- Properties of gas boilers

- What are wall-mounted double-circuit gas boilers

- Device and principle of operation

- The principle of operation of a double-circuit gas boiler

- Hot water operation

- Gas bypass selection options

- Combustion chamber type

- Dimensions and placement

- Heat exchanger configuration

- Power

- No. 9 - Hyer Falco L1P20-F21

- The structure of the gas heating system

- Installation of units

- No. 2 - Proterm Panther 12 KTZ

- What to look for when choosing

- Boiler gas single-circuit floor

- Advantages and disadvantages of equipment

- Pros and cons of single-circuit units

- Advantages and disadvantages of double-circuit boilers

Properties of gas boilers

Unfortunately, it is quite difficult to describe all the nuances of choosing equipment for space heating in one article. Consider the main characteristics of gas boilers offered by various manufacturers in our country. In the previous paragraphs, we found out that floor fixtures are more often used in private houses, and wall fixtures in apartments.

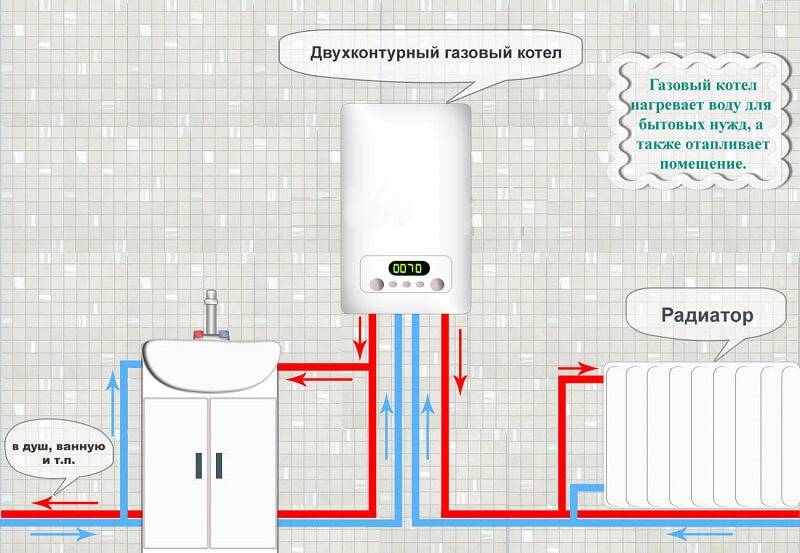

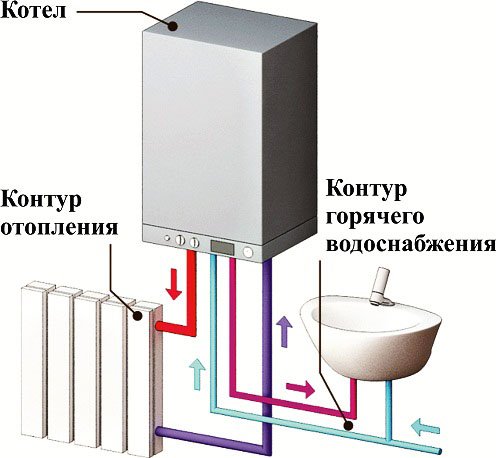

Now a few words about contours. How it works? The equipment heats water and delivers it to all rooms in a closed circle. The heat remains in the rooms, and the cooled liquid returns to the boiler. This is the principle of a single-circuit device.If you also need to heat water used for other domestic needs, then you should purchase a more sophisticated device equipped with two separate heating cycles.

Double-circuit boilers are more popular, as they free up space from other heating devices (boiler) and operate in several modes

When choosing such equipment, it is important to take into account not only the rated power, but also the losses for heating running water. Most often, experts focus on an indicator of 11 liters per minute

What are wall-mounted double-circuit gas boilers

Modern mounted double-circuit boilers have an excellent design, a minimum of communications around them and operate almost silently, so they can be installed in any room that meets the requirements.

Modern mounted double-circuit boilers have an excellent design, a minimum of communications around them and operate almost silently, so they can be installed in any room that meets the requirements.

