- TOP-10 rating

- Buderus Logamax U072-24K

- Federica Bugatti 24 Turbo

- Bosch Gaz 6000 W WBN 6000-24 C

- Leberg Flamme 24 ASD

- Lemax PRIME-V32

- Navien DELUXE 24K

- MORA-TOP Meteor PK24KT

- Lemax PRIME-V20

- Kentatsu Nobby Smart 24–2CS

- Oasis RT-20

- Optional equipment

- UPS for gas boiler

- How to choose a voltage stabilizer for a gas boiler?

- Gas-burners

- Room thermostats

- The principle of operation and arrangement of gas boilers

- Single-circuit and double-circuit devices - what's the difference?

- What you need to know when choosing a heater

- Gas bypass selection options

- Combustion chamber type

- Dimensions and placement

- Heat exchanger configuration

- Power

- Types by type of combustion chamber

- Choosing a floor boiler: how not to make a mistake

- Gas unit power

- Specificity of fuel consumption

- Optimal number of circuits

- Priority heat exchanger material

- Construction type and performance

- Best control system

- Acceptable design and dimensions

- Differences between an atmospheric gas boiler and a turbocharged one

TOP-10 rating

Consider the most popular models of double-circuit gas boilers, recognized by experts and ordinary users as the most successful in terms of design and operation:

Buderus Logamax U072-24K

Gas double-circuit boiler designed for wall mounting.Equipped with a closed-type combustion chamber and a separate heat exchanger - primary copper, secondary - stainless.

Heating area - 200-240 m2. It has several levels of protection.

Models with the index "K" perform heating of hot water in flow mode. It is possible to connect a room temperature controller.

Federica Bugatti 24 Turbo

Representative of Italian heat engineering, wall-mounted double-circuit gas boiler. Designed to work in a cottage or public space up to 240 m2.

Separate heat exchanger - copper primary and steel secondary. The manufacturer gives a 5-year warranty period, which indicates confidence in the quality and operational capabilities of the boiler.

Bosch Gaz 6000 W WBN 6000-24 C

The German company Bosch is known all over the world, so it does not need additional introductions. The Gaz 6000 W series is represented by wall-mounted models designed for operation in private homes.

The 24 kW model is the most common, it is optimal for most residential and public buildings.

There is a multi-stage protection, the copper primary heat exchanger is designed for 15 years of service.

Leberg Flamme 24 ASD

Leberg boilers are usually referred to as budget models, although there is no noticeable difference in cost with the products of other companies.

The Flamme 24 ASD model has a power of 20 kW, which is optimal for houses of 200 m2. A feature of this boiler is its high efficiency - 96.1%, which is noticeably superior to alternative options.

Works on natural gas, but can be reconfigured to liquefied gas (replacement of burner nozzles is required).

Lemax PRIME-V32

Wall-mounted double-circuit boiler, the power of which allows you to heat 300 m2 of area.It is suitable for two-story cottages, shops, public or office spaces.

Produced in Taganrog, the basic technological principles of assembly were developed by German engineers. The boiler is equipped with a copper heat exchanger providing high heat transfer.

It is calculated on operation in difficult technical conditions.

Navien DELUXE 24K

Korean boiler, the brainchild of the famous company Navien. It belongs to the budget group of equipment, although it demonstrates high performance.

It is equipped with all necessary functions, has a self-diagnosis system and frost protection. The power of the boiler is designed to work in houses up to 240 m2 with a ceiling height of up to 2.7 m.

Mounting method - wall, there is a separate heat exchanger made of stainless steel.

MORA-TOP Meteor PK24KT

Czech double-circuit gas boiler, designed for hanging installation. Designed for heating 220 m2. It has several degrees of protection, blocking in the absence of liquid movement.

It is possible in addition to connect an external water heater, which greatly expands the possibilities of supplying hot water.

Adapted to unstable power supply voltage (permissible fluctuation range is 155-250 V).

Lemax PRIME-V20

Another representative of domestic heat engineering. Wall-mounted double-circuit gas boiler, designed to service 200 m2.

The modulating burner makes it possible to distribute fuel more economically by changing the gas combustion mode depending on the intensity of the coolant circulation. It has a separate stainless steel heat exchanger, can be connected to a room thermostat.

There is a possibility of remote control.

Kentatsu Nobby Smart 24–2CS

Japanese wall mounted gas boiler providing heating of 240 m2 and hot water supply. Model 2CS is equipped with a separate heat exchanger (primary copper, secondary stainless).

The main type of fuel is natural gas, but when changing jets, it can be converted to the use of liquefied gas. Most of the performance characteristics correspond to European boilers of similar power and functionality.

It is possible to use several design options for the chimney.

Oasis RT-20

Wall-mounted double-circuit gas boiler of Russian production. Designed to work in rooms of about 200 m2. Equipped with an efficient heat exchanger copper and stainless secondary node.

The combustion chamber is of a turbocharged type, there is a built-in expansion tank and a condensate trap.

With an optimal set of functions and high build quality, the model has a relatively low price, which ensures its demand and popularity.

