- Types of gas convectors and their advantages

- Installation of a gas stove and convectors

- Principle of operation

- Benefits of using gas convectors

- Manufacturers

- Operating tips

- How to choose a gas convector

- Types of gas convectors

- Calculation of the amount of gas consumed

- Classification

- By location

- By fuel source

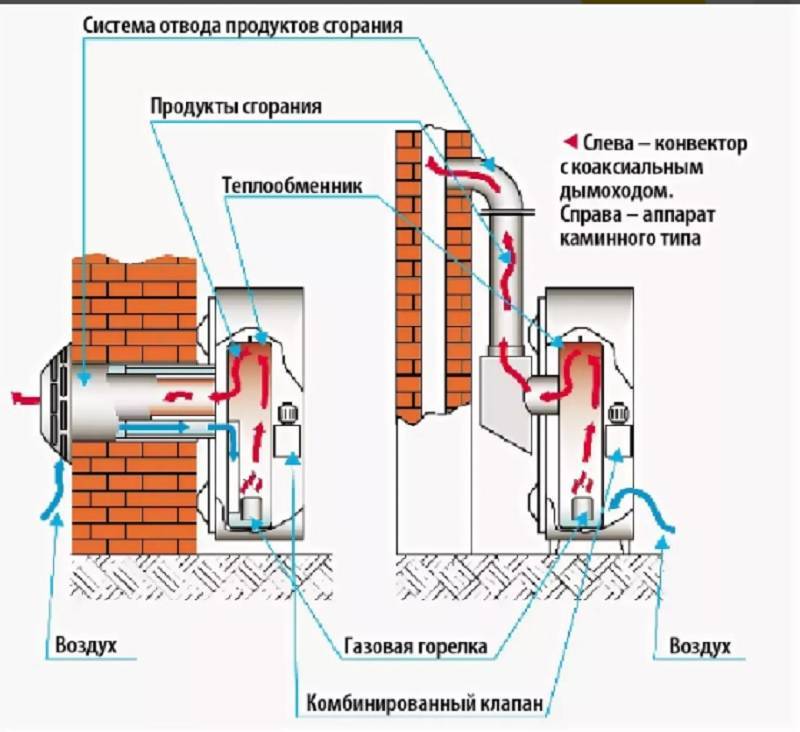

- Type of combustion chamber

- According to the material of the heat exchanger

- By launch method

- Availability of additional features

- Varieties of convectors

- Main criteria for choosing a convector

- Features of electrical devices

Types of gas convectors and their advantages

The heaters differ only in the presence or absence of a fan that blows over the combustion chamber, and in design.

Gas heaters vary greatly in terms of power. This factor is influenced by the volume of the heated room.

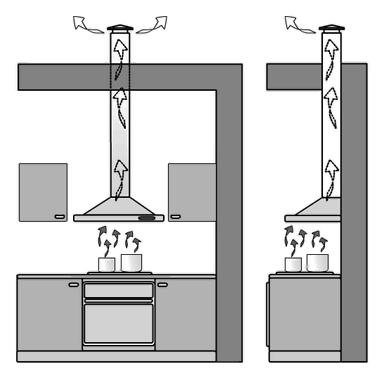

Scheme of installation of a gas convector.

Many sellers of convectors often argue in favor of their own product, declaring its compactness. At the same time, doubts immediately arise, since the convector looks more like a large fireplace than a miniature heating device.

Another indicator is the relatively low cost of production, which, of course, can also be argued with. After all, this price is much higher for a standard convector used for a conventional heating complex.

Among the real and worthy advantages of a gas convector, it is worth highlighting the absence of water as a heat carrier in the heating complex. This represents a great level of convenience in the winter, when you can not be afraid of freezing water in the pipes (this is beneficial to summer residents). Nevertheless, such changes in the temperature regime adversely affect the interior decoration of the house, there is a risk of dampness and frost, which can ruin the furniture. Accordingly, it is better not to use convectors in houses for permanent residence (even summer cottages). Such devices are more useful in non-residential premises (sheds, workshops, garages).

