which is good news. This is quite convenient because it allows the owner to determine when to set the heating system to economy mode, and when to use it at full power for maximum comfort, for example, after a long day when the whole family is back home.

We can distinguish the following types of thermostats:

- Devices with economy mode.It makes it possible to reduce the temperature in the room at a time when there are no residents in it, by a certain number of degrees, which will slightly reduce electricity consumption.

- Thermostats supplemented with a programmable timer. Temperature control is carried out by means of the set timer program. The timer sends commands to the temperature controller, thus adjusting the heating strength at a specific time.

- Intelligent programmable temperature controllers. On the screen of such a display, you can set the alternation of the specified modes. The device itself determines when and which program to execute, based on certain factors.

- Temperature controller with limit sensor. It makes it possible to set extremely low and high floor heating values at a specific air temperature. Thus, it is possible to guard against possible overheating, while maintaining the integrity of the existing floor covering.

What can thermostats control?

Thermostat for water floor heating

Depending on the type of heating, thermostats can regulate the following parameters:

- floor temperature. Sensors are installed in close proximity to the heating circuit and show the degree of heating of the finished floor covering. They are used in small circuits and low-power water systems used only as additional heating;

- air temperature in the room. For these thermostats, the sensors are mounted directly in the thermostat housing. The parameters are adjusted according to the comfortable room temperature. They are used on powerful systems and only in houses that meet the requirements of thermal insulation standards.Otherwise, large losses of coolants make its operation unprofitable;

- combined. The heating parameters are controlled according to the readings of two sensors: in the room and next to the heating system. They are rarely used only for the most modern systems. If desired, control can be performed based on the readings of one of the installed sensors.

Underfloor heating water - temperature distribution

The choice of a specific thermostat takes into account the maximum number of technical characteristics of the heating system, the heat saving indicators of the building, the climatic zone of the location and the wishes of the customer.

Device and principle of operation

The comfort of staying indoors largely depends on the heating system used. Control over the temperature of a water-heated floor is carried out using special devices - thermostats.

Many designs of such systems are used, but in most cases they use only a few fundamentally different methods of adjustment.

Watch video - setup process

But, before considering the principle of operation and the design of thermostats, you need to understand the object of regulation.

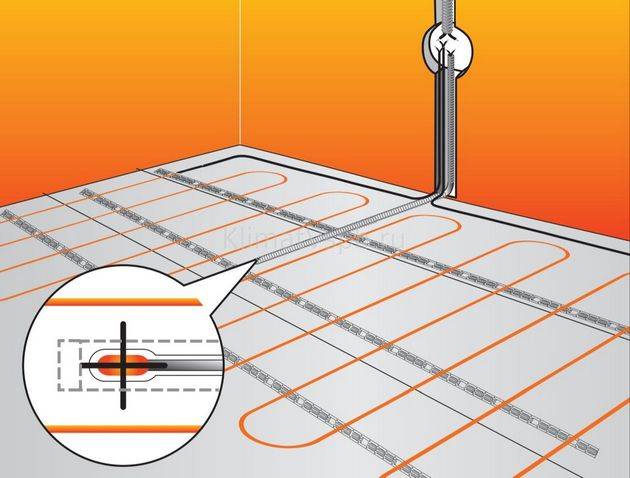

What is heating wiring

Heating a room with a water floor can be carried out in various ways. One of them is the use of the heat of heated water, which acts as a heat carrier. The transmission takes place through pipes. Previously, steel pipes were mainly used in heating, now they have been replaced by modern ones made of plastic materials.

The heating circuit can be located along the walls in the form of radiators, or it can be located under the floor surface, heating it and the air in the room.

The heating circuit can be located along the walls in the form of radiators, or it can be located under the floor surface, heating it and the air in the room.

Hot water or antifreeze is heated in the boiler, after which, using a circulation pump, it is fed into the heating circuit of the water floor.

Passing through its pipes, the coolant gives off heat to the closed surrounding space, heating the surface. The cooled liquid is returned to the boiler system. Depending on the temperature of the "return" in the mixing unit, it is heated or cooled by mixing in colder water from the tank.