Optional equipment

UPS for gas boiler

Volatile gas boilers must be equipped with uninterruptible power supplies (UPS) to ensure their reliable operation. These devices allow you to ensure the functioning of the electrical components of the heating system when the household network is inoperable. An uninterruptible switch for a gas boiler installed in a private residential building is not a luxury, but a necessity.

When choosing a UPS, attention is paid to:

-

the total electrical power of the heating equipment (decree in the passport of each device),

-

availability of on-line technology (double conversion),

-

the ability to connect additional batteries to ensure many hours of continuous operation of the equipment.

It is important to purchase batteries in the kit for the UPS, the capacity of which (measured in ampere-hours) must correspond to the calculated load and the operating time of the uninterruptible power supply in emergency mode.

How to choose a voltage stabilizer for a gas boiler?

Electrical equipment without proper protection is quite sensitive to voltage drops. The same exhaust fan, when the current and voltage drop in the network to which it is connected, reduces its speed, due to which its efficiency decreases. In addition, many boilers are equipped with electronic control systems. This is where special devices called stabilizers come to the rescue.

Before choosing voltage stabilizer for gas boiler, it is important to remember that the starting currents of the electromechanical devices of the heating system exceed the nominal ones (indicated in the passport) by 2.5 times, and at the output the device must produce a voltage form that is a regular sinusoid. A stabilizer designed for round-the-clock operation must show high efficiency in dealing with voltage drops in order to avoid damage to sensitive electronics, high stabilization speed. For this reason, it is better to select it in accordance with the working conditions with a specialist.

For this reason, it is better to select it in accordance with the working conditions with a specialist.

A stabilizer designed for round-the-clock operation must show high efficiency in dealing with voltage drops in order to avoid damage to sensitive electronics, high stabilization speed.For this reason, it is better to select it in accordance with the working conditions with a specialist.

Voltage stabilizers can be excluded from the general scheme for connecting a gas heating boiler if there is a UPS with a built-in stabilization system.

Gas-burners

When choosing gas burners for heating boilers, since each has its own parameters, the following features must be taken into account:

- compatibility with installed equipment,

- characteristics,

- manufacturer,

- model,

- price.

Room thermostats

room gas boiler thermostat allows you to automatically maintain the set temperature. By functionality, these devices are divided into:

- weekly programmers, through which you can observe the temperature regime in the premises at different time intervals;

- thermostats that allow you to adjust the temperature manually.

According to the connection method, thermostats are wired and wireless.

How to choose an electric boiler for heating? - here is more useful information.