In terms of environmental friendliness, some questions may also arise. The advantage is that the convector does not absorb oxygen. The temperature of the heating device (boiler or convector) should not exceed 60 degrees. Otherwise, the process of dust decomposition will begin, and you will have to forget about environmental friendliness.

However, can a gas convector maintain such a rather low temperature? If the convector performs a similar function, then this is quite important, otherwise it is also better to use it in non-residential premises

Installation of a gas stove and convectors

It is forbidden to install the convector at a distance of less than 4 meters from open sources of fire, including a gas stove. The hose suitable for the convector must have a dielectric insert, this will prevent a fire in the event of a short circuit in the wiring in a wooden house.

An important factor is the grounding of sockets located near the gas stove and convectors, although in a wooden house they must be grounded a priori.

There are three types of supply hoses that are allowed to a gas stove in a wooden house, namely:

- Rubber fabric - its plus is that it does not conduct electric current, but it is more susceptible to mechanical damage compared to analogues;

- Metal sleeve - when using it, a dielectric insert is necessarily inserted from the gas stove to the main, and otherwise it has the best performance among analogues. In addition, it is recommended by the latest approved standards. Its only disadvantage is the price, it bites;

- Rubber with a metal braid - it is more able to withstand severe shocks, and also, thanks to the rubber core, does not conduct current.

When buying a metal hose, you should pay attention to its coating, some manufacturers oriented to other markets, with other standards, use yellow insulation, which does not fulfill its main functions. Always ask for supporting documents when purchasing, and keep them in a safe place

Principle of operation

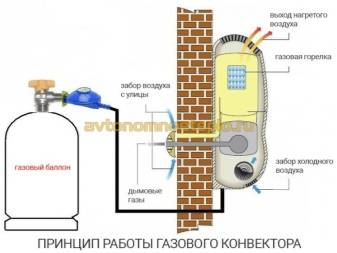

The basic principle of operation of a bottled fuel gas convector is a process of natural heat exchange, in which heated air rises and cold air descends to the floor surface. The continuity of this movement allows you to maintain the desired temperature in the room. In addition, in addition to natural convection, artificial injection of air masses can be additionally used. In this case, heat transfer is accelerated, the air heats up faster.

In fact, the whole process of equipment operation is reduced to the following points.

- The gas goes to the burner.

- Cold air enters the technological openings on the body - air intakes.

- Passing through the device, the air masses heat up, enter the space of the room, rise and circulate further.

- Combustion products are discharged through a coaxial chimney outside the premises.

