- Installation and operation

- Video description

- Briefly about the main

- Why is it worth buying a water pressure sensor in the heating and water supply system?

- What are thermostatic radiator heads

- Tips before you start installing your thermostat

- The practical use of a remote regulator - is it possible to do without it

- The principle of operation of the thermal sensor

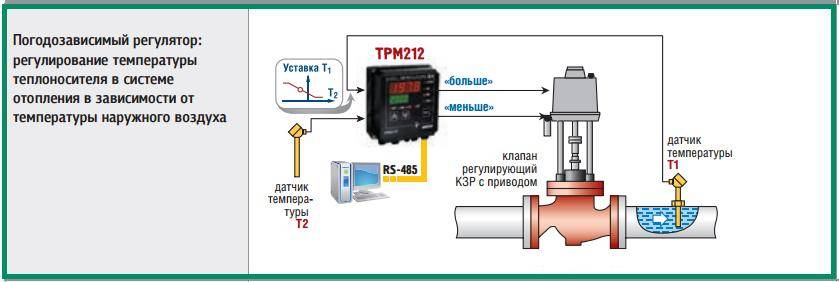

- Air temperature sensor for heating boiler

- The best choice

- Wired or wireless

- Temperature setting accuracy

- Possibility to set the hysteresis value

- Programming capability

- WiFi or GSM

- Safety

- Advantages of modern thermostats

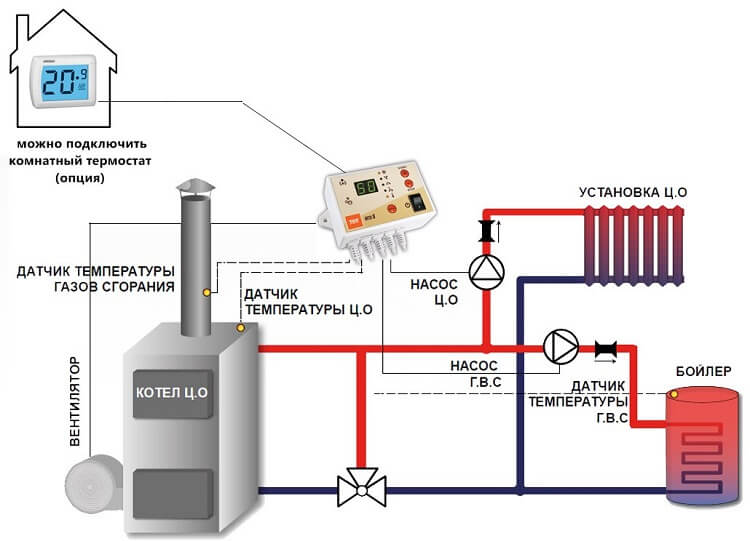

- Boiler temperature sensor connection

- Connecting an outdoor sensor

- Room sensor connection

- Connecting a sensor for a gas boiler

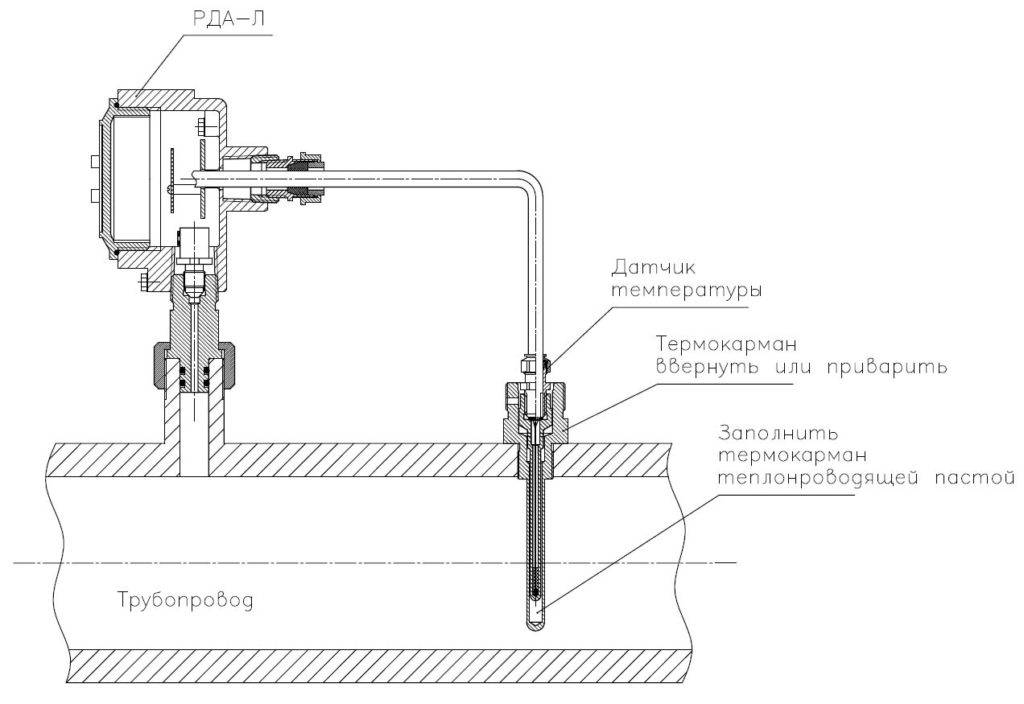

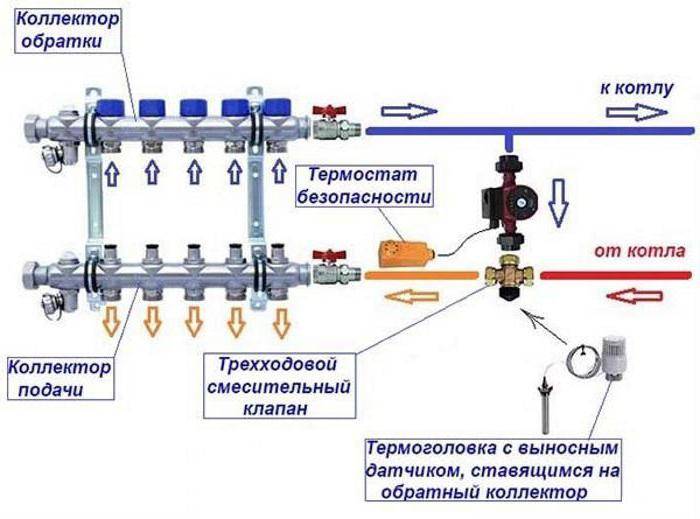

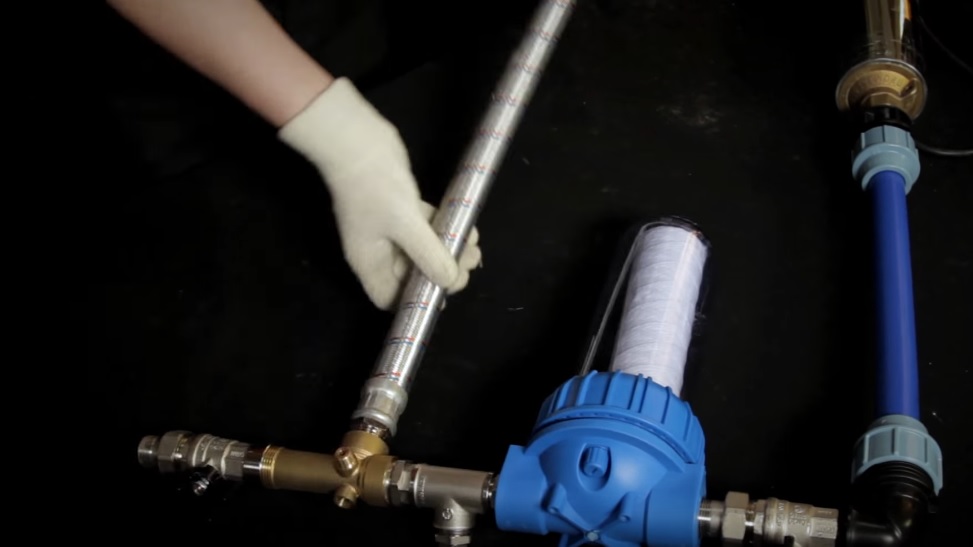

- Connecting a water temperature sensor

- Selection of temperature sensors

- Purpose of thermostats

- Criterias of choice

- Where is it profitable to buy a gas pressure sensor?

- What to look for when choosing?

- Setup and operation

- How the sensor works

- Conclusion

- Summarizing

Installation and operation

The installation process of the heat meter should be carried out only by specialized companies that have permission to do so. Self-installation is prohibited: the heat supply company will not accept the data, since the meter will not be handed over and sealed.

Video description

How profitable it is to install heat meters on the example of the inhabitants of Penza, they analyze in the following video:

The second condition is that a common house heat energy meter must be installed in the entrance.

Before installation, it is recommended to eliminate heat losses yourself, for example, to insulate corners or replace windows.

Installation takes place in several steps:

- A written application is submitted to the Criminal Code with a request to allow the installation of the device. A copy of the documents confirming the ownership of housing and a registration certificate are attached to it. The management company must provide technical conditions that specify all the requirements for the device and information about the heating network. If it is impossible to install a meter in the house, the management company will tell you about it right away.