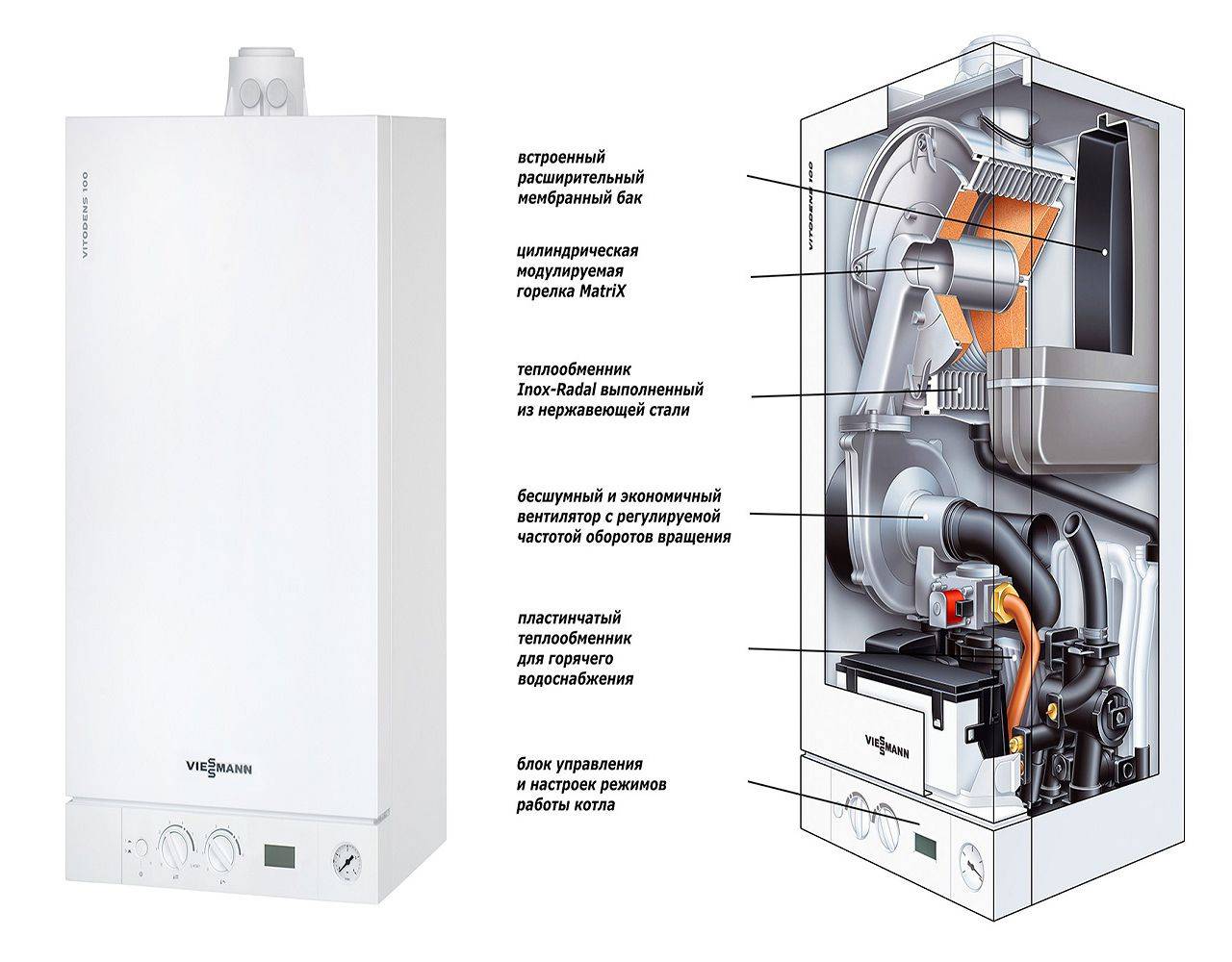

The principle of operation and arrangement of gas boilers

A gas boiler is a wall-mounted or floor-standing unit, predominantly of a rectangular-parallelepiped shape, which generates energy during the combustion of fuel and thereby ensures the functioning of heating and hot water supply systems.

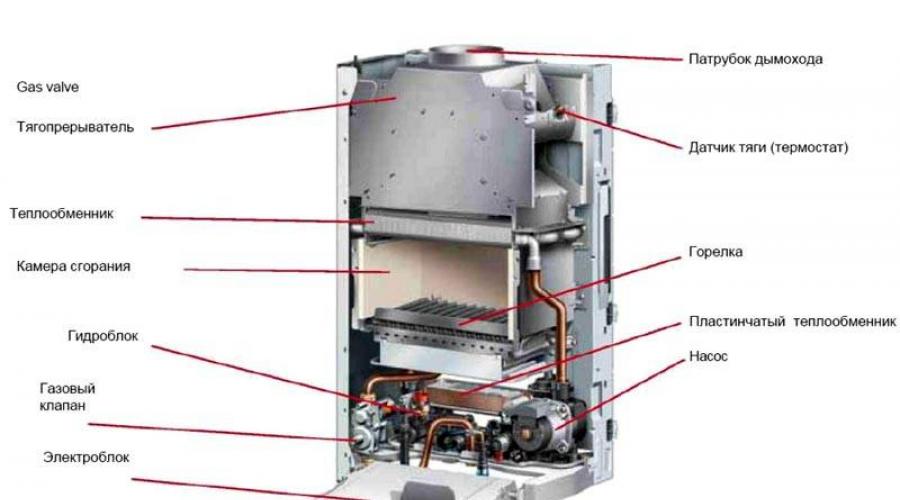

In general, the boiler consists of the following elements:

1. Housing;

2. Burner;

3. Heat exchanger;

4. Circulation pump;

5. Branch for products of combustion;

6. Block of control and management.

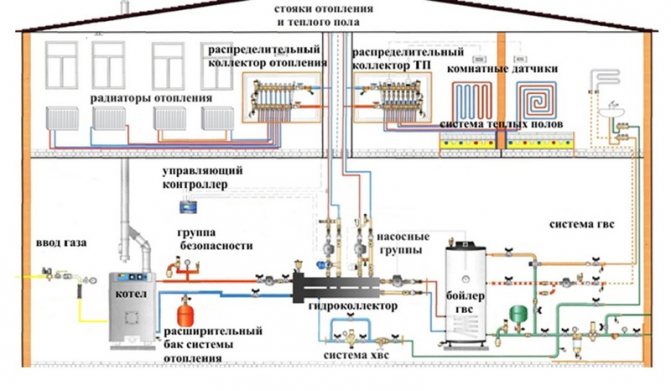

Depending on the design, the boiler operates in one of several modes - according to a simplified scheme: gas is supplied to the burner, which is turned on by a piezoelectric element or electricity; the fuel ignites and heats the coolant through the heat exchanger; the latter, with the help of a pump, is forcibly circulated in the heating system.

During operation, an important role is played by safety systems that prevent overheating, freezing, gas leakage, pump blocking and other troubles.

In the operation of the units there are individual features. In the variant with a 2-circuit model, hot water supply is additionally arranged. In the case of an open firebox, combustion products are removed through the chimney, with a closed chamber - through a coaxial pipe. In condensation models, steam energy is also used.