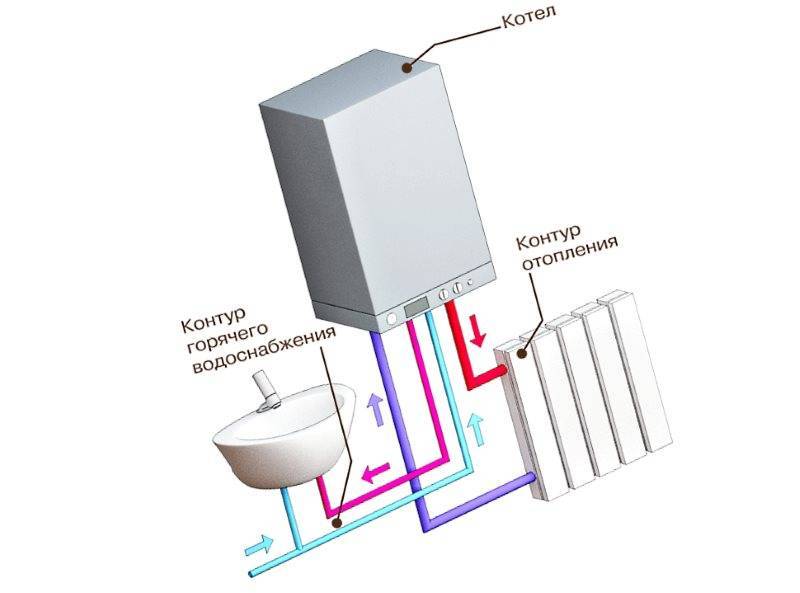

Gas hinged double-circuit models with the same dimensions and heating technical characteristics combine the functionality of two devices at once - the boiler itself and a flow-through (less often storage) water heater. The heat carrier from the heating circuit in double-circuit models does not mix with the sanitary water of the hot water circuit (DHW).

Another important point is the number of people living in the house, or rather the number of points of simultaneous consumption of hot water. Most double-circuit models work on the principle of DHW priority, i.e. when the point of consumption opens, heating the heating circuit. Less often, usually in more expensive models, where the distribution of performance is implemented using a three-way valve, the heating of the heating circuit does not stop completely, but the performance is still reduced.

In practice, this means that if several hot water consumption points are used at the same time, the capacity of the DHW circuit may not be enough, not to mention the heating circuit. Therefore, the total number of rooms with hot water consumption points (bathroom, guest bathroom, kitchen, etc.) should not exceed three.

Device and principle of operation

A clear principle of operation of double-circuit boilers with priority hot water supply (DHW).

A clear principle of operation of double-circuit boilers with priority hot water supply (DHW).