- An installation project is under development. To do this, you need to contact a specialized design company. The project indicates the type and model of the meter, calculates the heat load, possible heat losses and water consumption, and also attaches a diagram of the heating system with a note where it is planned to install the meter.

Heat meter installation

- Next, the heat meter itself is bought for heating. It must meet all the parameters calculated in the project, have a quality certificate.

- An engineering company orders a design solution for the installation of a meter. Only a licensed company can do this.

- Direct installation can only be carried out by specialists with the appropriate license and experience.

- In the end, an employee of the management company must seal the device and sign the work acceptance certificate.

If desired, the owner can simply contact a company specializing in the installation of heat meters and transfer all matters to them.This will cost much more than self-collection of documents and contacting organizations, but it will save time and effort.

Checking the counter

Subsequently, heat meter for heating radiator checked every four years at the expense of residents. To do this, you must contact Rostest, the manufacturer's service center or a company that has permission to conduct an inspection.

Briefly about the main

Heating meters are devices that record exactly how much heat was spent on heating a house. Thanks to them, you can not overpay.

They differ in size, purpose (for an apartment, house, entrance, office, etc.) and design features. Each model has pros and cons.

Not all rooms can be equipped with a heat meter. Before purchase and installation, you must obtain consent from the management company.

Design, installation and subsequent inspection may only be carried out by specialists with the appropriate licenses. Self-assembly is prohibited, data will not be accepted.

Why is it worth buying a water pressure sensor in the heating and water supply system?

