- Calculation of the power of devices

- TOP 3: HAJDU AQ PT 1000

- Work

- Device

- Insulation

- Advantages

- Peculiarities

- Technical specifications

- TOP 9: ETS 200

- Review

- Technical indicators

- Device

- Price

- Application

- Why is TEN needed?

- Choice

- Advantages of electric heating

- Installation steps

- Electrode Electric Boiler

- The device and principle of operation of the electrode boiler

- Pros and cons of using heating elements for home heating

- Solid fuel heating boilers with heating element

- Principle of operation

- TOP 10: Nibe BU - 500.8

- Application

- Peculiarities

- Technical indicators

- Buy

- The main type of heating

- Auxiliary heating of a private house

- Auxiliary apartment heating

- Characteristics of devices

- Disadvantages of heating elements of boilers

- The use of heating elements

- TOP 7: HAJDU AQ PT 1000 C

- Description

- Design

- Inner surface

- Buy

- Boiler heater example

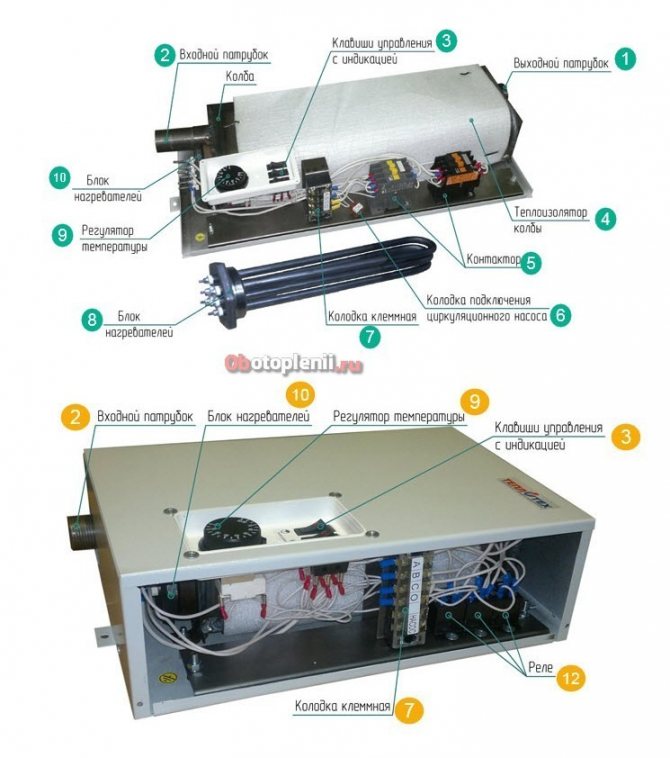

- Boiler EVP-18M, 380 Volt

Calculation of the power of devices

In order not to overpay for electricity and prevent emergency situations, it is necessary to calculate the required power before installing heating elements in the heating system. And to do it "by eye" will not work. Calculations are made on the basis that for heating 10 sq.m. premises require 1 kW of thermal energy. The formula for calculating the power of the heater is as follows:

Pm=0.0011*m(T2-T1)/t,

where Pm is the design power, m is the mass of the coolant, T1 is the initial temperature of the coolant before heating, T2 is the temperature of the coolant after heating, and t is the time required to heat the system to the optimum temperature T2.

Consider the calculation of power using the example of an aluminum radiator in 6 sections. The volume of the coolant of such a radiator is about 3 liters (exactly indicated in the model passport). Let's say we need to heat the radiator by connecting the heating element to the heating battery, in 10 minutes from 20 degrees to 80. We substitute the values \u200b\u200binto the formula:

Pm \u003d 0.0066 * 3 (80-20) / 10 \u003d 1.118, that is, the power of the heating element should be about 1-1.2 kW.

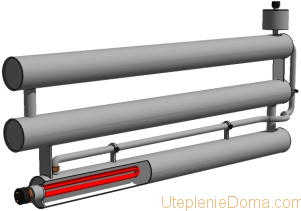

The heating element is installed in the lower section of the radiators

However, this is only valid if water is used as the heat carrier. If it is necessary to make calculations for oil or antifreeze, then a correction factor is used, which is about 1.5. Simply put, the power of heating elements for heating oil heaters should be increased by about one and a half times. Otherwise, the estimated time to reach the optimum temperature will increase.

TOP 3: HAJDU AQ PT 1000

Work

Models that take 3rd place in the TOP-10 can work from several sources (depending on the version):

- from the energy of the sun;

- gas boilers;

- coal, etc.