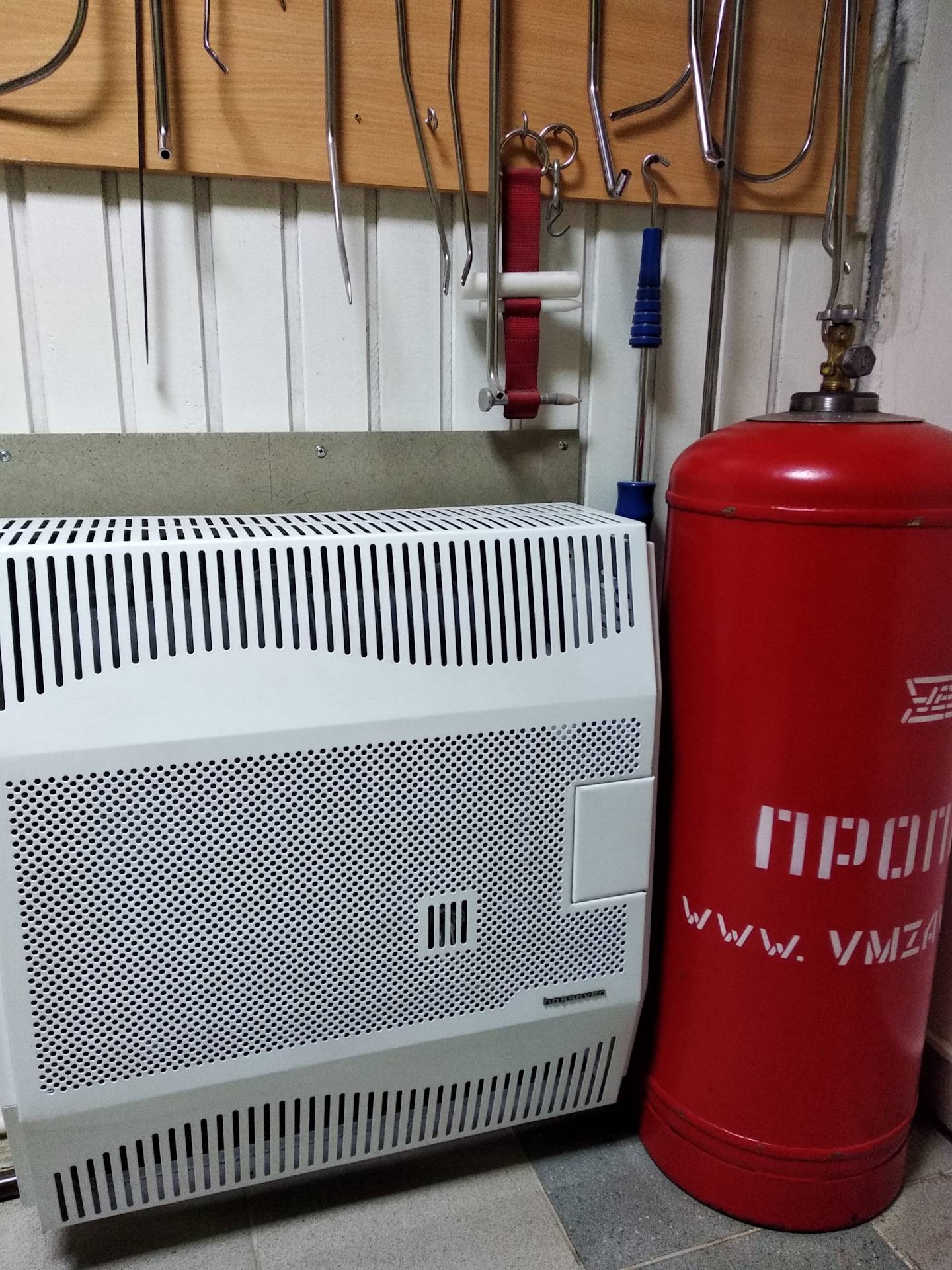

Gas convectors with balloon connection do not require access to main communications. In this case, the main source of fuel supply to the combustion chamber is the tank in which the injected propane is under pressure. In addition to conventional cylinders, options with liquefied gas can be used - in this case, the duration of the device at one gas station will increase by 2-3 times.

Models of gas convectors can be wall-mounted or floor-mounted. The first group of devices is mounted on a rigid connection to the surface of the walls in a vertical position, without moving during operation. Floor devices can be mobile, equipped with rollers for moving, or stationary.

The design of a gas convector with a balloon type of fuel contains the following components:

- a burner with a fuse used to burn fuel in a closed chamber;

- heat exchange element;

- gas trap and chimney pipe;

- thermal relay to maintain the set temperature;

- automatic equipment that cuts off the fuel supply in the event of a malfunction of the device;

- housing with technological holes to ensure heat exchange processes.

An optional air blower is installed. In addition, inside mobile-type equipment, you can find a compartment for installing a gas cylinder of a certain size. In "home" stationary convectors, a connection is used through flexible hoses for gas with the removal of a cylinder into a special outdoor cabinet, as required by fire safety rules.

Benefits of using gas convectors

Almost always, the decision to install a gas convector is explained by the advantages of such equipment. They are as follows:

- Economical operation with low operating costs;

- Use of the cheapest fuel today - natural gas;

- Lack of costs for the installation of a water heating system;

- Autonomous mode of operation combined with a simple and convenient control system;

- Ability to work both when connected to the gas line, and from the cylinder.

