- How to choose a floor gas boiler

- Double-circuit gas boilers

- Principle of operation

- So which boiler should you choose?

- Varieties of boilers

- The presence of contours

- combustion chambers

- Heat exchangers

- Burner type

- Use of flue gases

- Combustion chamber arrangement and types of smoke exhaust

- Open combustion chamber and natural draft through the chimney

- Closed combustion chamber and natural draft through a coaxial chimney

- Closed combustion chamber and forced draft

- Efficiency and gas consumption

- The best wall-mounted gas boilers

- 1. Kiturami Twin Alpha 13 15.1 kW dual circuit

- 2. BAXI ECO-4s 24F 24 kW double circuit

- 3. Bosch Gaz 6000 W WBN 6000-24 C 24 kW double-circuit

- 3 Baxi SLIM 2.300i

- Atmospheric or supercharged?

- 1 Vaillant ecoVIT VKK INT 366

- Benefits of underfloor gas heating boilers

- Which boiler is better to choose?

- 5 Teplodar Kupper OK 20

- What are its advantages of energy-dependent species

How to choose a floor gas boiler

When choosing, the most difficult thing is to choose the power of the device. This parameter can be calculated using the formula P=S/10, where P is the rated power of the floor-standing boiler, S is the area of the heated house.

It is worth noting that this formula is applicable only for houses with a high coefficient of heat transfer resistance, otherwise the power calculation is made using a more accurate formula.P=S*U/10*k, where S is the area of the heated room; U - specific power, the value of this parameter depends on the region (central region U=1.5; Southern - 0.7; Northern -2.0); k is the dissipation coefficient (for buildings with a high coefficient of heat transfer resistance and houses k=1; for the southern regions k=0.8).

Another important parameter when choosing a boiler is its cost. Today, consumers can choose from a wide range of domestic and foreign models. Considering various floor gas heating boilers which one is better is hard to say.

It is safe to say that foreign models are produced according to much more stringent requirements, especially in terms of efficiency and performance of the device. But you have to pay extra for this - imported models are much more expensive than domestic ones.

Russian floor-standing boilers attract buyers not only with an affordable price, but also with an inexpensive and convenient service - it will not be a big problem to purchase spare parts for Russian heat generators, and the repair and descaling of such devices is carried out by a large number of certified companies.

Double-circuit gas boilers

The double-circuit gas boiler is designed for heating water in the heating system, as well as for heating water used for domestic purposes. Due to this, it has clear advantages over a single-circuit analogue:

- reliability of work is ensured through the use of UPS;

- high safety provided by automatic control of gas combustion processes;

- the ability to regulate the optimal level of heating along the circuits, which achieves more rational gas consumption;

- the ability to use automatic operation settings, depending on the ambient temperature and weather conditions;

- no need to purchase additional heating equipment, as one system performs all functions.

If use coaxial chimney for gas boiler of a double-circuit type with a closed combustion chamber, you can significantly increase the efficiency of heating equipment.

The design of double-circuit boilers implies the presence of components such as a burner, an automatic control system, a boiler, and a boiler. In addition to them, the presence of an expansion tank, exhaust and make-up, and an electric pump is mandatory in the home heating system.

Like single-circuit counterparts, a double-circuit gas boiler can be floor and wall-mounted. The latter option is compact and highly reliable security system, however, it is suitable for supplying water to a small bathroom and warming up the temperature of a medium-sized house. The floor version has a higher efficiency, power and dimensions.

Double-circuit boilers are equipped with atmospheric and inflatable burners. The presence of the first implies the flow of air into the combustion chamber in a natural way. The second works in tandem with a fan that supplies oxygen forcibly.

In double-circuit boilers that require a permanent connection to the electrical network, special automatic piezoelectric elements are used for ignition. Non-volatile options use a constantly burning igniter. When it is attenuated, the automation turns off the gas supply, and the ignition is carried out manually.