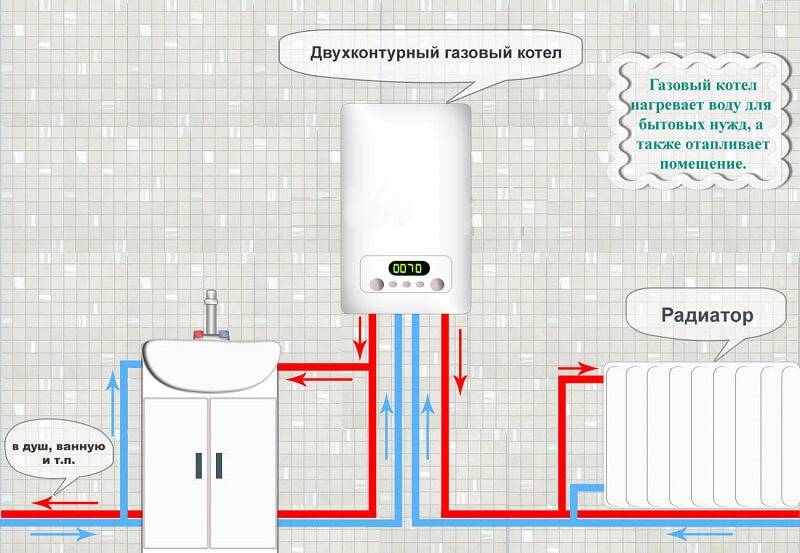

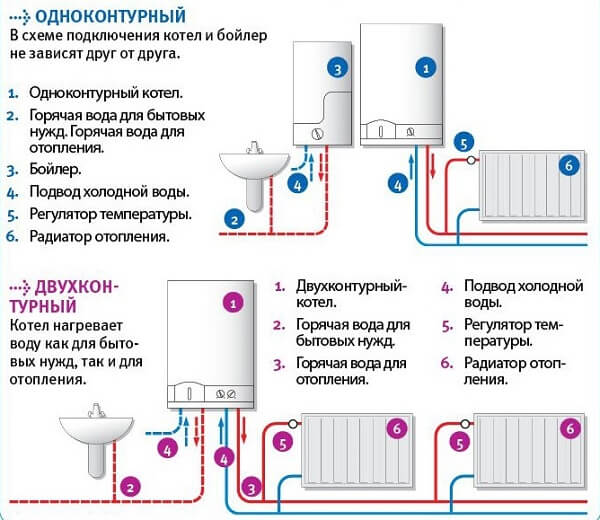

Single-circuit and double-circuit devices - what's the difference?

A single-circuit heating device differs from a double-circuit one only in that it is responsible only for heating the room. At the same time, a double-circuit boiler, in addition to heating, is also designed to solve the issues of providing hot water supply.

Owners of single-circuit boilers solve the tasks of hot water supply by installing additional equipment. Most often, this is an indirect water heating boiler connected to the boiler. What is more efficient single-circuit boiler or double-circuit? This is what we will now look into.

The main advantage of a single-circuit boiler in conjunction with a storage heater is that the water is heated to a comfortable temperature without cooling the home. While with significant water consumption in a double-circuit boiler, the circuit responsible for heating is automatically turned off, and the unit only works to heat water.

A single-circuit gas boiler with an indirect heating boiler completely solves the issue of hot water supply without disrupting the heating system

Consider the following factors before selecting a heater configuration:

- Heated housing area;

- Number of water intake points;

- Distance from water intake points to the boiler;

- The number of residents.

In a house with a small heated area, with economical use of hot water and close placement of water intake points, the best solution would be to install a double-circuit boiler.

With the simultaneous consumption of hot water from several points of water intake, the water temperature may be lower than required. In addition, with a large area of \u200b\u200bhousing, additional inconveniences arise. In double-circuit boilers, DHW is a priority; when hot water is consumed, the circuit responsible for heating is turned off.

But these issues are resolved at the level of unit design. There are double-circuit boilers that heat water in flow mode and are equipped with a built-in boiler.

The latter provide a supply of hot water at the level of 30-60 liters, but at the same time gas consumption slightly increases. In addition, the weight of the boiler and its overall dimensions increase significantly.

Floor-standing gas boiler with built-in indirect heating boiler provides a sufficient supply of hot water

It can be concluded that when meeting the needs, the best solution would be to install a double-circuit flow-type boiler. If you want to have a sufficient supply of hot water at a comfortable temperature at any time without cooling the home, then it would be preferable to install a bundle of a single-circuit boiler with an indirect heater.

In addition, if it is necessary to increase the demand for hot water, the boiler can always be replaced with a larger capacity boiler. As a result, the price of such a bundle will be higher than the cost of a double-circuit boiler, but the issue of hot water supply and heating will be reliably resolved.

What you need to know when choosing a heater

You can’t just go to the store and buy a gas heating boiler. To select a suitable model, it is necessary to prepare a list of requirements for the unit - to determine the thermal power, the necessary functions, the method of installation and other initial data.

What items are on the list:

- Calculate the amount of heat required to heat a cottage or apartment.

- Outline the scope of tasks for a gas boiler - it should only heat the building or, in addition, serve as a water heater for household needs.

- Allocate a place for the installation of a heat generator. The rules allow installing gas-using heating equipment in the kitchen (power - up to 60 kW), an attached boiler room or in another separate room located near the outer wall of the dwelling.