The disadvantages of using gas convectors include the need to obtain permission to connect to the main. In addition, sufficiently powerful equipment models are of considerable size. Another disadvantage is the need for a separate gas supply, and carried out outside the building, to each convector when using several heaters.

Manufacturers

Gas convectors are produced both by foreign manufacturers: Alpine Air (Turkey), Hosseven (Turkey), Emax (Hungary), FEG (China), Karma (Italy), GorenjeMora (Slovenia), Ferrad (Turkey), and domestic: TMT (Russia ), AKOG (Russia).

Consider the technical characteristics of gas convectors using the example of the two most popular brands: GorenjeMora (Slovenia) and Demrad (Turkey).

| Manufacturer | Characteristic |

|---|---|

| GorenjeMora (Slovenia) | This manufacturer is distinguished by the fact that its devices are equipped with steel heat exchangers. Both natural and liquefied gas can be used as fuel. They do not require electricity to work, the principle of operation is based on natural convection.The air from the room, passing through the convector through special holes, heats up and gets back into the room. |

| Ferrad (Turkey) | Convectors manufactured by Demrad can be used for heating both industrial and residential premises. There are modifications with natural and forced convection. The power of the devices is 2-5 kW. Convectors are characterized by rapid heating of the room, beautiful design, the ability to smoothly adjust the temperature, and quiet operation of the device. The fact that the heat exchanger is made of cast iron indicates a rather long service life (several decades). The convectors of this manufacturer are easily connected to the gas supply system in Russia, because they do not require high gas pressure to work. |

Thus, a gas convector is a good option for arranging a heating system for a house or apartment.

Operating tips

When operating gas convectors with cylinder connection, it is necessary to monitor the concentration of carbon monoxide in the room

This is especially important in the case of using models of an autonomous type that do not have a separate chimney. They are not recommended for use in rooms less than 60 square meters.

m, as well as in residential buildings due to the difficulties in ensuring fire safety and emissions of combustion products directly into the atmosphere. If it is still necessary to use the device, care must be taken to ensure a constant supply of fresh air.

For gas cylinder convectors with a chimney, correct installation is of great importance. In order for the equipment to work in the normal mode, it needs sealing of all docking points. A test run is also mandatory.It is carried out according to the following scheme.

- The docking nodes of the system along its entire length are covered with foamed soapy water.

- The valve responsible for supplying fuel opens. The appearance of bubbles at the joints indicates that the connection is not tight - there is a leak. If it is found, the violation must be corrected. If there are no signs of gas release into the atmosphere, you can proceed to the next stage.

- The convector turns on. At the first start, you need to fix the button for 60 seconds, and then wait for the gas to enter the combustion chamber.

- The burner ignites. You can start setting up the operation of the device, while adjusting the desired parameters.

A faint smell of burning in the first hours of using the device is the norm. To eliminate it, it will be enough to increase the air exchange in the room by simply opening the window. If an unpleasant odor persists for more than 2 days, it is imperative to contact the after-sales service.

About the gas convector, see the following video.

How to choose a gas convector

Are you planning to buy a gas convector for installation in a private house or in the country? Then we will help you make the right choice. First, let's look at the main types of these devices.

Types of gas convectors

Choose models with cast iron heat exchangers - they will last longer.

Consumers can choose from models with two types of heat exchangers - steel or cast iron. Steel convectors are characterized by an affordable price, but their service life is shorter than that of models with cast iron heat exchangers. If you want to purchase reliable and durable equipment, choose models with cast iron heat exchangers - they withstand thermal loads well and are characterized by corrosion resistance.

It should be noted that cast iron heat exchangers are also found in many heating boilers. Such boilers have a longer service life and resistance to rust formation.

