- Top Producers

- Communication Compatibility

- Shapes and dimensions (size, weight)

- Bathroom types

- Negative sides of steel baths

- How to check the quality of a steel bath

- Stainless steel bathtubs

- Additional features of baths and the feasibility of their use

- How to choose the right bath: acrylic

- Product dimensions

- Selection rules

- Comparison of cast iron bathtubs from different manufacturers

- Negative sides

- Classification by material of manufacture

- Installing a cast iron bath

- Helpful Care Tips

Top Producers

In our country, cast-iron bathtubs are treated a little as obsolete, outdated products, but in Europe they are considered a premium class.

Here are 3 European firms whose cast iron baths you should pay attention to:

Roca (made in Italy). They produce more than 30 different models of different price segments - from inexpensive to elite. Relatively low price with consistently high quality. They also produce other sanitary ware as a set for bathrooms. On the market for almost 100 years.

Jacob Delafon (manufactured in France) also offer a decent number of models from economy to elite class. On the cast iron bath market since 1926. One of the world leaders in the production of sanitary ware. There are models of non-standard width - 90 cm.

Novial (Spain) is slightly less on the market than the previous 2 firms. They have been operating since 1967. The production of their baths is characterized by infrared firing, which guarantees a high-class enamel finish. They produce inexpensive standard models, models of the middle price segment and very expensive, elite ones, with pneumatic control, hydro and air massage, as well as other modern inventions for the convenience and pleasure of the user.

How to choose? Tips and advice from experts

How to choose a cast iron bath that will outlive you and delight your grandchildren? Here's what the experts advise:

Buy licensed products from global manufacturers

If they are too expensive for you, then pay attention to domestic and Chinese manufacturers. However, you have to be very careful with cast-iron bathrooms from China - there are a lot of fakes.

Be sure to ask for certificates before buying!

Consider the size of the room where you will install the bath. It is better to leave a small gap than to buy a bathtub larger than necessary. 1-2 cm can still be cut into the walls, but more - no.

Consider existing communications if you don’t want to waste time wiring new ones. It is easier to buy a bathroom of the same size as the one that stood before.

When buying a bathroom, consider the width of the doorway. If it is too narrow, you simply cannot bring it into the room.

Before accepting the goods, check them for mechanical defects. Take a close look at the enamel. Any defects during operation will grow.

Check whether the product is fully equipped with legs, handles and other additional devices you ordered. For example, is the screen suitable.

If you have uneven floors, then buy a bathtub with legs. It can be adjusted so that it does not collapse and stands straight.

Pay attention to the thickness of the bathroom enamel. It is desirable that it be at least 1-1.2 mm

For the elderly and families with small children, an additional anti-slip coating, the presence of handles and a headboard are important. Accessories for cast iron bathtubs

Accessories for cast iron bathtubs

Additional devices can be legs, handles (1, 2 or 4), head rollers, armrests. With regards to enamel coating, there can also be additions in the form of adding silver ions or applying an anti-slip coating for safety. Of course, cast-iron bathtubs can be equipped with hydromassage or aeromassage. This increases their cost and makes them truly elite. Installing a cast-iron bath

It is quite possible to install a cast-iron bath yourself. For this you will need: level; sealant; spanners; tube stopper; hacksaw for metal; plumbing cable.

Preparatory work before installation includes: leveling the floor, laying tiles on the walls and floor (this stage can be done after installation), prepare communications. You can proceed directly to the installation after the final drying of all surfaces.

Detailed instructions for installing a cast iron bath:

Turn the bathtub on its side upside down to the wall where it will stand.

Using rubber gaskets, install overflow and siphon.

Install the first two support legs. Turn the bathroom upside down, propping it up with something.

Level the remaining supports.

Fix the outlet-outlet in the overflow pipe, connect it well to the siphon. Gently cover the cracks with sealant

During the installation process, you will need an assistant, because. cast iron is a very heavy metal and it is not possible to cope with its transfer on your own.

You can see how the master's cast-iron bath is installed in the form

Communication Compatibility

Bath connection

Bath connection

One of the crucial factors that are always taken into account when choosing a cast-iron bath is the location and condition of the drain communications in the bathroom.