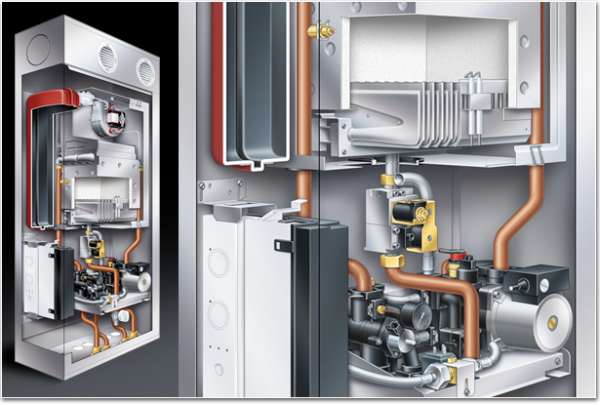

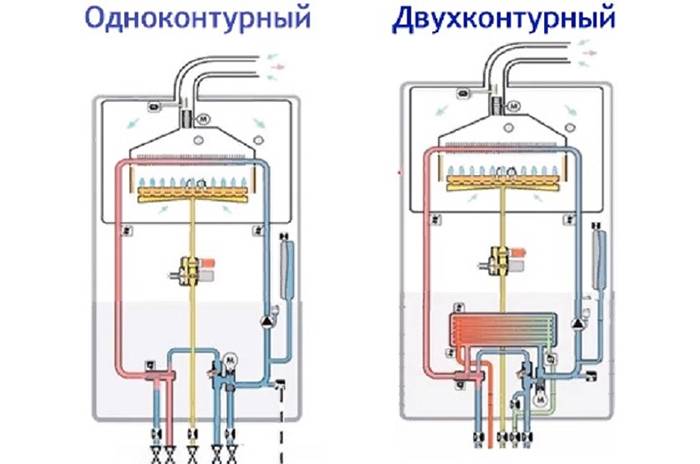

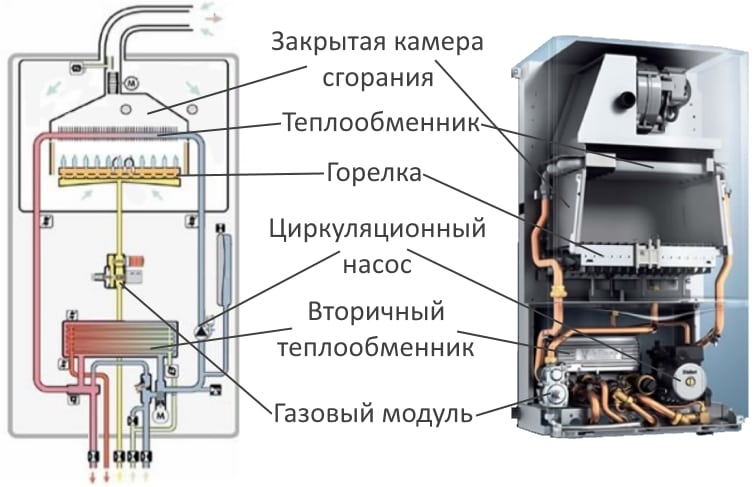

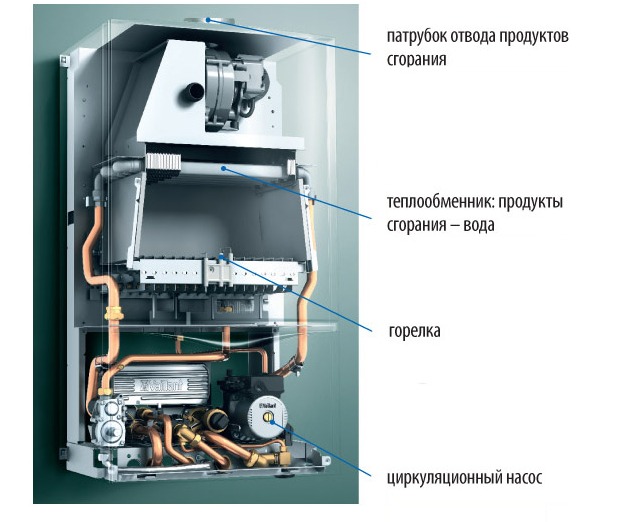

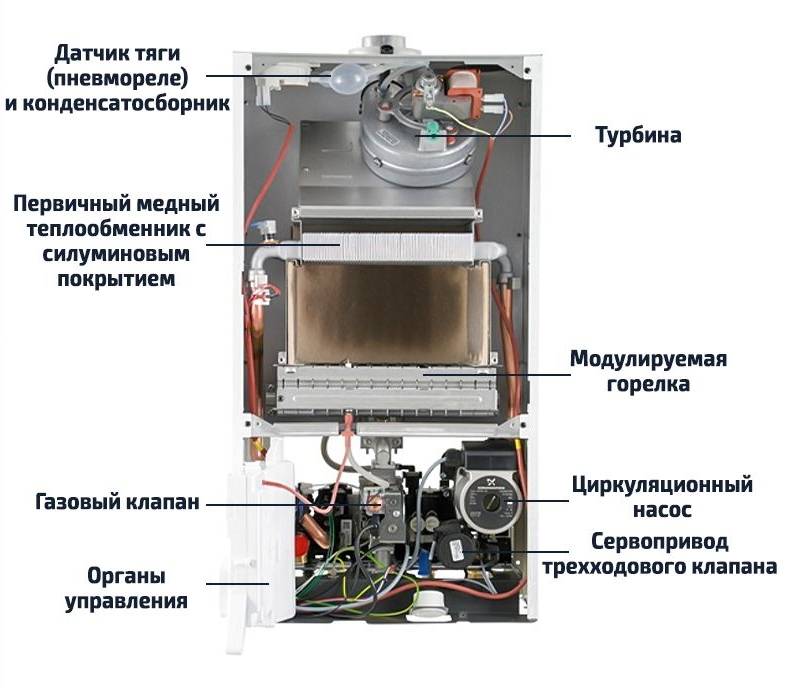

Double-circuit wall-mounted boilers differ from single-circuit only in the presence of an additional heat exchanger and the organs for distributing performance between the circuits. The technical device may vary from model to model, but the standard design is simple and clear: burner, which is supplied with gas and its igniters → primary heat exchanger, inside which the heat carrier of the heating circuit is located and the secondary heat exchanger, inside which the sanitary water of the DHW circuit circulates → product removal system combustion in the chimney.

All known and widespread models are already equipped from the factory with all the elements and assemblies necessary for the heating system: an expansion tank, a circulation pump, an automatic air vent, a safety valve, a pressure gauge, a set of sensors, etc. This means that for a standard heating scheme, it is enough just to connect the supply and return lines to the boiler, as well as the source of water for the DHW circuit (eg water supply).