In circuits with underfloor heating, which are connected by a separate circuit, a thermostat is installed for each of them, since they all have their own thermal regime. And the radiator heating circuits are heated to a temperature almost twice as high as for a warm floor.

How the principle of temperature control works

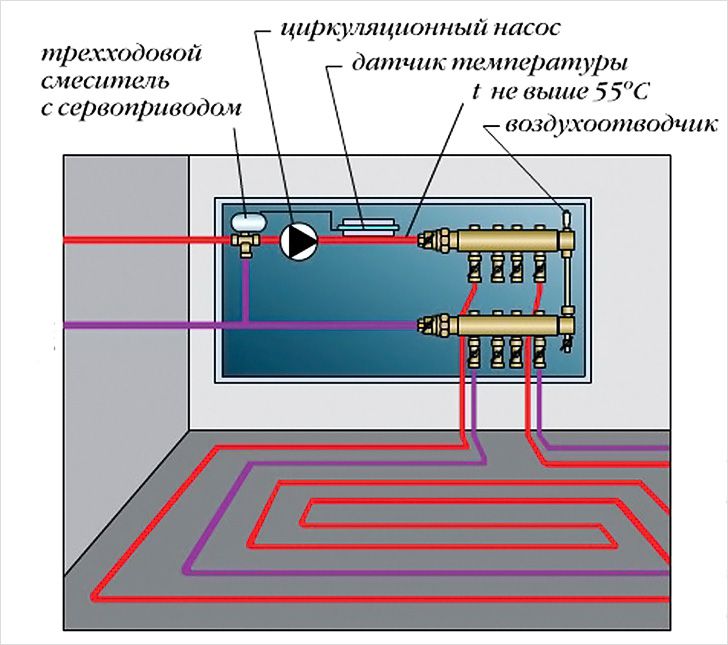

The main elements of heating control are servo drives, temperature sensors and thermostats. This composition of the equipment allows you to adjust the temperature of the water-heated floor steplessly in a continuous automatic mode. It happens like this:

The main elements of heating control are servo drives, temperature sensors and thermostats. This composition of the equipment allows you to adjust the temperature of the water-heated floor steplessly in a continuous automatic mode. It happens like this:

- If a signal about insufficient temperature comes from the temperature sensor, the servomotor opens the valve and more hot water enters the heating circuit.

- When the coolant overheats, the chilled water mixing valve opens, reducing the degree of heating in the circuit.

- However, manual adjustment is also possible by setting the valve to a certain position.But this method requires constant visual control, since the factors on which the heating mode depends change repeatedly during the day. With the relative cheapness of such devices, they are very inconvenient to use, since every change in the conditions in the room requires intervention in the operation of heating.

Adjustment Options

Watch video - adjusting the power of the temperature sensor unit

- The degree of heating of the floor covering. In this case, the heating sensor is installed in close proximity to it. Such a floor heating device is best suited for small rooms and low-power heating circuits, which are used only as auxiliary ones, in particular for underfloor heating.

- The air temperature in the room - with this control scheme, sensors are used that are mounted directly in the thermostat housing. The correct operation of such a device can only be achieved if all the requirements for the insulation of a heated building are met. Otherwise, it is difficult to achieve efficient heating operation - significant energy losses are inevitable. A properly built house with an extensive heating system and a thermostat can save up to 30% on resources.

- Combined control systems, in which water floor heating temperature sensors are installed both in the heated room and on the system of the mixing unit. The parameters are adjusted for reasons of the most comfortable temperature in the house. Such equipment with a thermostat is used in large rooms. Both sensors can be used simultaneously or one of them can be used for control.

Types of floor temperature controllers

Despite the fact that the main task of temperature controllers is the same, it is implemented in different ways. The main difference is in the way the parameters are set.

Mechanical Models

The most budgetary and most reliable class (breaks least of all). The desired temperature is set by turning the dial. It has a graduation that makes the process simple and straightforward. Sometimes the front panel of a mechanical thermostat for a water-heated floor has an on/off switch for the device. This device cannot provide any additional functions. Approximate prices are around 15 € (there are more and less expensive ones, depending on the manufacturer).