In the event that you are not going to completely change the piping in the room, it is best to be guided by the following considerations when choosing:

- the drain hole must match the connection point of the existing sewer pipes;

- the contours of the bath body should allow its installation, without dismantling the pipes;

- in some cases, you will have to make a pipe box.

In the case of a major overhaul, a new bathtub is first selected and installed, and only after that the pipes are laid out for it.

Shapes and dimensions (size, weight)

As noted above, cast iron baths are not encouraging with a variety of shapes. You can only buy:

rectangular;

oval.

Of course, these are the forms that are most often in demand by the consumer, but those who like square or corner baths will have to give up buying cast iron.

By type, such baths, like others, are divided into:

freestanding;

embedded.

On sale you can find cast iron bathtubs with dimensions:

width: 70, 75 and 80 cm;

length: 120-140 - sitting baths, 150-180 cm - standard baths;

the depth is usually 40-46 cm, minor deviations depend on the manufacturer.

The weight of cast iron bathtubs varies depending on the size. They weigh an average of 75 to 180 kg.

Bathroom types

When choosing the bathroom model you need, pay attention to such parameters as the size, color and configuration of the bathroom. Corner bath. corner bath

corner bath

corner bath

The small size of bathrooms is a problem that most people in our country have to face. Previously, this inconvenience had to be endured, but now even a very cramped room can be comfortable and cozy. After all, modern bathrooms still exist:

- corner;

- sedentary;

- triangular;

- in the shape of a circle.

Corner bathtubs are simply a great solution for most of the standard bathrooms in our country. They allow you to save a lot of scarce space. Now on the market corner bathrooms are:

- triangular;

- asymmetric;

- trapezoidal;

- one corner can be rounded or bevelled.

A very fashionable novelty in our plumbing market is a corner jacuzzi bath.

Sit-down baths are ideal for both the elderly and people with disabilities. This is an analogue of a wooden barrel in antiquity! Such baths are just a godsend for pregnant women, for people with a weak heart and for those who find it difficult to raise their legs due to illness. Sometimes these bathrooms are equipped with hydromassage devices.

Asymmetric bathtubs are gaining more and more popularity. The choice of the shape and size of such bathtubs is limited only by financial possibilities. Today there are oval, round and double bathrooms. A novelty - a bath in the form of a hammock.

Separately, it is worth highlighting the Jacuzzi baths. Jacuzzi is a bath that is equipped with a special device for hydromassage.

Until recently, it was believed that only wealthy people could afford the installation of a jacuzzi bath.Modern technologies make this luxury more accessible, allowing everyone to experience this water bliss at home.

Negative sides of steel baths

The disadvantages of steel baths are no less than the advantages, but most of them can be eliminated on their own, with improvised means:

- Rapid cooling of water. Steel bowls do not hold heat well - this is one of the main drawbacks. But they heat up quickly, so to take a shower we do not have to put our feet on a cold surface.

- Threat of tipping over. Having unsuccessfully placed in the bathroom and violating its stability, we risk falling with it.

- gravity deformation. Under a massive person or object, the bath sags, which leads to cracking of the enamel.

- Low sound absorption. The thin walls of the bathtub ring under the stream of water, so it will not work quietly to dial it.

- Rust on chips. Cast iron oxidizes much less than steel. Therefore, bowls made of this metal in places where the enamel has broken off almost do not rust. Steel containers do not have such a dignity, which is why they become unusable much faster.

Fortunately, improving the performance of a bathtub is not difficult.

The first thing to do when installing the bowl is to take care of its secure fixation. The standard "legs" that come with the kit are usually not enough. You can build wide supports of red brick (silicate does not tolerate moisture well) - this is the best solution. In order not to damage the appearance of plumbing, all auxiliary structures and pipes are covered with a decorative screen.

Applying mounting foam to the back of the bowl solves two problems at once: additional sound and heat insulation appears.As a result, the water does not hit the walls so loudly and keeps the temperature longer. Instead of foam, you can use a technical cork or vibroisol - a bitumen-based material designed to protect cars from noise.

How to check the quality of a steel bath

If in the question which bath is better, preference was given to a bowl made of steel, it is very important not to make a mistake with the choice when buying. Then such plumbing will last a long time, making water procedures truly comfortable.

At the same time, the cost of the product will be much lower than that of the same acrylic, which does not always have an adequate price-quality ratio.