Both floor and wall heating boilers can either use a boiler in their work as an integral part of the structure, or they can be flow-through. It all depends on the type of heating device.

Principle of operation

The principle of operation of a double-circuit gas boiler is based on the operation of a heat exchanger and two burners and is extremely simple, which significantly increases the reliability of the equipment.

The working process:

- ignition of the igniter. This process is carried out either manually with matches, or by pressing a button if a piezoelectric element is used. For this, a low-voltage electric current is generated by a built-in thermogenerator, and additionally feeds the gas valve.

- the pilot burner, which is in the “standby” mode, turns on immediately after the temperature sensor is triggered, which gives the command to open the gas valve when the temperature drops below the set minimum value.

- the temperature sensor, when the maximum set heating level is reached, commands the gas valve to close.

So which boiler should you choose?

From the foregoing, it is clear that the best selected boiler is the one that works for a long time and without breakdowns, and in order for this to happen, try to follow these tips:

- the selected boiler must not exceed the design capacity;

- the best burners for the boiler are made of stainless steel;

- the boiler security system must have a minimum set of protections: from flame extinction, from gas and water leaks, from loss of draft, from overheating of water at the outlet;

- all boiler piping must be bronze or stainless steel;

- if you have problems with heating, then your boiler must be double-circuit.

These are only the most general tips, for all other questions, contact consultants and, best of all, the company that will perform the boiler installation for you.

Varieties of boilers

It is necessary to carefully approach the choice of equipment, taking into account many factors, such as the area of \u200b\u200bthe room, the presence of thermal insulation and much more. In this matter, it is better to consult with a specialist. Floor-standing gas boilers for private houses are presented according to some characteristics:

The presence of contours

Single-circuit boilers are the most popular among buyers. This is facilitated by a low price, especially of a domestic manufacturer. As a result, cost savings. Plus, repairing a Russian boiler will cost less. The presence of one circuit indicates that only the coolant will be heated. It follows that the dimensions are quite compact and maintenance is easier. Gas consumption is economical. The only caveat is that in order for the house to have hot water, you also need to buy a water heater or an indirect heating tank.

Double-circuit boilers are of course more expensive, but technical capabilities are added to the price: first of all, simultaneous heating of water and space heating; secondly, most options are equipped with automation. Of course, the presence of automation increases the security system during operation, which is a huge plus. In addition, if a breakdown is detected, the system stops the operation of the unit. This indicates high reliability. If we talk about the shortcomings - the main one is dependence on electricity, if the boiler is equipped with automation.

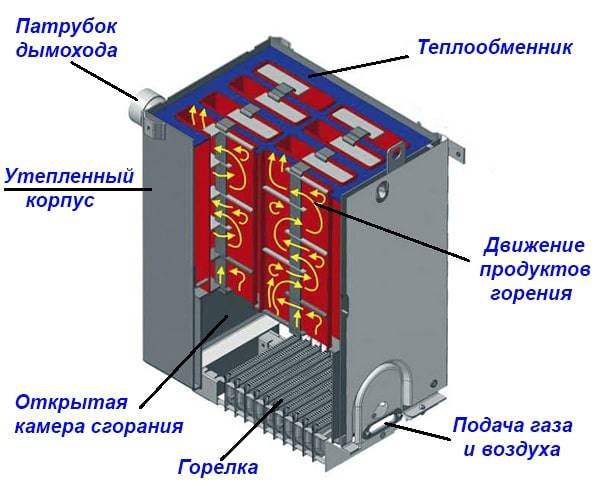

combustion chambers

With an open-type chamber, the advantage is in natural draft - oxygen is taken from the room for combustion, and combustion products are respectively removed through the chimney. Having a properly built chimney is a must! In addition, there should be ventilation in the room. This is also a must.

A significant disadvantage of such boilers can be called the dependence of the floor boiler on external conditions. The colder it is outside, the weaker the traction. The weaker the thrust, the worse the boiler burns and, accordingly, this directly affects performance.