NPP "Teplovodohran" offers to buy a liquid pressure sensor in water supply and heating systems, at a bargain price. Modern production with the introduction of innovative technical solutions allows our company for 20 years to produce high-quality and reliable devices that guarantee trouble-free operation during the declared service life.

All products of "Teplovodohran" are distinguished by the following features:

- lifetime warranty on manufactured sensors;

- own developments of the company, introduced into production;

- extended intervals for technical testing of sensors;

- complex solutions for the installation of accounting systems;

- operational terms of production and delivery.

What are thermostatic radiator heads

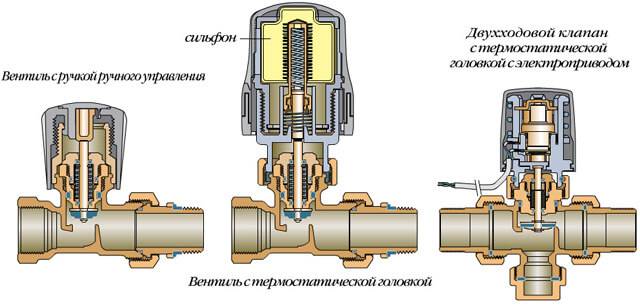

Thermostatic heads are of the following types:

- manual;

- mechanical;

- electronic.

They have the same purpose, but the custom properties are different:

- Manual devices work on the principle of conventional valves. When the regulator is turned in one direction or another, the coolant flow opens or closes. Such a system will not be expensive, it is reliable, but not very comfortable. To change the heat transfer, you must adjust the head yourself.

- Mechanical - more complex in the device, they can maintain the desired temperature in a given mode. The device is based on a bellows filled with gas or liquid. When heated, the temperature agent expands, the cylinder increases in volume and presses on the rod, blocking more and more the flow channel of the coolant. Thus, a smaller amount of coolant passes into the radiator. When the gas or liquid cools, the bellows decreases, the stem opens slightly, and a larger volume of coolant flow rushes into the radiator. A mechanical thermostat for a heating radiator is quite convenient to use and popular among consumers because of its ease of maintenance.

- Electronic thermostats are large. In addition to massive thermostatic elements, two batteries are included with them. The stem is controlled by a microprocessor. The models have quite a lot of functionality. You can set the temperature in the room for a certain time. For example, at night it will be cooler in the bedroom, warmer in the morning. During those hours when the family is at work, the temperature can be lowered and raised in the evening.Such models are large in size, they must be installed on high-quality heating devices in order to operate without problems for several years. Their cost is quite high.

Is there a difference between liquid and gas bellows? It is believed that gas responds better to temperature changes, but such devices are more complex and expensive. Liquid normally cope with their task, but a little "clumsy" in reaction. You can set the required temperature and maintain it with an accuracy of 1 degree. Therefore, a thermostat with a liquid bellows successfully solves the issues of adjusting the supply of coolant to the heater.

Tips before you start installing your thermostat

We suggest that you familiarize yourself with the following tips that should be remembered before starting the installation of the device.

Before installing the shut-off and control mechanism, you should read the manufacturer's recommendations.

The design of temperature controllers contains fragile parts that can fail even with a slight impact.

Therefore, care and attention should be exercised when working with the device.

It is important to foresee the following point - it is necessary to install the valve so that the thermostat takes a horizontal position, otherwise warm air coming from the battery may enter the element, which will negatively affect its operation.

Arrows are indicated on the body, which indicate in which direction the water should move. When installing, the direction of the water must also be taken into account.

If the thermostatic element is installed on a single-pipe system, then bypasses must be installed under the pipes in advance, otherwise, if one battery is disconnected, the entire heating system will fail.Semi-electronic thermostats are mounted on batteries that are not covered by curtains, decorative grilles, various interior items, otherwise the sensor may not work correctly

It is also desirable to place the thermostatic sensor at a distance of 2-8 cm from the valve

Semi-electronic thermostats are mounted on batteries that are not covered by curtains, decorative grilles, various interior items, otherwise the sensor may not work correctly. It is also desirable to place the thermostatic sensor at a distance of 2-8 cm from the valve.

The thermostat is usually installed on a horizontal section of the pipeline near the entry point of the coolant into the heater

Electronic thermostats should not be installed in the kitchen, in the hall, in or near the boiler room, since such devices are more sensitive than semi-electronic ones. It is advisable to install devices in corner rooms, rooms with a low temperature (usually these are rooms located on the north side).

When choosing an installation site, the following general rules should be followed:

- next to the thermostat there should be no devices that generate heat (for example, fan heaters), household appliances, etc.;

- it is unacceptable that the device is exposed to sunlight and that it is located in a place where there are drafts.

By remembering these simple rules, you can avoid a number of problems that arise when using the device.

The practical use of a remote regulator - is it possible to do without it

Many private homeowners and people living in apartments with individual heating are familiar with the situation when they have to adjust the intensity of the boiler to constantly changing weather conditions. It is easier to maintain a heat-generating gas appliance in an apartment, at least in terms of the compactness of living quarters. The owners of private houses, who part-time have to be operators of boiler equipment, sometimes have to run short distances if the boiler house is not in the main building.