For a visual understanding of the principle of operation of two-loop models, let's consider the functionality of each loop separately:

- heating - the basic circuit in which the coolant continuously circulates, heating up in the heat exchanger and giving off heat through radiators in heated rooms;

- water heating - is activated only when a hot water consumption point is opened, redirects all or a certain part of the heating circuit coolant to water heating.

After closing the consumption tap, the boiler switches back to the heating circuit and heats it up if the coolant has cooled down, or goes into standby mode (background heating) if everything is in order with the temperature.

Traditional double-circuit boilers are always characterized by a delay in the supply of already heated water (from 5 to 15 seconds), but there are models without such a delay, with a built-in boiler, operating on the principle of a storage heater, which we will talk about when describing the selection criteria. In any case, there is also a delay in the supply of hot water, independent of the boiler, due to the length of the pipeline between the boiler and the point of consumption in which the cooled water is located.

The device is based on the example of the well-known double-circuit BAXI ECO-4s 24F: compact classic layout, optimal materials, all modules are moved down for convenience.

The device is based on the example of the well-known double-circuit BAXI ECO-4s 24F: compact classic layout, optimal materials, all modules are moved down for convenience.

The principle of operation of a double-circuit gas boiler

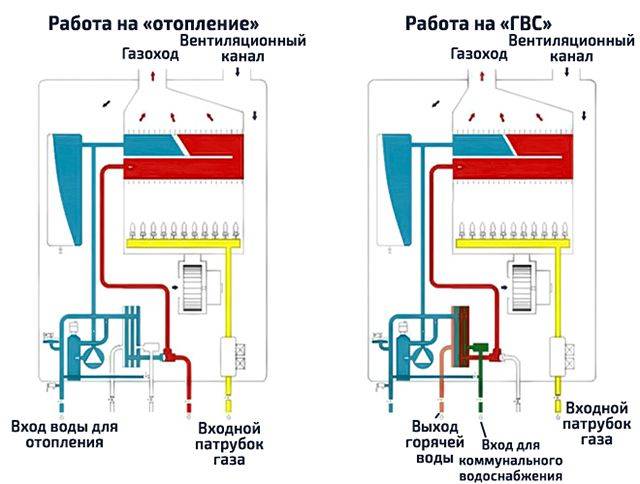

Now we will begin to analyze the principle of operation of a gas double-circuit boiler. We found out the purpose of individual nodes and modules, now this knowledge will help us understand how all this equipment works. We will consider the principle of operation in two modes:

- In heating mode;

- In hot water generation mode.

In heating mode, the boiler provides your home with heat.

Immediately, we note the fact that operation in two modes is immediately impossible - for this, double-circuit boilers have a three-way valve that directs part of the coolant to the DHW circuit. Let's look at the principle of operation during heating, and then find out how the technique works in hot water mode.

In heating mode, a double-circuit boiler works in the same way as the most common instantaneous heater. When first turned on, the burner works for a rather long time, raising the temperature in the heating circuit to the set point. As soon as the required temperature is reached, the gas supply will turn off. If an air temperature sensor is installed in the house, then the automation will take into account its readings.

The operation of a gas burner in double-circuit boilers can also be affected by weather-dependent automation that controls the temperature of the outside air.

The heat from the operating burner heats the coolant, which is forced through the heating system. The three-way valve is in such a position to ensure the normal passage of water through the main heat exchanger. Combustion products are removed in two ways - independently or with the help of a special fan located in the upper part of the double-circuit boiler. The DHW system is in the off state.

Hot water operation

As for the hot water circuit, it starts at the moment when we turn the handle of the water tap. The appeared current of water leads to the operation of a three-way valve, which turns off the heating system.At the same time, the gas burner is ignited (if it was turned off at that time). After a few seconds, hot water starts flowing from the faucet.

When switching to hot water mode, the heating circuit is completely switched off.

Let's look at the principle of operation of the DHW circuit. As we have already said, turning it on leads to the shutdown of the heating operation - only one thing can work here, either the hot water supply or the heating system. It's all controlled by a three-way valve.

It directs part of the hot coolant to the secondary heat exchanger - note that there is no flame on the secondary. Under the action of the coolant, the heat exchanger begins to heat the water flowing through it

The scheme is somewhat complicated, since a small circle of coolant circulation is involved here. This principle of operation cannot be called the most optimal, but double-circuit gas boilers with separate heat exchangers can boast of normal maintainability. What are the features of boilers with combined heat exchangers?

