- Tying the "indirect" with the boiler

- Advantages and disadvantages of gas boilers

- Result. Is it profitable to use a boiler instead of hot water from a central water supply system?

- Which water heater is better: instantaneous or storage

- What is a safety valve for?

- Other selection criteria

- Instructions for starting the Thermex boiler

- What to do if the safety valve is leaking

- Advantages and disadvantages

- Combined heating boiler

- The best storage water heaters for 100 liters

- Zanussi ZWH/S 100 Splendore XP 2.0

- Ariston ABS VLS EVO PW 100

- Stiebel Eltron PSH 100 Classic

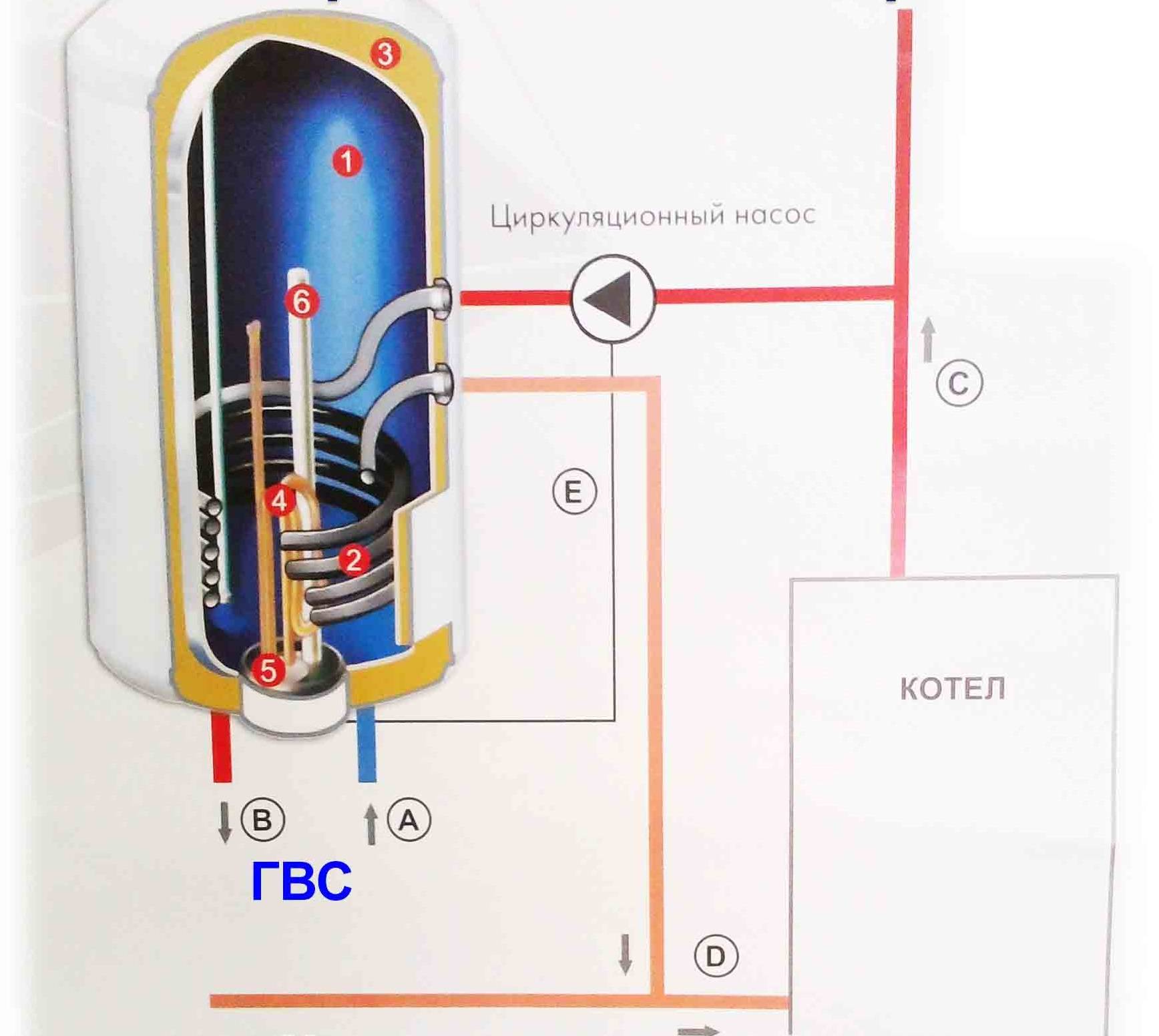

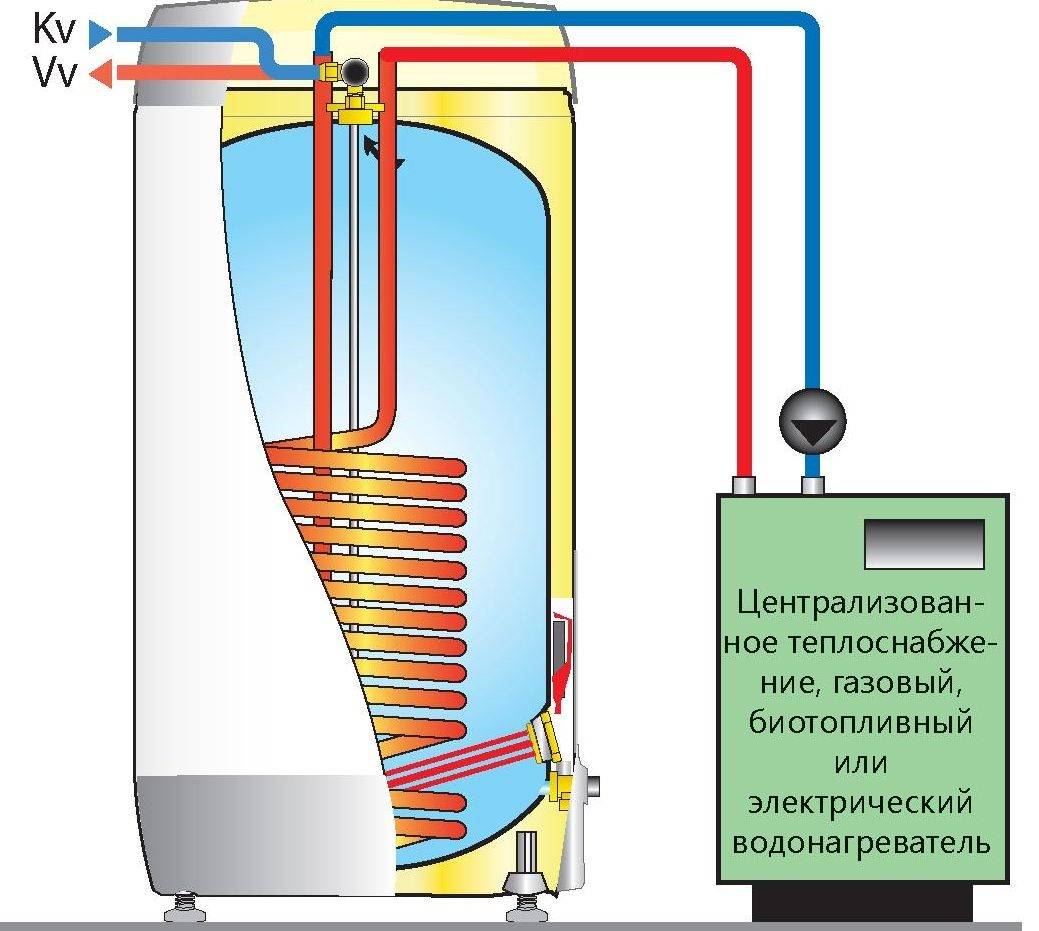

Tying the "indirect" with the boiler