All modern gas units are equipped with automation that regulates the intensity of the gas burner or the frequency of its on / off. The automatic control system clearly responds to changes in the temperature of the circulating fluid, maintaining the thermal regime in a certain corridor set by the owner. But the temperature sensor that sends signals to the electronic "brains" is installed in the boiler's heat exchanger, so it cannot respond to weather changes. As a result, we have the following situation:

- it has become sharply cold outside, and the household is beginning to freeze slightly;

- there is a sudden thaw outside the window, and the windows are wide open, because in rooms with temperature pluses there is a clear bust.

It is useful to ventilate the premises intensively, but along with kilojoules, savings fly away through the window, which will have to be paid on bills for the consumed energy carrier. Shaking with unusual coolness is also good for the body, but still a constant comfortable air temperature is more pleasant and natural for housing that claims to be called modern.

To maintain the temperature regime within comfortable limits, it is not necessary to hire a stoker or run to the boiler every hour.It is enough to install a thermostat for the boiler, which would read information about the actual temperature within the living space and transfer the data to the control system that regulates the operational activity of the heating equipment. Such a move will allow you to "kill a few birds with one stone":

- maintaining a constant comfortable temperature within the housing;

- significant energy savings (gas);

- reduced load on the boiler and circulation pump (they work optimally, without overloads), which prolongs their service life.

And these are not miracles, but the result of the work of a room temperature sensor - an inexpensive, but very useful device, which in European houses and apartments (and they know how to save on a "communal apartment") is a must-have addition to heating equipment. Even the most expensive remote thermostat with a liquid crystal touch display and many functionalities easily pays for itself during the heating season.

Gas boilers, as a rule, are equipped with the simplest system for regulating the heating of the coolant. The user sets the temperature parameters using a mechanical, less often an electronic controller.

Sensors that control the heating of the liquid in the heating system, giving a signal to the automation, turning off and on the gas supply. Such a device is ineffective, since it does not take into account the heating temperature of heated rooms.

Room thermostat for gas boiler, designed for precise adjustment. Installing the sensor reduces fuel costs by 15-20%.

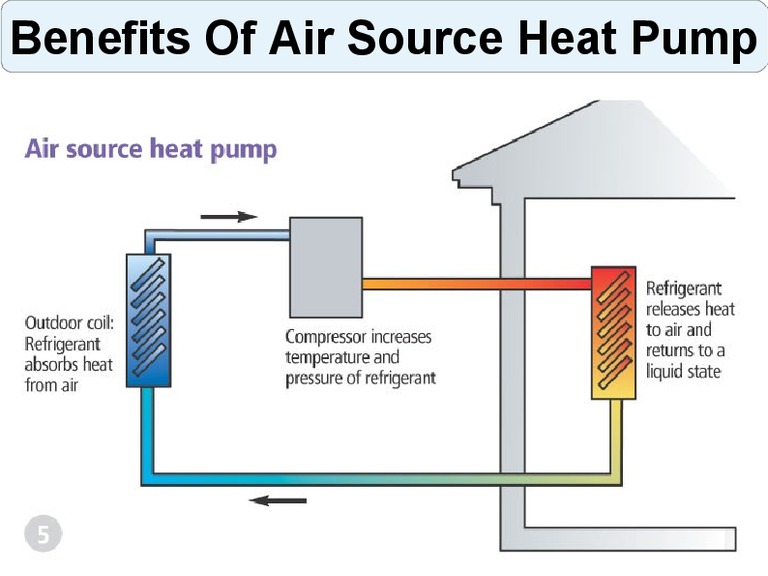

The principle of operation of the thermal sensor

You can control the heating system in a variety of ways, including:

- automatic devices for timely energy supply;

- safety blocks;

- mixing units.

For the correct operation of all these groups, temperature sensors are required that give signals about the functioning of the devices. Monitoring the readings of these devices allows you to identify malfunctions in the system in time and take corrective measures.

There are many types of instruments used to measure temperature. They can be immersed in heat transfer fluids, used indoors or located outdoors.

The temperature sensor can be used as a separate device, for example, to control the temperature of a room, or as an integral part of a complex device, for example, a heating boiler.

Such devices used in automated control are based on the principle of converting temperature indicators into an electrical signal. Thanks to this, the measurement results can be quickly transmitted over the network in the form of a digital code, which guarantees high speed, sensitivity and measurement accuracy.

At the same time, various devices for measuring the heating stage may have design features that affect a number of parameters (operation in a certain environment, transmission method, visualization method, and others).

Air temperature sensor for heating boiler

Such devices are relevant for owners of country houses who need full control over the operation of the entire heating system, directly affecting its "heart" - the boiler

It is very important to control the temperature in the source and circuits. It is for this purpose that the measuring sensor is used.

In this case, a thermostat with a water temperature sensor can be used, allowing you to track not only its change, but also the increase in volume due to heating.

The appearance of the thermostat for the boiler is unimportant, the main thing is that it works

The appearance of the thermostat for the boiler is unimportant, the main thing is that it works

The use of such a device allows not only to control the temperature regime of the boiler, but also to identify problems in a timely manner for their prompt elimination.

The best choice

Thermostat selection for heating boiler carried out based on the personal preferences of the owners of the premises. When choosing, you should consider what characteristics are required when using a particular boiler.