- Decide whether the boiler is to be installed on the floor or on the wall. For apartments, only the hinged version is suitable.

- Consider how your heating system works. Under the gravitational scheme with natural circulation of the coolant (the so-called gravity flow), an appropriate non-volatile heater operating without electricity is selected.

- Set the machine automation level according to your wishes. Examples of useful functions: maintaining the indoor temperature according to a schedule or signals from an external weather sensor, remote control via the Internet, and so on.

- Estimate the prices of various boilers and find out how much you are willing to spend on a gas boiler.

Before picking up a new one or changing an outdated one gas boiler for private heating at home, we highly recommend consulting the subscriber department of Gorgaz (or another management company). Why is it needed:

- in addition to the general rules, regional offices have internal instructions that restrict the use of gas equipment, these points should be clarified;

- a new or replacement boiler must be included in the project documentation, otherwise you risk getting a fine for installation without approval;

- experts will help you to properly place the heat generator in the house.

In the project of the boiler house, the location of all heat generators is indicated with dimensional references to building structures

Another example: you want to remove a horizontal (coaxial) chimney from a room in an apartment building, but the office does not agree on this decision, since the protruding pipe spoils the appearance of the facade. To understand all the subtleties, you will have to understand the existing varieties of gas heaters, but first ...

Gas bypass selection options

Despite the similar principle of operation, different models differ in a considerable number of fundamental parameters.

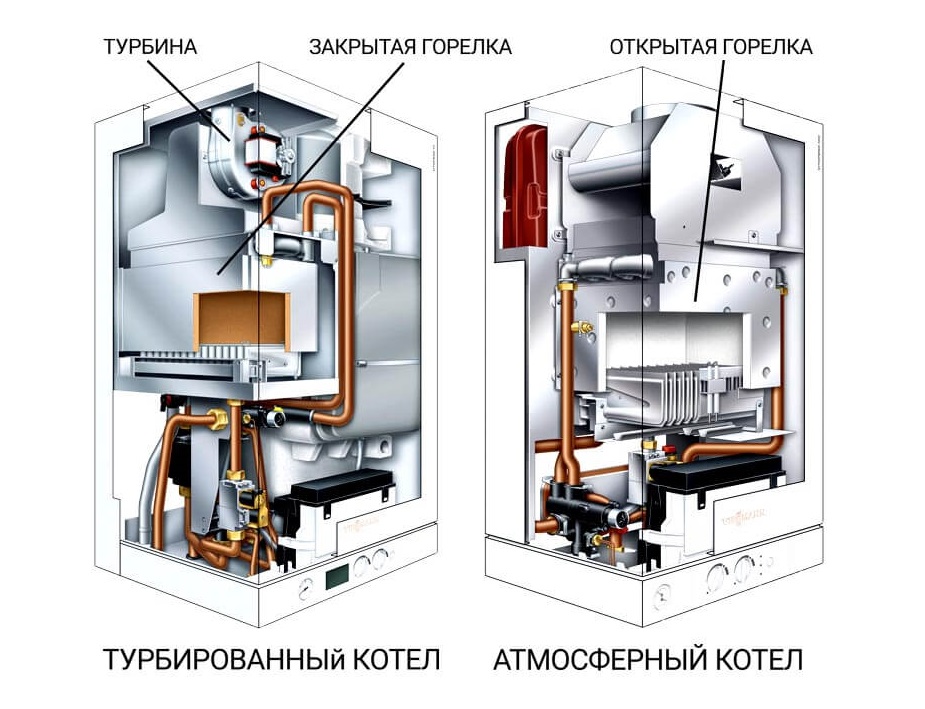

Combustion chamber type

Combustion chamber type

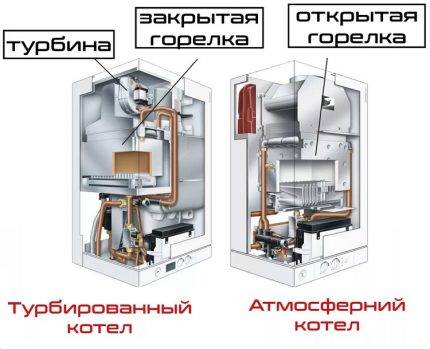

According to the type of combustion chambers, household gas heaters are divided into two types:

- with an open combustion chamber (atmospheric);

- with a closed combustion chamber (with forced air injection).

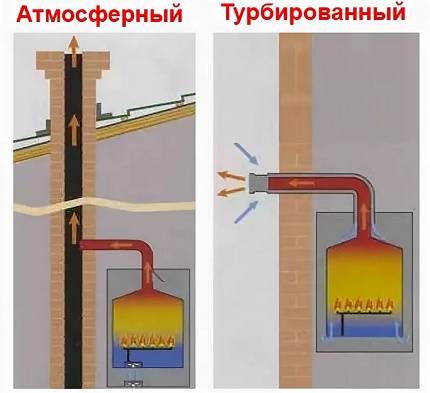

In the first case, the air necessary for the combustion of domestic gas is taken directly from the room in which the boiler is located. AT the bottom of the combustion chamber special openings are made for the influx of fresh air.