First of all, the unit must be installed on the floor or securely attached to a main wall made of brick or concrete. If the partition is built of porous materials (foam block, aerated concrete), it is better to refrain from wall mounting. When installing on the floor, keep a distance of 50 cm from the nearest structure - clearance is necessary for servicing the boiler.

Recommended technological indents from the floor boiler to the nearest walls

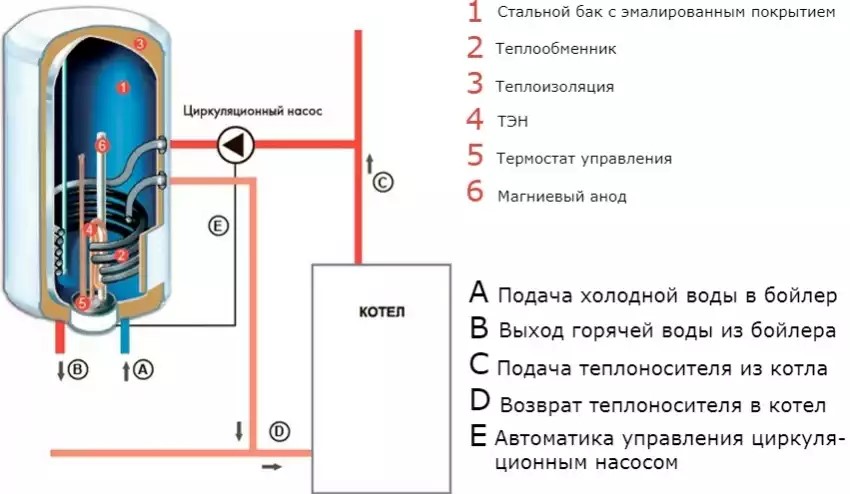

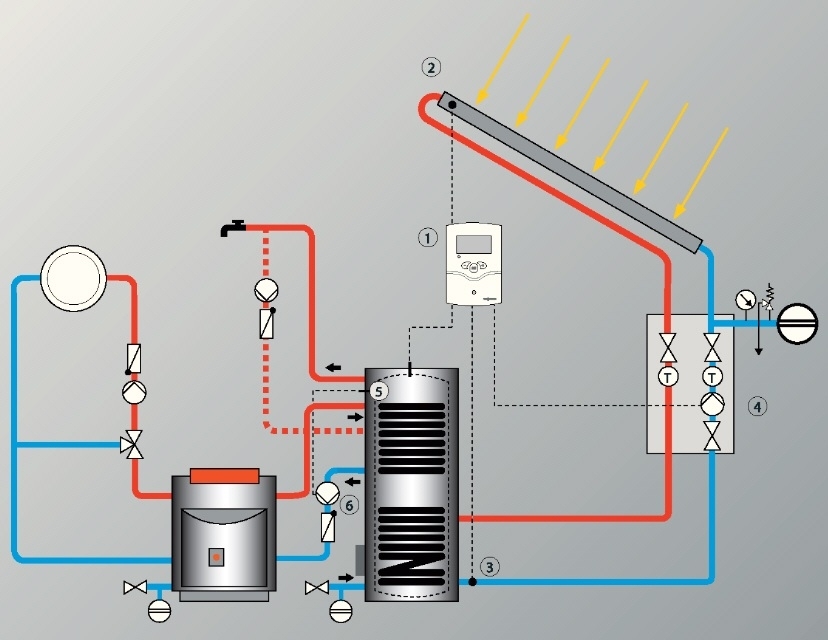

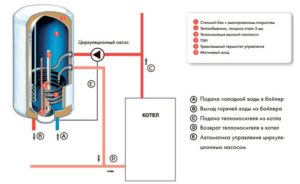

Connecting the boiler to a solid fuel or gas boiler that is not equipped with an electronic control unit is carried out according to the diagram below.