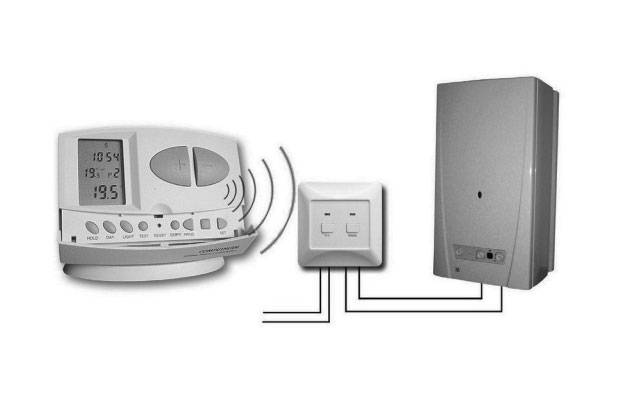

Wired or wireless

The communication of the control unit with sensors and the boiler for different models is carried out by wire or wireless. In the first case, a wire laying is required. The cable length reaches 20 m. This allows you to mount the control unit at a great distance from the room in which the boiler room is equipped.

Wireless thermostats for a heating boiler are designed as a receiver and transmitter. A distinctive feature of products of this type is the absence of the need for wiring. The transmitter signal can reach a distance of 20-30 m. This allows you to install the control panel in any room.

Temperature setting accuracy

Depending on the design of the room thermostat, the setting of the room temperature differs. Inexpensive models have mechanical control. The disadvantage of cheap thermostats is the error, reaching 4 degrees. In this case, the temperature adjustment step is one degree.

Products with electronic control have an error of 0.5 - 0.8 degrees and an adjustment step of 0.5o. This design allows you to accurately set the required power of boiler equipment and maintain the temperature in the room within a certain range.

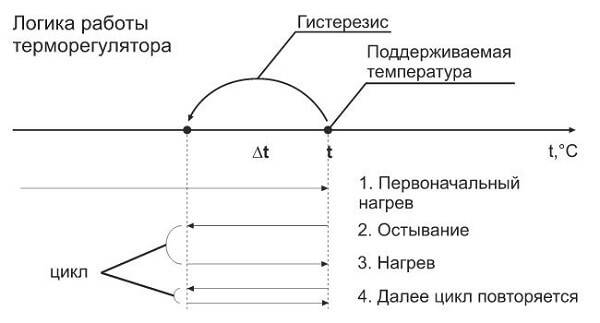

Possibility to set the hysteresis value

The room thermostat for a gas boiler has a difference between the on and off temperatures. It is necessary to maintain optimal heat in the room.

Hysteresis principle

Hysteresis principle

For mechanical products, the hysteresis value does not change and is one degree. This means that after switching off the boiler unit will start working after the air temperature in the room drops by one degree.

Electromechanical and electronic models have the ability to set a hysteresis. Adjustment allows you to change the value up to 0.1 degrees. Thanks to this design, it is possible to constantly maintain the temperature of the room in the desired range.

Programming capability

The function is only available for electronic or electromechanical thermostats. It is possible to program the control unit to set the temperature by the hour. Depending on the model, the thermostats are programmable for up to 7 days.

So it is possible to make the heating system with the gas boiler turned on autonomous. At a certain time, the thermostat connects, disconnects the boiler or changes the intensity of its work. With weekly programming, gas consumption can be reduced by up to 30 percent.

WiFi or GSM

Thermostats with built-in wi-fi and gsm module are connected to the Internet. To control the heating, gadgets with installed applications are used. This is how remote shutdown, connection of the boiler and adjustment of the temperature indicators in the heated room are carried out.

Using the gsm standard, the room thermostat transmits information about the occurrence of malfunctions in the heating system to the owner's phone.It is possible to remotely turn on or off the gas boiler.

Safety

When choosing a thermostat for gas boiler equipment, you should pay attention to the presence of security systems. Functions are available to prevent the stop of the circulation pump, protection against freezing or exceeding the maximum temperature in the heating system, etc.

The presence of such options allows you to safely use boiler equipment offline.

Advantages of modern thermostats

- They are fairly easy to install in new and existing heating systems because they are adapted to local temperature conditions. They can be operated without warning and maintenance during their entire service life, which is quite long;

- After equipping the radiators with thermostats, there is no need to open windows to control the temperature in the building;

- The temperature range in which temperature controllers operate is between 5 °C and 27 °C. The temperature can be set to any value within this range and will be maintained to within 1 °C;

- Temperature regulators provide uniform distribution of a cooling liquid in system of heating. In this case, even radiators located along the perimeter of the perimeter will effectively heat the room;

- The thermostat prevents excessive heating of the air in the room in case of direct sunlight into the room or an increase in temperature due to other factors (the presence of people or the presence of electrical devices);

- When using thermostats in autonomous systems, fuel savings can reach up to 25%, which positively affects both the cost of heating and the amount of hazardous waste after combustion.

Considering that the price of these devices is low, the advantages of using them are very significant:

- thermal energy is conserved;

- the microclimate in the room improves;

- simplified installation;

- no operating costs for thermostats.

In central heating conditions, temperature controllers provide comfortable regulation of the microclimate in the room.

General instructions for installing such equipment are as follows. In private homes, thermostats must first be installed on the upper floors. The reason is that the heated air rises, and the temperature difference between the rooms on the lower floors and upstairs changes quite a lot.

From an economic point of view, in a private house it is very effective to install low-power panel radiators with thermostats that quickly respond to the opening and closing of thermostatic valves.

Temperature controllers are certified, and high quality products must have a certificate of quality or conformity. There are two types of temperature controllers on the market: gas and liquid. The service life of such equipment is about 20 years.

