- Advantages and disadvantages

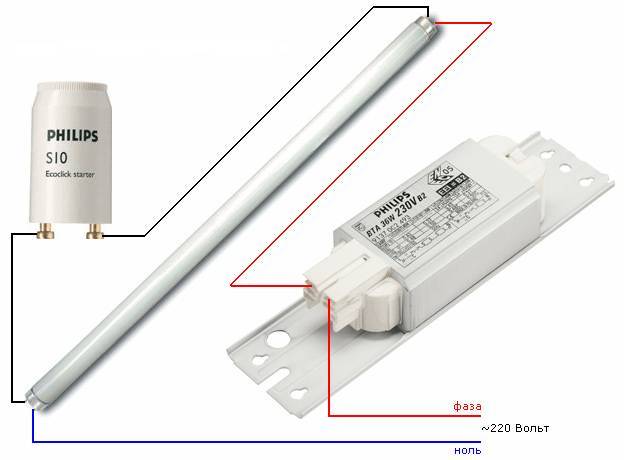

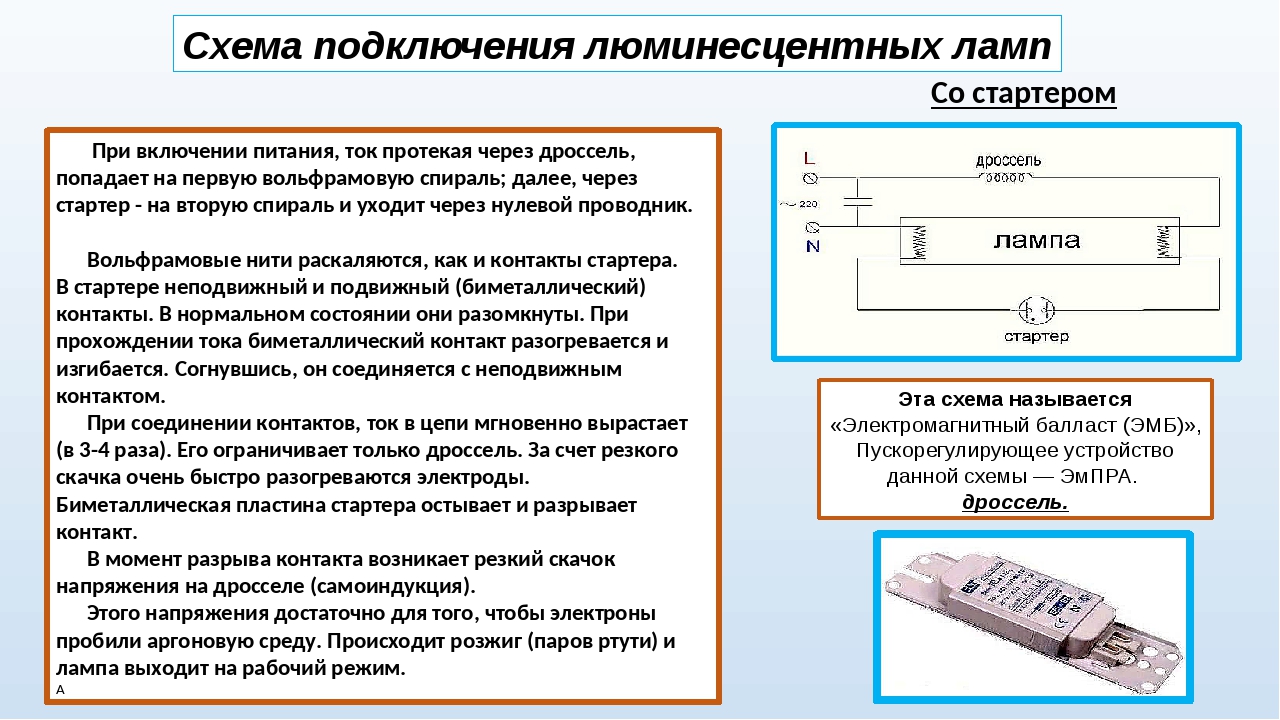

- Classic scheme using electromagnetic ballast

- The principle of operation of a fluorescent lamp

- What is a choke for?

- Differences between a choke and an electronic ballast

- Where could I buy?