Programmable Temperature Controllers

This is already a serious device that allows not only to maintain a constant floor temperature, but also to automatically change it depending on the time. There are models with the ability to program the temperature by time of day. What does this function give? Savings. At a time when no one is at home (everyone went to study or work), you can lower the temperature, and program it to increase a few hours before arrival. So save on heating, and live in comfort. Only such programming allows you to pay 20-30% less for heating.

These floor temperature programmers can change the degree of heating depending on the time of day or on certain days of the week. There are modifications that, along with a stationary control unit on the wall, have a portable control panel. Some allow you to control the work through a computer or tablet.

Also, these devices can control not only floor heating, but also the air in the room.This makes sense if a water heated floor is the only source of heat, and it is not so much the comfort of the feet that is important, but the general atmosphere.

Electronic and programmable water floor thermostats are very similar in appearance, but electronic ones have more buttons, as they offer more options.

Outwardly, they are very similar to electronic thermostats, only they have more buttons. The price may differ significantly. The simplest programmer with the ability to set the floor temperature over time costs from 40 €, and the most “fancy” ones can cost more than a thousand.

Programmable models of thermostats for a warm water floor can control not one circuit, but several. Such models are called multi-zone. They maintain the set parameters in each zone independently of each other. More simple models (mechanical and electronic) are installed one for each circuit. If only one pipeline loop is laid in one room, there is no need for a multi-zone device (their price is much higher).

Touch

Almost the same set of functions as electronic programmers, but the buttons are not tactile, but touch-sensitive. Prices vary greatly.

Radio thermostats and radio controllers

This system is new. It is offered by some European companies, for example, Uponor has it on the Russian market. Comprises:

- special servomechanisms controlled by radio signals;

- radiothermostat - a portable device that monitors the status of sensors;

-

a radio controller that receives signals from the radio thermostat and transmits non-servos.

There is also an optional SMS module that allows you to control the system via the mobile network and also monitor its status.

Now let's take a closer look at the components of the water floor temperature control system.

Programmable thermostat for underfloor heating

When heating large areas, energy savings are of great importance, especially when using underfloor heating. This problem is easily solved with the help of a programmable temperature controller, which is used not only with cable, but also with film systems.

The operation of programmable thermostats is carried out according to the same schemes as in conventional electronic devices. The fundamental difference is the ability to configure operating modes in accordance with the calendar. In this case, all the necessary time intervals and temperature values are set for each day of the week, which leads to a reduction in electricity consumption by up to 70%.

For this, periods are assigned when underfloor heating should operate at full capacity or, conversely, be turned off for a certain time. All adjustment processes occur automatically, after all the necessary settings. For example, the days from Monday to Friday and Saturday and Sunday are separately configured. The cycle will be constantly repeated until the settings are changed.