What to look for:

The wall thickness of the steel bath should be 2.5 - 3 mm. In the store, we will not determine this indicator by eye, but we can move the container to feel its weight. If the bath easily succumbed under our pressure, the manufacturer clearly saved on material by making the walls thinner than required by the standard.

Enamel defects are another sign of low-quality plumbing. Sagging or an excessively thin layer through which the base shines through, roughness, foreign inclusions and other flaws of this kind are unacceptable. If the enamel is not laid evenly, over time it will crack from uneven loading, making the bath unusable. The "correct" coating is smooth and pleasant to the touch, has a uniform color.

It is better to purchase plumbing from leading manufacturers - this is the most reliable guarantee. The German companies Kaldewei and Bette have proven themselves well, the same Roca and BLB from Portugal.Among domestic companies, the products of the Verkh-Isetsky Metallurgical Plant, which meet modern standards and are cheaper than foreign analogues, are trustworthy.

Stainless steel bathtubs

We are accustomed to metal hot tubs with enamel coating, but there are, although less common, stainless steel models. So which bath is best?

Stainless steel bowls are superior to enamel bowls in all respects except ... price. Such bathtubs cannot be called budgetary in any way - they will cost much more than plumbing fixtures made of cast iron or acrylic.

But we get a highly environmentally friendly, durable and resistant to damage of any kind product with an original, unique design.

Tip: to get rid of traces of water, which are very noticeable on polished shiny metal, every time after bathing the bowl should be wiped with a piece of dry natural cloth.

Stainless steel sanitary ware is the perfect choice for a minimalist, high-tech or loft style bathroom.

Additional features of baths and the feasibility of their use

The presence of additional functions in its design may directly depend on what material the bathtub is chosen from.

- Cast iron or steel bath - additional options, most often absent.

- Bathtub made of acrylic or quartz - depending on the model, hydromassage, aeromassage, chromotherapy, an empty bathtub disinfection system and a water level sensor can be built in.

Hydromassage

Hydromassage is realized due to the operation of a special installed pump, which pumps water into the nozzles provided in the walls of the font. As a result, the effect of water flow is produced in the filled bath. This has a positive effect on the human body, relaxation and improvement of tone are produced.

Air massage

Aeromassage, like hydromassage, is produced thanks to the operation of a low-power electric pump. The only exception is that from the nozzles located on the walls of the bath, not a jet of water is supplied, but oxygen bubbles. Often plumbing, which combines both air massage and hydromassage, is called in one word - a jacuzzi.

Chromotherapy

Chromotherapy is a system designed to increase the general tone, improve the functioning of blood vessels and affect the human body with a weak antibacterial effect. The principle of chromotherapy is the work of violet lamps in special reflectors during the adoption of water procedures. The “blue lamps” built into the walls of the font illuminate the body of a lying person from all sides.

The auto disinfection system is an additional option that, after taking a bath and draining the water, delivers a disinfectant to the walls of the font through special holes, which the system automatically rinses off later.

Water level sensor - in principle, an adult does not need it. The main task of the sensor is to determine how full the bath bowl is with water, since, for example, if you turn on hydromassage or air massage when the font is empty, then the main pump and all systems can quickly fail. The water level sensor, in turn, simply will not turn on the hydromassage when the bowl is empty.

How to choose the right bath: acrylic

Acrylic bathtubs are considered to be the queens of design today. Of all the models offered by manufacturers, they are perhaps the only ones that can be presented in a wide variety of forms and designs. If cast iron products are still classic oval shapes, then acrylic can take any. It all depends on the ideas of designers and consumer demand.And with the help of compact baths, you can design any design even in the smallest bathroom. Perhaps for this reason, the relevance and demand for acrylic products is growing every day.

Photo 2. Acrylic bath.

Photo 2. Acrylic bath.

According to their technical characteristics, acrylic models of sanitary equipment are in no way inferior to their cast-iron sisters. They even outperform them in some respects. Despite the fact that they look rather fragile and unreliable, since their thickness rarely exceeds 6 mm, bathtubs are guaranteed to last about ten years. Acrylic is a fairly durable and elastic material, it perfectly withstands the physical and dynamic loads that occur during operation.