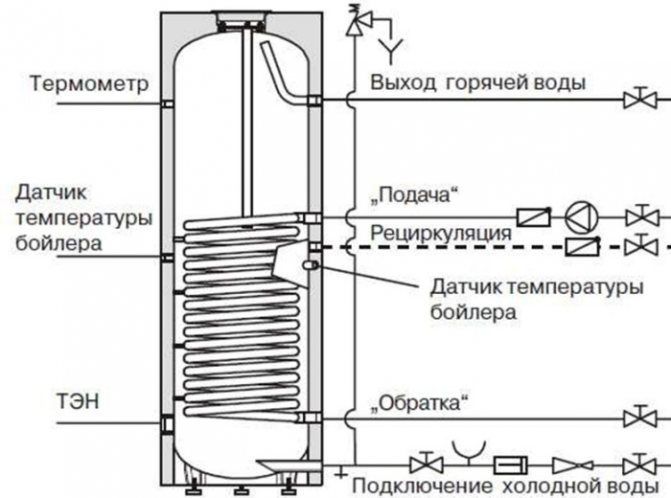

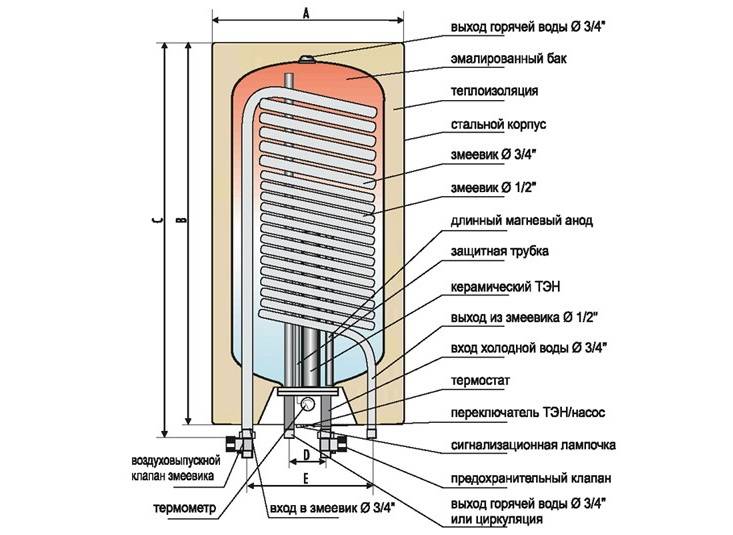

We list the main elements of the boiler circuit and indicate their functions:

- an automatic air vent is placed at the top of the supply line and discharges air bubbles that accumulate in the pipeline;

- the circulation pump provides the coolant flow through the loading circuit and the coil;

- a thermostat with an immersion sensor stops the pump when the set temperature inside the tank is reached;

- check valve eliminates the occurrence of parasitic flow from the main line to the boiler heat exchanger;

- the diagram conventionally does not show shut-off valves with American women, designed to turn off and service the apparatus.

When starting the boiler “cold”, it is better to stop the circulation pump of the boiler until the heat generator warms up

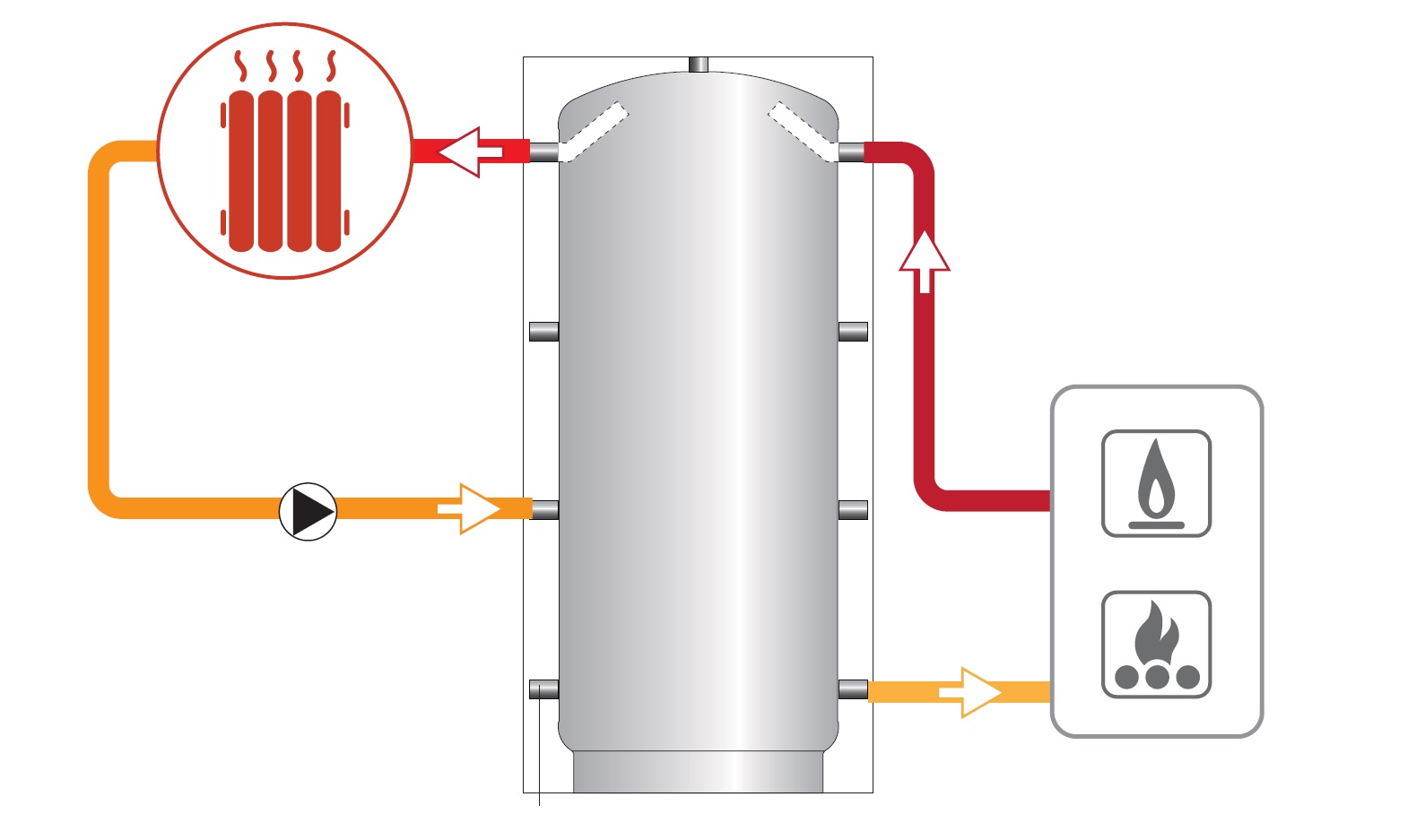

Similarly, the heater is connected to more complex systems with several boilers and heating circuits. The only condition: the boiler must receive the hottest coolant, therefore it crashes into the main line first, and it is connected directly to the hydraulic arrow distribution manifold, without a three-way valve. An example is shown in the primary/secondary ring tying diagram.

The general diagram conventionally does not show the non-return valve and boiler thermostat

When it is required to connect a tank-in-tank boiler, the manufacturer recommends using an expansion tank and a safety group connected to the coolant outlet. Rationale: when the internal DHW tank expands, the volume of the water jacket decreases, there is nowhere for the liquid to go. Applied equipment and fittings are shown in the figure.

When connecting tank-in-tank water heaters, the manufacturer recommends installing an expansion tank on the side of the heating system

The easiest way is to connect an indirect heating boiler to wall-mounted boilers, which have a special fitting. The remaining heat generators, equipped with electronics, are connected to the water heater via a motorized three-way diverter valve controlled by the boiler controller. The algorithm is this:

- When the temperature in the tank drops, the thermostat signals the boiler control unit.

- The controller gives a command to the three-way valve, which transfers the entire coolant to the loading of the DHW tank. The circulation through the coil is provided by the built-in boiler pump.