With a closed-type chamber, everything is simpler - it has a fan that removes gases and supplies air. In this case, the presence of a chimney is not required. There everything will be done by the supply and exhaust ventilation system. Such a camera increases the efficiency. Efficiency and lower fuel consumption. Safety. Minus - such boilers are very noisy and electrically dependent. And they're also more expensive.

Heat exchangers

Floor gas boilers for a private house have 3 types of heat exchangers:

Cast iron: absolutely indifferent to corrosion, but the temperature difference is very dangerous for them. They can crack easily. This will lead to repairs, and they are very heavy and difficult to replace. However, they can last up to 30 years.

Steel: mostly light and very strong, and they do not deform. Minus - over time, unfortunately, they corrode. They can burn out. From this, their service life, again with proper handling, is about ten or fifteen years. At high temperatures for a long time, much more fuel will be consumed.

Copper: light weight, corrosion, fortunately, do not give in. Good thermal conductivity. Only now they are used extremely rarely. Metal is expensive and wears out quickly.This option is more often used for low-power wall-mounted boilers.

Burner type

There are atmospheric boilers and inflatable ones. Atmospheric work very noisy, but the cost is low. The burner is already in the apparatus. Inflatable boilers, of course, due to the presence of a fan, are very noisy. They are also dependent on power supply. The cost is high, but this is according to the configuration.

Use of flue gases

Typically, boilers are designed in such a way that flue gases, together with water vapor, are immediately discharged to the outside. Such floor solutions for a private house are called convection. But their temperature is high and the heat obtained at the outlet can be reused. Condensing units collect steam during the combustion of gaseous fuel and, as a result, the resulting heat is sent to the heating circuits. Due to this use of energy, the performance of both the boiler as a whole and the heating circuit increases. This is fuel economy and an increase in efficiency up to 100% and more. The only drawback is the high cost. Convection appliances are simpler and much cheaper.

It is also important to consider that condensing boilers are effective only in low-temperature systems, such as water heated floors. In other cases, they work similarly to a convection unit.

Combustion chamber arrangement and types of smoke exhaust

According to the method of oxygen entering the furnace (it is required to maintain an active flame), all double-circuit gas boilers are divided into two categories:

- with an open type combustion chamber (atmospheric boilers) - they take air directly from the room itself, in which the equipment is installed;

- with a closed-type combustion chamber (turbocharged boilers) - they do not draw in heated air from the room, but take it from the street through a coaxial chimney, which reduces heat loss.

The type of combustion chamber determines how exactly the output of combustion products should be organized: through the shaft to the roof of the house or directly through the wall.

Open combustion chamber and natural draft through the chimney

In boilers with an open combustion chamber and natural draft, flue gases are removed through a full-fledged vertical chimney leading to the roof. This whole design has a simple device - for this reason, it is not expensive and, theoretically, more reliable. But the installation of atmospheric boilers is complicated.

The installation of such boilers is only allowed separately from living rooms, subject to all the rules for organizing a chimney and placing a boiler room:

- the diameter of the chimney pipe is at least 130–140 mm, and the length is 3–4 m;

- it is made of stainless acid-resistant steel or asbestos;

- the minimum area of the boiler room is 3.5–3.7 m2 with a ceiling height of 2.2–2.5 m;

- the room has at least one window from 0.6–0.7 m2 and good ventilation.

If at least one of the listed rules is not observed, it would be wiser to prefer a device with a closed combustion chamber, with a chimney outlet through the wall. Otherwise, at best, the equipment simply will not be able to work, and at worst, carbon monoxide will begin to accumulate in the room, which is life-threatening.

Closed combustion chamber and natural draft through a coaxial chimney

Parapet non-volatile gas boiler Lemax Patriot-16 complete with coaxial chimney.