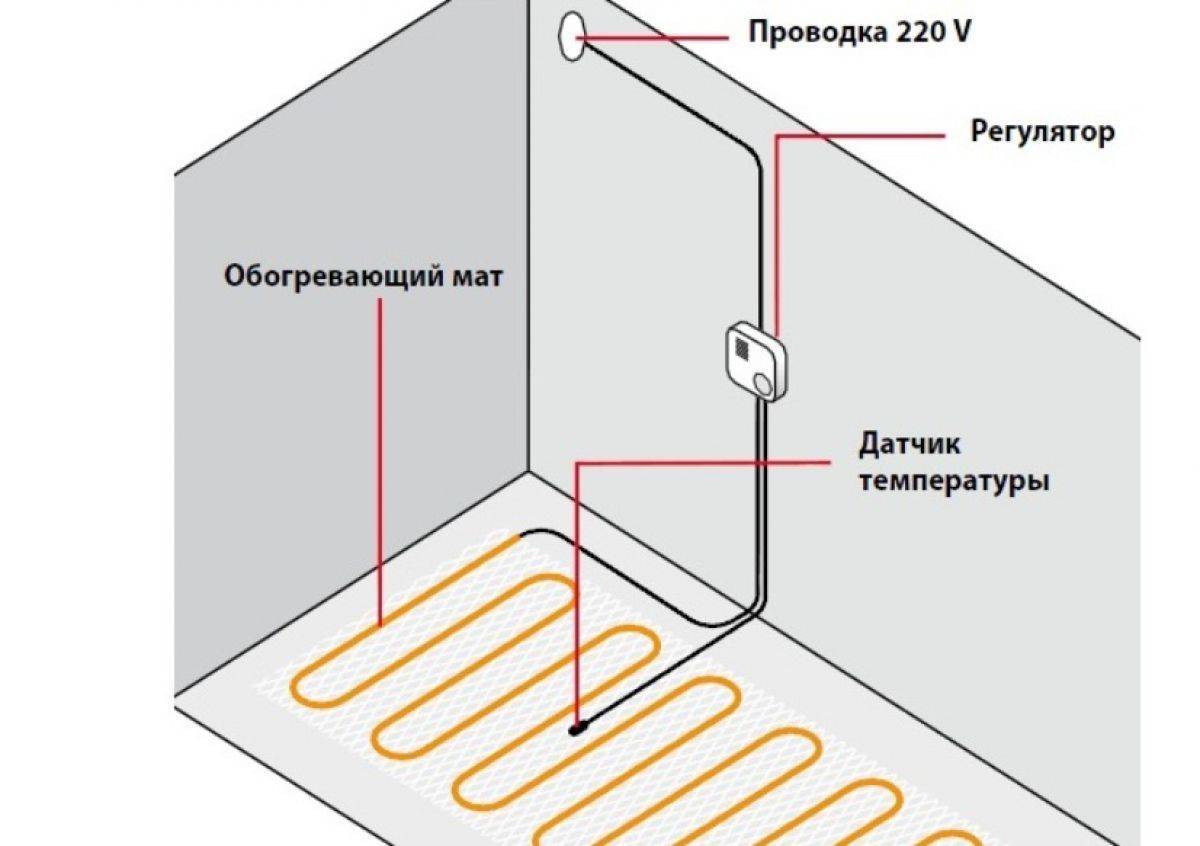

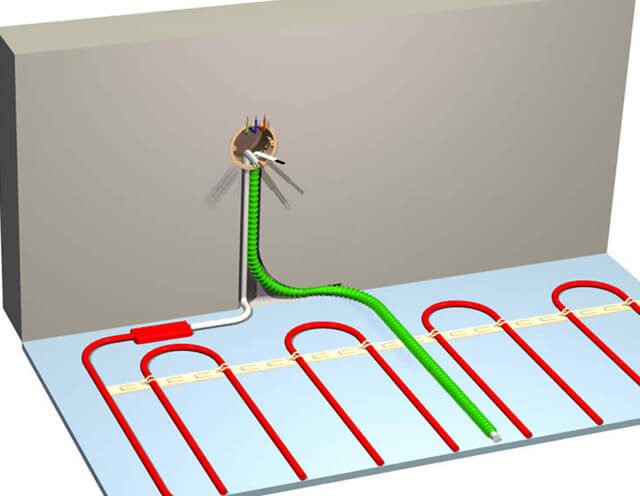

How to install a floor heating sensor

Consider the procedure for mounting the sensor, as well as related issues.

Mounting procedure

So, how to connect the sensor? For installation, you will need the following tools and materials:

- perforator;

- corrugation, the length of which is equal to the length of the temperature sensor conductor;

- clamps for mounting wires;

- putty.

Instead of a puncher, you can use a chisel or any other tool with which you can make a groove in the surface of the wall.

If you need to hide the wire leading to the temperature sensor in the wall, you will need a perforator for installation

If you need to hide the wire leading to the temperature sensor in the wall, you will need a perforator for installation

Installing a sensor for underfloor heating requires the following steps.

- Installation of a thermostat. At a height of about 1 m from the floor, a thermostat is installed to which the sensor will be connected.