- Upon reaching the set temperature, the electronics receives a signal from the boiler temperature sensor and switches the three-way valve to its original position. The coolant goes back to the heating network.

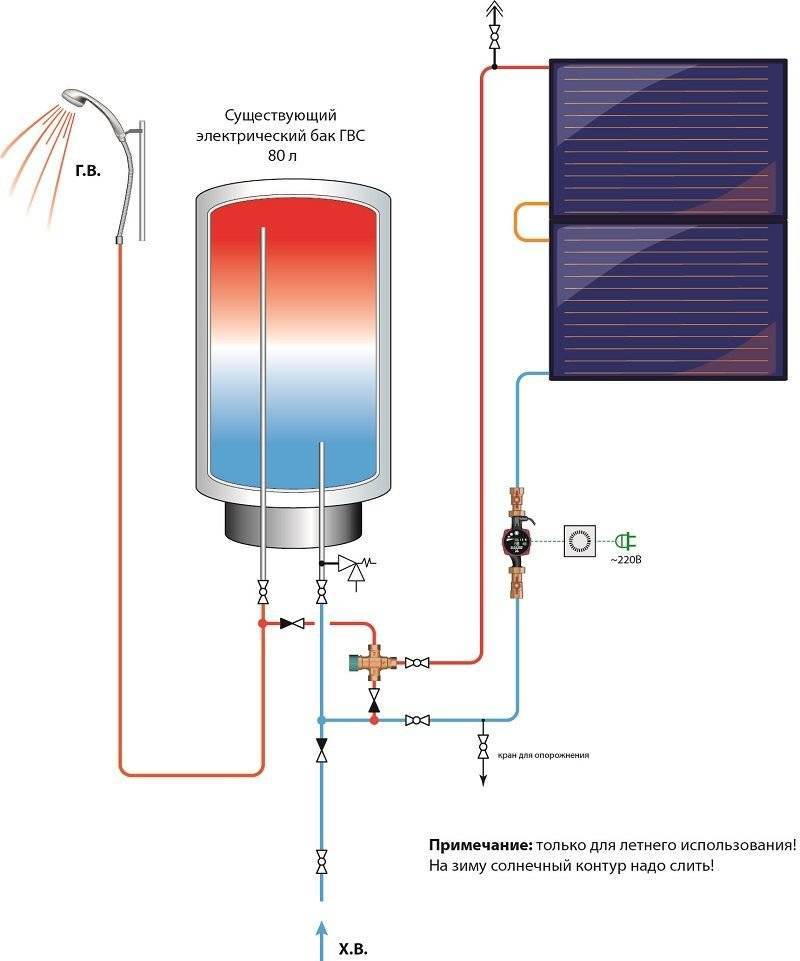

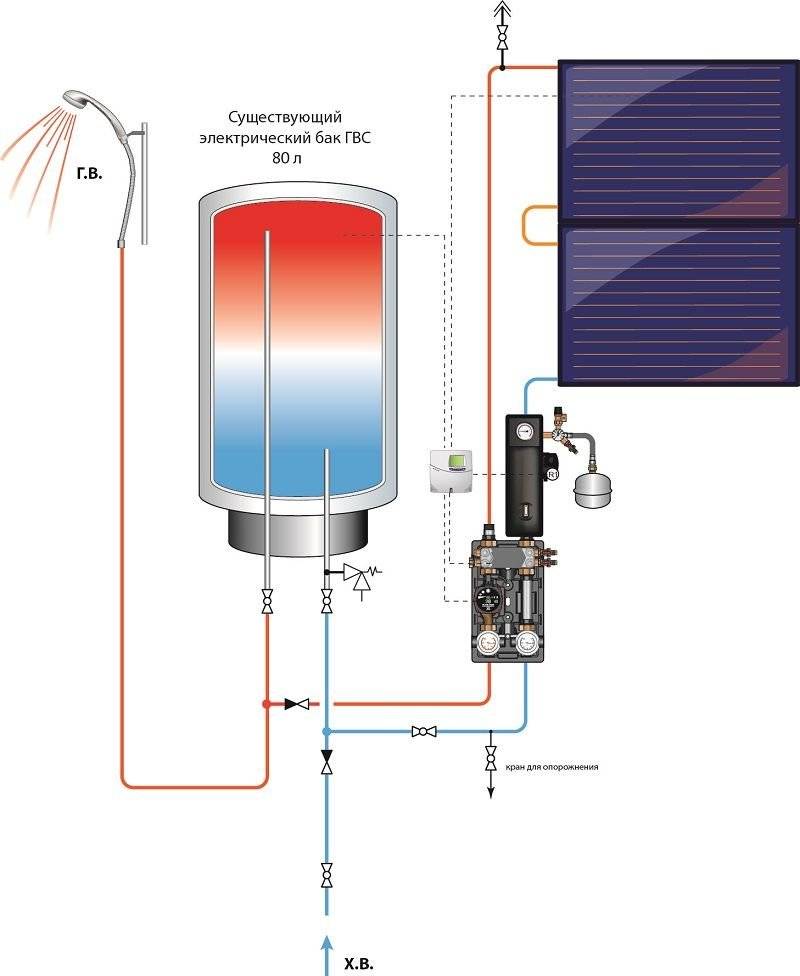

The connection of the solar collector to the second boiler coil is shown in the following diagram. The solar system is a full-fledged closed circuit with its own expansion tank, pump and safety group. Here you can not do without a separate unit that controls the operation of the collector according to the signals of two temperature sensors.

Heating water from the solar collector must be controlled by a separate electronic unit

Advantages and disadvantages of gas boilers

When choosing storage boilers for heating water, pay attention to their advantages and disadvantages. Consider the pros:

- Fast water preparation - gas boilers heat water somewhat faster than their electric counterparts;

- Profitability - the cost of gas for heating will be lower than the cost of electricity;

- No dependence on electricity - power outages happen many times more often than with gas supply;

- Possibility of use in non-electrified country houses;

- Stable outlet water temperature;

- Instant supply of hot water - no need to wait until it warms up to the desired temperature.

Not without drawbacks:

- Increased danger - whatever you say, but gas equipment is always more dangerous than electric, you need to be wary of possible leaks;

- Connection difficulties - the installation of gas equipment must be registered with the gas services;

- Inability to use in some rooms - if it is forbidden to use any gas appliances in the building, except for kitchen stoves, it will not be possible to install a gas boiler.

Result. Is it profitable to use a boiler instead of hot water from a central water supply system?