Metals are not used in the manufacture of products, so you will never see rust on their surface. In addition, acrylic refers to materials that have an antibacterial effect. Therefore, their products are the most hygienic. Keeping them clean is as easy as washing your hands under the tap. And if you doubt the cleanliness of the bowl, you can use any household chemicals to wash it.

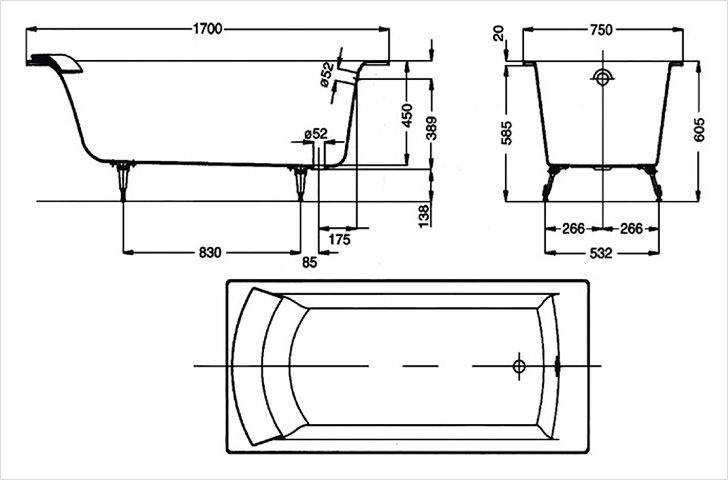

Product dimensions

Previously, in Soviet times, only standard sizes were made of cast iron baths, and there was no choice at all. Today in the sanitary ware market you can find cast iron bathtubs of all sizes, both small, standard, and large.

Plumbing is considered small, the length of which does not exceed one and a half meters, usually its width is not more than 65-79 centimeters. You can also find products with such dimensions: 70 by 130, 70 by 120, etc.

When buying plumbing, you need to take into account that a person whose height is more than 175 centimeters will not be comfortable in it, so if the parameters of the bathroom allow you to buy a cast-iron bath of standard or large sizes, it is better to choose it for convenient use by all family members.

The most popular among consumers are standard products with sizes: 150 by 70, 140 by 70 centimeters. In a product measuring 150 by 70 cm, a person is able to take a bath, in a comfortable reclining state.

If your bathroom can be called large, then for it it is better to take large cast-iron bathtubs, the length of which reaches 170 by 70, 180 by 85, 185 by 85 centimeters and even two meters in length. This will be the best option available, and both a short and a tall person can fit in it.

Selection rules

Professionals recommend choosing a bathtub for an already selected bathroom interior, even if its appearance does not fully correspond to the desired image. In many ways, the choice will be determined by the cost of this type of plumbing equipment. Cheaper options may have certain defects that significantly reduce the life of a cast iron sanitary ware.

What you need to pay attention to when choosing:

Location for sewerage. If the bath is matched to an already finished interior, this nuance will become the main thing when buying a cast-iron bath. If the product is purchased during the repair, then the place where the sewerage is connected does not play a big role - the installation can be carried out as needed.

- Dimensions. If the width is greater than the width of the doorway, you will have to look for alternative options for delivering plumbing fixtures to the bathroom.Therefore, it is advisable to make a choice based not only on the size of the bathroom, but also on the width of the doorway.

- external walls of the bathroom. A quality model will not have unexpected roughness, dents or various defects. On the contrary, their absence indicates the high quality of the selected product.

The enamel applied to the inside should be even and smooth, without any noticeable defects, whether it be a wavy surface, chips or scratches. The poor quality of the enamel will lead to the inevitable corrosion of the metal, and hence to the replacement of the installed bath.

In addition, low-quality enamel quickly absorbs and retains dirt, which will require frequent and lengthy cleaning of the inner surface.

When choosing a sanitary ware, you need to pay attention to the edges and corners of the bathroom. The smooth surface and the correct geometric lines of the corners indicate that the bathtub is made with all quality requirements in mind, which ensures a long service life.

Producing country

Its price, shape and appearance, as well as additional functionality depends on the place of manufacture.