- Fluorescent lamp device

- How does the lamp start and work

- Choke classification

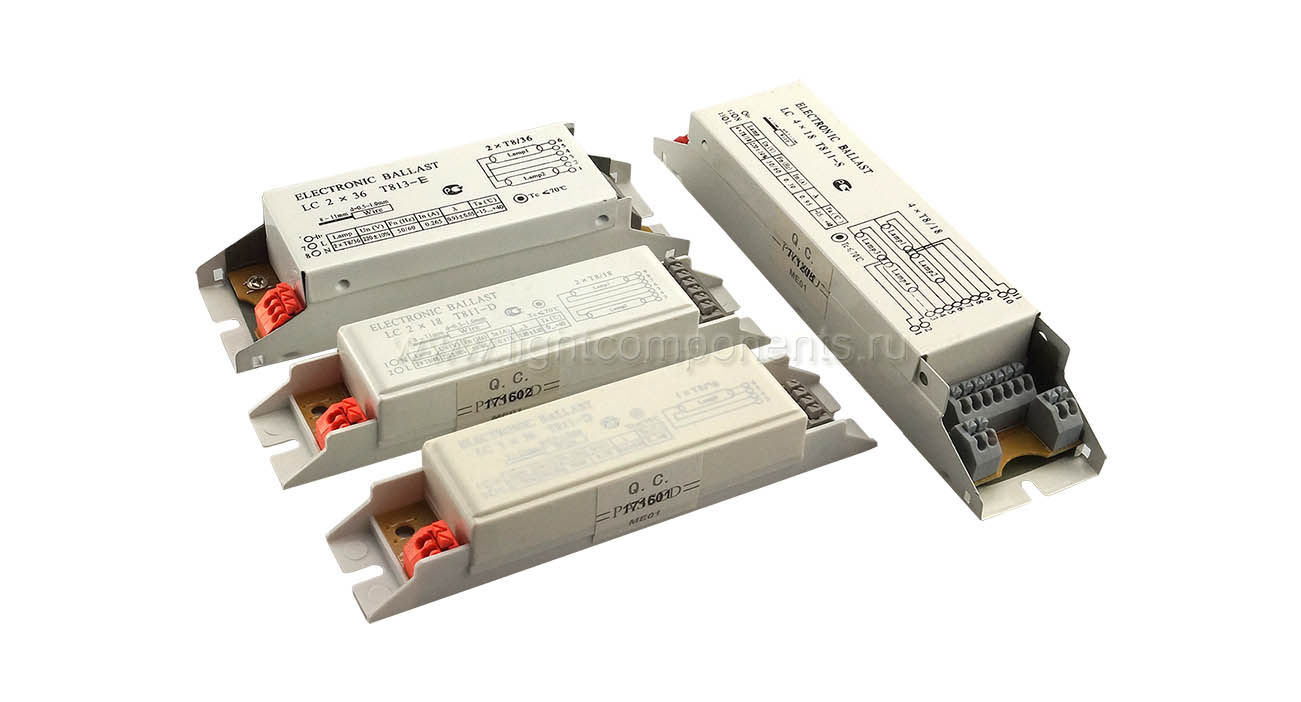

- Varieties of ballast

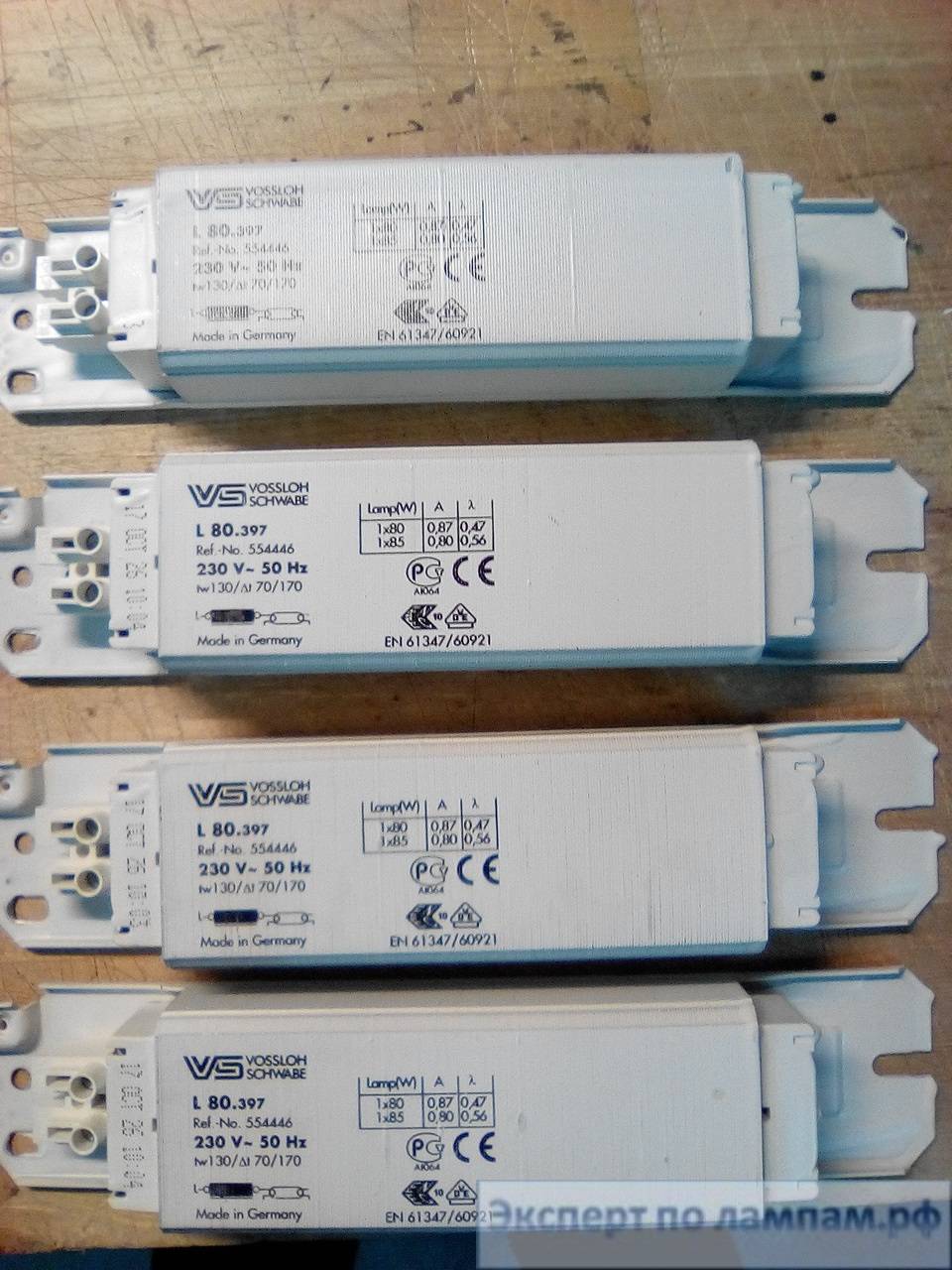

- Electromagnetic implementation

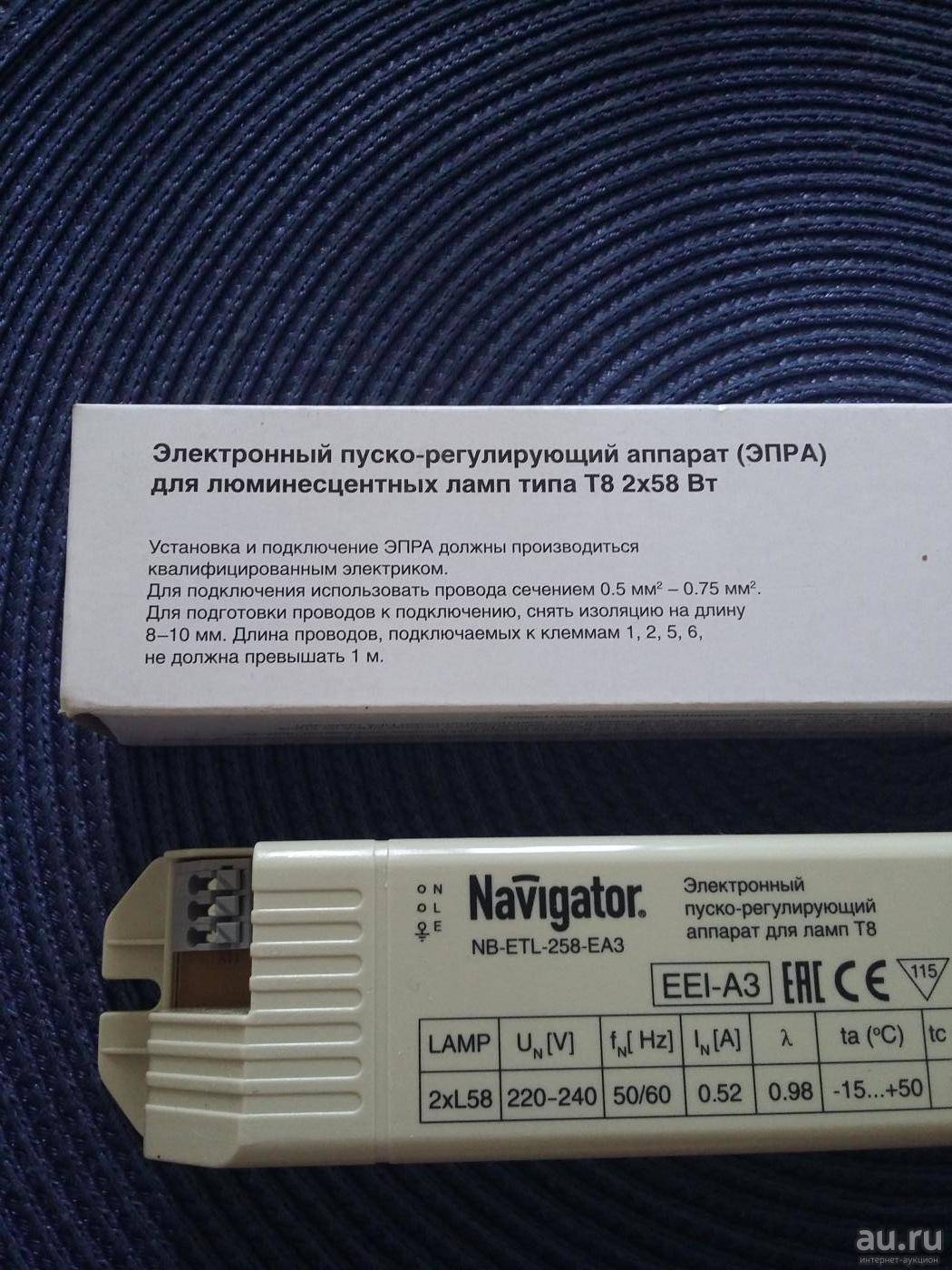

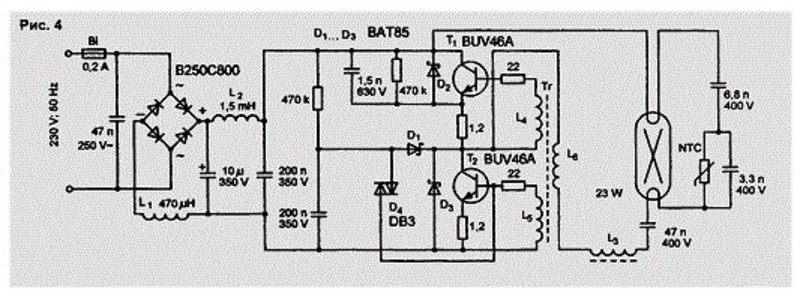

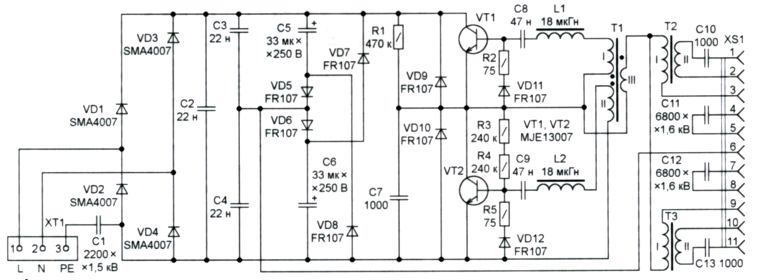

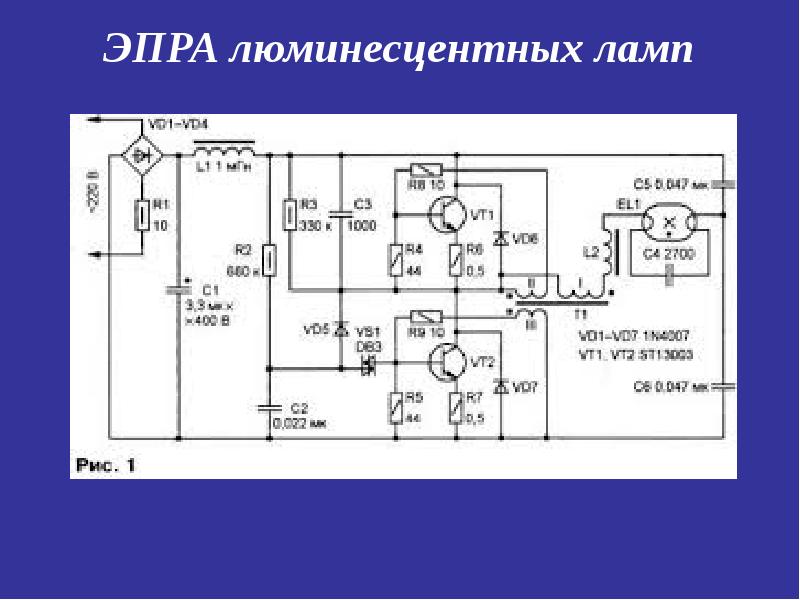

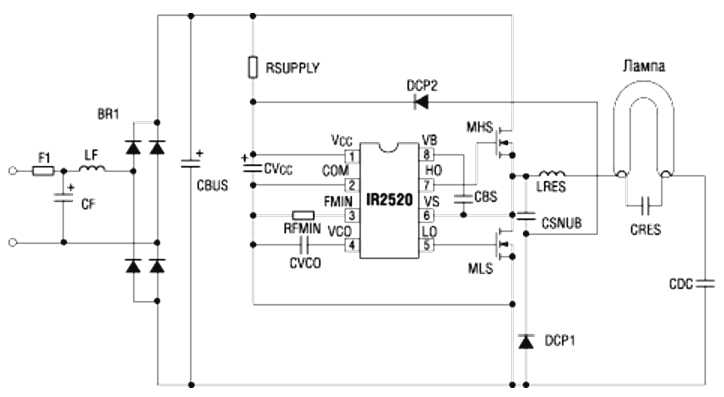

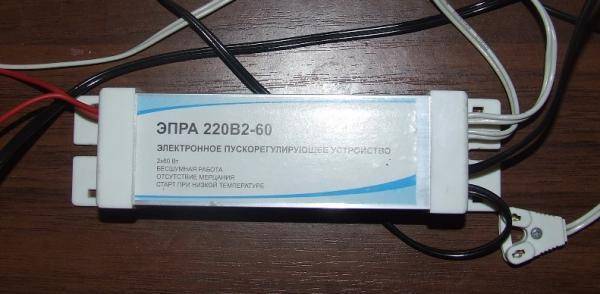

- Electronic implementation

- Repair of a fluorescent lamp. Major faults and their elimination. Instruction

- How to check the electronic ballast for fluorescent lamps?

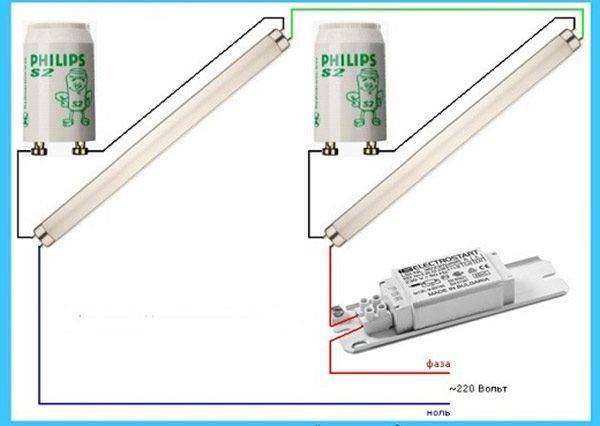

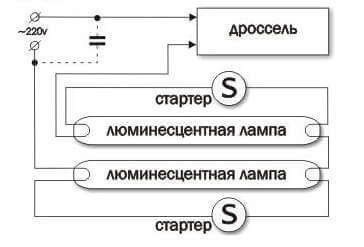

- Pair of lamps and one choke

- Ballast for discharge lamp

Advantages and disadvantages

Thanks to advances in the technological features of electronic ballasts, these accessories have become widely used in fluorescent lamps (FL).

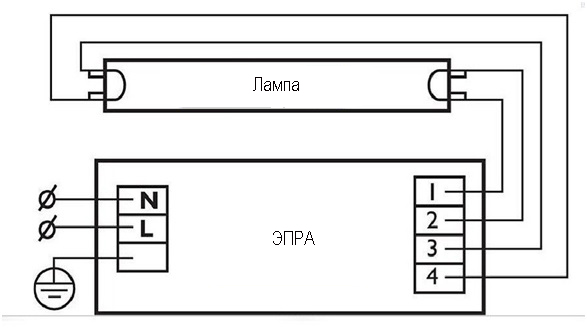

EB connection block

EB connection block

Important benefits:

- Design flexibility and excellent control characteristics. There are various types of ballasts with adjustable functions that can drive LLs at different output levels. There are ballasts for low light and lower power consumption. For higher illuminance, high light output ballasts are available that can be used with fewer lamps and higher power factor.

- Great efficiency.Electronic chokes rarely generate much internal heat and are therefore considered more efficient. These EBs provide flicker-free and constant power fluorescent lamps, which is one of the most notable benefits.

- Less cooling load. Since the EBs do not include a coil and a core, the heat generated is minimized and hence the cooling load is reduced.

- The ability to operate more devices at the same time. One EB can be used to control 4 luminaires.

- Lighter in weight. Thanks to the use of electronic ballasts, the luminaires are lighter. Because it does not include a core and coil, it is comparatively light in weight.

- Less lamp flicker. One of the greatest benefits of using these ingredients is to reduce this factor.

- Quiet work. Another useful feature is that EBs operate quietly, unlike magnetic ballasts.

- Superior Sensing Capabilities - EBs are sensing capable as they detect the end of lamp life and turn off the lamp before it overheats and fails.

- Electronic chokes are available in a huge range at many online electronics stores at affordable prices.

The disadvantages include the fact that with electronic ballasts, alternating currents can generate current peaks near voltage peaks, creating a high harmonic current. This is not only a problem for the lighting system, but can also cause additional problems such as stray magnetic fields, corroded pipes, interference from radio and television equipment, and even malfunctioning IT equipment.

The high harmonic content also causes overloading of transformers and neutral conductors in three-phase systems. The higher flicker frequency may go unnoticed by the human eye, however, it causes problems with infrared remote controls used in home multimedia devices such as televisions.

Additional Information! Electronic ballasts do not have the circuitry to withstand power surges and overloads.