- Laying paths. Grooves are laid in the wall and floor, along which the conductors connecting the temperature sensor and the regulator will pass.

- Wire placement. Wires are placed in pre-prepared tracks and fixed there with clamps. They must be protected by corrugation. Otherwise, damage to the insulation and the occurrence of a short circuit or contact failure may occur.

The grooves located on the wall are plastered. Those on the floor are covered with tiles, laminate, parquet.

Sensors must be installed prior to coating placement. After all, placing a temperature sensor for a warm floor under a tile or parquet, when they are already laid, will not work.

The corrugation must be sufficiently rigid and not deform under the weight of the floor covering. This will make it possible to replace the connected temperature sensor without dismantling the entire structure.

The described installation procedure is suitable for any type of floor cladding.

Schematic representation of the location of the temperature sensor on the floor

Schematic representation of the location of the temperature sensor on the floor

You can do without creating grooves in the walls without violating their integrity. In this case, the wire is laid inside a special plastic casing. It can be purchased at any hardware store. Such a casing is placed above the wall and attached to its surface.

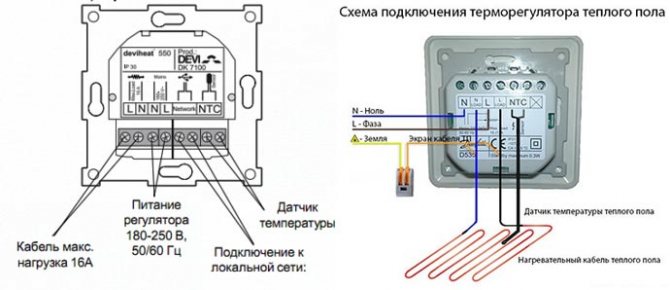

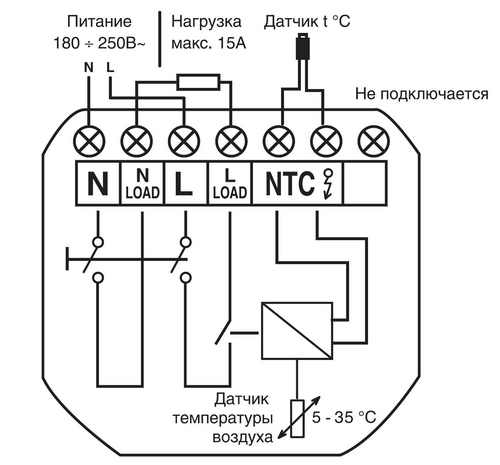

Wiring diagram

The connection scheme for the sensor for underfloor heating may differ depending on the design features of the thermostat. However, the differences are minor. Usually, advice on how to install the sensor can be found in the instructions for this device. Most often, the device is connected to two contacts, which are indicated on the regulator body with three Latin letters NTC. Polarity is not required.

The most common temperature sensor connection scheme

The most common temperature sensor connection scheme

Selecting the location of the instrument

The floor sensor is important to position correctly. The place is selected in such a way that it reflects the temperature of most of the heated surface.

This is usually the center of the heated floor. This is due to the fact that the temperature is somewhat lower at the edges. Therefore, if you mount the temperature sensor exactly there, it will work when most of the heated surface has not yet had time to cool down. This will cause an excessive rise in temperature and is fraught with failure of the heating elements.

Setting

Let's talk about how to properly configure the sensor. The setting is carried out using a thermostat. The thermostat itself cannot be adjusted. The setting comes down to setting the temperature values at which floor heating starts or stops. They directly depend on the resistance that the temperature sensor has at a particular temperature. It is this parameter that takes into account the equipment.

The temperature is set in such a way that people using the warm floor feel as comfortable as possible.