- Additional functionality. Plumbing equipment manufacturers are trying to reach the maximum number of potential buyers, which means they produce models that are suitable for both children and elderly family members. This may include:

- jacuzzi;

- handles that allow you to climb;

- a rough layer applied to the bottom of the bath, preventing children from slipping;

- antibacterial layer containing silver ions;

- special ledges in the form of shelves for the necessary cosmetic products or hygiene products;

- supports for pillows under the head and other additional features.

Comparison of cast iron bathtubs from different manufacturers

Along with general recommendations for choosing cast iron bathtubs, it is necessary to take into account the specific features inherent in specific manufacturers.

Consider the rating of manufacturers of such plumbing:

- It is headed by European companies, including the Spanish "Roca" and the French "Odoksan" and "Porcher". The products of these enterprises are distinguished by stable quality and interesting design, but they belong to products of a high price category.

Roca cast iron bath

- More accessible products of Chinese and Turkish firms:

- However, products from China often have low adhesion of cast iron and enamel, which leads to delamination and cracking.

- Models produced by Turkish companies are made from high-quality metal, but due to poorly established quality control, products with a defect can also be purchased.

- Russian manufacturers of cast iron bathtubs are represented by the Kirov Plant and the Universal Plant. Domestic products are distinguished by the largest thickness of metal, which ensures the strength of products. However, the quality of the enamel is sometimes inferior to Western samples, and the variety of forms is limited.

Bathtub manufactured by the plant "Universal"

Having decided that you still need a cast-iron bath, you can find out which manufacturer is better by comparing products from different manufacturers.

All technical parameters of cast iron baths must match the data specified in the accompanying documents. Their absence may indicate both the low quality of the goods and the dishonesty of the seller.

When choosing a bathtub made of cast iron, it is necessary to compare the offers of various manufacturers and find the best value for money. You can also pre-examine customer reviews of products from various companies.The opinion of consumers will help weed out unscrupulous manufacturers and choose a bath that fits perfectly into the interior and will retain its technical parameters and original appearance for a long time.

Negative sides

What is the best cast iron bath? It all depends on a variety of requirements, for example, the area of \u200b\u200bthe shower room or the physical parameters of the owners. Naturally, like many other materials, cast iron has its drawbacks. It doesn't take much time to figure them out. However, suffice it to say that the weaknesses are very specific, but it is impossible not to mention them. Weak sides:

- The most common and objective disadvantage of cast iron products is always considered to be their large mass. A standard bathtub will weigh a little over 100 kg, which makes it very difficult to transport, carry, and install. But given the fact that considerable weight gives stability to the structure, the disadvantage develops into a virtue, although this is a controversial statement.

- An additional difficulty is the need for additional grounding. This material, like other metals, conducts electricity well. Therefore, it is worth thinking about security.

- Relatively, the limitation in shape and size still makes itself felt. Unlike other materials, cast iron cannot boast of a special variety. Modern models include the main types of design - oval or rectangular. The low ductility of cast iron does not allow the production of original forms from it.

- The high cost of a cast-iron bath can spoil the mood for many. Compared to products made from other materials, cast iron is much more expensive.However, the price-quality ratio eventually leads to an inverse balance in favor of cast iron products.

- When using cast iron plumbing, there is always the possibility of purely accidental damage to the enamelled surface. Of course, this is very problematic to do, however, if this happens, then it is already impossible to restore the enamel! What makes the use of such baths very difficult in terms of practicality.

Classification by material of manufacture

Before choosing, you need to compare the dimensions of your bathroom with the dimensions of the future bathroom. This is done for your convenience and comfort. What is the best bath, from what material?

In plumbing stores you will be given the following types of bathtubs to choose from:

- acrylic bathtubs;

- cast iron baths;

- steel tubs.

Acrylic bathtubs are gaining more and more fans today. They are made from polymethyl methacrylate and, thanks to a special technology, take on any shape and size. The bottom of the acrylic bathtub is reinforced with a special metal frame and chipboard form.

Advantages of acrylic bathtubs:

- Low noise when filling water.

- Acrylic bathtubs retain heat for a long time, the water will be hot for a long time.

- The ability to create any form.

- Can be easily restored.

- Ease of maintenance.