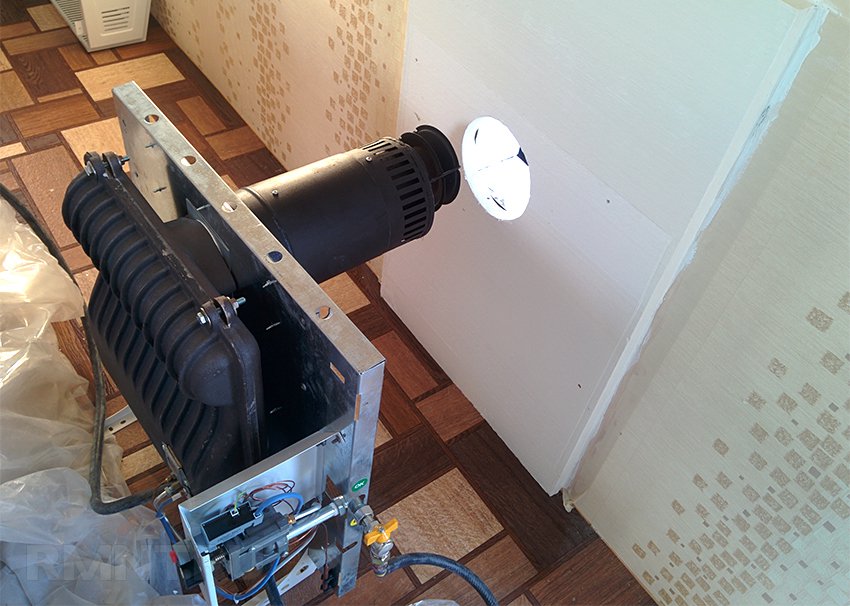

Gas convectors have open or closed combustion chambers. The former take air directly from the room, removing combustion products through a standard chimney. The organization of a good chimney leads to additional costs, so models with a closed combustion chamber are in greatest demand. They work with coaxial chimneys that exit directly through the wall next to (or on which) the heating devices themselves are installed.

Gas cylinders used for the operation of the device can be placed outdoors in special boxes.

Gas convectors differ in the type of fuel used. It can be natural or liquefied gas. The price of a gas convector on bottled gas is almost the same as the cost of a similar device on natural gas. Choose models that run on liquefied gas if you need to provide independent heating. To heat gasified buildings, you can use convectors running on natural gas.

Also, floor and wall models of gas convectors are presented at the choice of consumers. The former are most often characterized by higher power. In addition, universal models are on sale that can be installed on the floor or on the wall.

Calculation of the amount of gas consumed

Gas equipment is characterized by low gas consumption. The basic indicators for calculating consumption are the following parameters:

- 0.11 cu. m of main gas per 1 kW of thermal power;

- 0.09 kg of liquefied gas per 1 kW of thermal power.

Based on this, you can calculate how much gas this or that convector will consume. For example, a 5 kW model, designed for approximately 50 sq. m, burn 0.55 cubic meters. m of gas per hour of its work. A little more than 13 cubic meters will be released in one day. If we take into account that the equipment does not work around the clock, then the gas consumption will be less. Similarly, we make calculations with liquefied gas.

Choose gas convectors with some margin of power - so you can compensate for heat losses in the premises. Increasing the capacity of the equipment will have almost no effect on gas consumption.

Classification

At the moment, several types of gas heating equipment are produced, each has its own characteristics. Devices are usually classified into several categories.

By location

There are wall and floor models. The first are characterized by ease of execution, compact size, low weight. In addition, the standard place for their installation is under the window, which creates an additional thermal curtain. But, you need to understand that limited loads are allowed on the wall, therefore, power restrictions apply for such products.

Floor models of gas equipment are suitable for heating large areas. Units of this type easily produce hundreds and even thousands of kilowatts of thermal energy. However, they require a seriously equipped base.

By fuel source

Many users believe that only natural gas can be used as a fuel. This is not entirely true.Naturally, it is initially assumed that the convector will be connected to the main pipeline, but a special adapter kit allows it to be easily converted to bottled gas.

The convector operating on propane has the following features.

- The cost of liquefied gas per 1 kW of energy will be similar to electricity. For this reason, this option is not particularly suitable if the main goal of installing the system is savings.

- A gas heater will be an excellent solution to the issue of heating if there are problems with the supply of electricity in a residential area or there is none at all.

- Strict requirements are imposed on systems operating on bottled gas. Of course, you can install them yourself, but in the absence of skills, it is better to seek help from qualified specialists.