- A simpler design;

- High probability of scale formation;

- Higher efficiency for DHW.

As we can see, the disadvantages are closely intertwined with the advantages, but separate heat exchangers are valued more. The design is somewhat more complicated, but there is no scale here.

Please note that at the time of DHW operation, the flow of coolant through the heating circuit stops. That is, its long-term operation can disrupt the heat balance in the premises.

As soon as we close the tap, the three-way valve is activated, and the double-circuit boiler goes into standby mode (or the heating of the slightly cooled coolant immediately turns on).In this mode, the equipment will be until we open the tap again. The performance of some models reaches up to 15-17 l / min, which depends on the power of the boilers used.

Having dealt with the principle of operation of a gas double-circuit boiler, you will be able to understand the purpose of individual components and even be able to independently understand the issues of repair. At first glance, the device seems very complicated, and the dense internal layout commands respect - after all, the developers managed to create an almost perfect heating equipment. Double-circuit boilers from companies such as Vaillant. are actively used for heating buildings for various purposes and for generating hot water, replacing two devices at once. And their compactness allows you to save space and get rid of the need to purchase a floor boiler.

Gas bypass selection options

Despite the similar principle of operation, different models differ in a considerable number of fundamental parameters.

Combustion chamber type

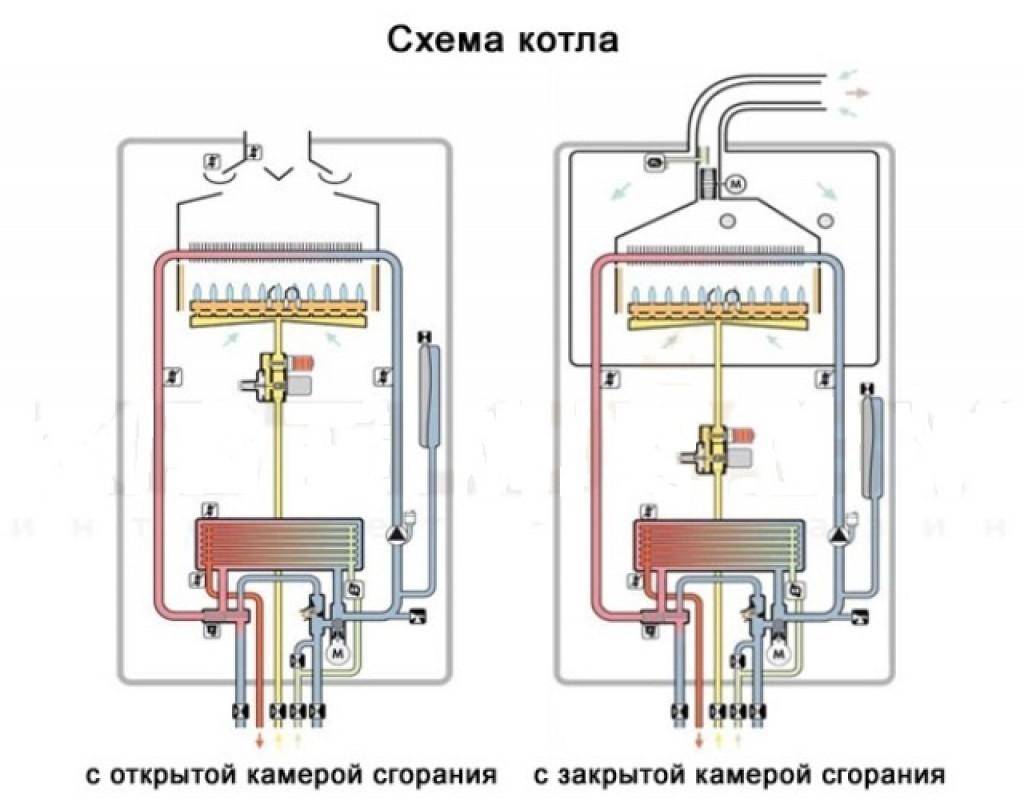

According to the type of combustion chambers, household gas heaters are divided into two types:

- with an open combustion chamber (atmospheric);

- with a closed combustion chamber (with forced air injection).

In the first case, the air necessary for the combustion of domestic gas is taken directly from the room in which the boiler is located. In the lower part of the combustion chamber, special holes are made for the inflow of fresh air.

Having participated in the combustion process, it, along with other decay products, enters the ventilation duct and exits through the chimney to the street. The construction of a chimney with good draft is a must for this type of boiler.