So if you are wondering whether it is worth installing a water heater, then the answer will be simple - it is worth installing, but not for savings, but for comfort.

If you have a large family, have small children, everyone gets up at about the same time, then you will have to install a boiler with a large tank, or wait until the water heats up again. It is very uncomfortable.

And if it costs more, then it loses all meaning.

The only time when it is worth replacing hot water from pipes with a water heater is if this very water is very low. The requirements for cold water are higher, so it is easier to use it.

As for saving, read this note: more than 40 ways to save money.

Which water heater is better: instantaneous or storage

Deciding which water heater to buy - a boiler (accumulative) or a protochnik - in principle, is not difficult.First of all, the limiting factor is the power consumption: for storage it is maximum 3-4 kW, for instantaneous water heaters it is pointless to take less than 7-8 kW - they can only provide heating of a very small amount of water. Not everyone has the opportunity to install such powerful equipment.

Secondly, you need to look at whether you will constantly use an electric water heater or only periodically. With occasional use, especially in the summer, instantaneous water heaters are convenient, and moreover, of an open type (individual, which are installed next to the sink). For example, this is a great way to heat the water in the summer shower in the country to a comfortable temperature if the sun has not coped with this task. It is also a way to solve the problem in apartments when the hot water supply is turned off for repairs.

For permanent and regular use, storage water heaters are more economical and convenient. Modern models “keep” the temperature for more than a day, so the electricity consumption here will be rather less than more.

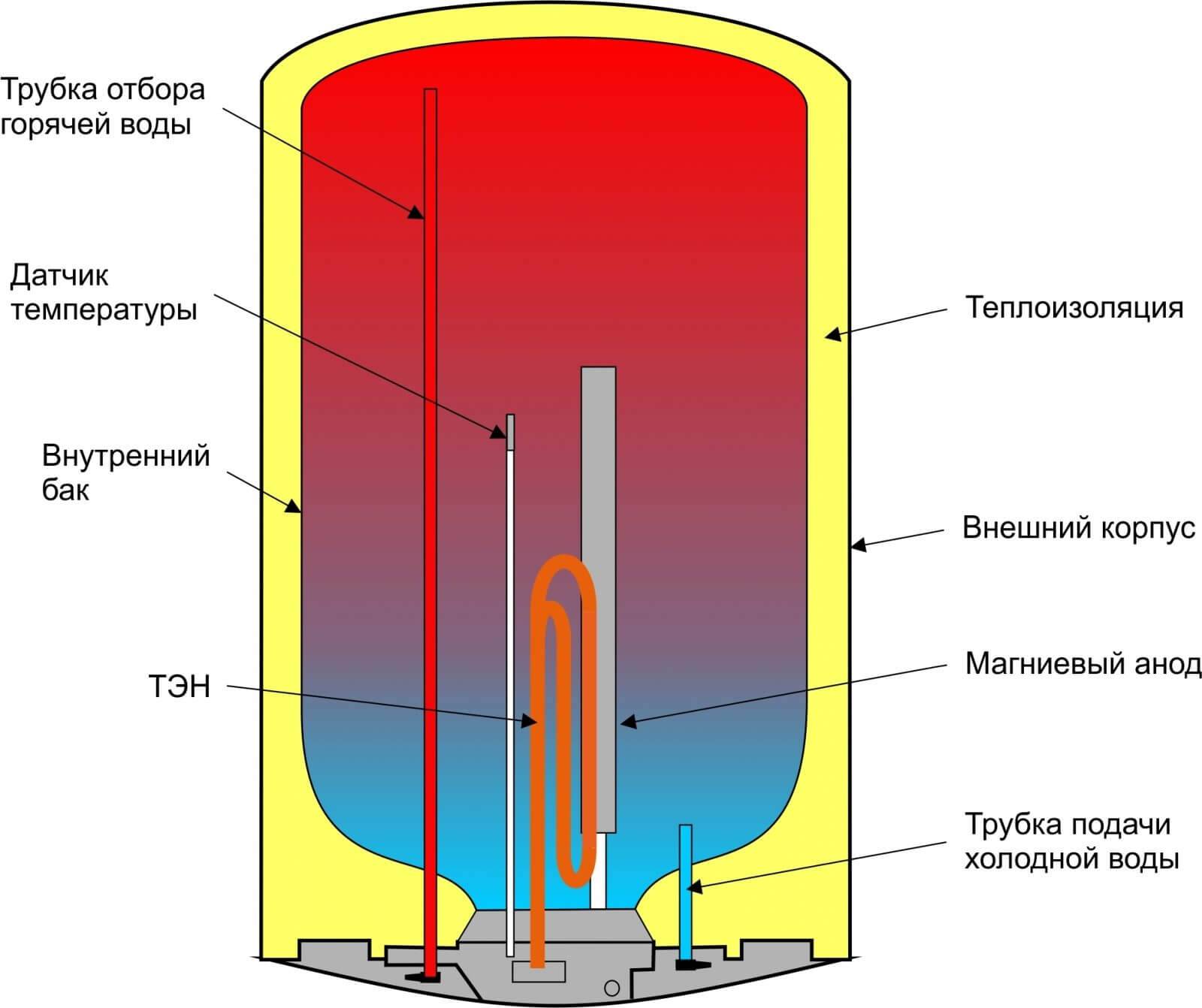

What is a safety valve for?

The safety valve, which is included in the delivery set of any storage water heater, is an integral element of the safety group of this device. It is prohibited by the manufacturer to operate the water heater without it, and it is simply unsafe. Any water heater has a working water pressure that has both a minimum threshold (the minimum pressure required for normal operation of the device) and a maximum threshold (exceeding which can damage the device). The maximum threshold, in turn, consists of two values:

- Pressure in the water supply line. This is the pressure with which water is supplied to the device.

- The pressure that occurs in the water heater tank when water is heated.

The safety valve is designed for a pressure no greater than the maximum working pressure of the water heater. The valve is installed in accordance with the instruction manual for a specific model of the water heater. For most models of water heaters, it is mounted on the cold water supply pipe and performs the following functions:

- prevents spontaneous draining of water from the water heater when the cold water supply is turned off in the main network;

- relieves excess pressure in the internal tank of the water heater;

- can be used to drain water from the appliance;

Now let's look at these functions in more detail:

The figure above shows the safety valve in section. One of its elements is the check valve mechanism. It is he who is responsible for retaining water in the EWH tank and does not allow it to return to the water supply system

Accordingly, when installing the valve, it is important to prevent damage to this mechanism, therefore, manufacturers recommend twisting 3-3.5 turns of the thread. In the valves offered by our company, this problem is solved systemically, by means of a restrictive metal platform, beyond which it will not be possible to screw the valve, and therefore it is impossible to damage the check valve mechanism.