Device

It consists of:

- steel container (tank);

- polyurethane thermal insulation;

- protective cover;

- faux leather covers.

There is no corrosion protection inside, so the tank can only be used for its intended purpose. It is not suitable for storing drinking water.

Insulation

Like its counterparts, it is made of polyurethane foam, which keeps the water temperature for a long time without requiring it to be heated. Protection thickness 10 cm.For the casing, as mentioned, artificial leather is used.

Insulated cover, easy to remove. It is convenient when transporting, installing and dismantling the device.

Advantages

Chief among them is the possibility of temporarily equalizing discrepancies in heat production and consumption.

Important:

- Heat exchangers with storage tanks must not be subjected to high pressures. This is dangerous!

- It is mandatory to install a safety valve, purchased at an additional cost.

- It is forbidden to install any water stop valves between the valve and the accumulator.

Peculiarities

- Ergonomics.

- Good thermal insulation.

- Well placed pipes.

- Removable insulation and casing.

- Painted outer surface.

- Possibility of connecting a heating electric cartridge.

- Compatible with various types of boilers.

- Long service life.

- Convenient installation dimensions.

Technical specifications

- Volume - 750 l;

- Weight - 93 kg;

- Storage type water heater;

- Heating method - electric;

- Fastening - floor;

- Diameter with and without insulation - 99 and 79 cm;

- Height - 191 cm;

- Internal tank - made of steel;

- Anti-corrosion protection - not provided;

- Working pressure - 3 bar;

- Producer - Hajdu, Hungary;

- Voltage - 220 V.

TOP 9: ETS 200

Review

These heat accumulators for heating boilers have a steel body and heat-resistant insulation on top. Below it are blocks that accumulate heat. They are made of a composite material of high thermal conductivity, which are heated by heating elements.

For the fastest heating, the fan is built in a design.

Important: In order to mono regulate the room temperature, in other words, to control the discharge, you need a built-in regulator, which is not included in the package, so it must be purchased separately. There is a switch on the front panel, thanks to which it is possible to manually adjust the amount of charge

There is a switch on the front panel, thanks to which it is possible to manually adjust the amount of charge.

In order to be able to set the start and end time of charging (during the duration of energy benefits), it is mandatory to install an electrical annunciator (signal) or timer. It's not included in the kit either. Get it for an additional fee.

Technical indicators

- Power value, kW - 2.0;

- Dimensions, mm - 650x605x245 (HxWxD);

- Weight, kg - 118;

- Range of working temperatures, hail - +7-+30;

- Manufacturer - Germany;

- Mounting type - floor;

- Warranty period - 3 years.

The purpose of the model is to regulate the return of heat received from one or another source for efficient heating of the room.

Device

Inside there is a tubular heater, for the manufacture of which high-quality steel is used. It heats stones capable of accumulating heat, they give it away, cooling naturally, to the air passing through them under the action of a fan.

By installing a sensor in the room, it is possible to regulate heat with high accuracy, saving (due to the built-in battery) a significant part of the electrical energy.

Price

| Where could I buy | Price in rubles |

Application

In what cases does it become expedient to operate a heating system based on electric heating elements? These elements can be used to organize autonomous, local heaters, additional heating of the coolant or in the structure of a centralized heating system.

Such a solution looks especially relevant if it is necessary to create an “emergency” housing heating system. With extremely unstable heating operation, the heating elements maintain a comfortable level of heat and protect the radiators from freezing.

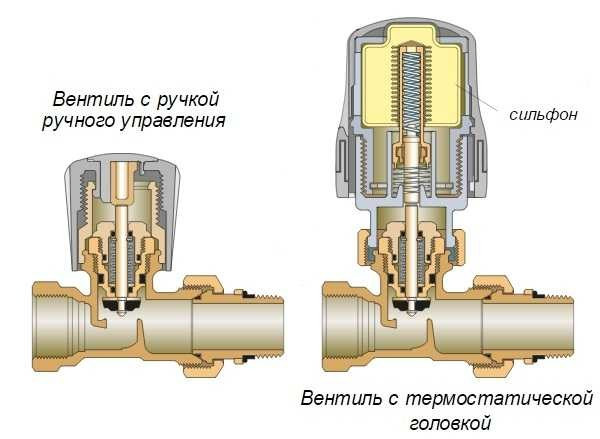

The use of functional thermostats along with heaters allows you to accurately adjust the temperature of the coolant. The presence of special temperature sensors protects the device from overheating.

In addition to the main ways to use shadows, there are a number of additional functions:

- Turbo mode - with appropriate control of the thermostat, the heating element produces maximum power for some time. This makes it possible to quickly and efficiently heat the room until the required temperature is reached.