The sensor itself cannot be configured - the necessary parameters are set using the thermostat control unit

The sensor itself cannot be configured - the necessary parameters are set using the thermostat control unit

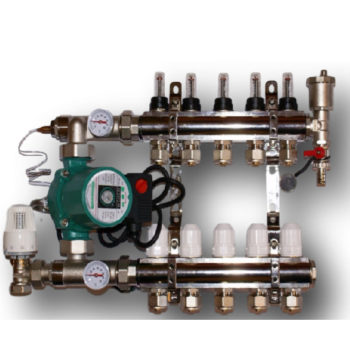

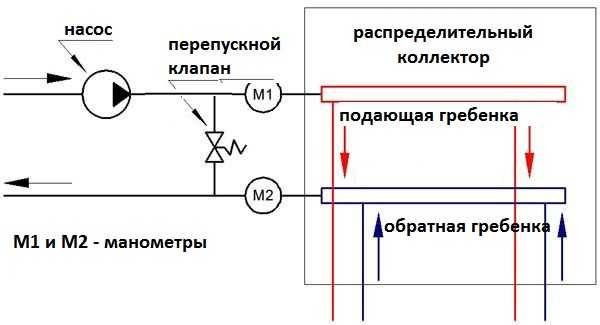

water floor

Heating is carried out by heating contours from pipes.The temperature change is made by changing the amount of coolant supplied to the circuits. Various ways of laying the contour are used. The most optimal is the "snail". The advantages of such a circuit are that it provides a uniform distribution of heat and minimizes its losses.

Collector

Collector

Both ends of the circuit are connected to a manifold, which is a distribution unit. The collector consists of two combs:

- serving;

- reverse.

Through the first comb, heated water from the heating boiler is supplied to the circuits, through the second, the cooled water is collected in one stream and sent to the boiler. When connecting the circuit to the central heating, the water is respectively directed to the batteries.

The most primitive way is to change the temperature by means of control valves, which are installed at the inlet or outlet of each circuit. The method is cheap, but a lot of trouble with it - you often have to turn the valves to raise or lower the temperature for each individual circuit in the living room, bathroom, etc.

An improved option is to use flow meters that allow you to see the volume of water that circulates in the circuits. But in this case, you can only change the temperature in manual mode.

Servo

Servo

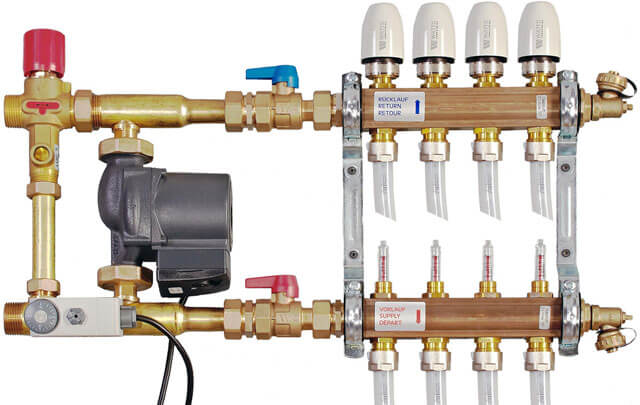

The automation of the regulation process with the help of thermostats and servo drives makes life much easier. The first carry out control and management, the second - carry out commands coming from thermostats.

Servo drives are placed on the feed comb. At the command of thermostats, these thermoelectric devices either increase or decrease the supply of heated water.

Each room has its own thermostat.Depending on the model, they can monitor both the temperature of the air and the floor. There are models that control both parameters. The principle of operation is simple: the desired temperature is set on the body of the device. When deviating from it by one degree, the temperature sensor gives a signal to the regulator, which in turn to the servo.

If the sensor measures the temperature of the room air, it is located in the thermostat housing, if it is on the floor or, more precisely, the finishing floor covering, it is mounted separately between the pipes with heat carriers at an equal distance from them and at least half a meter from the wall, and the connection to the thermostat is provided through a cable.

Thermostats are installed on the wall (height 1-1.5 meters). Near it should not be sources of cold and heat. The controller must not be exposed to direct sunlight. It must not be exposed to drafts.

If the thermostat controls both temperature indicators, it has two meters (one temperature sensor in the housing, the second is remote, connected via cable).

By design and thermostats are of the following types:

- mechanical;

- simple electronic;

- programmable;

- radio-controlled (wireless).