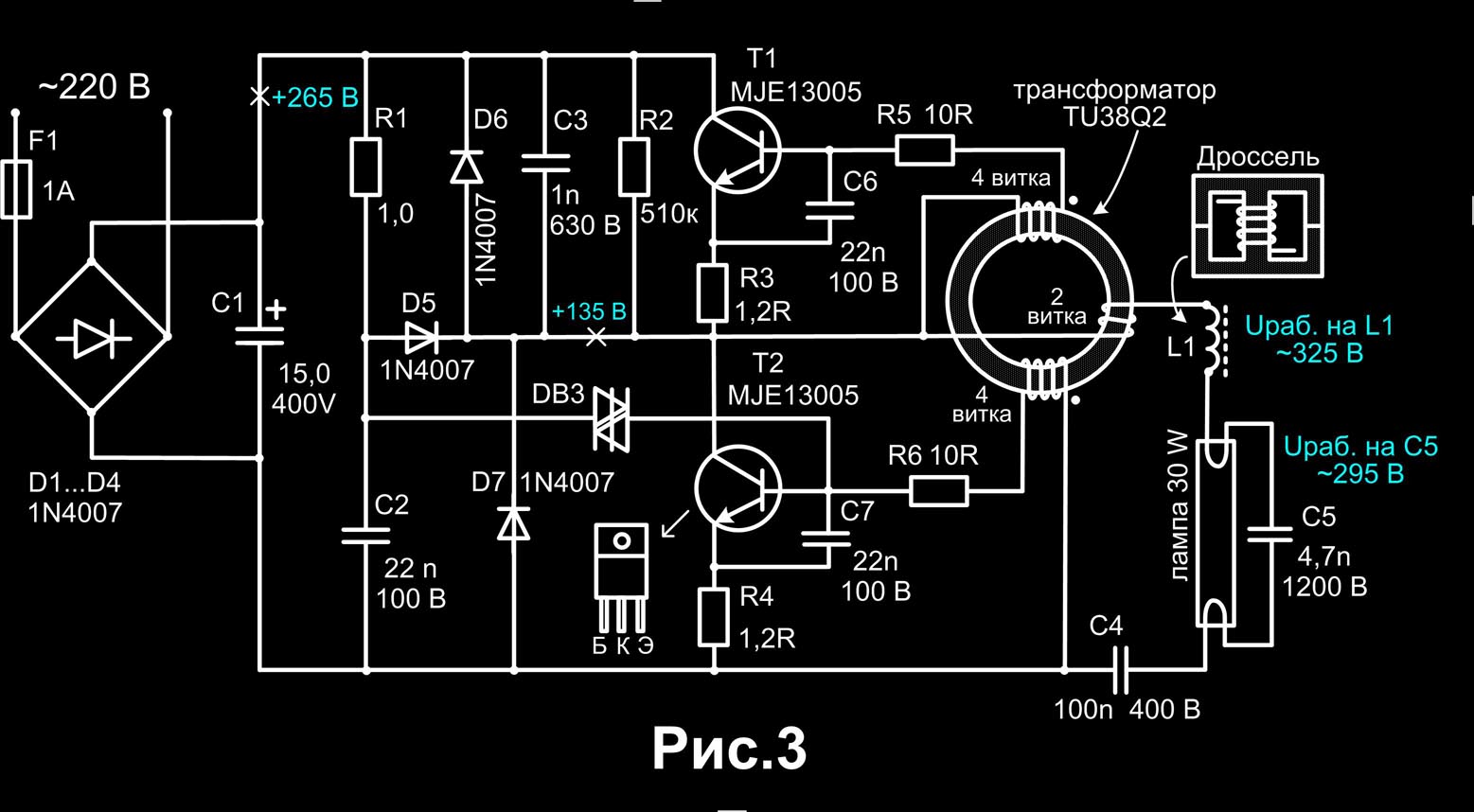

Classic scheme using electromagnetic ballast

The combination of a throttle and a starter is also called an electromagnetic ballast. Schematically, this type of connection can be represented in the form of the figure below.

To increase the efficiency, as well as reduce reactive loads, two capacitors are introduced into the circuit - they are designated C1 and C2.

- The designation LL1 is a choke, sometimes it is called a ballast.

- The designation E1 is a starter, as a rule, it is a small glow discharge bulb with one movable bimetallic electrode.

Initially, before the current is applied, these contacts are open, so the current in the circuit is not supplied directly to the light bulb, but heats the bimetallic plate, which, when heated, bends and closes the contact. As a result, the current increases, heating the heating filaments in the fluorescent lamp, and the current decreases in the starter itself and the electrodes open. The process of self-induction begins in the ballast, leading to the creation of a high voltage pulse, which ensures the formation of charged particles, which, interacting with the phosphor of the coating, provide the appearance of light radiation.

Such schemes using ballast have a number of advantages:

- low cost of the required equipment;

- ease of use.

The disadvantages of such schemes include:

- "Flickering" nature of light radiation;

- significant weight and large dimensions of the throttle;

- long ignition of a fluorescent lamp;

- buzz of a working throttle;

- almost 15% energy loss.

- cannot be used in conjunction with devices that smoothly adjust the brightness of the lighting;

- in the cold, the inclusion slows down significantly.

The inductor is chosen strictly in accordance with the instructions for a particular type of fluorescent lamps. This will ensure the full performance of their functions:

- limit the current value in the required values when the electrodes are closed;

- generate a voltage sufficient for the breakdown of the gaseous medium in the lamp bulb;

- ensure that the discharge is maintained at a stable constant level.

Inconsistency in selection will result in premature lamp wear. As a rule, chokes have the same power as the lamp.

Among the most common malfunctions of luminaires that use fluorescent lamps, the following can be distinguished:

- choke failure, outwardly it appears in the blackening of the winding, in the melting of the contacts: you can check its performance yourself, for this you need an ohmmeter - the resistance of a good ballast is about forty ohms, if the ohmmeter shows less than thirty ohms - the choke must be replaced;

- starter failure - in this case, the lamp starts to glow only at the edges, flashing starts, sometimes the starter lamp glows, but the lamp itself does not light up, the malfunction can only be eliminated by replacing the starter;

- sometimes all the details of the circuit are in good order, but the lamp does not turn on, as a rule, the reason is the loss of contacts in the lamp holders: in low-quality lamps they are made of low-quality materials and therefore melt - such a malfunction can only be eliminated by replacing the sockets of the lamp holders;

- the lamp flashes like a strobe, blackening is observed along the edges of the bulb, the glow is very weak - troubleshooting lamp replacement.