Having participated in the combustion process, it, along with other decay products, enters the ventilation duct and exits through the chimney to the street. The construction of a chimney with good draft is a must for this type of boiler.

In the room where the boiler with an open combustion chamber is installed, there must be good ventilation, regardless of whether it is a kitchen or a boiler room.

In boilers with a closed combustion chamber air with suction fans is sucked in from the street, and the gaseous products of combustion are removed there forcibly. For such boilers, special coaxial chimneys are used. Exhaust gases are emitted along the inner contour, and fresh air is taken in from the outer one.

Expert opinion

Torsunov Pavel Maksimovich

Boilers with a closed combustion chamber are indispensable in cases where the construction of a full-fledged chimney with good draft is impossible. This type is relevant even for city apartments in old houses, when there is no connection to the central hot water system.

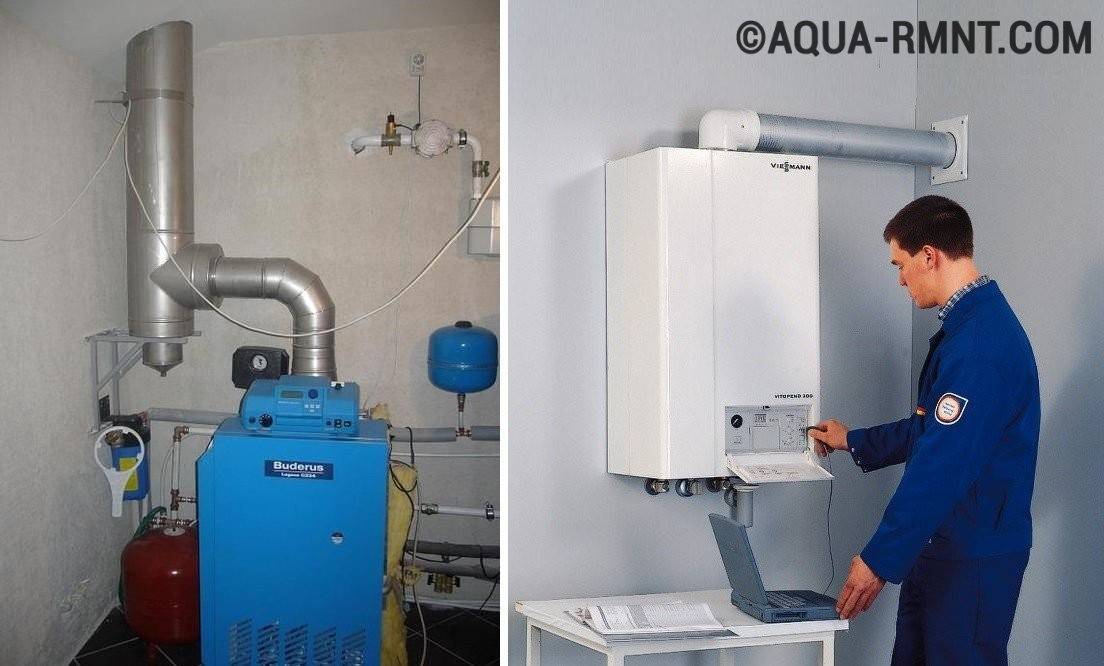

Dimensions and placement

All gas double-circuit valves are divided into two types according to dimensions and type of fastening:

- Wall. The power of these devices usually does not exceed a certain limit - usually 50 - 60 kilowatts. The main trump card is compactness. Wall mounting practically does not take up usable area. You can place the device in the kitchen, providing a sufficient supply of ventilation in advance. Also, users of such devices are attracted by the aesthetics of execution - Italian and German products are distinguished by their elegant design. Wall-mounted boilers are suitable for use in houses up to 150 - 200 square meters, depending on the insulation and hot water consumption.

- Floor.These devices are usually placed in a boiler room - a special technical room. It is easier to organize forced ventilation in it, and a rather noisy boiler will not interfere. For large houses with an area of 400 - 500 squares, powerful units are used that require installation in the basement or in a separate extension.

What type of gas boiler is installed in your home?