Mechanical thermostats

They have a simple design, are reliable and inexpensive. The desired temperature is set by turning the dial with a gradation scale. After the floor is heated to the required temperature, the thermostat is activated and the heating system is turned off.

Mechanical thermostat

Mechanical thermostat

Electronic thermostats

In terms of their functionality, they are not much different from mechanical ones, but the design is different. A small digital screen and several buttons are built into the case.The current or set parameters of the system are displayed on the screen. Buttons often have arrows "Down", up", which, when pressed, lower or increase the temperature. Instead of buttons, there may be sensors.

Slightly more expensive than mechanical regulators.

programmer

Programmable thermostats (programmers)

These are already more advanced devices with a wide range of functions. Button and touch types are available. The price of such thermostats can vary quite a lot depending on the number of functions performed. For example, there are chronothermostats. These are regulators with a built-in timer. They allow you to program the temperature according to the time of day. During the day, when people are at work, there is no need to keep the apartment in a comfortable temperature zone. A special program will keep the temperature cool, and by the time of the scheduled arrival home will raise it to a comfortable level.

Programmers allow you to control not one circuit, but two (two-zone) or several (multi-zone).

Radio controlled regulators

The latest technology. They work via radio signals. The functionality is almost the same as that of programmers. They are very expensive.

Thermostat connection diagram

Thermostat connection diagram

How to set up the thermostat?

Before buying a thermostat

It is necessary to decide which mode of its operation is preferable: manual or automatic? This is important for its further adjustment and tuning. Sometimes the choice is stopped at the usual mechanical

But the usual electronic should set the hours and days of the week, as well as make other settings specified in the instruction manual.By simultaneously pressing the "up" and "down" keys, the child lock function is set so that they cannot knock down the set operating mode of the device. In the same way, unlocking occurs.

Setting the thermostat depends on its functions and design capabilities. You can figure out electronic (both touch and push-button) on your own. But in order to install complex programmable thermostats, you need a specialist who understands such tuning systems.

Water floor servos

Automatic temperature control of a warm water floor is impossible without the presence of servo drives. These are small electro-thermal devices that open / close the coolant supply. They are also called servomotors, and the official name is “electrothermal servo drive”. In principle, the same devices can be put on radiators, but this is done infrequently.

This is how the servos look "live" on the manifold

How do servos work? The main working element is the bellows. It is a small airtight and elastic cylinder, which is filled with a substance, the volume of which strongly depends on temperature. Around the bellows is an electrical heating element. When a command is received from the thermostat, power appears on the heating element. It is included in the work, the substance inside the bellows is heated and begins to expand. The enlarged cylinder presses on the stem located below. And he, in turn, blocks the flow of coolant. As you can see, no motors and gears, only electricity and thermal energy. That is why they are called thermoelectric.

Servo drive - appearance and internal structure

A little about varieties.There are normally closed and normally open servos. These names show what position the valve is in when there is no power: the first one is normally open, and closes when a signal appears, the second, respectively, is normally closed, and opens when a signal is present.

Which one is better to use? For our country, it is better to give preference to normally open servomotors. And here's why: if it fails, the coolant will continue to circulate and the floor will not freeze (although long and low temperatures are needed for the pipes in the screed to freeze).

There are also devices that operate on AC 220 V, or on DC 24 V. To supply 24 V, you will need to install an inverter.

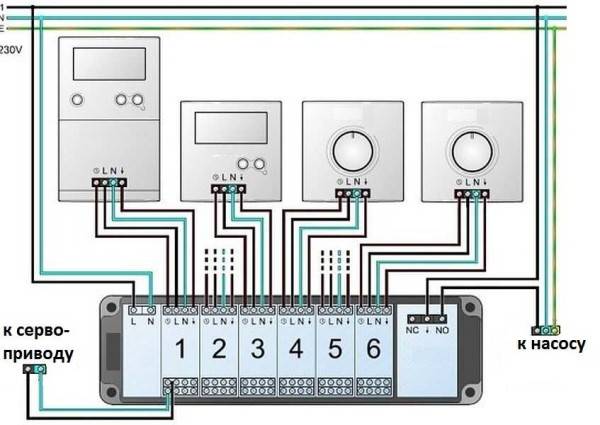

How to connect servos

The connection scheme may be different and depends primarily on the type of thermostat. If the thermostats control one underfloor heating circuit, then they are directly connected to the corresponding servomotors by wires. If the thermostat is multizone, then the wires start from the corresponding terminals.