In the room where the boiler with an open combustion chamber is installed, there must be good ventilation, regardless of whether it is a kitchen or a boiler room.

In boilers with a closed combustion chamber, air is sucked in from the street with the help of suction fans, and the gaseous products of combustion are removed there by force. For such boilers, special coaxial chimneys are used. Exhaust gases are emitted along the inner contour, and fresh air is taken in from the outer one.

Expert opinion

Torsunov Pavel Maksimovich

Boilers with a closed combustion chamber are indispensable in cases where the construction of a full-fledged chimney with good draft is impossible. This type is relevant even for city apartments in old houses, when there is no connection to the central hot water system.

Dimensions and placement

All gas double-circuit valves are divided into two types according to dimensions and type of fastening:

- Wall. The power of these devices usually does not exceed a certain limit - usually 50 - 60 kilowatts. The main trump card is compactness. Wall mounting practically does not take up usable area. You can place the device in the kitchen, providing a sufficient supply of ventilation in advance. Also, users of such devices are attracted by the aesthetics of execution - Italian and German products are distinguished by their elegant design. Wall-mounted boilers are suitable for use in houses up to 150 - 200 square meters, depending on the insulation and hot water consumption.

- Floor. These devices are usually placed in a boiler room - a special technical room. It is easier to organize forced ventilation in it, and a rather noisy boiler will not interfere.For large houses with an area of 400 - 500 squares, powerful units are used that require installation in the basement or in a separate extension.

What type of gas boiler is installed in your home?

OutdoorWall

Heat exchanger configuration

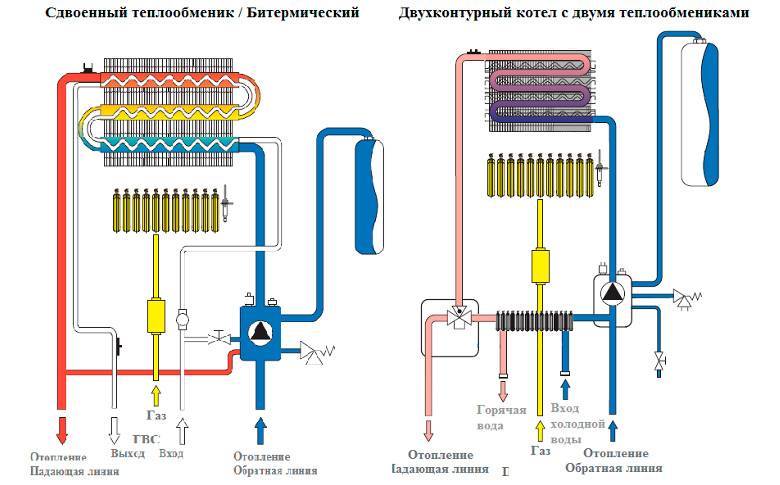

The primary and secondary heat exchangers can be two elements spaced apart in the housing during installation or combined into one structural unit.

The separate system contains a tubular primary heat exchanger equipped with a radiator to improve thermal conductivity, and a secondary plate heat exchanger that combines a small heating circuit with tap water pipes.

The bithermic system consists of two tube circuits, one of which is placed inside the other. Typically, the outer channel serves to circulate the coolant, and water flows through the inner channel for the DHW system.

| Andrey Musatov, sales assistant at a heat engineering store, Moscow: |

| The bithermic system is less common: firstly, it is structurally more complicated, and secondly, if scale and deposits form in the internal channel, dismantling and cleaning are more difficult. For boilers with a separate arrangement of heat exchangers, the plate module is removed and cleaned quite easily. But bithermic boilers are more compact, and their efficiency is slightly higher. |

Power

The larger the area of \u200b\u200bthe house, the more powerful the boiler needs to be. At the same time, in a double-circuit unit, only about 30% of the power is spent on heating, the rest goes to the rapid heating of DHW water.When calculating the power, it is necessary to take into account not only the water consumption, but also the degree of insulation of walls, roofs and floors, as well as the degree of cold penetration through the windows.

Small wall-mounted boilers for small houses start at 8 kilowatts, and powerful units for installation in a boiler room can consume more than 150 kW.

No. 9 - Hyer Falco L1P20-F21

On the 9th place in the ranking is the double-circuit boiler Haier Falco L1P20-F21. It has a modulating burner. Power - 20 kW. The temperature is adjustable from 35 to 90 degrees. The expansion tank is designed for 6 liters. Dimensions - 70x40x32 cm. The pressure in the heating system is maintained up to 6 bar.