Parapet gas boilers are neither floor-mounted nor wall-mounted.In addition to the method of placement, they differ in that they have holes in the body, so they can be used as a radiator and heat the room in which they are installed. They need a coaxial chimney, for which one pipe is inserted into another: the smoke is removed through the inside, and air from the street is sucked in through the intermediate gap.

Such equipment is installed anywhere, the main thing is below the line of window sills (for example, instead of a battery) and in any premises: a private house, a household. building, commercial building and even an apartment in a high-rise building. The only limitation is that the horizontal pipe section should not exceed 2.8–3.0 m.

Closed combustion chamber and forced draft

In boilers with a closed combustion chamber, there is an inflatable fan (turbine), which forcibly removes smoke from the furnace immediately to the street and automatically sucks in new air from the street through the same coaxial pipe. The devices are easy to install, because they are not demanding on the arrangement and size of the boiler room.

The main advantage of the turbine unit is that it does not have access to an open source of fire, which reduces the likelihood of carbon monoxide entering the house.

In general, gas boilers with a closed combustion chamber are installed in rooms for any purpose, but some nuances must be taken into account:

- the turbine located in the boiler creates a little additional noise;

- the coaxial pipe is brought out through, which affects the appearance of the wall;

- the exit of smoke at eye level does not allow you to be closer than 4-6 m from the pipe outside the house;

- the turbine unit consumes 40-50 W / h more than a standard chimney.

Forced draft appliances are more expensive than conventional ones, but they do not require the construction of a full-fledged chimney, so installation is cheap.

Efficiency and gas consumption

The coefficient of performance (COP) of a heating boiler is an indicator that directly affects the efficiency of its use of energy resources.

For standard gas units, the efficiency value is in the range of 90–98%, for condensing models 104–116%. From a physical point of view, this is impossible: this happens if not all of the released heat is taken into account, therefore, in fact, the efficiency of convection boilers is 86-94%, and condensing boilers - 96-98%.

According to GOST 5542-2014, 9.3 kW of energy can be obtained from 1 m3 of gas. Ideally, at 100% efficiency and average heat loss of 10 kW, fuel consumption for 1 hour of boiler operation will be 0.93 m3. Accordingly, for example, for a domestic boiler of 16–20 kW, with a standard efficiency of 88–92%, the optimal gas flow rate is 1.4–2.2 m3/h.