One of the switching nodes of the water floor heating

Underfloor heating switches are used to organize the wires. In addition to the standard function of connecting and connecting different devices, they also perform a protective role. When all circuits of the water floor are closed, a signal is given to turn off the operation of the circulation pump. This is convenient if automated heating boilers are installed (the pump will not idle without flow, and the system will not fail due to overpressure).

How to connect devices through a water floor switch node

But in systems with conventional solid fuel boilers, pumps cannot be turned off: the boiler will not go out and turning off the pump threatens to break the system. In this case, install a bypass and a bypass valve (see connection diagram). The bypass valve is set to a pressure just below the maximum pressure of the pump (if it has a maximum of 5 meters, set it to 3-4 meters). When this value is reached in the system (it happens if a small number of underfloor heating circuits remain open), the bypass valve begins to turn part of the coolant flow into the “return” and feed it back to the boiler.

Switching circuit with a bypass valve to prevent the system from running "idle"

This scheme will work with any type of boilers, not only solid fuel ones. But for them, it is practically the only inexpensive way to protect the system from overheating.

Tips for installing thermostats

Before performing installation, you need to familiarize yourself with the instructions and the connection diagram so that the installation of the underfloor heating sensor is done correctly. It is shown on the back of the case. If the connection order is violated, the device will fail.

Therefore, at this stage, the correct connection is very important, on which depends how efficiently the entire self-regulating system will work. Of course, it is also important how competently the installation of the contours of the warm floor was done.

Thermostats should be located closer to electrical outlets, at a height of 0.5 to 1 meter from the floor. If the family has a small child, then the device must be mounted higher. This is especially true of programmable electronic models, which are easily disabled by inept handling.

The equipment works from a network of 220 V (except for radio-controlled ones).

The electrical connection of all appliances must be carried out in accordance with the rules for electrical installations.

Temperature error

Please note that the temperature directly on the remote sensor will always be higher than the temperature in the room, which the regulator shows on its display. This is due to the depth of the sensor in the screed

This is due to the depth of the sensor in the screed.

Usually this delta, between t on the floor surface and t inside the screed, does not exceed 5-7 degrees.

On the displays of electronic devices, you can see both parameters, but in mechanical devices with a wheel, often degrees are not even prescribed around the circumference, but only the numbers 1-2-3, etc. are indicated.

With five digits, one division corresponds to approximately 8 degrees.

Degrees are not indicated for a specific purpose, so as not to confuse the user. You set +25C on the thermostat housing, and the room thermometer in the apartment will show only +20C.

The majority will immediately have a question, why does the regulator work with such an error? Isn't he broken?

If degrees are indicated on your mechanical thermostat, this means that it mainly works and focuses on its own air temperature sensor built into the case.

The one that connects to it from the outside and hides in a screed only plays the role of protecting the cable from overheating.

Supply 220V to the L and N terminals through an RCD with a leakage current of not more than 30mA.

The scheme for connecting a warm floor directly through a thermostat from different manufacturers is the same and looks like this.

Summing up

The underfloor heating sensor is a device that, depending on the temperature of the floor, changes the degree of its heating. The main element of most of these devices is a thermistor that independently changes the resistance. This happens when the temperature rises or falls. The sensors are connected to the floor controller. The wires leading to the device are placed in a special groove made in the wall. They are placed in a solid corrugation. This makes it easier to replace a broken temperature sensor. Mounting on a wall surface is also possible. Before installation or in case of incorrect operation, the device is checked with a multimeter. If its resistance differs from the passport, the device is changed. In case of more serious malfunctions, the wizard is called.