The principle of operation of a fluorescent lamp

A feature of the operation of fluorescent lamps is that they cannot be directly connected to the power supply. The resistance between the electrodes in the cold state is large, and the amount of current flowing between them is insufficient for a discharge to occur. Ignition requires a high voltage pulse.

A lamp with an ignited discharge is characterized by low resistance, which has a reactive characteristic. To compensate for the reactive component and limit the flowing current, a choke (ballast) is connected in series with the luminescent light source.

Many do not understand why a starter is needed in fluorescent lamps. The inductor, included in the power circuit together with the starter, generates a high voltage pulse to start a discharge between the electrodes. This happens because when the starter contacts are opened, a self-induction EMF pulse of up to 1 kV is formed at the inductor terminals.

What is a choke for?

The use of a choke for fluorescent lamps (ballast) in power circuits is necessary for two reasons:

- starting voltage generation;

- limiting the current through the electrodes.

The principle of operation of the inductor is based on the reactance of the inductor, which is the inductor. Inductive reactance introduces a phase shift between voltage and current equal to 90º.

Since the current-limiting quantity is inductive reactance, it follows that chokes designed for lamps of the same power cannot be used to connect more or less powerful devices.

Tolerances are possible within certain limits. So, earlier, the domestic industry produced fluorescent lamps with a power of 40 watts. A 36W inductor for modern fluorescent lamps can be safely used in power circuits of outdated lamps and vice versa.

Differences between a choke and an electronic ballast

The throttle circuit for switching on luminescent light sources is simple and highly reliable. The exception is the regular replacement of starters, since they include a group of NC contacts for generating start pulses.

At the same time, the circuit has significant drawbacks that forced us to look for new solutions for turning on lamps:

- long start-up time, which increases as the lamp wears out or the supply voltage decreases;

- large distortion of the mains voltage waveform (cosf

- flickering glow with double the frequency of the power supply due to the low inertia of the luminosity of the gas discharge;

- large weight and size characteristics;

- low-frequency hum due to vibration of the plates of the magnetic throttle system;

- low reliability of starting at low temperatures.

Checking the choke of fluorescent lamps is hampered by the fact that devices for determining short-circuited turns are not very common, and using standard devices, one can only state the presence or absence of a break.

To eliminate these shortcomings, circuits of electronic ballasts (electronic ballasts) have been developed. The operation of electronic circuits is based on a different principle of generating a high voltage to start and maintain combustion.

The high voltage pulse is generated by the electronic components and a high frequency voltage (25-100 kHz) is used to support the discharge. The operation of the electronic ballast can be carried out in two modes:

- with preliminary heating of electrodes;

- with cold start.

In the first mode, low voltage is applied to the electrodes for 0.5-1 second for initial heating. After the time has elapsed, a high-voltage pulse is applied, due to which the discharge between the electrodes is ignited. This mode is technically more difficult to implement, but increases the service life of the lamps.

The cold start mode is different in that the start voltage is applied to the cold electrodes, causing a quick start. This starting method is not recommended for frequent use, as it greatly reduces the life, but it can be used even with lamps with faulty electrodes (with burnt filaments).

Circuits with an electronic choke have the following advantages:

complete absence of flicker;

wide temperature range of use;

small distortion of the mains voltage waveform;

absence of acoustic noise;

increase the service life of lighting sources;

small dimensions and weight, the possibility of miniature execution;

the possibility of dimming - changing the brightness by controlling the duty cycle of the electrode power pulses.

Where could I buy?

The modern mechanisms used to drive a fluorescent lamp are not only sold by electronics retailers, but also by many companies that have websites.

When choosing a ballast device, it must be remembered that the power indicators of such a device should not exceed the power of the light source too much, since in this case overheating and a quick failure of the lamp are noted.

The reverse excess is also allowed, but within reasonable limits, since such a situation often causes the ballast itself to burn out.

Connecting a more powerful light source to a less powerful ballast is quite possible, but will require a competent assessment of the decrease in the brightness of the lighting device and control of the heating of the ballast.

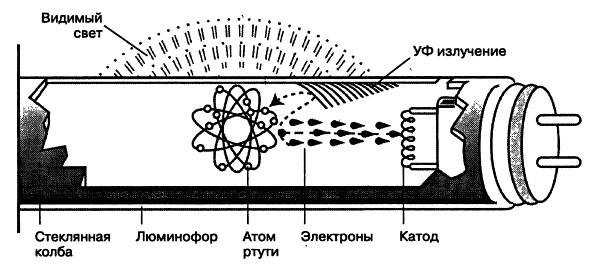

Fluorescent lamp device

In order to understand the principle of operation of a single-lamp lamp, you need to get acquainted with its circuit. The luminaire consists of the following elements:

- glass cylindrical tube;

- two socles with double electrodes;

- starter working at the initial stage of ignition;

- electromagnetic choke;

- capacitor connected in parallel with the mains.

The flask of the product is made of quartz glass. At the initial stage of its manufacture, air was pumped out of it and an environment was created consisting of a mixture of an inert gas and mercury vapor. The latter is in a gaseous state due to the excess pressure created in the internal cavity of the product. The walls are covered from the inside with a phosphorescent compound, which converts the energy of ultraviolet radiation into light visible to the human eye.

An alternating mains voltage is supplied to the terminals of the electrodes at the ends of the device. The internal tungsten filaments are coated with metal, which, when heated, emits a large number of free electrons from its surface. Cesium, barium, calcium can be used as such metals.

An electromagnetic choke is a coil wound to increase the inductance on an electrical steel core with a large magnetic permeability.