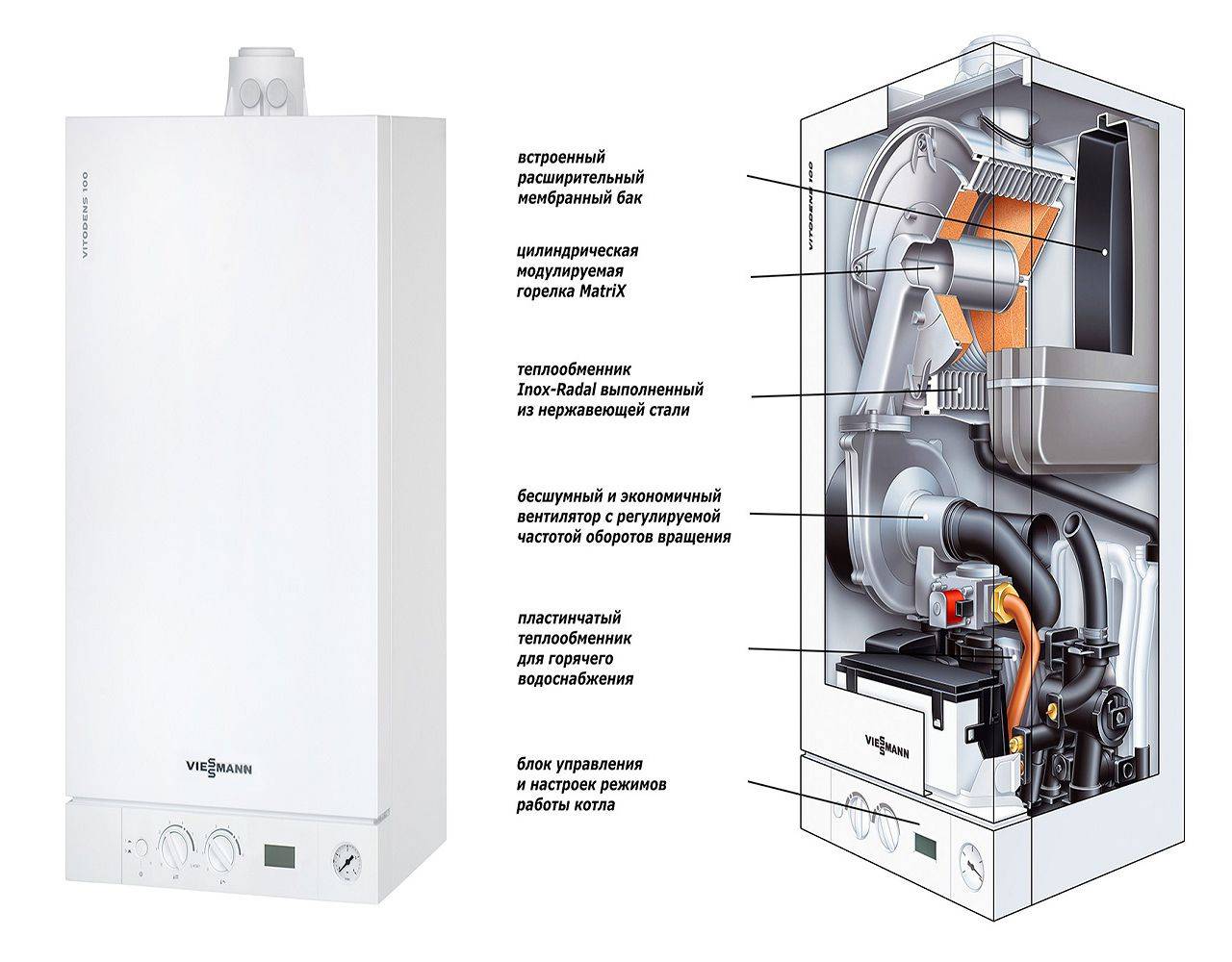

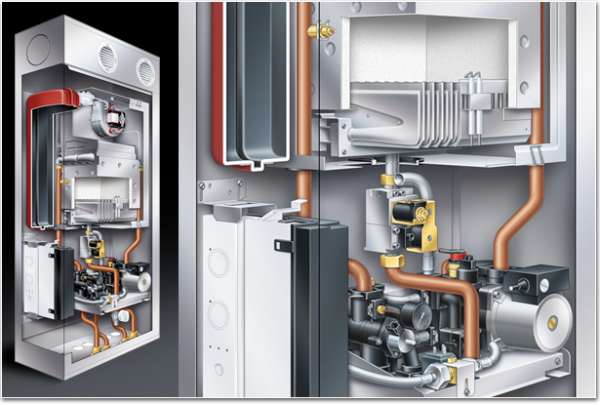

The best wall-mounted gas boilers

Wall-mounted boilers are smaller and lighter than floor-standing ones. With dimensions of about 850 × 500 × 500 mm, they weigh no more than 50 kilograms. As the name implies, such solutions are mounted on the wall. In most cases, wall-mounted models are double-circuit, so they can both heat the home and provide hot water. In addition to smaller dimensions, the devices also boast built-in thermometers, pressure gauges, expansion tanks and pumps, so there is no need to provide a place for their installation. Another important plus of wall-mounted units is the possibility of using a vertical chimney pipe, thanks to which the boilers in question are also suitable for an apartment.

1. Kiturami Twin Alpha 13 15.1 kW dual circuit

Advantages:

- remote control;

- price-quality ratio;

- good efficiency of 91.2%;

- closed combustion chamber;

- complete thermostat;

- frost protection.