OutdoorWall

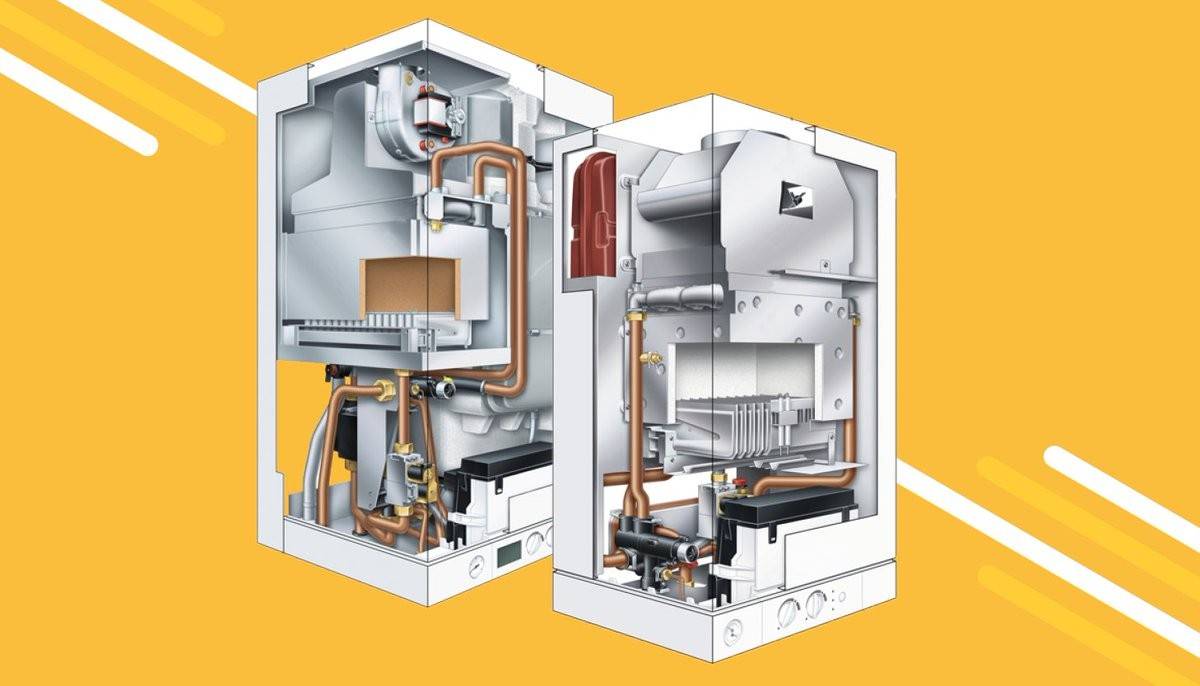

Heat exchanger configuration

The primary and secondary heat exchangers can be two elements spaced apart in the housing during installation or combined into one structural unit.

The separate system contains a tubular primary heat exchanger equipped with a radiator to improve thermal conductivity, and a secondary plate heat exchanger that combines a small heating circuit with tap water pipes.

The bithermic system consists of two tube circuits, one of which is placed inside the other. Typically, the outer channel serves to circulate the coolant, and water flows through the inner channel for the DHW system.

| Andrey Musatov, sales assistant at a heat engineering store, Moscow: |

| The bithermic system is less common: firstly, it is structurally more complicated, and secondly, if scale and deposits form in the internal channel, dismantling and cleaning are more difficult. For boilers with a separate arrangement of heat exchangers, the plate module is removed and cleaned quite easily. But bithermic boilers are more compact, and their efficiency is slightly higher. |

Power

The larger the area of \u200b\u200bthe house, the more powerful the boiler needs to be. At the same time, in a double-circuit unit, only about 30% of the power is spent on heating, the rest goes to the rapid heating of DHW water.When calculating the power, it is necessary to take into account not only the water consumption, but also the degree of insulation of walls, roofs and floors, as well as the degree of cold penetration through the windows.

Small wall-mounted boilers for small houses start at 8 kilowatts, and powerful units for installation in a boiler room can consume more than 150 kW.

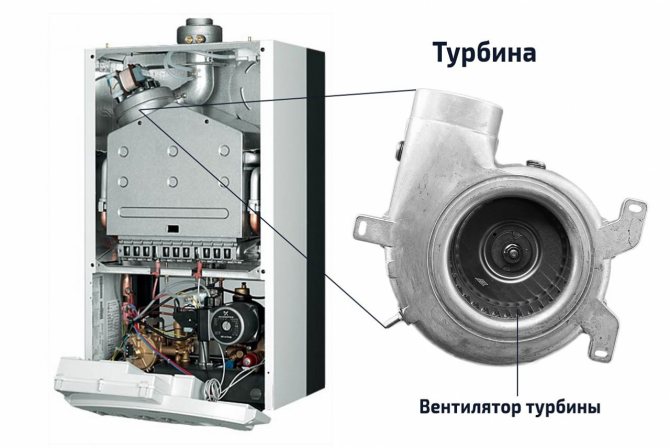

Types by type of combustion chamber

There are two types of combustion chambers:

- atmospheric (open). They work on the traditional principle - air is taken directly from the surrounding atmosphere, and smoke is removed using natural draft. For the operation of such boilers, appropriate conditions are needed, so they are not in great demand. However, atmospheric units are capable of operating in a non-volatile mode;

- turbocharged (closed). The fully sealed design requires an air supply, which is done by a turbofan. This method allows you to control the mode of combustion and the output of combustion products. It is considered the most convenient and safe.

The choice of the combustion chamber is determined by the design of the boiler - all non-volatile models are atmospheric, and dependent units can be either open or closed.

Turbocharged vehicles are preferred.

Choosing a floor boiler: how not to make a mistake

Before you go to the store, you should carefully analyze the features of the heated object in order to clearly understand the operating conditions of the device. Based on this, the characteristics of the equipment are selected.

Gas unit power

One of the main factors determining the choice of the boiler.Standard recommendations suggest determining the required power of the device from the following ratio: 1 kW of power produced by the unit is required per 10 sq.m of the building.