The next item on the list, but not least, is the safety valve mechanism. As mentioned earlier, for any EWH there is a maximum water pressure threshold, which consists of two indicators: the pressure in the water supply system and the pressure that occurs when the water expands during heating

When the total pressure begins to exceed the value of the maximum threshold, the stem begins to compress the safety valve spring and thus opens the fitting hole to drain the water. The pressure is released and the water heater continues to operate normally.

From here there are several important points that I would like to draw your attention to:

It is important to know the pressure in your water supply system, with a high value, the likelihood of a permanent operation of the safety valve increases significantly. In this case, it is recommended to install a reducer to reduce the main pressure in the network

The gearbox is not included in the EWH delivery set and must be purchased separately.

It is strictly forbidden to restrict the movement of the forced pressure release handle by rigidly fixing it in its normal position, as this makes it impossible for the safety mechanism rod to move and thus does not allow excess pressure to be released.

Since the release of excess pressure is accompanied by the appearance of drops of water from the fitting for draining water, it is recommended to drain from the fitting of the safety valve (any flexible tube or hose is enough) into the sewer (sink, bathtub, drain tank or siphon). Another function of the safety valve is to drain water from the device. Due to its time-consuming nature (this is not the fastest process, especially for large volumes), this method is relevant mainly in cases where the installation of the device did not provide for the possibility of quickly draining water. To do this, you must: disconnect the EWH from the network, shut off the cold water supply to it and open the hot water tap at the water intake point (mixer).After that, raise the handle for forced water discharge and drain through the fitting.

ATTENTION!!! The safety valve is not intended to protect the device from sudden pressure surges in the water supply network. To solve this problem, a special device is installed in the system - a hydraulic shock absorber.

It is forbidden to use the storage water heater without a safety valve, or with a valve whose pressure exceeds the maximum set for this device. In the event of the above violations, the consumer's warranty obligations do not apply to the water heater.

Other selection criteria

Floor standing and wall mounted gas boilers

When choosing, you need to focus on the method of attaching boilers. Wall-mounted gas boilers for hot water are compact and can be used in small spaces. As for floor models, they are more spacious, so it is recommended to install them in separate rooms, for example, in boiler rooms.

Gas boilers for direct water heating are the most common water heaters. We will see them in the gas equipment store. Heating here is carried out directly from the built-in gas burner. If we talk about gas boilers for indirect heating of water, then they are very rare and are practically not found on sale.

Instructions for starting the Thermex boiler

If the installation of equipment is usually carried out by specialists, then the owners themselves have to deal with its launch at least once a year.Let us consider in more detail how to turn on the Termex water heater so as not to negatively affect its performance properties. After all, the duration of operation and the frequency of maintenance largely depend on the correct execution of the process.

Work order

Turning on the boiler: the steps for starting the water heater and setting it up may differ slightly. It all depends on whether a flow device or a storage device is used. However, despite the structural differences, the order of their inclusion has the same principle. The universal instruction for starting the Termex boiler is as follows:

- Before turning on the water heater, the shut-off valves for supplying hot liquid from the common riser are closed. This is done even if a non-return valve is installed on the pipe.

After all, with a slight malfunction without blocking the channel, the device will heat the central water supply.

- Before connecting the Termex storage water heater to the network, it is filled with water. The outlet of the hot liquid device and the mixer are opened in turn, and after them - the inlet of the cold stream. These manipulations are necessary to force air out of the system.

- After the water has flowed in an even stream, you can turn it off, turn on the unit in the power grid and, after setting the settings and waiting for an hour or two, start using it.

The Thermex water heater connection diagram when using flow-through devices will be similar, except that the result will be felt immediately.

The next stage after switching on is a performance check. Before using the Termex water heater, you need to:

- Make sure that the power indicators light up when plugged in.

- Measure the temperature of the liquid supplied to the mixer.

- After 20 minutes, take a look at the sensors of the equipment, if the boiler with the touch panel is connected correctly, the temperature indicator should already increase on the device. In the absence of an electronic panel, it is necessary to measure the degree of water heating at the outlet of the mixer again.

What to do if Termex does not turn on

The process of installing a Thermex instantaneous water heater or any other model requires the presence of serviceable network elements: sockets, circuit breakers, cables of sufficient thickness. The devices have a very high power, so if they do not work, first of all, armed with a tester, you need to check the presence of electricity in the outlet, then the power terminals. Video instructions for installing a Termex water heater will help you find their location, and a tester will help you take readings. If the voltage is zero, then the cable of the electrical appliance is broken.

What to do if the Termex water heater does not turn on, or rather, power is supplied, but it gives an error - the most popular question. In this case, you need to open the device manual and look at the explanation corresponding to the code indicated on the display. If this is not possible, the causes of the problem may be as follows:

The heating element has a damaged or burned out spiral. A sign is often a breakdown of electricity on the case, then the RCD machine immediately trips and turns off the power supply. The only way to deal with this is by replacing the heating element.

The protection is activated if the heating of the coolant rises above the set limit (usually more than 90 degrees), which occurs both when the control thermostat breaks down and when scale accumulates on the heating element, after which it overheats.

The tank is not filled with water. How to turn on the Thermex ID 50V boiler for the first time or another model was discussed above, and if the requirements for etching air from the nozzles are not met, the protective mechanism is triggered

Note that you need to do this even if the system is full, but it has not been used for a long time.

What to do if the safety valve is leaking

The safety valve has an important function, it corrects the operation of the entire water heater. When heated, water increases in volume, which creates increased pressure in the boiler, when this pressure begins to exceed the allowable rate, the spring in the safety valve compresses and opens it. Excess fluid is bled off, then the pressure returns to normal. A "leak" in a water heater's safety valve is actually an indication that it is working properly. During the heating process, up to one and a half liters of liquid can flow out of the safety valve.

If the valve leaks when the unit is turned off, a pressure reducer must be installed, as your network pressure exceeds the allowable atmospheric value of 4.

Advantages and disadvantages

Storage boilers have a number of advantages over instantaneous water heaters:

- availability of access to hot water within the available volume provided by the design;

- round the clock use;

- maintaining the temperature in the selected range for a long time;

- ease of use and temperature control.