2. BAXI ECO-4s 24F 24 kW double circuit

Excellent quality and reliability offers an economical gas boiler BAXI ECO-4s. Its appearance is similar to the single-circuit model Four 1.24 discussed above from the same line. In addition to the design, the dimensions remained unchanged - 40 × 73 × 29.9 cm. But the weight increased by 2 kg and for this device it is 30 kilograms.

The temperature of the coolant in the popular BAXI gas boiler model varies from 30 to 85 degrees. The performance of hot water at 25 and 35 degrees is limited to 13.7 and 9.8 liters per minute, respectively. The nominal pressure for natural and permissible for liquefied gas in the ECO-4s 24F are declared at 20 and 37 mbar.

Advantages:

- easy to mount;

- low noise level;

- ease of maintenance;

- accuracy of maintaining the set temperature;

- high quality assembly;

- construction quality;

- built-in protection made of composite materials;

- several modifications.

Flaws:

- there is no possibility of power adjustment;

- There are errors in assembly.

3. Bosch Gaz 6000 W WBN 6000-24 C 24 kW double-circuit

First of all, Bosch specializes in wall-mounted boilers. And the quality of such products of the German manufacturer does not cause any complaints, which allowed the Gaz 6000-24 model to take a leading position in the corresponding category.

Its thermal power is in the range of 7.2-24 kW. The heat exchanger of the device is made of copper. The boiler runs on natural or liquefied gas, consuming them at a rate of 2.3 cubic meters. m or 2 kg per hour, respectively. The dimensions and weight of the 6000-24 are 400×700×299 mm and 32 kg.

The manufacturer provides a 2-year official warranty for its device. However, the service life declared by the company is 15 years. The productivity of hot water in the monitored boiler is 11.4 and 6.8 l / min for a temperature of 30 and 50 degrees.

Advantages:

- expansion tank 8 liters;

- optimal performance;

- excellent German quality;

- economical gas consumption;

- Ease of controls;

- the heat exchanger is made of copper;

- accurate assembly, management.

Flaws:

some buyers are experiencing an EA error.

3 Baxi SLIM 2.300i

The Italian gas boiler Baxi SLIM 2.300 i has a built-in boiler with a capacity of 50 liters. Thanks to this design, there will always be a sufficient supply of hot water in the house. The security system includes a closed combustion chamber, protection against overheating and freezing, from blocking the pump, there is a draft sensor. The boiler can also be operated from liquefied gas. Additionally, it can be equipped with a timer and remote control. The double-circuit convection boiler is adapted to Russian conditions.

Consumers note the versatility of the boiler, its efficiency, ease of installation, the ability to work on liquefied gas. The main disadvantage is the high cost.

Atmospheric or supercharged?

In turbocharged heaters, air is forced into the closed chamber by means of a fan. This provides the following benefits:

- instead of a traditional chimney, you can use a coaxial one in the form of a double-walled pipe that goes outside directly from the boiler;

- The efficiency of the supercharged unit reaches 92-93% (condensing - 95%) versus 88-90% for the "aspirated";

- ease of use due to a high degree of automation;

- the turbo-boiler remains the only alternative for apartments not equipped with chimney ducts.

Design of a gas turbine boiler with a closed combustion chamber and an air blower

In practice, you will not feel the difference in efficiency of 3%, so this advantage is rather illusory. Although gas-fired heating boilers with forced air supply are more expensive than atmospheric ones, they eliminate the need to install a traditional chimney. On the other hand, they are more difficult to maintain.

Floor heat generator with open type combustion chamber (atmospheric)

When you live far from large cities where service centers for servicing gas-using equipment are located, you should not buy an expensive “tricked out” pressurized gas boiler. Try to choose a simpler and more reliable modification of the atmospheric type, so that in the event of a malfunction, you do not have to pay fabulous money for the arrival of specialists.

The issue of the price of equipment and its maintenance is especially acute in the case of condensing gas boilers. They are expensive and complex, and therefore such a purchase is justified only for large heated areas (over 500 m²).