- Anti-freeze function - maintains a minimum temperature, preventing the coolant from freezing in the heating radiator.

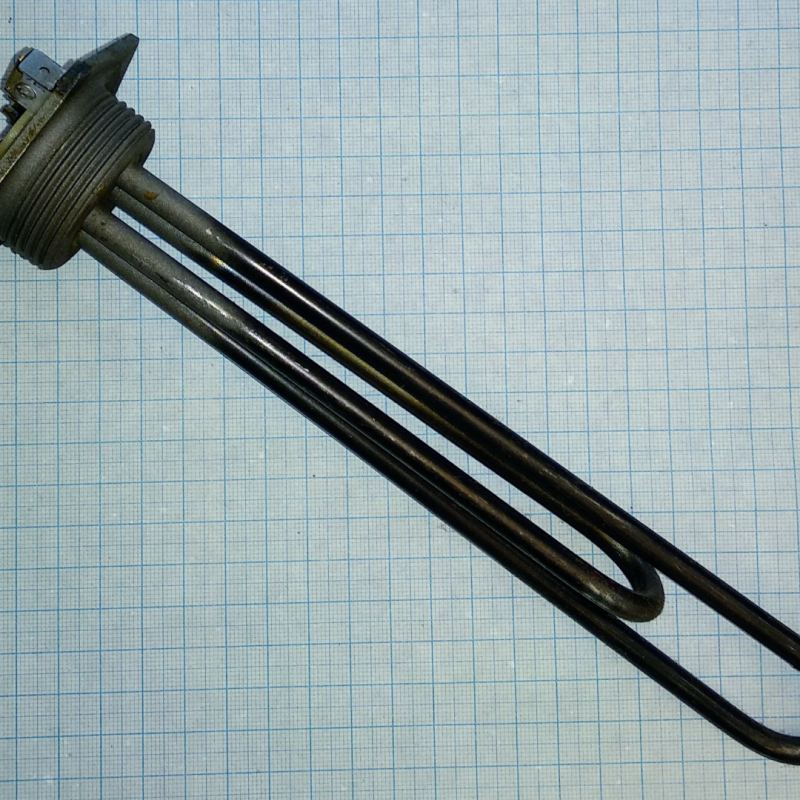

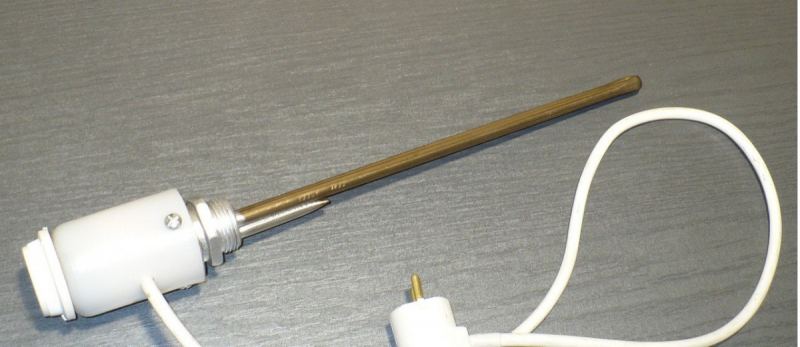

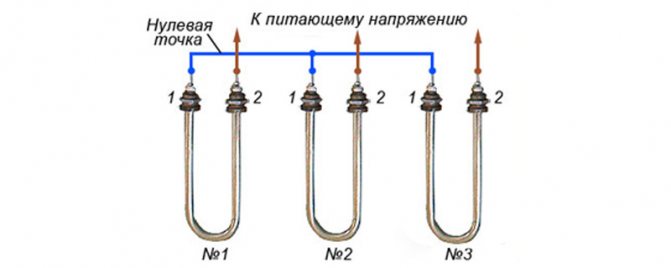

Why is TEN needed?

TEN for radiators ensures uninterrupted operation of the heating system, even if it is not possible to use the usual heating method. In fact, a heating element is a metal tube with a spiral sealed inside it. These elements are isolated from each other using a special filler. The heating element is connected to the pipeline system as an additional equipment. In addition, a heating element inserted into an old cast-iron battery will be able to heat a small garage, greenhouse or other outbuilding.And there are a lot of such examples, if you believe the statements of our skilled men on various thematic forums.

Installing heating elements for batteries allows you to take advantage of all the advantages of electric heating - ease of operation, reliability and high efficiency. But unlike electric heaters, these devices are installed directly into the system, so they are completely invisible and do not take up additional space. Thanks to the temperature control function, the heating element is able to maintain the set temperature.