Depending on the area and the availability of the necessary highways, one or another type is selected.

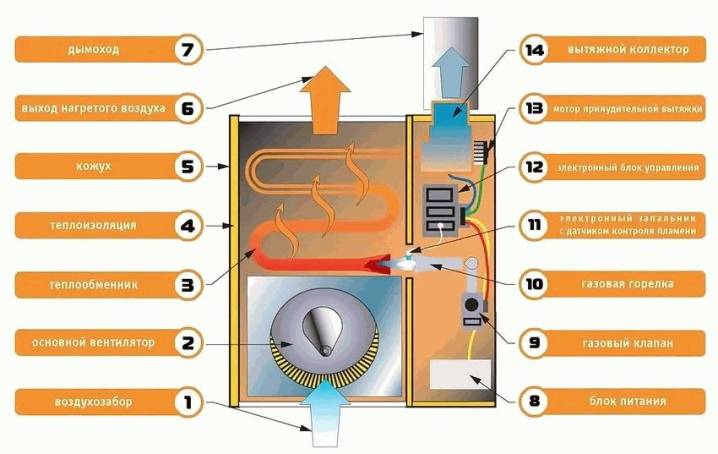

Type of combustion chamber

In a conventional convector, the principle of operation is similar to a stove: air is taken from the room and removed through a vertical chimney. Such a device is characterized by an obvious drawback: only good ventilation is capable of providing a constant flow of air, and you will have to work hard on arranging the chimney passing through the floors and roof.

Modern models have a closed combustion chamber. In this case, a special coaxial (pipe in pipe) chimney is connected to the heat exchanger. An internal cavity is used to remove exhaust gases, and air is taken in through the annulus.

To maintain draft in such devices, there is a fan built into the chimney. The equipment is considered to be volatile, so noise may be heard during operation.At the same time, models with a closed chamber are safer, more environmentally friendly and easier to install.

According to the material of the heat exchanger

During operation, the heat exchanger is exposed to large temperature effects, and its failure can lead to more serious problems. It is recommended to choose devices with a cast iron heat exchanger. This material has a specific structure that provides uniform heating and a service life of about 50 years. However, this option will be expensive, and the unit will weigh more.

Cheaper models are equipped with a steel heat exchanger. The service life of a quality metal combustion chamber is usually within 10 years.

By launch method

There are two types of burner ignition mechanism: electronic and piezoelectric. In the first case, spark discharges are generated by the electronic board. The advantage of this circuit is simplicity and reliability, but it requires a battery that must be grounded.

The piezoelectric method is characterized by energy independence, but its use requires certain skills. This ignition option is preferable in cases where you want the heating system to be independent of electricity.

Availability of additional features

Some models of gas equipment have additional features. One of them is a built-in fan, thanks to which the heating is faster and more uniform. In addition, its task is to supply air to the heat exchanger housing, which is necessary to cool the system. This makes it easier to use the device and extend its service life.In particular, an integrated fan is preferred when the heat exchanger is integrated into the system for several hundred kilowatts.

Also, convectors can have a timer that allows you to set the time to turn on and off the heating. For example, the setting is carried out in such a way that the device starts heating the room an hour before the owners arrive home.

Varieties of convectors

Household convector heaters are divided into several types.

Heating method:

- Electric convectors. Air heating in the convection chamber is carried out with the help of heating elements.

- Gas convectors. They are heated by gas burners.

- Heat convectors for the home or heat guns. They differ from electric convectors in the presence of a fan that creates a directed air flow.

The choice of a heater is carried out taking into account the main parameters. These include power, dimensions, weight, inertia, temperature maintenance range

It is also worth paying attention to the presence of additional functions.

Main criteria for choosing a convector

The first thing you need to do before buying a gas convector is to find out the area of the room or house in which it will be installed. Tip: if the area is too large, then the best solution would be to purchase a boiler that also uses gas for its work.