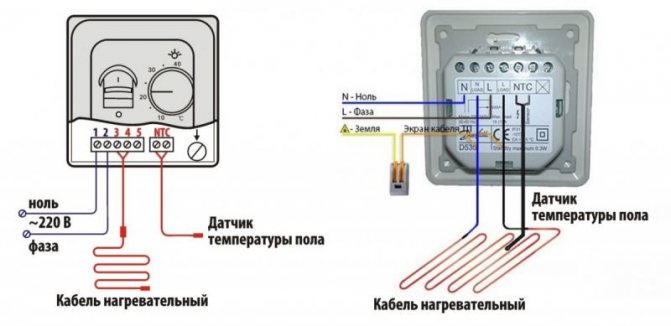

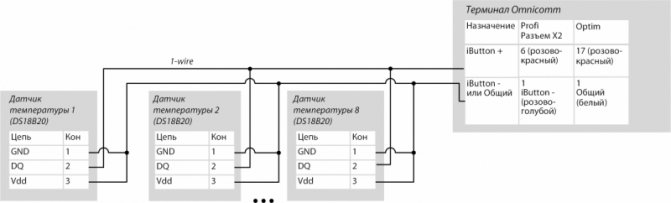

Boiler temperature sensor connection

All temperature sensors must be connected to a thermostat or a special control controller responsible for the operating modes of the boiler. At the same time, it is necessary to carefully study the connection instructions so that the connection requirements coincide with the technical characteristics of the sensors.

It is generally recommended to purchase sensors recommended by the boiler manufacturer.This is due to their high compatibility and guarantee of correct operation.

If there are none on sale, then you need to pay attention to certified analogues.

Connecting an outdoor sensor

The outdoor temperature sensor for the boiler is mounted on the outside of the wall of the house with the obligatory fulfillment of the following requirements:

- it is necessary to exclude direct sunlight on its surface;

- the wall contact surface must be non-metallic;

- cable laying in places with high humidity, in the presence of chemical or biological factors that can damage the insulation, is prohibited;

- the height of the sensor on the wall should be at the level of 2/3 of the height of the house, if the number of floors is up to three, or between the second and third floors, if the building is multi-storey;

- it is necessary to eliminate negative factors that reduce the sensitivity or measurement accuracy of the sensor.

Outdoor temperature sensor for boiler

Outdoor temperature sensor for boiler

The temperature sensor is connected when the power supply to the boiler is switched off. For connection, a solid cable with a core cross section of 0.5 mm2 and a length of up to 30 m is used. The connection points of the wires to the boiler and the sensor must be sealed and insulated.

When connecting, it is important to observe the polarity, depending on the type of temperature sensor. If the cable section runs along the street, then it should be protected with a special corrugated tube

After completing all installation work, it is necessary to check their quality, and then adjust the thermostat. If mistakes were made, then they should be corrected, otherwise there is a high probability of boiler breakdowns or insufficient heating of the premises.

Room sensor connection

The room temperature sensor for the boiler is mounted on the outer wall of the building from the inside of the room. The seating requirements are as follows:

lack of nearby sources of heat or cold;

constant access to the space of the room (lack of decor items, interior, which can obscure the sensor and affect the reliability of measurements);

the height from the floor should be 1.2-1.5 m;

when installing electrical sensors, it is important that there are no sources of electromagnetic radiation nearby: laid electrical wiring, installed powerful electrical appliances, etc. Room temperature sensor for the boiler

Room temperature sensor for boiler

Room temperature sensor for boiler

The connection method is similar to the method for an external temperature sensor, carried out in accordance with the requirements of the boiler manufacturer. It can be mounted in a specially prepared recess in the wall or on the surface, the main thing is that the sensitive element is not closed from the outside.

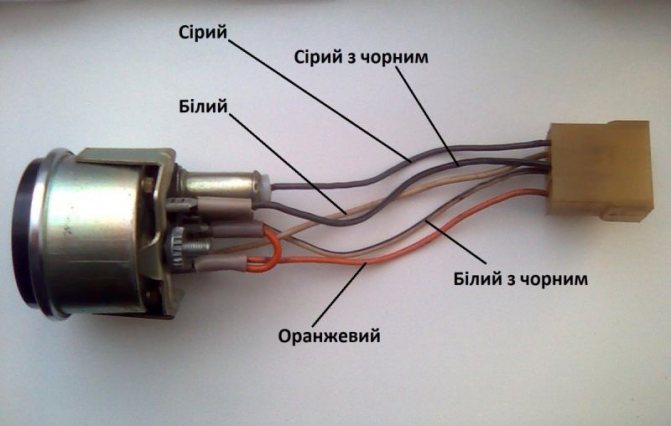

Connecting a sensor for a gas boiler

The wireless temperature sensor for a gas boiler is mounted directly on the controller or on the gas valve. Wired temperature sensors are connected in the manner provided by the manufacturer and described in the instructions.

Connecting a water temperature sensor

The water temperature sensor for the boiler in a multi-circuit system is installed on the surface of the heating return pipe or inside it, and installation on the circulation pump is also acceptable. This situation is due to the need to prevent the high temperature coolant from getting back into the boiler.

In a single-circuit or one-pipe system, the option of installing the sensor on a return pipe with a heat carrier is prohibited.In the event of an increase in heating, the circulation will be blocked and a significant temperature gradient will arise between the far and near rooms.