Choice

When determining the required power, it is worth proceeding from considerations of the heat transfer of the radiator and the incomplete use of the power of the tubular electric heater. For example, battery sections made of cast iron "give" 140 watts, aluminum - 180 watts.

Thus, in the first case, a radiator of ten conventional sections will require a heater power within 1 kW, in the second - Heating element for aluminum radiator must have a power of 1.4 kW.

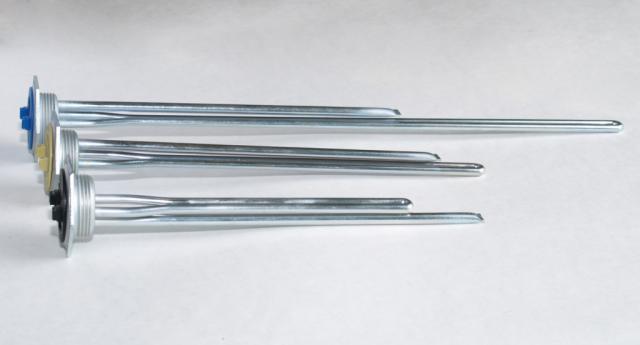

- The length of the tubular electric heater directly affects the quality of circulation inside the radiator

, therefore, in the optimal case, the length of the heating element should be only a few centimeters less than the battery. - Structurally, heating elements differ in the material from which the plug is made and the shape of the outer part of the body

. The standard plug has a diameter of 1 1/4″, and the thread type can be either right or left.

- The automation system that controls the tubular electric heater can be mounted inside the tube or located outside, the instructions in this embodiment for its installation are simple

. In the latter case, the heating element is connected through a thermostat that controls the temperature in the room. In the case of indoor installation, the sensor measures the temperature of the coolant, and the thermostat is installed in the outer part of the housing.

Advantages of electric heating

Heating equipment with a thermostat that operates from the mains is a good choice for heating suburban housing. Compared to centralized gas and solid fuel heating, electric heating has a lot of obvious advantages:

- Electricity prices are not rising as fast as other sources of energy, which contributes to some savings.

- Heating elements can be used not only in cast iron batteries, but also in aluminum radiators.

- Electric heating without problems provides a comfortable level of temperature in a country house of almost any area.

- Heating can be equipped with additional automation.

- Batteries with built-in heaters can be used not only as the main, but also as an additional source of heat.

- Installation of a heating element does not require registration of permits.

- The use of modern aluminum heating elements in electric heating systems allows you to maintain the aesthetic appeal of the interiors.

Installation steps

Regardless of the manufacturer, a heating element is installed in heating radiators according to a single principle. To install the heating element yourself, just follow the instructions:

- The device where the installation will be made must be de-energized.

- The supply of working fluid to the batteries is suspended, after which it is drained.

- Instead of the bottom plug, a heating element is installed, which must enter the water supply pipe.

- The fluid supply is restored, and then the radiator is checked for leaks.

- The heating element is connected to the mains.

Precautionary measures

Applying heating element for heating system radiatorscertain safety requirements must be followed.

When installing heating, it is important to check the reliability of the ventilation. Also, when performing work, it is necessary to move flammable and explosive substances to a protected, hard-to-reach place at a safe distance from the heater.

Before connecting a heating device with a heating element and a thermostat, it is worth once again checking how the electrical wiring copes with the load placed on it

Exceeding the permissible power is fraught with overheating of the wires, the occurrence of short circuits and fires.

- When connecting heaters with heating elements, the use of ordinary household carriers should be avoided. The best option is the operation of network filters. This solution allows you to automatically de-energize the device during power surges in the system.

- It is absolutely unacceptable to use batteries with an electric heating element to dry things.

- During the operation of the heating element, the working fluid is intensively heated. Its operation for a long time leads to the burning of oxygen. Therefore, a long stay in such a room hides a health hazard.

Electrode Electric Boiler

Electrode electric heating boilers, are highly efficient and economical.Heating of the coolant occurs almost instantly. Hot water begins to flow into the heating system a few minutes after the electric boiler is turned on.

The efficiency of electrode-type electric boilers is almost 50% higher than that of heating elements analogues. There are also disadvantages associated with the internal structure and principle of operation.

The device and principle of operation of the electrode boiler

The principle of operation of the electrode electric boiler is associated with the direct effect of electric current on the coolant. Heating electrodes are positively and negatively charged. An electromagnetic field is created, under the influence of which, the ions begin to move chaotically, with an intensity of at least 50 oscillations per second.