Advantages:

- protection provides shutdown in case of burner attenuation, overheating, excessive pressure in the circuit, blocking draft;

- two-layer design;

- reliable stainless steel burner;

- small dimensions for this class of devices;

- coaxial type chimney;

- the presence of a circulation pump equipped with a protective mechanism against jamming.

Minuses:

- comments on the location of the nozzles;

- lack of Russified information on the display.

All the shortcomings are covered by sufficient power and a large area of the heated room.

The structure of the gas heating system

Such a system implies:

- Boiler room. This is a room in which the AOGV outdoor gas boiler and a number of devices regulating the operation of the system are located directly. Depending on the complexity, the number of control devices may increase.

- pipeline. This communication makes it possible to move heated water to different rooms. Wiring can be hidden or open, depending on the project and the wishes of the customer.Sometimes the pipeline is also used as an element for installing a warm floor. Connection can be single-circuit or double-circuit. In the first case, as far as the distance from the boiler, the pipes will lose the set temperature regime, since the connection is obtained in series. The second option provides that the installation itself and the material will cost much more, but it will allow you to regulate the temperature of each room separately. In the same case, it is easy to organize and regulate the supply of hot water, regardless of the season.

- convectors. Or, speaking Russian, - ordinary batteries. With their help, you can increase the area of \u200b\u200bheat transfer.

As you can see, the pipeline and convectors are identical to the usual heating system of the apartment.

Installation of units

Floor-standing gas boilers for heating a private house should be installed and connected by specialists licensed for this type of activity. Most often, this is done by employees of the gas supply organization, but related to the service department. The same department will then be responsible for the maintenance of the unit.

Heating wiring around the house, installation of the boiler can be done by hand. But tie-in and connection should only be carried out by a licensed specialist. This condition is mandatory. Otherwise, the connection will be considered illegal and dangerous to others. The master does the installation on the basis of the scheme and the passport for the equipment. The same goes for the chimney. It must pass inspection and fire safety inspection.

- Before turning on the equipment for the first time, check the tightness of the pipe supply. This can be done by smearing the joint with soapy water.If bubbles appear, turn off the gas supply, ventilate the room and eliminate the leak.

- Do not expose the device to mechanical stress. The body of the gas equipment is not designed for shock.

- If you smell gas during operation, call the emergency service. Do not try to repair the damage yourself.

No. 2 - Proterm Panther 12 KTZ

In 2nd place, the TOP of the best models is occupied by the Protherm Panther 12 KTZ wall-mounted boiler. This double-circuit device has a power of 24 kW with adjustment from 10 kW. The rate of hot water supply to the water supply system reaches 11.6 l / min. There is an adjustable smoke exhaust fan. The body of the boiler is made of stainless steel.

Advantages of the boiler:

- increased service life;

- full security guarantee;

- high efficiency (up to 94 percent);

- attractive design;

- simple and convenient control system;

- silent operation;

- does not require frequent maintenance.

No significant deficiencies were found. A reliable control system and trouble-free operation puts the device among the leaders.

What to look for when choosing

Equipment with an open combustion chamber burns indoor oxygen, unlike devices with a closed combustion chamber.

All gas double-circuit boilers are divided into two categories - with an open and closed combustion chamber. An open combustion chamber provides for the combustion of gas fuel with the natural removal of combustion products through a classic chimney. Such boilers (atmospheric) are simpler in design and less prone to breakdowns. In addition, they have a low noise level.

Models with a closed combustion chamber are good because they do not require a chimney, and they can be installed in rooms without windows and ventilation shafts. The sealed combustion chamber provides for air intake from the outside of the building through a special double chimney. Through it, the removal of combustion products is carried out. A powerful variable-speed fan is responsible for air intake and smoke removal.

To install atmospheric double-circuit boilers, a chimney and a normal ventilated room are needed so that the device does not lack air. Models with a closed combustion chamber are installed in any premises, with the output of the coaxial chimney behind the nearest wall.

Consider another selection criterion - these are double or separate heat exchangers. The first option is cheaper, but it has significant drawbacks. The main disadvantage is that scale often occurs in a dual heat exchanger. Another negative feature is low maintainability. Models with separate heat exchangers are more intricate, but they are easy to repair and scale does not form in them, and their disadvantages are the low efficiency of the DHW circuit and a higher price.

Boilers with a dual heat exchanger, although cheaper, are less durable.

You also need to pay attention to the availability of condensing boilers for sale. They work on a similar principle, only they involve an additional system for extracting heat from the combustion products. Such boilers are characterized by higher efficiency and save gas fuel.