The device of a turbocharged condensing boiler with a cylindrical chamber. The heater is designed for wall mounting

1 Vaillant ecoVIT VKK INT 366

The gas boiler from Germany Vaillant ecoVIT VKK INT 366 has the highest efficiency, which is 109%! At the same time, the device produces 34 kW of energy, which allows you to heat a house up to 340 square meters. m.German specialists achieved the maximum result from gas combustion through the use of a modulating burner, flame control, conservation of latent heat of condensation, a multi-sensor control system, an information and analytical center, electronic ignition, etc.

Consumers highly appreciated such qualities of this single-circuit boiler as functionality, reliability, stylish appearance. It is worth noting that electronics are very sensitive to voltage drops in the mains. Therefore, it is necessary to additionally install a voltage stabilizer in the house.

Benefits of underfloor gas heating boilers

Using a double-circuit boiler for heating a private household or apartment allows not only to create a comfortable temperature regime, but also to ensure an uninterrupted supply of hot water. In addition, a double-circuit gas boiler has the following advantages:

- At maximum thermal power, double-circuit installations provide economical gas consumption;

- Design features and materials used allow to achieve maximum heat transfer efficiency;

- The power of floor gas boilers allows you to heat not only private houses, but also large production areas;

- The electronic control unit provides complete autonomy of the system;

- The devices are characterized by a long service life and easy maintenance;

- Despite the high power characteristics, the devices are quite compact;

- The use of cast iron for the manufacture of the heat exchanger significantly increases the corrosion resistance;

- The price of outdoor units is affordable for most owners of private houses.

In addition, it should be noted that the installation of a double-circuit gas boiler eliminates the additional cost of purchasing a boiler.

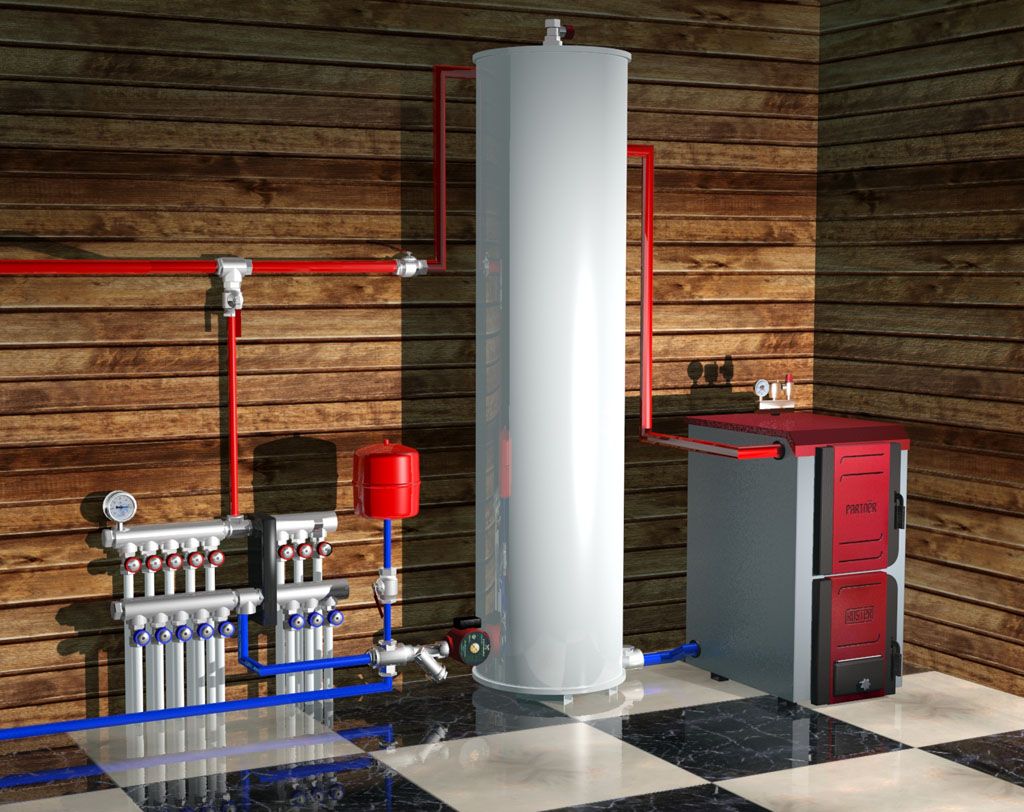

Which boiler is better to choose?