Disadvantages of boilers:

- the inability to use water in excess of the tank limit, which is inconvenient in large families;

- the need for periodic maintenance;

- the risk of flooding the premises during a breakdown;

- relatively low cost of service;

- the availability of an electric energy carrier at the installation sites, because gas is not present in every settlement;

- continuous heating of water to the desired temperature.

Advantages of flow heaters in comparison with storage boilers:

- no need to wait for water heating from the carrier;

- no restrictions on the amount of hot water;

- ease of use of any design;

- ease of installation and maintenance.

Flaws:

- the need to carefully monitor the equipment;

- modern designs are significantly more expensive than standard boilers;

- the need to choose a solution to provide the whole house with water, or each point separately.

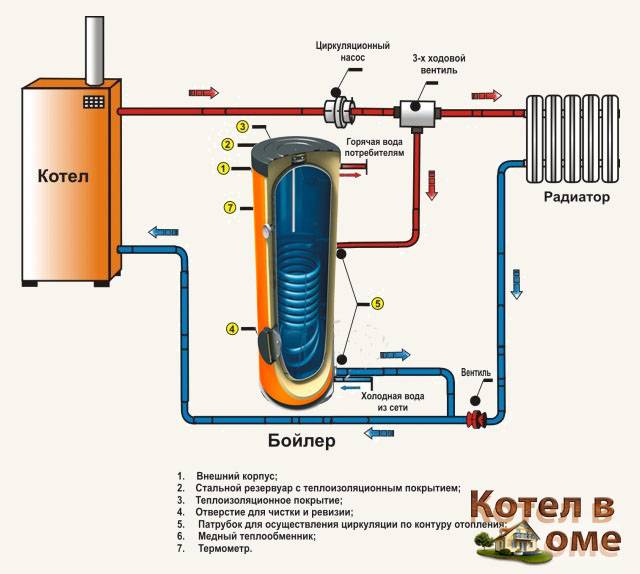

Combined heating boiler

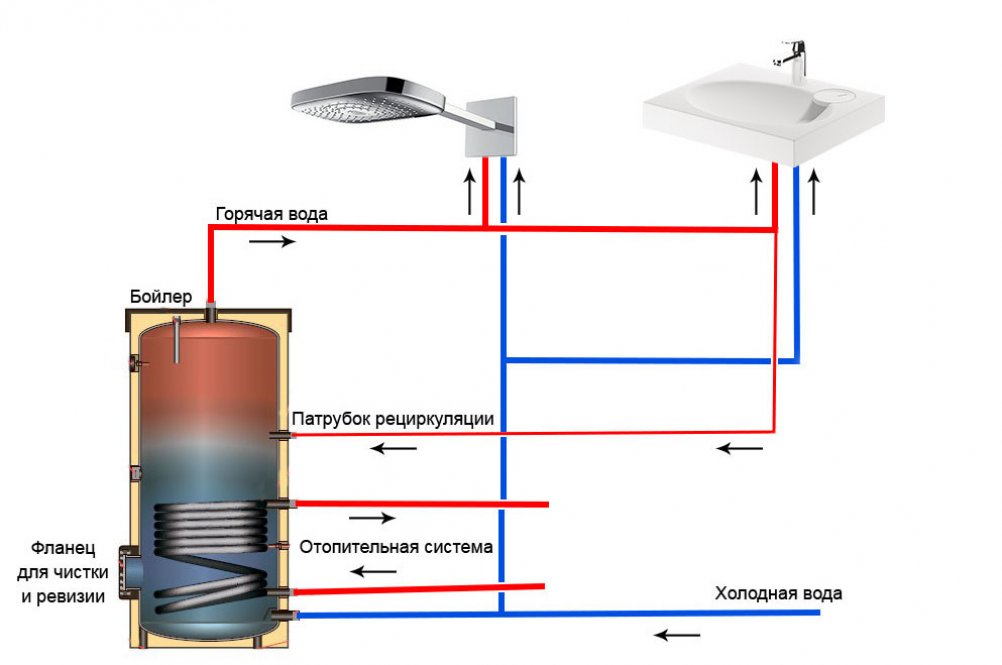

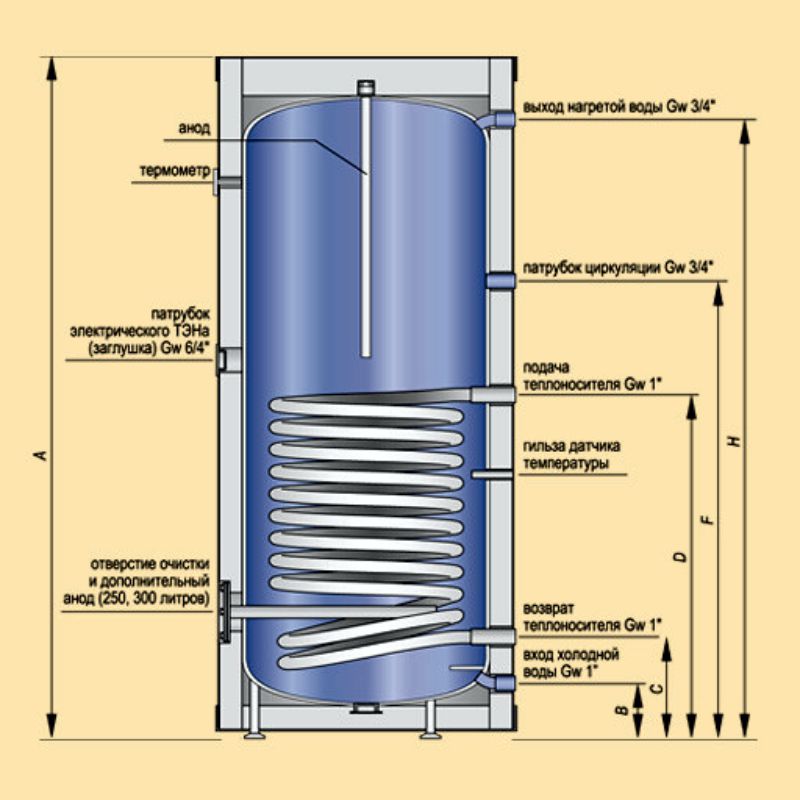

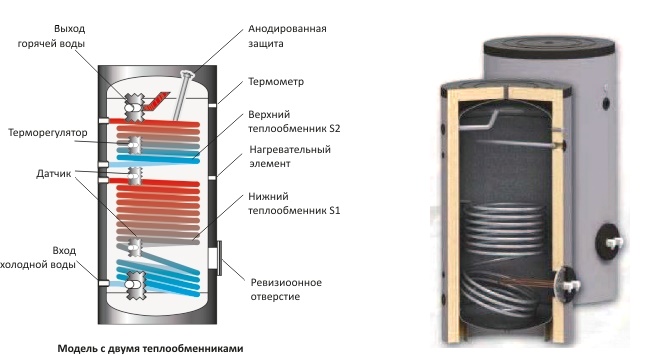

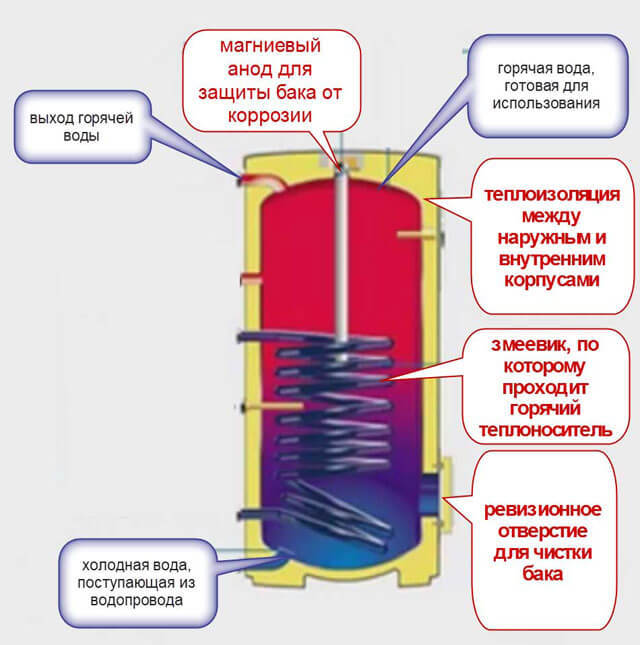

A combined heating water heater is a device that can simultaneously heat water with different energy sources.

This type of boiler is a tank through which the coil passes, and also has a built-in electric heater. Hot water from the boiler flows through the coil, and with the help of a heating element, the liquid is heated.

The main advantage of a combined heating boiler is, first of all, the ability to function in different modes. In addition, there are a number of other advantages that such a device has:

- simple installation;

- fast heating of water;

- temperature control;

- overheat protection;

- simple service.

Combined boiler connection diagram

The combined water heater is used both in country houses and in small enterprises.

Water circulation is carried out thanks to the pump installed in the main part of the equipment.

Combined heating boilers are considered the most powerful equipment and are currently in great demand.

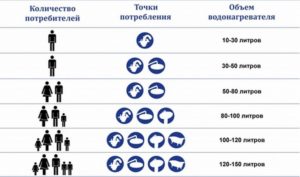

Boiler capacity calculation

When choosing a boiler, you first need to decide how much tank you need. Boilers with tanks of 5-10 l, 30-80 l, 100 l, 120 l, 150 l and more are produced.

The volume of the tank should be selected based on what the boiler will be used for. If only for washing dishes, then a tank with a volume of 5 to 30 liters will be enough for you.

If for carrying out hygiene procedures, taking a shower, etc., then here you should be guided by the number of people living in the apartment. One person will need 80 liters, 2-3 - 120-130 liters, and 4-5 or more - 150-200 liters.

To extend the life of the direct and combined heating boiler, it is necessary to clean it periodically.

The best storage water heaters for 100 liters

Large volume boilers are most often in demand in residential areas where there is no water or supply occurs very rarely, in summer cottages and in country houses. Also, a large device is in demand in families where the number of members is more than 4 people. Any of the 100-liter storage water heaters proposed by experts will allow you to bathe and perform household tasks with hot water without turning it on again.

Zanussi ZWH/S 100 Splendore XP 2.0