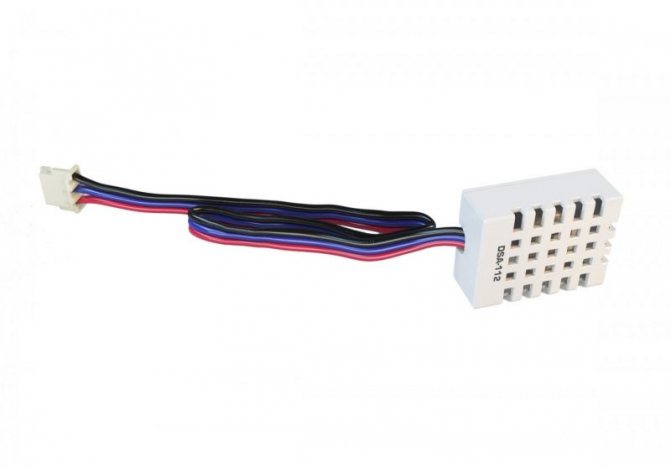

Selection of temperature sensors

When choosing such devices, factors such as:

- The temperature range in which measurements are taken.

- Necessity and possibility of immersion of the sensor in an object or environment.

- Measurement conditions: to take readings in an aggressive environment, it is better to prefer a non-contact version or a model placed in an anti-corrosion case.

- The lifetime of the instrument before calibration or replacement. Some types of devices (for example, thermistors) fail quite quickly.

- Technical data: resolution, voltage, signal feed rate, error.

- Output signal value.

In some cases, the material of the housing of the device is also important, and when used indoors, the dimensions and design.

Purpose of thermostats

.

The use of a thermostat is economically justified and provides significant cost savings due to the fact that the device automatically turns off the heating equipment when the set temperature limit is exceeded.

Then, in the case when the temperature drops below the permissible level, the temperature sensor is triggered, again turning on the heating.

If you adjust the temperature even within one degree, then the amount of energy consumption reduction can be 4-6%. Additional savings of up to 30% can be obtained by setting the device to a special mode, when at night or in the absence of residents, the temperature will drop by several degrees.

Thermal sensors find their application for such options:

- electric boilers;

- gas boilers;

- solid fuel;

- convectors;

- heaters.

Anyone who experiences difficulties associated with increased energy consumption for heating can purchase and connect a thermostat to their equipment if it was not included in the kit.

Criterias of choice

The choice of temperature sensor should be carried out taking into account the following criteria:

- range of measured temperatures, the sensor must be as sensitive as possible and respond to heating changes with a minimum delay;

- technical features of the installation: submersible or fixed, is there enough space for installation, etc.;

- measurement conditions under which it is possible to minimize negative influencing factors;

- characteristics of the sensor: the need to supply voltage, the speed of the transmitted signal, the measurement error, the admissibility of operation in specific conditions;

- service life, maintenance periods, the need for calibrations;

- output signal value.

Immersion temperature sensor for boiler

Immersion temperature sensor for boiler

Where is it profitable to buy a gas pressure sensor?

In addition to air and water pressure sensors, the range of products manufactured includes gas pressure sensors. They are used in control systems and automatic regulation of heating and ventilation systems, gas supply. The purchase of devices also fully justifies itself: the price of the Pulsar gas pressure sensor is quite acceptable, and its installation makes it possible to increase the economic efficiency of systems.

Sensors can be used as part of automatic systems for monitoring and accounting for energy resources.A large product range allows you to choose the best options for performing various tasks, while the price of an air pressure sensor in any case will be minimal. Measurement accuracy and low sensor error, reliability and long service life - all this allows you to use the unit as efficiently as possible.

You can purchase pressure sensors for gases, water and other resources and get comprehensive technical information on the entire range by sending a request by e-mail or by calling our specialists - both at the main office located in Ryazan, and at any of the branches.

What to look for when choosing?

In order to give preference to “exactly that” temperature sensor, when choosing it, experts recommend paying attention to the following nuances:

It is better to opt for proven and well-established brands.

It is good if both the boiler and the temperature sensor are made by the same manufacturer. This will avoid device incompatibilities and increase their productivity.

Before buying a device, you should definitely take into account its technical parameters (power, dimensions). Otherwise, there will be a chance of equipment downtime

It is necessary to determine in advance the type of temperature sensor. If the device is installed during a major overhaul, then in this case it is advisable to give preference to a wired device. If repairs are not provided, it is better to choose a model with radio communication. Verify that the temperature control range is within the user's requirements.

Important! Before buying a thermal sensor, you need to make sure that the power supply is able to withstand the appropriate voltage level. A temperature sensor for a heating boiler is a practical and useful device that will allow you to create a comfortable microclimate in the house and save the family budget

A temperature sensor for a heating boiler is a practical and useful device that will allow you to create a comfortable microclimate in the house and save the family budget.

Setup and operation

You can use temperature sensors, in principle, already with industrial settings. But they will almost certainly differ from the optimal parameters. Correction begins with the start of the heating system without a regulator and with the measurement of the resulting temperature. This measurement is made strictly in the place that needs to be serviced in the first place. For your information: when setting up, doors and windows are thoroughly closed, leaving even small gaps.

The head of the thermostat is set to a mode that provides a fully open gap. As soon as the temperature exceeds the desired value by 5 degrees, the regulator is switched to the closed position. Having found the temperature drop to the most acceptable level, the control device should be opened smoothly. Then, noticing the noise and the beginning of the heating of the radiator, you should stop further manipulations and record the current position of the regulator. Subsequently, in order to live in comfort, you will have to specify exactly this position of the regulator.