In the process of heating the coolant, electrolysis gas is formed, therefore, from time to time, it will be necessary to bleed air from the heating system.

The advantage of the electrode boiler is the high efficiency of heating the coolant, due to the absence of intermediaries in heat transfer. There are also limitations. Heat carriers, on which electrode electric boilers operate, have a high salt content. You can make a saline solution yourself, but, as practice shows, it is better to use ready-made mixtures.

The material of which the electrode in the boiler is made must be neutral to the formation of scale, have good throughput and a long service life. Manufacturers use three types of materials. Budget electric boilers, equipped with graphite and stainless steel electrodes. Boilers of premium class, equipped with titanium rods.

Pros and cons of using heating elements for home heating

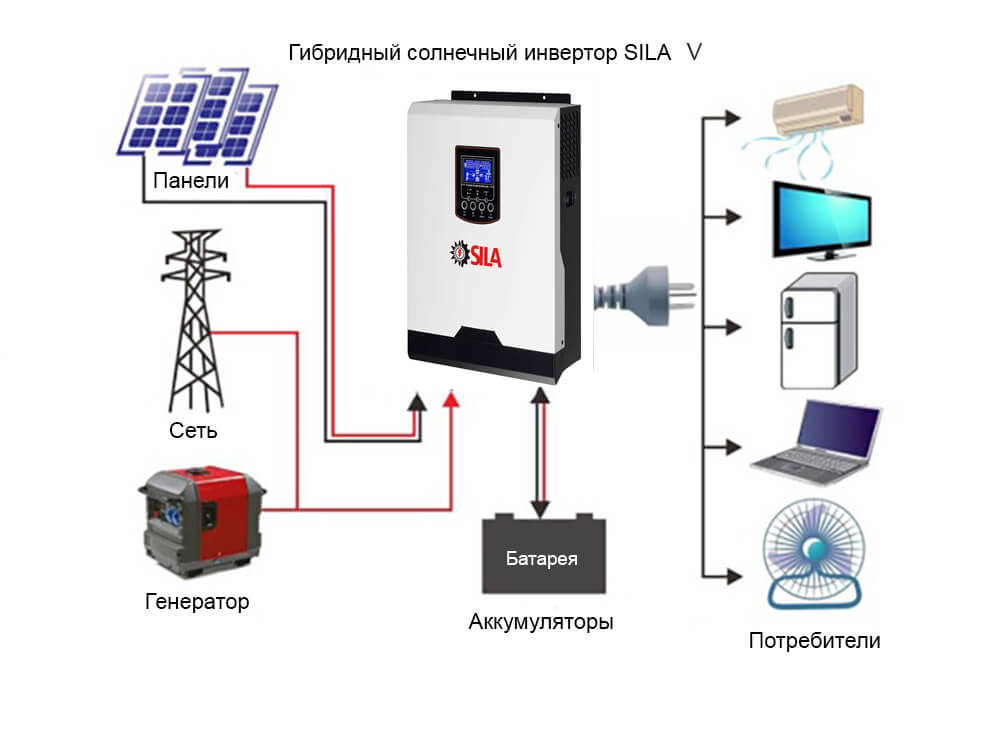

The main disadvantage of this heating method, as in the case of other electrical appliances, is the cost of operating costs. Electricity is still the most expensive source of heat (unless, of course, you have the opportunity to use free solar or wind energy, and you are connected to the main power grid). Another disadvantage is the impossibility of repair in case of failure of the spiral. However, there are some positive aspects that in some cases may become a priority.

- Environmental friendliness of the heating system. When using electric heaters, there is no need to store and store any kind of fuel, and there are no harmful combustion products that enter the environment;

- The possibility of autonomous installation of the heating system in the absence of access to other thermal resources (for example, gas);

- Small dimensions and a large selection of models in terms of power and functionality;

- Possibility of automating the heating process: installation of heating elements with a thermostat;

- Low purchase and installation costs. There are models, the cost of which does not exceed 1000 rubles. And the installation of heating elements in heating radiators can be done independently.

And finally some tips for self-installation tubular electric heaters. How to properly embed a heating element in a heating system? First of all, you need to choose the right model by measuring the diameters of the radiators where the heating element is supposed to be installed and making power calculations. Then carefully read the instructions for the device, which should indicate whether additional sealing is required or not.This is one of the most important points, since contact of the conductor with the heat transfer fluid will cause your radiators to be energized, and this is dangerous for residents. If the manufacturer indicates the need for additional sealing, then it must be done. In addition, the use of electrical heating devices without grounding is unacceptable.