Acrylic bathtubs have fewer disadvantages than advantages, but they should be mentioned. If you drop a heavy load on such a bath, even a shower head, then cracks on the surface are possible. When soaking colored laundry, traces of paint may appear on the surface of the tub. And you need to carefully install the acrylic bath on the floor. The frame is responsible for its stability, it must be reliable in order to avoid loosening during operation.Even in rare cases, the bathtub can be deformed from too hot water.

Advantages of cast iron bathtubs:

- The average service life is from 25 years.

- Great resistance to deformation.

- No accumulation of dirt, thanks to the smooth surface.

- Quiet and vibration free.

The disadvantages of cast iron baths include their heavy weight and the difficulty of restoration at home.

Advantages of steel baths:

- simple care;

- a light weight;

- have various forms.

The disadvantages of such baths are enough:

- loud noise during water intake;

- high thermal conductivity - that is, water cools quickly;

- the possibility of rapid deformation and cracks in the enamel.

Installing a cast iron bath

It is quite possible to install a cast-iron bath yourself. For this you will need:

- level;

- sealant;

- spanners;

- tube stopper;

- hacksaw for metal;

- plumbing cable.

Preparatory work before installation includes: leveling the floor, laying tiles on the walls and floor (this stage can be done after installation), prepare communications. You can proceed directly to the installation after the final drying of all surfaces.

Detailed instructions for installing a cast iron bath:

- Turn the bathtub on its side upside down to the wall where it will stand.

- Using rubber gaskets, install overflow and siphon.

- Install the first two support legs. Turn the bathroom upside down, propping it up with something.

- Level the remaining supports.

- Fix the outlet outlet in the overflow pipe, connect it well to the siphon.

- Carefully cover the cracks with sealant.

During the installation process, you will need an assistant, because. cast iron is a very heavy metal and it is not possible to cope with its transfer on your own.

You can see how the master's cast-iron bath is installed in the video:

Helpful Care Tips

The service life of a good cast iron bath can significantly exceed the period specified in the warranty card. This will happen if the rules for care and use are followed.

Buying an elite Italian bath, covered with enamel, remarkable in its performance, you can count on a 20-30-year friendship with her

First, you can not overload the bath. The instructions for each product indicate the maximum allowable load - the weight of a person + the weight of water. Overloading is fraught with unpleasant consequences, when the legs or the fasteners that hold them may not withstand and break.

Secondly, cast iron bath cleaners should be chosen without acids, chlorine, abrasive particles. It is better to use the fluids recommended by the manufacturer, if possible.

Separately, it is worth noting the care of the anti-slip coating. It requires thorough washing after each use. Otherwise, the smallest particles of dirt will accumulate, which will lead to its rapid darkening.

Thirdly, after using the container, it must be rinsed and wiped dry. If the tap is leaking, then it should be repaired as soon as possible - an indelible yellow coating forms on the enamel from a constant leak.

Convenient handles on the sides, which facilitate the process of getting out of the bath, also require careful care. They need to be wiped down so that there are no streaks left.

Fourth, do not drop heavy and angular objects into the bath - a hammer, sink or toilet. These impacts can crack the cast iron bottom, rendering the product unusable.

In case of damage to the enamel coating, there is no need to get upset and prepare to buy a new one. It is for cast iron baths that you can choose the most convenient way to restore enamel. These products respond well to this kind of repair work.

The fastest way to restore is to install an acrylic liner. This type of work can be done independently or with the involvement of specialists from a good company.

Another option is to pour liquid acrylic onto the prepared surface. Here it is also possible to cope on your own, but some skill is required.

For the bulk method, the shape and size of the cast-iron bath does not matter. Acrylic liners produce only 10 of the most common models.

The third way is to cover the surface with enamel paint. This method is more labor intensive. Without experience and enough patience, it will be difficult to cope. Indeed, to achieve an excellent result, you will need to apply 2, 3 or more layers of enamel.

The service life of the restored surface is from 5 to 20 years - everything will depend on proper care and respect for the new coating.

![How to choose a bath: 5 points + and - [acrylic - steel - cast iron]](https://fix.housecope.com/wp-content/uploads/7/f/8/7f8b0aee2c30e9ce15569b68867f57df.jpg)

![How to choose a bath: 5 points + and - [acrylic - steel - cast iron]](https://fix.housecope.com/wp-content/uploads/e/8/7/e8707b6701b72353642f369b2e74264c.jpeg)