Of course, there will be no universal provision for it. Additional settings are performed when the season changes or when there is a sharp cold snap (thaw).If the device will be configured manually, it is advisable to immediately mount it where access is most convenient. However, for automated systems, the same rule applies in most cases. After all, access will still be needed for installation, initial configuration, maintenance, repair and subsequent dismantling.

Before setting up, it is recommended to turn off the hoods and air conditioning equipment. If the regulator is made on the basis of modern electronics, the setting is reduced to the choice of heat supply modes. In suburban housing and dachas, most often they choose intensive heating on weekends and the prevention of freezing of the system on weekdays. Of course, depending on individual needs, the situation may be quite different. The remaining nuances of the settings depend on the features of the equipment used.

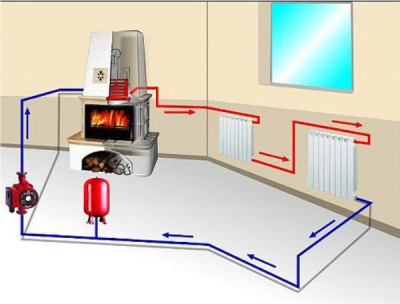

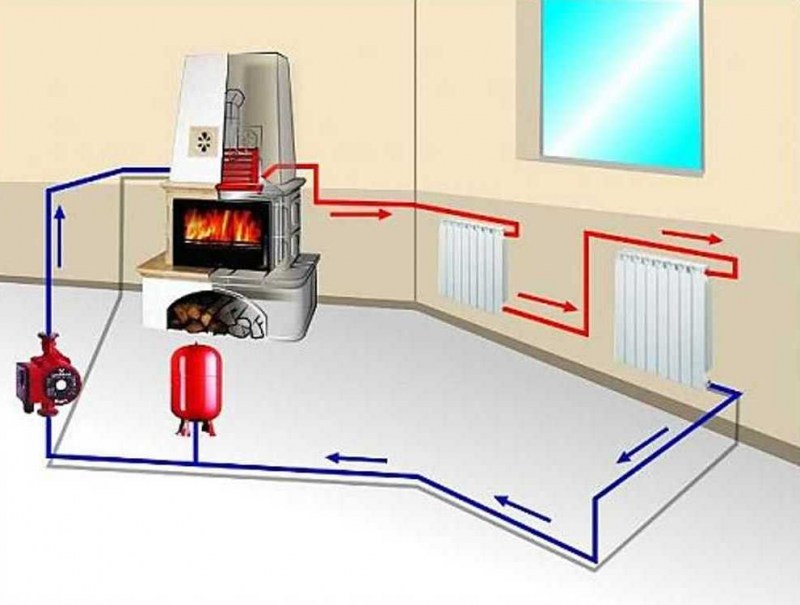

How the sensor works

To make it clearer why it is necessary to connect a temperature sensor to the boiler in the heating system, it is necessary to determine the structure of the system in more detail.

First of all, the heating system begins with a heating boiler. In it, the fuel burns and heats the coolant, which moves through the pipes to the radiators.

Passing through the radiator, the coolant gives off heat to it and returns to the boiler already cooled down through the system.

When turning on the heating, the user sets the desired upper heating limit and lower cooling limit.

Many people think that such a system is very convenient, but this is not always true. In the autumn and spring periods, switching on and off occurs too often, which leads to a breakdown of the heating device.

It is for such cases that external sensors are installed. They determine the temperature not in the coolant, but in the room.

Due to this, there will be no frequent switching and excess energy will not be wasted. Be sure to familiarize yourself with the temperature sensor connection diagram in advance.

Conclusion

It is clear that the heat in the house can be set manually, but you must admit that it is more convenient when the entire heating process occurs automatically without your participation. Not a small role here is played by temperature measurement sensors, working in tandem with autoregulators.

It is enough to correctly configure the equipment once and the specified thermal regime will be maintained throughout the house by itself. This achieves significant energy savings.

A boiler without thermostat control consumes more (25-30%) energy than a boiler equipped with automatic room temperature control. Additionally, the comfort of living in the house increases, the durability of the pipes increases, and the wear of the boiler itself decreases. In the end, all invested funds for automating the heating process will quickly pay off.

Summarizing

Based on the above, we can conclude that the use of programmable air control thermostats in the premises will create comfortable microclimate conditions and the operation of individual heating equipment, and, most importantly, will significantly reduce gas costs. Manufacturers of thermostats such as Danfoss (Denmark) and Siemens (Germany) have established themselves as high-quality and relatively inexpensive products. Of the more expensive models, Vaillant equipment will be a good choice, which, in turn, will allow you to connect to the heating system and independently regulate the temperature, save heating costs, reduce boiler operation time and wear

Of the more expensive models, Vaillant equipment will be a good choice, which, in turn, will allow you to connect to the heating system and independently regulate the temperature, save heating costs, reduce boiler operation time and wear

Manufacturers of thermostats such as Danfoss (Denmark) and Siemens (Germany) have established themselves as high-quality and relatively inexpensive products. Of the more expensive models, Vaillant equipment will be a good choice, which, in turn, will allow you to connect to the heating system and independently regulate the temperature, save heating costs, reduce boiler operation time and wear.