At choosing the best boiler Please note that each type of equipment is designed for specific conditions. Under which they will show maximum efficiency, allow you to achieve the expected result and level the shortcomings.

Therefore, it is so important to determine your requirements and take into account living conditions. So, if the equipment is selected in an apartment and there is no extra space for installation, then a double-circuit wall-mounted boiler will be an ideal option.

And although it is inferior in power to floor models, it is quite capable of meeting the needs of residents.

For a summer residence or a private house, where there is a separate room for the arrangement of a boiler room, a great solution would be to install a floor-mounted single-circuit gas boiler in conjunction with a boiler of the required volume. That will provide the needs of the family in hot water and heat.

When installing any model of floor single-circuit boiler with a boiler will require an order of magnitude more space than for dual-circuit analogues

And the load on the equipment in this case will be higher, so it is important to choose the right boiler power. If you are choosing a heating unit for a country two-story house or cottage, then in this situation it is best to stop at a powerful double-circuit floor-standing boiler with a built-in large-volume heater

If you are choosing a heating unit for a country two-story house or cottage, then in this situation it is best to stop at a powerful double-circuit floor-standing boiler with a built-in large-volume heater.

Floor-standing gas boilers with one and two circuits are more powerful than their wall-mounted "brothers". They are also mostly non-volatile. This is quite convenient, especially if there are power outages in the region.

We have given more recommendations and important criteria for choosing gas boilers in the next article.

5 Teplodar Kupper OK 20

A lot of Russian settlements are waiting for the gas pipeline to be connected, and the only heating alternative available to its residents for some time is the installation of a heating system based on a solid fuel boiler. The Teplodar company has developed a universal design - the Kupper OK 20 model, capable of working both on wood, pellets and coal, and on natural gas. It is possible to transfer the unit from one type of fuel to another using the optional Teplodar burners. Thus, the same boiler can be used as the main source of heat on solid fuel, or as a backup - in areas with unreliable gas supply.

The basic kit includes a block of 3 heating elements with a power of 2 kW. It is impossible to heat the house with them on an ongoing basis; their task is to maintain the coolant in the event of a complete burnout of the fuel or in an emergency. Another feature of the device is the possibility of retrofitting an external control and a capacitive hydraulic separator. These elements perfectly balance the heating system, improve controllability to the level of mono-fuel boilers and extend the service life, but at the same time increase the cost of boiler equipment by more than 2 times.

What are its advantages of energy-dependent species

Non-volatile installations operate only on a mechanical principle, without needing to be connected to the power supply system.

This makes them indispensable in remote villages, in areas with dilapidated or overloaded electrical networks. Frequent shutdowns cause the heating to stop working, which is unacceptable in the conditions of the Russian winter.

Non-volatile models provide continuous heating of the house, regardless of external conditions. However, such possibilities limit the possibilities of non-volatile boilers. They work only on natural physical processes - the circulation of the coolant requires the installation of the heating circuit at a slight angle and is based on the rise of warm liquid layers upwards.

Smoke removal occurs under the action of conventional draft in the chimney. It should be borne in mind that natural processes proceed with minimal intensity and are unstable, therefore, external additional devices are usually installed - a turbo nozzle and a circulation pump.

They make the unit more productive, and operation in a non-volatile mode occurs only during a power outage.

If there is no power supply to the house at all, only the basic capabilities of the unit are used.