However, this is a very average figure. It does not take into account the heat loss of the building, the height of the ceilings in the room, the number of doors and windows, their thermal insulation, and much more. If possible, a specialist should calculate the required boiler power.

One more moment. It is usually recommended to select a boiler with some power reserve. This is fair, but this margin should not be large. Otherwise, this will lead to rapid wear of equipment and constant excessive consumption of fuel. For single-circuit boilers, the power reserve should not exceed 15%, for double-circuit boilers 25%.

Specificity of fuel consumption

If possible, it is desirable to choose the most economical boilers. These include all condensation models. Compared to traditional appliances under similar conditions, they consume 15-30% less fuel. The electronic ignition system will also help save money.

Standard piezo ignition requires constant operation of the pilot burner, which leads to excessive gas consumption. This is not required for an electronic system. Such boilers have a high cost, but in the process of operation, investments quickly pay off.

Double-circuit boilers are very convenient for small buildings, as they allow you to simultaneously heat the house and provide it with hot water.

Double-circuit boilers are very convenient for small buildings, as they allow you to simultaneously heat the house and provide it with hot water.

Optimal number of circuits

It makes sense to think about purchasing a double-circuit boiler only if there is a need for hot water supply. In this case, it is worth installing a device with two circuits only in a building of a small or medium area.

For large houses, the installation of double-circuit boilers is impractical, since the power of the device for full-fledged work is most often not enough. In addition, the security of the system suffers.

Priority heat exchanger material

Copper is not considered in this case. Only steel or cast iron. The first option is chosen if you want to save money. But you need to be prepared for the fact that after a few years you will have to change the heat exchanger. For long trouble-free operation of the boiler, a cast iron assembly is chosen.

Construction type and performance

For floor gas boilers, efficiency is considered normal, varying in options from 80 to 98%. Condensing models differ in efficiency in range from 104 to 116%. The higher this value, the more efficient the boiler is and uses less fuel.

For double-circuit models, the performance of the DHW system can vary from 2.5 to 17 liters per minute. The performance and power of the unit affect its cost, the higher it is, the higher the price of the device.

Best control system

The most convenient and safe to use are boilers with automatic control. They are able to function autonomously, without constant control of the owner. These are expensive complex systems.

It is also possible to use more budgetary manually controlled boilers, but in this case, its operation will have to be controlled by turning the device on / off to obtain a comfortable temperature in the room.

Great option in operation of the gas boiler is the presence of a built-in thermostatic sensor. If it is not available, it is recommended to purchase and install a thermostat so as not to waste energy and not overload the heating equipment.

The most convenient to use are floor boilers with automatic control. They do not require constant monitoring, while working safely and efficiently

The rules for adjusting the gas equipment automation unit are given in the article, the contents of which we advise you to read.

Acceptable design and dimensions

The dimensions of the boiler and its appearance are selected based on the area of the furnace room. Manufacturers offer a large selection of a wide variety of models of various designs and dimensions, which allows you to choose the device that is most suitable for a particular room.

It is important to remember that the boiler and additional equipment must be provided with completely free access.

The best models of gas boilers are presented in the article, which details the selection criteria, provides all the arguments on the basis of which you can make a balanced purchase.

Differences between an atmospheric gas boiler and a turbocharged one

Gas equipment, on the basis of which autonomous heating systems are built, is represented on the market by two options. The consumer can now purchase either a turbocharged or atmospheric (chimney) type.

The first group is equipped with a coaxial chimney, as well as a closed combustion chamber. Due to the minimum requirements for the ventilation system, it can be installed in apartment buildings. A traditional chimney is required to operate an atmospheric boiler. It is installed in low-rise private buildings.

The main differences between atmospheric and turbocharged types of boilers are in the design and principle of operation of the gas burner.

The main differences between atmospheric and turbocharged types of boilers are in the design and principle of operation of the gas burner.

In the main working unit of an atmospheric gas boiler, which is of an open type, air is taken from the room.The combustion process with the traditional release of its products takes place openly, therefore, for the installation of atmospheric equipment, a boiler room is equipped, separated from the residential area of the house.

An atmospheric type burner is a set of small nozzles through which gas passes under pressure. During combustion, the right amount of air enters the chamber, which intensifies the flame. As a result, during the heating of water in the system, the atmospheric boiler spends a minimum of fuel. Smoke is removed through a stainless steel chimney.

An open burner burns oxygen from the air mass of the boiler room during operation. Even if we take into account that this is a priori non-residential premises, a powerful ventilation device is required. After all, a constant supply of air is required for normal combustion.

The turbocharged boiler has a closed combustion chamber. Oxygen is driven into the chambers through a coaxial pipe by a fan. Equipment can be installed anywhere.

A feature of the wall-mounted turbocharged boiler is that the combustion chamber is made of copper, which limits the power to 35 kW. In floor boilers, it is made of cast iron, which can significantly increase power.

Atmospheric varieties of gas boilers need to be connected to a standard chimney with a vertical channel. Turbocharged can be equipped with a coaxial chimney - it is easier and cheaper to install