The starter operates at the initial stage of the glow discharge process in the gas mixture. Its body contains two electrodes, one of which is bimetallic, capable of bending and changing its size under the influence of temperature. It performs the role of a circuit breaker and a circuit breaker in which the choke is included.

How does the lamp start and work

At the moment the lighting device is turned on, the starter starts to work first. It heats up the electrodes, causing a short circuit. The current in the circuit increases sharply, due to which the electrodes almost instantly heat up to the required temperature. After that, the starter contacts open and cool down.

Visual launch scheme

At the moment of breaking the circuit, a high-voltage pulse of 800 - 1000 V comes from the transformer. It provides the necessary electric charge on the contacts of the bulb in an inert gas and mercury vapor environment.

The gas is heated and ultraviolet radiation is produced. By acting on the phosphor, the radiation causes the lamp to glow with visible white light.Then the current is evenly distributed between the inductor and the lamp, maintaining a stable network performance for a uniform glow without ripples. There is no energy consumption from the ballast at this stage.

Since the voltage in the circuit during lamp operation is low, the starter contacts remain open.

The throttle helps to get rid of this effect. It turns the alternating low-frequency voltage of the household network into a constant one, and then inverts it back into an alternating one, but already at a high frequency, the ripples disappear.

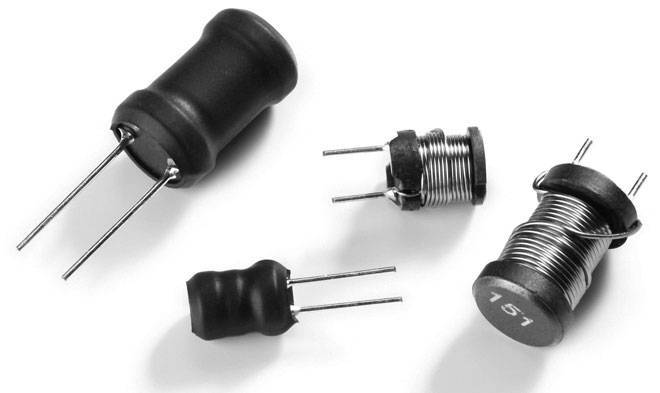

Choke classification

In fluorescent lamps, electronic or electromagnetic type chokes (EMPRA) are used. Both types have their own characteristics.

An electromagnetic choke is a coil with a metal core and a winding of copper or aluminum wire. The diameter of the wire affects the functionality of the luminaire. The model is quite reliable, but power losses up to 50% cast doubt on its effectiveness.

Electromagnetic structures are not synchronized with the mains frequency. This results in flashes just before the lamp is ignited. Flashes practically do not interfere with the comfortable use of the lamp, but they negatively affect the ballast.

Varieties of electronic and electromagnetic devices

The imperfection of electromagnetic technologies and significant power losses during their use lead to the fact that electronic ballasts are replacing such devices.

Electronic chokes are structurally more complex and include:

- Filter to eliminate electromagnetic interference. Effectively extinguishes all unwanted vibrations of the external environment and the lamp itself.

- Device for changing the power factor. Controls the phase shift of the AC current.

- Smoothing filter that reduces the level of AC ripple in the system.

- inverter. Converts direct current to alternating current.

- Ballast. An induction coil that suppresses unwanted interference and smoothly adjusts the brightness of the glow.

Electronic stabilizer circuit

Sometimes in modern electronic ballasts you can find built-in protection against voltage surges.

Varieties of ballast

Various types of ballasts are grouped according to the types of implementation: electronic and electromagnetic implementation. In addition, models are classified according to the scope for lighting devices, among which are:

- High frequency electronic ballast for fluorescent fixtures, with and without preheating. The first model improves the performance and life of the device, as well as reduces the noise effect. Ballast without preheating consumes less energy.

High frequency ballast for sodium lamps. This is a less bulky ballast than conventional models mounted on low pressure luminaires, easy to install, with little power consumption for its own needs. - Electronic ballast for gas discharge devices. This model is usually designed for high pressure sodium and metal lamps, which increases their life by up to 20% compared to the standard. The startup time is reduced, as are the flashing effects. It should be noted that these ballasts are not suitable for all fixtures.

- Multi-tube ballast. It has the advantage that it can be used with several types of fluorescent devices, including aquarium lighting, creating an optimal primer.It has the function of recording all lighting parameters in its memory.

- Ballast with digital control. This is the latest generation model, offering many possibilities for flexibility and modularity in the installation of luminaires. This improves the economic aspect of the LED lamp and the comfort of the brightness. At the same time, it is the most expensive model.

Electromagnetic implementation

Magnetic ballasts (MB) are old technology devices. They are used for the fluorescent lamp family and some metal halide devices.

They tend to cause hum and flicker because they regulate the current gradually. MBs use transformers to convert and control electricity. When the current arcs through the lamp, it ionizes a larger percentage of the gas molecules. The more of them are ionized, the lower the resistance of the gas. Thus, without MB, the current will rise so high that the lamp will heat up and break down.

Electromagnetic implementation

Electromagnetic implementation

The transformer, which is called a "choke" in MB, is a wire coil - an inductor that creates a magnetic field. The more current flows, the greater the magnetic field, the more it slows down the growth of current. Since the process takes place in an alternating current environment, the current only flows in one direction for 1/60 or 1/50 of a second and then drops to zero before flowing in the opposite direction. Therefore, the transformer only needs to slow down the flow of current for a moment.

Electronic implementation

The performance of electronic ballasts is measured by various parameters. The most important is the ballast factor.This is the ratio of the light output of the lamp, controlled by the EB under consideration, to the light output of the same device, controlled by the reference ballast. This value is in the range of 0.73 to 1.50 for EB. The significance of such a wide range lies in the levels of light output that can be obtained using a single EB. This finds great application in dimming circuits. However, it has been found that too high and too low ballast factors degrade luminaire life due to lumen wear resulting from high and low current, respectively.