Location of heating elements in a cast-iron radiator

The installation of heating elements in cast iron radiators has a number of features. They are associated with the diameter of the pipe and the direction of the thread. In general, the procedure for installing heating with heating elements in an existing system is as follows: disconnect the heating system from the heat source, drain the water, install the heating element, fill in the coolant, check the system's performance. When using heating elements with thermostats in the system of heating radiators, it is also necessary to check their performance after installation. It is also advisable to install water sensors and check the angles of the radiators. Since air congestion can significantly affect the operation of the entire system and disable the heating element.

Solid fuel heating boilers with heating element

The solid fuel boiler has the following advantages:

- the device is designed for cold winters, its efficiency is 65-75%;

- due to the presence of a grate system, wood waste and low-quality fuel with a humidity of even 70% are burned;

- reliable insulation is used, consisting of a water jacket with high-quality thermal insulation materials plus a protective casing that can withstand more than 1300 degrees.Despite the high power, the surface temperature of the device is absolutely not a threat to humans;

- there is a screen that protects from flames;

- loading stone has increased depth;

- the device is durable and small in size;

- the device has a modern design;

- there is a thermomanometer;

- ease of installation work;

- easy operation and maintenance.

Some models have additional elements:

- TEN for a heating boiler with a power of 2 kW, equipped with a thermostat and a temperature limiter;

- draft regulator, which allows you to automatically regulate the flow of air into the combustion chamber of the device.

Principle of operation

The action of an electric heating element is quite simple for the average user to understand. Due to the difference in the weight of the cold and heated coolant, a unidirectional flow occurs. The heated liquid tends to rise. At the same time, the medium, which has already managed to give off heat and cool down, goes down.

For home-made batteries with heating elements, the best option is to use transformer oil as a coolant. Such a working fluid quickly heats up and cools down extremely slowly, having a low freezing point. Automotive antifreeze has similar properties.

TOP 10: Nibe BU - 500.8

Application

This type of heat accumulator is used for a heating boiler with different heat sources, whether it be a heat pump or a boiler, a solar collector or another, and also, as an alternative supplier, effective when turning off the centralized supply.

Important: when operating with boilers using solid fuel, overheating of heat accumulators is excluded, the efficiency increases and the period of operation of boiler equipment is extended. Additionally, it is possible to reduce the frequency of loading it with fuel

Peculiarities

For this model of the heat accumulator, they are as follows:

- attractive design;

- effective polystyrene foam thermal insulation up to 140 mm thick. It lay down to remove to reduce the size of the device if it is impossible to pass through doorways. It is similar in appearance to molded panels, the outer side of which is covered with white PVC;

- allows connection of more than one electric heater;

- use as an alternative source, in the absence of centralized heating;

- the ability to consume cheap energy (night rate) when working with two-tariff meters and electric boilers;

- the presence of additional coils in individual modifications installed in the lower part. Thanks to them, you can connect additional heat sources;

- there are flanges for connecting heating elements and a thermometer;

- the ability to distribute the coolant along the entire height of the device, thanks to the vertical bar that the heat accumulator has at the inlet (left);

- suitability for the organization of the most complex heating systems, including those for which the value of the heat load is large enough.

Technical indicators

- Type - outdoor;

- Tank capacity - 500 liters;

- The limit value of pressure in the external tank is 6 bar;

- The maximum heating temperature is 95 Cº;

- Device weight - 106 kg;

- Diameter - 750 mm;

- Height - 1757 mm.

Buy

The main type of heating

Let's take a closer look:

- They are used in small rooms with a non-permanent stay of a person in them, for example:

-

- utility rooms;

- garages;

- workshops of various kinds.

The refusal to use water in the heater is due to the possibility of its freezing at low temperatures. Such a heater is identical to an oil cooler and does not need to be connected to a central or local heating system. Oil circulation occurs exclusively inside the heater.

- Another use case is for occasionally visited country houses or summer cottages. The device is created according to the same principle as in the first case, but more devices are installed.

- In regularly heated houses, buildings, offices and cottages with no centralized heating system. In this case, the main source of heat is also a heating device with a heating element installed inside.

Auxiliary heating of a private house

If there is a centralized heating system in the house that uses a single water circuit, tubular electric heaters can be used for auxiliary heating of the coolant.

Possible applications:

- With boilers using coal or firewood as the main fuel element, heating elements can be used to heat the coolant. This is especially true in those moments when there is no possibility of servicing the boiler and filling it with fuel.

- In heaters operating on liquid fuel or liquefied gas, heating the coolant with heating elements will not be more expensive. And in the case of installing a two-tariff meter for electricity, savings are also possible, the nightly tariff is usually much cheaper than the daytime one.