A gas convector is best used for a private house or an outbuilding with a small total area. Also, this unit is suitable for rooms where the plan does not provide for a place for a boiler room.An important criterion for choosing a convector is how often people are in the house. For permanent residence, it is preferable to choose a boiler, but for giving it is a gas convector that will be the ideal solution.

In addition, this heater has another advantage - when used as a backup source of heat, it has no equal. The issue of fuel consumption and the resulting heat is also important during the selection and purchase of the unit.

It is important to remember that most often a simple formula works - for 1 kW of energy / 10 m2 of area. The height of the ceilings in this case should be no more than 2 meters.

It should be remembered that another 1 kW should be added to the resulting power. It will compensate for the heat loss that is inevitable during the operation of the dwelling. A compact device - a thermostat - will help to avoid high temperatures in the room or gas costs. In most models, it is already built into the case, but sometimes it will need to be specially purchased and installed.

When choosing a heat exchanger material, it is important to remember that the most durable are devices whose combustion chamber is made of cast iron. An additional advantage of this material is that it allows to achieve uniform heating and has a high efficiency.

If we talk about the shortcomings, then it is important to remember that cast iron has a large mass, respectively, such a gas convector can not be installed in every room. The cost of cast iron products is higher than steel products, and power indicators do not exceed 5 kW.

Features of electrical devices

Electric convectors for heating a private house are the most common.They are easy to design and install. The following parameters and features are distinguished:

Power. For a private house, electric convectors with a power of 0.4 to 3.5 kW are used. When choosing a heater, it is necessary to correctly assess the requirement for this parameter. If there is no heating in the room, it is recommended that the calculation be made based on the norm of 1 kW for every 10 square meters. m area. When there is heating, but does not create comfortable conditions, you can reduce the required power to 0.4-0.5 kW per 10 square meters. m area. For regions with cold climates, it is worth taking care of a power reserve of 15-25%.

Installation method - wall-mounted, floor-mounted, floor-mounted option. Universal devices are produced for wall and floor installation, as well as small-sized devices built into the plinth. The wall heater does not take up useful space in the room, which makes it indispensable in small rooms. The advantage of the floor convector is mobility - it can be easily rearranged and moved. Such devices are convenient for a country or country house.

If the main focus is on design, then built-in devices are most suitable.

Heater type. The heating rate and the reliability of the entire apparatus depend on it.

The following varieties are possible:

Needle heating element. This is a plate with a chrome or nickel thread. The main disadvantage of the heater is the lack of protection against moisture, and therefore it is used only in rooms with dry air. It has the lowest cost, but also a reduced service life.

Tubular heater. It is a steel tube with a nichrome helix. The cavity of the tube is filled with a special powder.The heater is not afraid of humid air and is able to work in economical mode. The main disadvantage is the noise when starting the device. Such a device is optimal for a wooden country house or a modest frame private house, because it is affordable and relatively durable.

monolithic type. This is the most reliable heater with high efficiency. Only the increased cost limits its use.

Dimensions. They depend on the type of convector. The minimum size of wall models is 40x40 cm. The average height of the device is 50-55 cm. When choosing according to thickness, it should be remembered that increasing it gives an increase in heat transfer.

The form. Electric convectors are available in square, rectangular, oval and round designs. The choice is based only on the features of the interior design.

Temperature regulator. Its task is to maintain the temperature for a long time. Convectors can have the following regulators:

Mechanical. It provides step adjustment with an accuracy of 2-3 degrees. Advantages - low cost and resistance to power surges. The last advantage allows you to safely use the regulator in rural areas. Cons - the fragility and complexity of the tuning system.

Electronic. Such a regulator maintains the temperature with an accuracy of 0.1-0.2 degrees. In addition, it allows you to set the temporary operation mode of the equipment, which makes it possible to save electricity. The disadvantage is that it is afraid of sudden power surges.

All electrical devices must be properly protected. First of all, the devices are equipped with protection against overheating. The housing must have a certain tightness against water and dust.The minimum acceptable security class is IP24. The RCD system must protect against electric shock. Modern models are equipped with a sensor that automatically turns off the equipment when it falls and overturns.