When EVs are to be compared within the same model and manufacturer, the ballast efficiency factor is often used, which is the ratio of the ballast factor expressed as a percentage to the power and gives a relative measure of the system efficiency of the whole combination. A measure of the efficiency of a ballast with a power factor (PF) parameter is a measure of the efficiency with which the EB converts the supply voltage and current into usable power supplied to the lamp with an ideal value of 1.

Repair of a fluorescent lamp. Major faults and their elimination. Instruction

If the lamp does not try to light up, before troubleshooting it, you need to measure the voltage at its input terminals. If it is, then the search sequence is as follows:

Slightly twist the lamps around the longitudinal axis. When properly installed, its contacts should be parallel to the plane of the lamp. This position is determined by the maximum effort to rotate or when re-installed with the memorization of their position in space.

Replace the starter with a known good one.Electricians who maintain fluorescent light fixtures always have a supply of starters on hand to test. In its absence, you can temporarily remove the starter from a working lamp. At the same time, you can leave it in operation - the starter does not affect the performance of an already lit fluorescent lamp.

Check lamp(s) for proper operation. In fixtures with two lamps, they are connected in series. The starter and choke are common to them. Four-lamp luminaires are structurally two two-lamp luminaires combined in one housing. Therefore, when one lamp fails, the second goes out with it.

The serviceability of the lamps is checked by replacing them with serviceable ones. You can measure the resistance of the filaments with a multimeter - it does not exceed tens of ohms. Blackening from the inside of the lamp bulb in the area of \u200b\u200bthe filaments does not indicate a malfunction, but it is checked first.

If the starter and lamp are OK, check the throttle. Its resistance, measured with a multimeter, does not exceed hundreds of ohms. You can use an indicator screwdriver by checking the passage of the “phase” through the throttle: if it is at its input, then it should be at the output. If in doubt, the throttle is replaced.

Check lamp wiring

Pay attention to the contact connections of the throttle, starter and lamp sockets. For the convenience of performing this operation, it is better to remove the lamp from the ceiling and put it on the table.

This will make it easier and safer.

Scheme of a fluorescent lamp with one lamp If the lamp unsuccessfully tries to light up, then they look for the cause in the order: starter, lamp, throttle.Their failure in this situation is equally probable.

Scheme of a fluorescent lamp with two lamps

When using electronic ballasts (electronic ballasts), it is not easy to determine its serviceability using a multimeter. In this case, changing the lamps to new ones, checking the serviceability of all contact connections, replace the electronic ballast. It can be repaired, but this requires knowledge in electronics: the ability to check electronic components and work with a soldering iron, understand the circuits and the principles of their operation.

Electronic control equipment

If the brightness of the lamp has decreased, then it must be replaced. At negative temperatures, fluorescent lamps take longer to light up or do not light up at all.

How to check the electronic ballast for fluorescent lamps?

If in a dark room, when the light source is turned on, a barely noticeable glow of the filaments is noted, then the failure of the electronic ballast device is likely, as well as a breakdown of the capacitor.

The standard scheme of all lighting fixtures is almost identical, but may have significant differences, so at the first stage of the test, you need to decide on the type of electronic ballast.

Ballast check

The test begins with the dismantling of the tube, after which it is required to short-circuit the leads from the incandescent filaments and connect a traditional 220V lamp with low power ratings. Diagnostics of the device in a professional repair shop is carried out using an oscilloscope, a frequency generator and other necessary measuring instruments.

Self-checking involves not only a visual inspection of the electronic board, but also a consistent search and identification of failed parts.

Budget ballast devices are characterized by the presence of rapidly failing capacitors for 400V and 250V.

Pair of lamps and one choke

Scheme with one choke

Two starters are needed here, but an expensive ballast can be used alone. The connection diagram in this case will be a little more complicated:

We connect the wire from the starter holder to one of the light source connectors

The second wire (it will be longer) should run from the second starter holder to the other end of the light source (bulb)

Please note that it has two nests on both sides. Both wires must go into parallel (identical) sockets located on the same side.

We take the wire and insert it first into the free socket of the first and then the second lamp

In the second socket of the first we connect the wire with the socket connected to it

We connect the bifurcated second end of this wire to the choke

It remains to connect a second light source to the next starter

We connect the wire to the free hole in the socket of the second lamp

With the last wire we connect the opposite side of the second light source to the throttle

Eggplant: description and characteristics of 53 popular and unusual varieties for open ground and greenhouses (Photo & Video) +Reviews

Ballast for discharge lamp

Discharge lamp - mercury or metal halide,

similarly to luminescent, it has a falling current-voltage characteristic. That's why

it is necessary to use a ballast to limit the current in the network and ignite the lamp. Ballasts

for these lamps are in many ways similar to fluorescent lamp ballasts and will be here

described very briefly.

The simplest ballast (reactor ballast) is an inductive choke,

connected in series with the lamp to limit the current. Turns on in parallel

capacitor to improve the power factor. Such a ballast can be calculated

easily similar to those made above for a fluorescent lamp. It must be taken into account

that the current of a gas-discharge lamp is several times higher than the current of a fluorescent lamp. That's why

do not use a choke from a fluorescent lamp. Sometimes impulse is used

igniter (IZU, inginitor) to ignite the lamp.

If the mains voltage is not enough to ignite the lamp, then the inductor may be

combined with an autotransformer to increase the voltage.

This type of ballast has the disadvantage that when the mains voltage changes

the luminous flux of the lamp changes, which depends on the power proportional to

voltage squared.

This type of ballast with constant wattage has received the most

distribution now among inductive ballasts. Supply voltage change

network by 13% leads to a change in lamp power by 2%.

In this circuit, the capacitor plays the role of a current-limiting element. That's why

the capacitor is usually set large enough.

The best are electronic ballasts, which are similar

fluorescent lamps. All that is said

about those ballasts is true for and for gas discharge lamps. Moreover, in such ballasts

you can adjust the lamp current, reducing the amount of light. So if you are going

use a gas discharge lamp to illuminate the aquarium, then it makes sense for you to purchase

electronic ballast.

back to index