Auxiliary apartment heating

In multi-storey buildings, offices or various types of industrial and utility rooms with connected central heating, it is also possible to install heating elements in batteries. This method of heating is used if the central heating supply cannot provide the required parameters of the coolant in the radiators.

But this type of installation of heating elements has several negative points:

it is not legally possible to use cast-iron radiators with heating elements connected to central heating system, since it is very difficult to obtain such permission from a service organization;

- the high cost of work on the re-equipment of the heating system;

- it is not economically feasible during operation, since the additionally heated coolant will leave and heat other apartments. If, however, the radiator is blocked from the flow of coolant from the central heating system, heating bills will still have to be paid.

Characteristics of devices

Consider the positive and negative aspects of using heating elements:

| pros |

|

| Minuses |

|

Disadvantages of heating elements of boilers

Indirect heating of the heat carrier in the tank of the heating element of the boiler significantly increases the time of its heating. It takes more than 10-15 minutes to warm up such a boiler.

This is a subjective shortcoming, which is perfectly compensated by the safety and clean operation of the heating elements of the boilers.

However, due to indirect heating, 10-15% of the heat released by the heating elements is lost even at the heating stage. This negatively affects the efficiency of such boilers.

The weak point of the heating elements of the boiler are the heating elements themselves. Being constantly in an aggressive environment, they rust, corrode and salt deposits. A simple metal heating element will require replacement in 5-6 years.

The use of heating elements

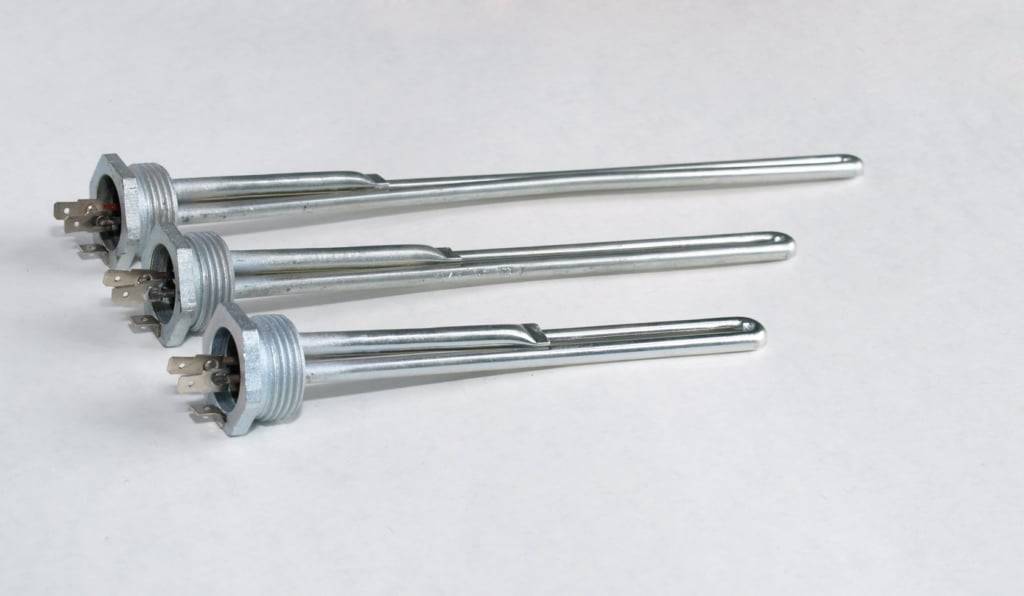

Tubular heaters

Installation of heating elements is so simple that any home master can perform all the required work.Complete with a heating element, as a rule, everything necessary for installation, protection, connection and automation is supplied. Thanks to this, it is enough to screw a heating element equipped with a thermostat into the radiator socket and connect it to the mains. The system must be filled with coolant. After such simple work, the heating element can be used for its intended purpose. When installing, make sure that the mounted heater is in a strictly horizontal position.