A rectangular compact boiler with a large capacity will allow you not to limit yourself in water procedures, while saving electricity and free space in the room.Stainless steel will protect against dirt, damage, corrosion. For comfortable control, the Smart electronic system, display, light indication and thermometer are provided. Power Zanussi ZWH / S 100 Splendore XP 2.0 2000 W, the check valve will withstand pressure up to 6 atmospheres. Protective functions will save the device from running dry, overheating, scale and corrosion. It will be possible to bring water to 75 degrees in an average of 225 minutes.

Advantages

- Compactness and light weight;

- Clear management;

- Water sanitation system;

- Timer;

- Safety.

Flaws

Price.

Maximum heating accuracy down to a degree ensures uninterrupted stable operation. Good thermal insulation and anti-freeze preserve the integrity of the body, and this guarantees a long service life. The manufacturer notes that inside the tank the water is disinfected. Inside the Zanussi ZWH / S 100 Splendore XP 2.0, a good check valve and RCD are installed.

Ariston ABS VLS EVO PW 100

This model demonstrates impeccable aesthetics and concise design. The steel snow-white body in the shape of a rectangle does not take up as much space as round boilers with greater depth. The increased power of 2500 W guarantees heating up to 80 degrees much faster than expected. Mounting can be either vertical or horizontal. For clear control, there is a light indication, an electronic display with information and an accelerated work option. Safety is ensured by a temperature limiter, overheating protection, non-return valve, auto-off. Unlike other nominees, there is a self-diagnosis here.

Advantages

- Convenient form factor;

- 2 anodes and heating element with silver for water disinfection;

- Increased power and fast heating;

- Display for control;

- Good security options;

- Exposure to 8 atmospheres of water pressure.

Flaws

- There is no fasteners in the kit;

- Unreliable display electronics.

In terms of quality and functions, this is an impeccable device for home use, which is confirmed by numerous reviews. The control system is not so durable, after some time it can issue inaccurate information. But this does not affect the performance and safety of the Ariston ABS VLS EVO PW 100 boiler.

Stiebel Eltron PSH 100 Classic

The device guarantees a high level of performance, classic design and quality. With a volume of 100 liters, it can operate at a power of 1800 W, heating water in the range of 7-70 degrees, the user sets the desired option. The heating element is made of copper, resistant to mechanical stress, corrosion. The water pressure should not exceed 6 atmospheres. The device is equipped with protective elements and systems against corrosion, scale, freezing, overheating, there is a thermometer, mounting bracket.

Advantages

- Low heat loss;

- service life;

- High security;

- Easy installation;

- Convenient management;

- Ability to set the optimum temperature.

Flaws

- No built-in RCD;

- A relief valve may be required.

Unlike many nominees in this device, you can set the water heating mode up to 7 degrees. The boiler consumes not so much electricity, withstanding heat longer due to the polyurethane coating. The inlet pipe inside the structure provides 90% of the unmixed water in the tank, which also protects the water from rapid cooling.