However, some experts are confident that an efficiency rate of over 100% is nothing more than a marketing ploy.

Such boilers are characterized by higher efficiency and save gas fuel. However, some experts are sure that an efficiency indicator of over 100% is nothing more than a marketing ploy.

Boiler gas single-circuit floor

This type of heating units is one of the most popular.

- Profitability. The cost of such a variant of equipment is much lower than analogues - no more than 20 thousand rubles. And if you still choose a Russian outdoor gas boiler, then the price will surprise you even more. In this case, the quality will be at the proper level. Don't forget about maintenance. Repair of a domestic unit will cost significantly less.

- Simple structure, easy to maintain. Easy to operate.

- Can heat large areas.

- Economical gas consumption.

The gas single-circuit floor boiler can be produced with a closed and open combustion chamber, with a steel or cast iron heat exchanger. There are automated models. The disadvantages include the fact that for the hot water system you will have to buy a separate water heating system.

So, we want to buy a floor gas boiler. Which to choose? Reviews recommend buying such a device in houses and apartments that have central hot water supply. Below we consider two-circuit systems.

Advantages and disadvantages of equipment

Both types of gas boilers are easy to operate, efficient and durable. And they also have an attractive appearance.

The design of each type of gas boiler is designed to meet the needs of various categories of users, which clearly demonstrates their advantages and disadvantages.And they also provide an opportunity to understand the differences between a single-circuit gas boiler and its double-circuit counterpart, helping a potential buyer make the right choice.

Pros and cons of single-circuit units

Such products are able to provide stable heating of premises of any size, number of storeys, remoteness from the heat exchanger.

And, in addition, single-circuit boilers:

- more reliable than their double-circuit counterparts, the design of which is more complex, which leads to a slightly larger number of breakdowns;

- easier to maintain, which is also caused by design features;

- cheaper.

An important advantage is that single-circuit units can become the basis for connecting other equipment. That will expand their functionality and increase the comfort of living.

You should always remember that if necessary, provide hot water in the premises, along with a single-circuit boiler, you will have to buy a storage boiler. And this will lead to significant additional costs. And a set of the listed equipment will take up a lot of space, which can be critical for small apartments.

Connecting storage boilers will provide the premises with hot water. Moreover, water will be supplied hot at any time, which is not always possible to achieve from double-circuit analogues.

In this type of equipment, in the absence of the need for hot water supply, there are no pronounced shortcomings. But otherwise, the lack of universality immediately affects. Which leads to the need to purchase an additional electric heater.

As a result, its joint operation with a single-circuit boiler leads to:

- high costs for the purchase, installation, maintenance;

- a limited amount of water for domestic needs - boilers are most often bought for sharing with single-circuit units, so the question may arise about the rational consumption of water, the volume of which depends on the storage capacity;

- greater load on the wiring.

The last drawback is relevant in cases where the house or apartment has old wiring or powerful electrical equipment is used in parallel. So, it may be necessary to upgrade the wiring and select a cable with a larger cross section.

You should also be aware that a set of a single-circuit boiler and a boiler takes up significantly more space than one double-circuit boiler. And with limited space, this can be a significant drawback.

Advantages and disadvantages of double-circuit boilers

Units that belong to the specified type with some restrictions, but are still capable of providing hot water to two systems at once (heating, hot water supply). They also take up less space than their boiler counterparts. As a result, double-circuit boilers are more convenient to use.

Both types of gas boilers are easy to operate, efficient and durable. And they have an attractive appearance.

In addition, the competitive struggle of manufacturers has led to the fact that the difference in the cost of both types of units is gradually leveled.

Therefore, today you can find a double-circuit boiler whose price exceeds that of a single-circuit product slightly. Which in some cases can also be considered an advantage.

If we talk about the disadvantages of double-circuit boilers, then the most important is the inability to instantly provide hot water of the same temperature to all points of water consumption in a house or apartment.

So, in their heat exchangers, the amount of water that is needed right now is heated. That is, the stock is not created. As a result, the water temperature may differ from what is expected or change during use. This happens when the pressure changes, for example, after opening / closing the second tap.

When using a double-circuit boiler, often the water temperature differs at two different points of water intake - hot water can be delivered to the desired point with a delay, and significant. Which is inconvenient and leads to additional costs

As for installation, the installation of double-circuit boilers is a more complicated procedure, especially at the design stage. Since you will have to follow the numerous recommendations of the manufacturer