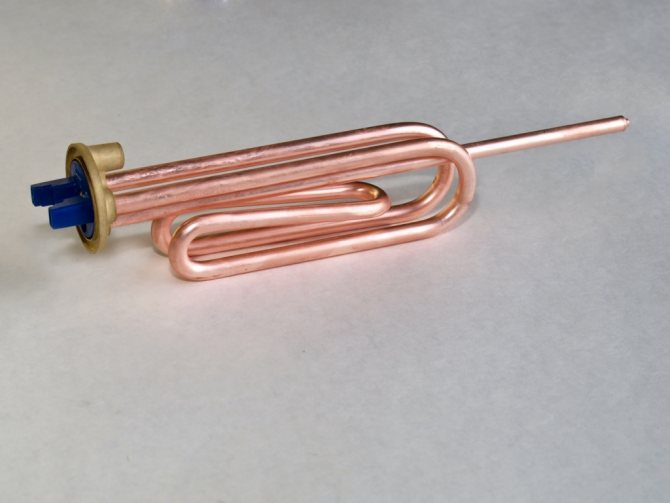

There are models of different capacities on the market. They are suitable not only for domestic but also for industrial use. The basis of the design is a stainless steel pipe with a nichrome wire spiral placed inside. Using a brass nut with a right or left thread, the heating element is screwed into the pipeline. These units can be used with any radiator having a 1" mounting thread.

The heating element for radiators is a collapsible design, so the body can be detached if necessary, even during operation. One of the most important issues that arise when using electric heating is safety. Among all electrical appliances, the heater is the most secure. To protect against overheating, double control is used due to the main and additional temperature sensors. The main sensor is located inside the case, and the additional one is in a special tube.

Differences depending on the model and type of radiator

The heating element for the battery can operate in two modes. When used as the main source of heating, the heating element is turned on at full power. Thanks to this, it quickly warms up the room to a comfortable temperature and maintains it at a given level.In houses with irregular residence, heating elements can be used as protection for an autonomous heating system from freezing. In this case, the device will operate at minimum power, maintaining the temperature of the coolant in the pipes at a level that does not allow it to freeze.

The power of the heating element is one of the main parameters when choosing a model. Low-power products will not be able to cope with the tasks assigned to them. After all, with the help of a small boiler it is impossible to heat the water in the bathroom - you will need a more powerful one. In the same way, when installing a low-power heating element, the water in the system will cool faster than it will heat up to the set temperature.

When calculating the power, it is necessary to take into account not only the volume of water in the radiator where the heating element will be installed, but also the initial and final temperature of the coolant and the time taken by the device to heat it. To perform the most correct calculations, special formulas are used. For a simple layman, they can be difficult, so a complete calculation is ordered by heating specialists. A simpler calculation is that the temperature of the coolant in the cast-iron radiator should be within +70 degrees.

Modern radiator

In addition to power, other technical parameters of the unit must be taken into account. The main ones are:

- The shape and diameter of the heating element tube.

- Heating tube length.

- The total length of the device.

- Insulator dimensions.

- Attachment type.

- Type of connection to the radiator.

TOP 7: HAJDU AQ PT 1000 C

Description

The buffer structure, in addition to storing excess heat generated by a solid fuel boiler or any other alternative energy source, can redirect it to a heat accumulator.

Their advantage is that they supply almost free heat all year round, even with low lighting. Even in cloudy weather, the heating system can receive tens of kilowatts of energy from them.

Design

Inside the Hajdu AQ PT 1000 C tank there is a heat exchanger in the form of a spiral. Its area is 4.2 square meters. The coolant heated by the sun's rays, flowing through the coil, gives off its heat, which is sent for heating to the heating system.

The dimensions of the device allow it to function in tandem with a solid fuel boiler, whose power is 25-35 kW.

Important: the system that provides the accumulation of heat with a buffer tank can only function in a heating system with a forced cycle, and is not suitable for a gravitational one. Hoidu brand designers did not limit themselves to the described function of the device, i.e.

ability to store heat. Therefore, they provided a technological hole, which makes it possible to install 2, 3, 6, 9 - kilowatt heating elements. The importance of this decision is the ability to increase the time between downloads. This was appreciated by those living in country cottages and dachas

Designers of the Hoidu brand did not limit themselves to the described function of the device, i.e. ability to store heat. Therefore, they provided a technological hole, which makes it possible to install 2, 3, 6, 9 - kilowatt heating elements

The importance of this decision is the ability to increase the time between downloads. This was appreciated by those living in country cottages and dachas

Recommended:

- Portable chargers for phones: advantages, features, price - TOP-7

- Thermal accumulators: purpose, features, price - TOP-6

- TOP-6: inexpensive solar collectors for heating and heating swimming pools, prices and where to buy

Now they can load cheap heat, i.e. load the energy storage device at a reduced rate. At the same time, a tie-in into the heating system of the electric boiler is not needed, because the heaters heat the drive directly, during the day giving the heat accumulated during the night into the system.

Inner surface

On the inside, the walls do not have an enamel coating, like boilers with indirect heating water heaters, so it is not recommended to use heat accumulators for hot water supply.